-

Posts

5,995 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by fredk

-

Frodo posted something earlier and deleted it A sort of sap, aka a cosh, was used by the Normans at the Battle of Hastings [1066]. They can be seen on the Bayeux Tapestry [approx 1070s] The thing is always over-looked, unless you know its there. The Romans, [500 BC to 500 AD] certainly used 'saps' in battle In early Medieval times a weighted leather bag attached to a wood handle was used by Churchmen who went into battle. Churchmen were not forbidden in killing but they could not shed blood, so the swingy sap was useful. The only time I ever used a weighted 'weapon' was when I was a postman. A lead bar wrapped in newspaper. To 'gently' tap certain dogs on the snout or head if they attacked me. The owners thought I was using a non-harmful newspaper, but the dogs knew and learnt differently

-

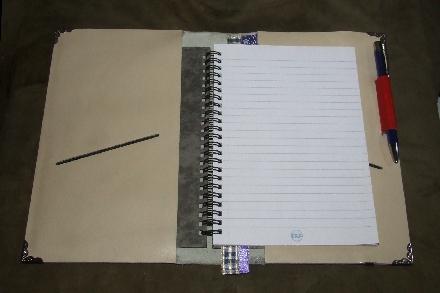

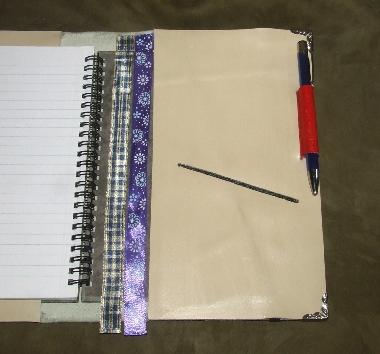

I don't have any photos of the insides of the 'expensive' one Here are photos of the inside of a 'half-way' one. Larger than the other two. They take a small A6 size [closed size, about 4.5 inches wide x 6 inches high] notebook or diary, this one is for A5 sized [about 6 inches wide by 8.5 inches high] books Inside front; Inside rear; This one is closed by a piece of elastic going around the front. The girl didn't want the pen type closure Again, just glued together, no sewing. Used a thick chrome tan on this one. Its was plenty stiff. For the slit pockets, I cut the slot and glued on the back of the piece some very thin pig skin leather. I glued that just around the edges, so a small ruler or very small note book, or a credit card can be slipped in On this cream one the pen holder goes through a slit and is just glued to the back of the flap piece

-

There is no way that those pieces of leather are 10 ounce!! 10 oz = 4mm. What he is sewing is closer to 2 to 2.5mm or 5 ounce However, the last time I used my 99 was just to punch holes along the edge of a wallet. Total thickness was nearly 3mm, or about 7oz. But punching holes and sewing are different poodles

-

No, I do not think you will be able to turn it . . . . unless you totally soak the leather with water

-

I bought my 99 just for putting holes and sometimes thread through 1mm leather. I'll not say 'sew' as the job isn't actually sewing The main reason it was chosen was for the non-stop stitch spacing, ie variable spacing without 'stops' at different settings

-

frayed knot, never took photos of them. I gotta make a few bags soon. Maybe I'll take photos as I do

-

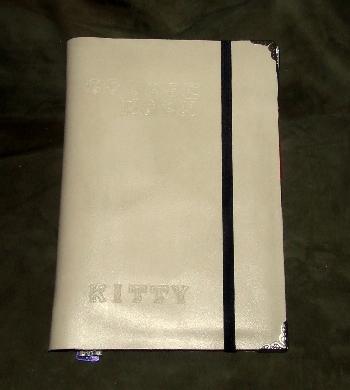

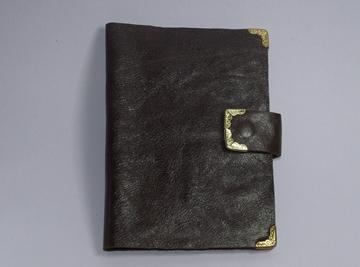

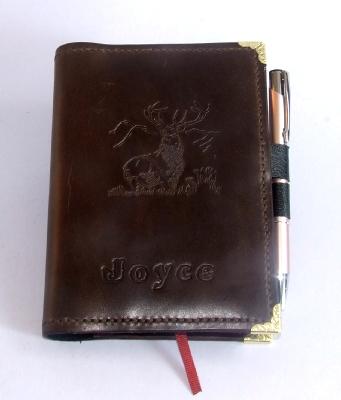

I do one style of book cover. One is a cheapie made in upholstery grade leather and is just glued together, for the other I use 2.5mm [afair] 'belting' leather. That one is much stiffer but not unduly so The cheapie, the leather is very soft and pliable. It relies on the stiffness of the book covers; [the same book cover, its the camera exposure which makes it look different] The 'expensive' one, same basic pattern as the cheapie but a bit different with pockets in the front & rear flaps and I use a pen to 'lock' it Absolutely no problems with this one opening and closing. No self-closing, no cracking or wrinkling of the spine/bendy bit I think it comes down to your choice of leather and the 'temper' it has. I choose my leather for a project according to which leather will work best without me having to fight it

-

Leather hats

fredk replied to Trikegator's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Trilby = looks like a fedora but with narrower brim and the turned up rear of the brim and slopey look to the crown If you have to adapt a fedora pattern; just reduce the width of the brim, [down to about 2 or 2.5 inches ], and wire the edge so you can turn it up at the rear. Narrow the top of the Crown piece and reduce the size of the Crown former, this will give the crown that sloped inwards look -

Leather hats

fredk replied to Trikegator's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I would describe that hat as a Trilby -

Leather hats

fredk replied to Trikegator's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

There be a couple of fedora type on this https://tandyleather.com/blogs/leathercraft-library/2662-leather-hat-pattern-pak?_pos=3&_sid=63393a5f8&_ss=r dieselpunk does a few patterns, eg; https://www.etsy.com/uk/listing/628831400/leather-hat-pattern-diy-pattern-hat-diy?click_key=3192e9a2829f90051e7f7d3184613984aa5867f2%3A628831400&click_sum=77f64076&ref=shop_home_active_168&pro=1&sts=1 or this one from another seller https://www.etsy.com/uk/listing/976301141/leather-hat-pattern-digital-pdf-template?ref=internal_similar_listing_bot-2 I have the dieselpunk one. I dunno if I can share it with you. -

Bic pen spring = too small in diameter, but would do

-

Same thread

-

All that spring does is to keep that lever over into its slot. My spring isn't geat and its only between the side and the end of the lever, When I rotate the lever the spring compresses slightly. It doesn't and wont affect sewing at all

-

I think I may have figure out what that spring is for; That bar which the big screw goes thru - you lift its end and move to the front of the machine. This to get the bobbin case out. Under that lever is a thin metal spring type thing which bears on the bobbin case. The coil spring seems to bear on that to keep it tight on the bobbin case edit; nope, I'm wrong. All that spring does is to keep that lever over into its slot. My spring isn't geat and its only between the side and the end of the lever, When I rotate the lever the spring compresses slightly

-

press the bobbin ejection lever and see if springs back down. I turned my machine a good few times [I have it converted to manual] and I could not see anything happening to that coil spring edit; I checked my manual. Nothing about the spring. But it says, never loosen that big screw. Doing that will alter the clearance of the thread between the bobbin case and the bobbin position bracket

-

-

Why do we use Sham Poo to wash our hair? Is Real Poo not as good or too expensive?

-

I don't have the red fuzzy but I do have a coiled spring there. Almost looks like yours is detached or broken. I've no idea what it does or what its for though

-

first dice cup.

fredk replied to chuck123wapati's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Good one. Your tooling is fine and the colour is nice Did you go by a supplied picture or something? to match the old one? Ach, sure you have a heart of gold and the faeries will always smile at you PS. I hate lacing too, I always try to avoid it -

Ornamental picture frame corners or box corners Examples; https://www.ebay.co.uk/itm/163857612955?hash=item2626acc09b:g:lgoAAOSwyRNdePnc https://www.ebay.co.uk/itm/164169067027?_trkparms=amclksrc%3DITM%26aid%3D1110006%26algo%3DHOMESPLICE.SIM%26ao%3D1%26asc%3D20200818142055%26meid%3D35e844301b78429cb361ea5359562c0a%26pid%3D101113%26rk%3D7%26rkt%3D12%26sd%3D174909568862%26itm%3D164169067027%26pmt%3D0%26noa%3D1%26pg%3D2563228%26algv%3DDefaultOrganicWeb&_trksid=p2563228.c101113.m2108

-

I never ever use any thing like just nfo on my book covers. I've had experience of this coming off on paper. I do use a nfo/wax mix to polish them but I only use a real minimal amount Actually, you not really want the book cover to be too pliable. A stiff cover is better imo

-

Here is what I do 1. on both the front & rear panel I glue on slightly stiff coloured lining leather - but 2. on the front panel I just glue around the edges and leave a middle section unglued. I also leave a long strip along near one side unglued. These have been decided before hand and marked. At the top of these patches which are not to be glued I cut a slot at the top of them. Thus when the lining is glued in these form a pocket and a slot for a pen or pens 3. on the rear lining I do much the same but I cut a wider slot and glue a zipper over that slot, so when the lining leather is glued in that forms a zippered pocket. 4. Sometimes I've mixed these, with a small zippered pocket on the front as well as an 'open' one and the pen slots on the back panel with an open or zippered pocket or even pen slots on the gussets The glued edges are caught up in the main assembly sewing of the bag

-

All my machines use the same bobbin [15 class] so I use a cheap Singer clone machine for bobbin winding. I got the machine in a charity [thrift] shop for £10 as a 'non-runner' [needle was down, bent and jammed in the dogs]

-

Small bag from A4 piece

fredk replied to imocow's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks, gotchya. Its a fine bit of using what you have to the mostest degree