-

Posts

4,828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dikman

-

Looks pretty good to me, Joe, considering you only wanted to knock something up in a hurry. Stacked leather handles are a lot of work, even when you have lathes and stuff!

- 20 replies

-

- leather mallet

- leather maul

-

(and 2 more)

Tagged with:

-

I just love looking at things that folks have cobbled together! Fortunately I'll only be generating a fraction of the dust that Brian does so controlling it shouldn't be too much of an issue. You may have noticed that my grinder is mounted right next to the doorway, I did that deliberately when I installed my first grinder, and if I'm likely to be doing a bit of work on it I use a floor fan blowing out the doorway.

-

Local scrap yard? No such thing. We do have a rubbish dump, of course, but the days of being able to rummage through it and find useful stuff are long gone.

-

Thanks Spyros, you really know how to cheer someone up! My original intention was to move it (temporarily) outside the shed onto a table when I wanted to do any extended/very dusty grinding, but by the time I got it all set up I realised it wasn't a practical idea. Oh well. I generally wear a dust mask if I'm doing extended grinding as I'm well aware of the dust it creates, you only have to blow your nose afterwards to see!! For the time being I'm going to rig up a catcher right under the belt that can be connected to a shop vac outside the door. I've seen how much of a mess sanding leather makes and the beauty of this machine is I can slow it down for wood/leather/antler so the dust won't be thrown up everywhere by a high speed belt, theoretically the vac should work under those conditions. I know the dust extraction systems you're talking about as I looked into one a long time ago, the difficulty I had (have) is where to put it - outside, obviously, but then I will have to build something to protect it from the elements and given where my gear is that's a problem.

-

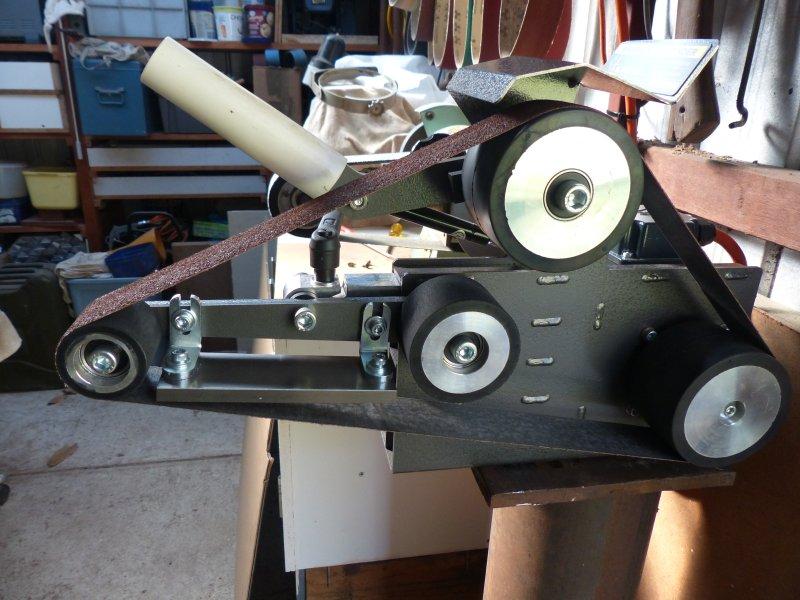

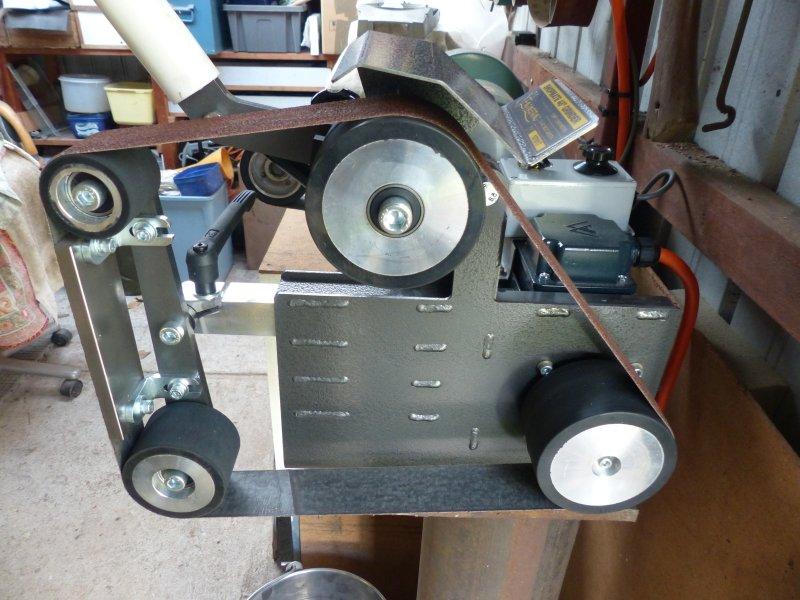

Took some photos while I'm waiting for my frozen scones to thaw. The third one shows the platen arm rotated so it can be used as a slack belt. The work table has two settings, as you can see from the slots in pic 4. There is also an attachment available (which I didn't buy but may make myself) to allow use of a very small diameter contact wheel, it's on their website.

-

There's no doubt that this is a bit of an extravagance, given that I'm not a knifemaker, but I thought what the hell, I'm not getting any younger and I do like nice machinery (read:toys ). Brian, I'll take a couple more photos shortly, there are a couple of vids on youtube that the makers put out. As for dust collection, normally knifemakers put a bucket of water below the belt to catch the metal grindings, but dust from wood/antler/leather is another issue, something that I'm thinking about. I figure a collector of some sort (probably from the plumbing shop) and a piece of pipe to attach a vacuum line to, supported on an adjustable stand to move around below the belt should work.

-

Yeah, I'm pretty chuffed with it. It's Australian-made (for a change ) - https://www.artisansupplies.com.au/product-category/knife-making-supplies/knifemaking-belt-and-disc-grinder-parts-and-accessories/84-engineering-48-inch-belt-grinders/ I first saw one at the Adelaide Knife Show a couple of years ago but I thought it was a bit expensive for my needs. I recently started thinking about getting a new belt grinder and started looking around. I found a beautiful unit, also Australian made, called the Radiusmaster, but it was over twice what I ended up paying for this one! I also wanted a 72" unit, but the problem I had with that is they take up more space, which would be an issue where I wanted to put it. This unit turned out a lot more compact than I expected, which is a bonus. I toyed with the idea of building one as the construction of this is actually relatively simple and Artisansupplies also sell all the various wheels etc, but in the end I figured it was too much trouble so just bought one. I bought the motor from them as their pricing was good, but they wanted $800+ for a programmed VFD!! Mine cost me $200 off ebay (and I could have bought a different one for half that) plus a bit of work fitting it and watching lots of youtube vids to figure out how to programme it. It will outlast me and I've no doubt it will eventually be "inherited" by one of my sons-in-law. Edit: Bert, belt size is 48" x 2", (a standard size).

-

Figured I should post a couple of pics, after all we all like looking at pics. The little box on top of the motor is the remote control I just fitted, so I don't have to keep opening the VFD enclosure. The platen arm can be tilted/rotated to place the contact wheels at the front and there is a work table, of course, but I normally leave it off. The grinder alongside is my original one, which uses 36" belts but is too fast for leather. I made a fitting for it to use 48" belts but now that I have the new one I decided to go back to the 36" on it. The white pipe is a piece of plastic conduit that I slid on the handle that releases the belt for changing, it's a bit easier on the hand than the metal handle.

-

I'm not sure how you managed to reach that conclusion. Yes, there is a section about sewing machines, and that section has a quite a lot of posts, but that's inevitable because sewing machines cause people a lot of problems! There are, however, many other sections, covering all manner of subjects related to leatherwork - tools, finishes, dyes, carving, stamping, stitching, braiding, making various bags/belts/holsters/motorcycle stuff etc etc etc. Exactly what are you looking for that you can't find on here?

-

There is a sticky, by Wiz, above these posts about the type of machine you need to sew leather, if you haven't read it then it's a great place to start. You mention holsters, unfortunately they will require a heavier machine than one used for wallets and belts (I'm talking dress belts here). It is an unfortunate fact that there is no one sewing machine that can do it all.

-

I have a belt grinder which I use a lot - metal, wood, plastic, nylon and yes, leather. The problem is it's too fast and burns the leather and wood if I'm not very careful. So I bit the boolit, so to speak, and treated myself to a new grinder, something I've wanted for years. This one is designed primarily for knifemakers and runs 48" belts, and I went the whole hog and bought a 3-phase motor with it and a separate VFD. It took a while to figure out how to programme the VFD but now I can run the grinder from almost nothing to flat out! No more burning leather. I'm so impressed with the VFD/3-phase motor setup that I'm thinking of fitting one to my lathe.

-

Elk Hide Gun Sheath

dikman replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Sounds like a subject for a new thread. -

Looking good, Dave. I just bought a packet of acorn nuts from the hardware store for mine (quick and easy).

-

I'm with chuck. Anyone can make a blade very hard, but the downside is it's brittle. Wusthof-Trident kitchen knives made their knives harder and used it as a selling point, but if you dropped one on a hard surface the tip usually broke. They replaced them under warranty if this happened (they really had no choice if they wanted to maintain their reputation). A chef I knew told me that professional chef's didn't like them as they were too hard and difficult to maintain a good edge on. A flat grind is probably the most practical to use.

-

Tooled Braces/Suspenders

dikman replied to AlexOstacchini's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Alex, I just had a look at your arty things link - very nice work there, my friend. The forged blades are well done, simple and clean designs. -

Creasing vs stitch grooving

dikman replied to Scootch's topic in Gun Holsters, Rifle Slings and Knife Sheathes

As Arturomex said, some maintain that cutting a groove in the surface of the leather weakens it, which it probably does, but if it's thick leather then it's not likely to be much of an issue. I have yet to see anyone providing proof that doing this has lead to premature failure of the product. On the other hand as Dwight said it provides protection for the stitches and in my opinion looks neat and tidy. Bottom line is to do what you like and what works for you. You're not breaking any rules. -

The bent nail welded to the nut (for a handle) might be a bit of a giveaway?

-

Tooled Braces/Suspenders

dikman replied to AlexOstacchini's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

With all that hand tooling and hand stitching, not forgetting the time in laying out the design, it beats me how you could make any money on it. -

Elk Hide Gun Sheath

dikman replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's a lot of fringing! -

Elk Hide Gun Sheath

dikman replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I think some of this should have been put in the 3D printing section? -

Tooled Braces/Suspenders

dikman replied to AlexOstacchini's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That is jaw-dropping stuff! Absolutely amazing! Makes my plain ones look, well......plain. You've given me something to aspire too. -

2 Snake skin Sheaths

dikman replied to Bawarrior's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice, the sheath colours set off the snakeskin, particularly the first one. -

Mailbag-inspired satchel

dikman replied to bgillespie's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That leather is real nice! It almost has a used look about it right from the start. The bag looks like a fairly complicated build, you've done well. -

Elk Hide Gun Sheath

dikman replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Brian, you've done it again! If you need to cut longer fringes than your jig allows could you cut them and then slide it up to extend the cuts? I'm also wondering if it would work with a head knife, using a rocking motion with the knife rather than dragging it. -

It's a domestic sewing machine. It might sew thin garment leather but that would be its limit, it's simply not designed to sew leather.

.jpg.d60258221c476480a6e073a8805645bb.jpg)