-

Posts

4,854 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dikman

-

How much retention?

dikman replied to hwhleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

It depends what you want the holster for. If it's for "normal carry" then obviously you want some retention so it won't fall out (assuming no retention strap or hammer thong), but for Single Action (Cowboy) shooting many like zero retention so it clears the holster easily - which is what I do. -

Patria, 8 industrial, one Chinese shoe patcher and 2 domestic - a drop in the ocean compered to your horde! I quite like the stand, but I have no chance of putting it in the house!!! In fact, I'm not sure where I'm going to put it. Gregg, thanks for that brochure, it explains exactly what the mysterious vertically moving piece is for, it moves the cutting/trimming arm (which I don't have) up and down. It also explains another strange bit that came with it that I couldn't figure out, it's the release for the cutter. It looks like the normal thread tensioner is a fairly generic type so I need to look at replacing that peculiar setup on this machine - it obviously works but I don't like it. Yeah, madmax, I my wife said I'd better stop looking! I've got a bit of work ahead of me, what with restoring that treadle, cleaning up this machine and making a table to suit it.

-

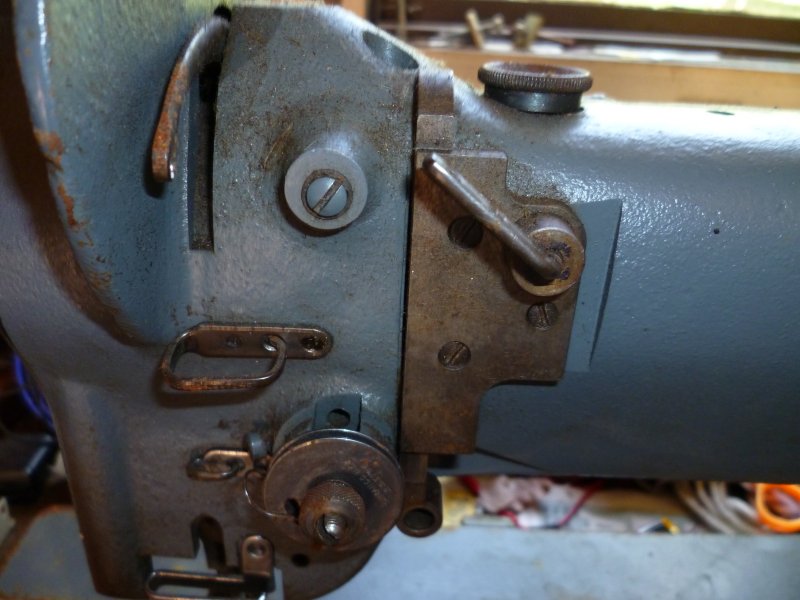

When I first saw this I thought no, table looked shot, rust on the baseplate and the motor was old. No model number listed. After looking at the photo on the sale site (rear only) I thought it looked like a 155. Hmm. So I rang the guy, he didn't know the model number offhand but it belonged to his father-in-law who use to repair sails. Asked him how much he wanted (I pointed out the obvious shortcomings) and we agreed on $100. I couldn't very well say no, could I? When I got there and saw it was a W117, and not a 115, I figured I might as well take it anyway, even though I don't know anything about the model. As it turned out the rust looks worse than it is and the baseplate should clean up ok, fortunately the rust didn't penetrate underneath. The table is scrap, but the stand looks rather nice and appears to be cast (although non-height adjustable). The motor will be going straight in the garbage. The guy has put a crude wooden handle on the handwheel. So, out of this I've got a nice old stand, kneelifter, yet another bobbin winder and a few bits and pieces. And the head unit, of course. My intention was to drop it onto one of my existing tables, but the baseplate is longer than all the other Singers I have!! Information on the 117 appears to be scarce but mine has this peculiar looking (to me) thread tension arrangement - I haven't seen it on any other 117 pics in Google. Also, in the second photo there is a vertical bar behind the plate with the thread guide, this bar moves up and down with the needle. No idea what it's for. Finally, what's the depression next to the feed dog for? It's not the heavy duty machine I was hoping for, but maybe it's a candidate for my treadle table (when I get it finished). Oh, my wife said I'd better stop looking, she's trying to downsize our household but she said I keep bringing more things in .

-

Excellent info, guys, now I have a clearer picture of how it should fit together. It won't be hard to make up a replacement connecting piece from steel. You may be right, cdthayer, about the collection of parts as the wheel still has remnants of what was probably the original black paint, as does the protective guard, whereas the rest has been painted gray. The belt holes line up with the flywheel and judging by the mountings underneath it was motor powered. I figure I'm lucky that I seem to have enough parts to be able to get it working, as people want ridiculous amounts of money here for the old treadle assemblies. And as for spare parts...... I think I'm going to need a lot of paint stripper to get rid of that yukky gray!

-

This treadle is proving interesting. I've spent a lot of time with my friend Mr. Google and so far haven't found out anything about the clutch/pulley stack, not even a photo (yes, it has Singer painted on it). The treadle pedal is also a bit of a mystery. I found out where the broken bit fits, and should be able to weld it back on (the break looks like it's cast steel, not cast iron). There appear to be two types of treadle pedal, one that has the bit sticking out like mine and the other has a piece sticking out that has a hole in it, where the end of the connecting rod (at top of photo) fits into. So the connecting rod on my large wheel could never attach to the treadle that I have! So I have two options - weld the broken bit back and make a new connecting rod to suit the existing bracket, or fabricate a complete new piece, to suit the existing connecting rod, and weld that on to the treadle. The latter will be more work, but that connecting rod end has a ball and socket in it to allow for angle changes when operating so is probably the better way. Just thought of a third option, weld the piece back and fabricate a bracket of some sort to connect the two together. Whatever I do is not going to be as original condition, so it probably doesn't matter what it looks like.

-

cdthayer, it's a 12" wheel. I had a feeling it was probably a domestic treadle when I saw it, so thanks for confirming that, and yeah, home-made but not a bad job. There are two plates, with bolts, mounted underneath the table and I figure that's where the motor was mounted (probably just an ordinary 1/4 HP or similar). All the parts appear to be there (including the protective cover that fits in front of the treadle wheel) and the belt guides, although there is a snapped off bolt in one of them. There is also one small part that appears to have been cut off from somewhere (haven't found where yet) that looks like a belt guide maybe. I just have to work out how the crank linkage attaches to the treadle plate, there's no obvious way I can see and no sign of where anything has broken or been cut off. I'll start looking at google photos to compare various treadle plates. The head unit doesn't have any Singer decals anywhere, so I'm guessing it's been repainted, but if so it's a pretty neat job. I'm not too concerned with the head unit yet, I'll concentrate on getting the treadle sorted. I reckon finding one with that step pulley might be a stroke of luck, as I haven't seen one in any of the ads I've looked at before.

-

When I mentioned to my wife that I just saw this machine on Gumtree (local ebay) and thought I'd buy it she didn't even bat an eyelid. My daughter and son-in-law just shook their heads and sort of laughed. Bit of a worry.....Well, it was only $120 and was advertised as an industrial treadle machine. Yes, it is an industrial machine, but I was only really interested in the treadle and stand. The guy selling it buys and sells stuff and I'm guessing this came as part of a pile of stuff he bought and he just wanted to move it quickly. He didn't know anything about it and said it came as is.The machine itself looks ok, serial no. indicates 1923, no rust and everything appears to move ok. Came with a small pile of bits and pieces - assorted feet, bobbins, two hook/race assemblies, needles wrapped in an oily rag and some bits that I haven't figured out yet. I should add that I don't really need this machine as it's essentially the same as my 331K4. Anyhow, on to the stand. The table is obviously not original and has been built from 1 1/4" tongue and groove planking. The stand wasn't set up but the pulley stack just bolted straight on to existing bolts in the table. I don't know much about these things, but it appears that this may have been a "convertible" version of the treadle that Singer made, wherein a motor could be connected via the pulley stack in lieu of the treadle. That would account for the fact that it has a clutch built into it (plus the treadle wheel looks a bit small). I've figured out that I need to make a cone-shaped bolt to replace the one missing from the side of the treadle wheel (simple enough) but I can't work out how the Pitman rod from the wheel crank attaches to the treadle itself - there's no attachment point, nor can I see where anything may have broken off. Can anyone provide any photos (or a parts list, if there is one) for a complete treadle of this type? I reckon I'll have to get rid of the yukky grey colour of the stand and give it a shot of black, and at some point make a decent table top. My intention is to fit one of my spare walking foot heads to it. This is becoming an obsession - scary stuff!

-

I'd say you did very well, Jim, that's not something I'd try! Those clutch motors are literally a dead weight.

-

Are Pfaff 335 and Adler 69 cylinder arm caps interchangeable?

dikman replied to Uwe's topic in Leather Sewing Machines

Whose a clever boy, then?. Just shows it pays to look "outside the box". -

For what it's worth, I completely dismantled the tables of every machine I bought, made it much easier to pack safely in my car, plus I didn't need any help to move them.

-

Unfortunately, Redbone, the "all-around leather sewing machine" is a mythical beast. It all boils down to what you want to sew. Probably not the answer you really wanted.

-

I can only agree with Uwe, as I have broken a few needles through deflection and hitting the feed dog. The thicker the leather the easier it is to deflect the needle. Even if it doesn't break the needle it can easily damage the point.

-

Thanks Wiz, there's no way I could have figured that out from the photos. Quite a neat setup, in that case, but yeah, that motor is still essentially a domestic machine motor. I guess they had little choice, though, in trying to make it a compact, portable machine.

-

Just looked at the specs. for the motor and at 1/10th HP and 1.5 A I would consider it on the puny side for driving needles through leather. Probably not much different to the motor on my domestic Singer, and that buzzes (and stops) if I try to make it do too much.

-

It might be worth dismantling the clutch and checking the condition of the clutch material and making sure it's smooth and the facing plate is clean and smooth, BUT it takes a bit (a lot?) of practice to learn to control a clutch motor, particularly if you want to go slow for leatherwork. You could fit a smaller pulley to the motor and fit a speed reducing pulley setup, but for a newcomer a servo is probably the way to go, as it will give you control and inspire confidence.

-

Patria, can you take a closeup photo of the designation plate on that Ho Hsing motor? That should at least tell us whether it's an AC clutch motor or a DC servo.

-

New Seiko STH-8bld-3 - somewhat off topic

dikman replied to leecopp's topic in Leather Sewing Machines

Great deal, that thing looks almost mint in the photo! Isn't it nice how some of these machines fit Singer tables? If you replace that handwheel with a bigger pulley you'll get even more grunt out of it (albeit a bit slower). You did real well. -

A bike, sewing machines and shooting - life's pretty good at the moment (beats the heck out of working ). I reckon that new machine will be a bit of fun to get sorted.

- 24 replies

-

- adler sewing machine

- efka

-

(and 1 more)

Tagged with:

-

Juki DNU-241, Consew 206rb, request for advice

dikman replied to pattyharrington's topic in Leather Sewing Machines

400 lbs weight! I like the foot operated reverse, neater than jamming a piece of wood on the lever.- 24 replies

-

- juki

- consew 206rb

-

(and 1 more)

Tagged with:

-

You did well with the moving - nothing like a bit of brute strength! (Sadly lacking in my department). I looked at the first photo again, and while having all those settings to play with would appeal to my technical side, I've realised that for what I'm doing (leatherwork) having a simpler, basic machine is preferable - there's enough to go wrong without added complications. A bit like my motorbikes, having computer-controlled fuel injection was great as it allowed me to hook up a computer and fiddle with the tuning (which I did a lot, and it was fun) but the bike I'm keeping has carby's and no computer!

- 24 replies

-

- adler sewing machine

- efka

-

(and 1 more)

Tagged with:

-

Home made walnut stain?

dikman replied to dikman's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Hmm, airbrush.... I have a few lying around, haven't used them for years. Once I've finished brewing my dye I'll give it a try. My neighbour has a walnut tree, might have to ask him if I can have the ones that the birds are dropping on the ground so that I can make a bigger batch. Thanks veedub. -

sewing machine worth saving and rebuilt ?

dikman replied to patria's topic in Leather Sewing Machines

Good grief!!!! Just how many machines do you have in there? -

Are Pfaff 335 and Adler 69 cylinder arm caps interchangeable?

dikman replied to Uwe's topic in Leather Sewing Machines

Uwe, my 335 also came with a closed end cap like Brian's, and the end also looks the same. -

Nice video, Brian. Your beard looks like mine, except yours has a bit of colour in it , but you've definitely got more hair on top than me!!! Diyer, I think the big issue with clutch motors is that most of us hobbyists get a (hopefully) suitable machine and just want to get straight into sewing leather. Slow speed control is really essential for this and very few of us will have the time to learn to control a clutch motor (plus leather is probably not the ideal material to start to learn on). I tried, and that included making speed reducers and fitting larger pulleys to the head units, but to no avail. I doubt if I could do what I am if a servo hadn't been available. I am in awe of those who can crawl a clutch motor.

-

Home made walnut stain?

dikman replied to dikman's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Thanks Karina. I made a small batch last year, using some dried whole walnuts ( including the husks) that I had, using a similar method. While it is certainly a dark colour itself it only produced a very light colouring in the leather (dipping it, as I'm reluctant to soak the leather), and over time most of the water has evaporated and left a thick dark syrup which is too thick to soak into the leather. I'm currently making another batch from this year's meagre crop - the walnuts/husks have been soaking in a bucket of water for several weeks and I have a nice dark brew. Once this is ready I'll add last years to it. How do you apply your stain? Do you concentrate it by removing most of the water to thicken it, do you apply it several times to build up the colour or do you just soak the leather, and if so how long?

.jpg.d60258221c476480a6e073a8805645bb.jpg)