-

Posts

3,265 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by RockyAussie

-

Time and money and sometimes skill..

-

Because of the height of this bag I would not want the Techsew 860 as it has a low height post. For the ease of stitching the base in and getting down low on those long sides I would be looking more at the Techsew 85017 which has a 17" height post compared to the 7" height of the other. Doing this form of side seam and base is quicker than other methods if you have the right machine . This machine can do a very wide range of applications but just a word of caution all the same for the OP ....if I were just starting off with out any other machines I would be looking more at a cylinder machine. You can easily make tote bags with them as well but not with this construction method. If the leather you use is soft and floppy you may get close to doing it but you would want to be pretty desperate to try.

-

How to connect thread to 91k5, 91k6

RockyAussie replied to ddiuni's topic in Leather Sewing Machines

This one shows the size of needle for the 46x1 80 https://www.strima.com/46x1-80-schmetz-sewing-machine-needle-g06-1box-100-pcs/item-432714 -

How to connect thread to 91k5, 91k6

RockyAussie replied to ddiuni's topic in Leather Sewing Machines

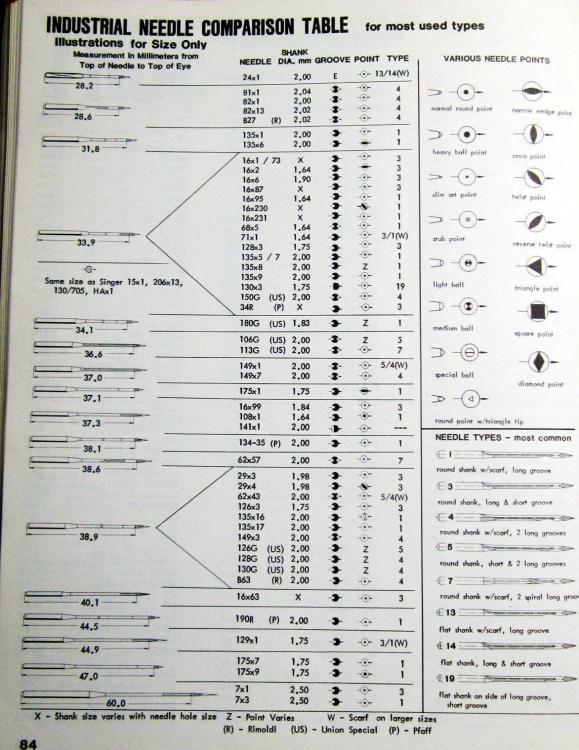

I am not understanding this variation. Will a needle with a shank diameter of 1.75 like the needle in the chart above shown as 175x1 fit up into the needle bar or not? Sanding down from 37.1mm to 35.7 mm would not be very hard to do. I did ask if you could post a picture of both sides of one of these needles and with a ruler along side would be better if the picture can clear enough to see well. This is what comes up when I google 46x1 needles https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=NDL-46x1 -

How to connect thread to 91k5, 91k6

RockyAussie replied to ddiuni's topic in Leather Sewing Machines

I can not be certain of that I am sorry. If you want to measure the diameter of the needle and the length from the end to the eye and maybe do a close up picture of both sides of the needle you may find another alternative. Sometimes if the diameter is the right size you can shorten them a bit to suit. This chart should give you some ideas -

How to connect thread to 91k5, 91k6

RockyAussie replied to ddiuni's topic in Leather Sewing Machines

This is a copy of the comment in the video .Groz-Beckert.........Nm 100/16, 251 EL, 251 LG, 29 BNl, 29 CB, LW x 5 T. This link may be of help - https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=NDL-251 -

How to connect thread to 91k5, 91k6

RockyAussie replied to ddiuni's topic in Leather Sewing Machines

I believe what you have there is a what we call a chain stitch machine and the bottom thread looks like this normally. As there is no bobbin you can not get a lock stitch to form as many other machines do. I think you have it as good as you can get it for now. -

Had another thought........If you loosen your presser foot off enough to lift the feet up with your thumbs (that is often about the right setting on light stuff for me) when you lift them up high does your top back tension discs open up. In other words when you are stitching something thicker than 3/8" does that top back tension discs open up some??

-

Sounds like some progress. The clunky noise just may be that spring being bent over into the presser bar shaft as it lifts. I would do that squaring up first. If it is not missing going forward but is in reverse ....I have to ask what needle size thread size and point tip you are running??? It may be just that the the needle is not angled right. A picture would help. It may be that if your using a light gauge needle it is too far away from the hook. That can be adjusted with shims normally but I you may not want to do that in a hurry if you are planning on using a thicker needle and thread combination. I don't think that any timing adjustments will come into it if it stitches forward but not in reverse. Make sure you are using a new needle.

-

How to connect thread to 91k5, 91k6

RockyAussie replied to ddiuni's topic in Leather Sewing Machines

Pictures are very blurry and hard to make out. I can not see a thread return spring nor a thread take up lever. From the angle of the last photo above could you take a picture with the needle down then one with the needle 1/2 way up? Do not reduce the photo size quite so much. -

Singer 17-23 hook to needle clearance

RockyAussie replied to Wyowally's topic in Leather Sewing Machines

Having had a look at Alexander Dyer's video and the ease with which a shim was added I can see no particular reason why a little can not be removed from the shuttle race holder at the rear. It is nice and flat. I was a little concerned about the needle plate movement around the 5 minute 40 sec mark but the dog foot and needle plate have no connection to the shuttle race so I assume the dog foot is rubbing the needle plate slightly but perhaps only because of loose screws. -

Singer 17-23 hook to needle clearance

RockyAussie replied to Wyowally's topic in Leather Sewing Machines

Thanks for the info Wiz. -

Thanks for the feedback @garypl. Hopefully some of the other people who now have them will share with us how they found theirs in use. I do gotta ask ...Did you actually get to stitch that holster that close to the edge at that thickness?

-

Singer 17-23 hook to needle clearance

RockyAussie replied to Wyowally's topic in Leather Sewing Machines

Is there some safe way to do this Wiz?? -

That link look promising but the options show from 2mm up. Strange that the picture they show shows a 1mm black???

-

Nah...I only keep um to save me havin to go out and slash all the weeds all the time. Saves me a small fortune in time and diesel. Oh and factory windows

-

Help identifying this Pfaff 335

RockyAussie replied to evilblackdog's topic in Leather Sewing Machines

Good to know that. If it is not too much trouble could you post a few close up pictures? I've got a 335 I might convert but not if the needle to edge is still like 11mm. -

Topy sheet soling

RockyAussie replied to ScottEnglish's topic in Shoes, Boots, Sandals and Moccassins

That is good if it works for you. Generally the first signs of heel pain are caused by bad arch support. When the shoe is not a good fit on the foot it allows over extension which then leads to the tendons tearing away from the calcaneus heel bone. Many modern shoes are not built with decent shanks in them if they even have them at all. As you get older you may find that with lower heels you start to suffer Achilles tendon tearing and spurs etc. If you mostly walk around on soft ground and such then you won't generally have many problems but if on concrete ............not good. -

I don't much use foam in wallets myself but in a fair few purses and bags we do it a lot. At the moment I am working on a new range for a customer and this prototype one I just finished has 1mm foam in the lid, base and around the sides as well. Once I finished it I took it outside to get a few pics and of course my nosy girls just had to have an inspection. Ginger here reckons the colour just does not go for her Bomba on the other hand well ......the colour is great and she wants it NOW. Hardware except the zip and brand badge is all from the Buckle Guy.

-

How to connect thread to 91k5, 91k6

RockyAussie replied to ddiuni's topic in Leather Sewing Machines

Show a picture please. It may be just needing tighter top tension or it may be too tight down below for some reason. -

Sorry mate that is something I do with my band knife splitter here. I can not get sheets at 1mm thick in Australia. I can get about 2mm and I split from there. Here is a link that may do what you want https://www.ebay.com.au/sch/i.html?_from=R40&_trksid=p2510209.m570.l1313&_nkw=fun+foam+eva+1mm&_sacat=0 You could try googling fun foam eva 1mm

-

Help identifying this Pfaff 335

RockyAussie replied to evilblackdog's topic in Leather Sewing Machines

AS yet I have not seen or heard of anyone that has done the change over. Many people still claim that they can stitch with it fine as a standard sewer and they can do a decent job but another issue that bugs me more is that the needle is about 11 mm from the edge which is terrible when you are trying to get in there with tight gussets and stuff. The more standard types like say a Techsew 2600 will get you right up to about 1/4" from the edge.https://www.techsew.com/us/techsew-2600-narrow-cylinder-leather-industrial-sewing-machine.html -

Juki 1342 Clone - Something Is Rubbing

RockyAussie replied to Arturomex's topic in Leather Sewing Machines

If its not the centre foot lightly rubbing the back foot somewhere it could be just that type of leather. Some leathers I use can be quite squeaky when sewn especially when doubled up. They are normally a little dry to the feel. Try a couple of other leathers and see if that can be ruled out first. Another thing....try dropping your foot pressure back as far as possible and see if that stops it. May be some rubbing from the presser foot spring. IF the presser foot catches a bit when you lift off of the job your doing then that could be it. -

How to connect thread to 91k5, 91k6

RockyAussie replied to ddiuni's topic in Leather Sewing Machines

I do not know this machine myself. This video that you may not have seen does look to be a similar type and in the comments section below it they have answered someone as to what needle type they use. You may be able to contact them. If you could take some pictures showing the thread path in the top of the machine may help. It may also be out of timing and normally you can see this by Watching where the scarf of the needle is when the hook is passing the needle. The eye of the needle should be 1 to 2mm below where the hook is passing the needle. If this is not the case then the hook has to be adjusted around. The hook in your pictures does look very worn down.