kgg

Contributing Member-

Posts

3,350 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

AXIS 2962B - Is anyone familiar with this machine?

kgg replied to HanSewlo's topic in Leather Sewing Machines

As Wiz said it is a Singer 29k72 clone. The AXIS brand appears to be Tomsewing (www.tomsewing.com) which is Liya international Group (http://www.liyainternational.com) house brand who mostly deal in used sewing equipment out of China. These machines can also be found on Ebay. Good, bad or indifferent who knows but I would expect little after sales support. kgg -

Update your 3D printer to cut leather or Acrylic

kgg replied to chrisash's topic in 3D Printers and Lasers

I am not a fan of the Chinese 3d printers but it looks like the Ender finally found something it can do reasonably well. kgg -

Supreme / Singer / Landis Sewing Machine Question

kgg replied to Yamborghini's topic in Leather Sewing Machines

What are you planning on sewing? kgg -

Supreme / Singer / Landis Sewing Machine Question

kgg replied to Yamborghini's topic in Leather Sewing Machines

If you go to the Landis site ( http://landisinternational.ca ) you maybe able to find some close matches. The important point is what are you planning on sewing and with what thread sizes. Then look at machines which will be able to handle those projects. From looking at the other ads the owner has up they may have been used in a shoe repair shop environment. Looking at the condition of the machines my thoughts are : i) The post bed looks like it has seen better days as it appears to have been stored for some time, rusted parts maybe present. ii) The Singer appears to be maybe a model 17-41? and parts like shuttles maybe hard to find and limited to V92 thread. iii)The flatbed seems like some form of a Seiko STH-8BL or similar and appears to be in good cosmetic shape and probably able to handle V138. iv) All three machines have clutch motors which you should replace with servo motors for many reasons. If any of these machines meets your needs go take a look and see if they will sew your stuff with the thread size you want to use. kgg -

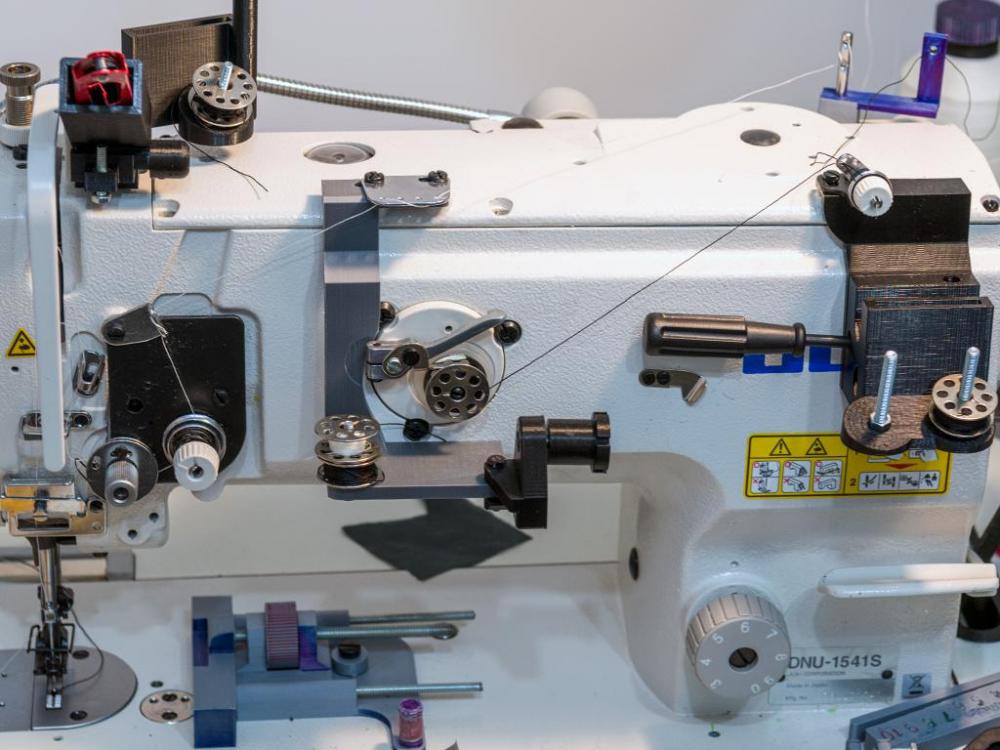

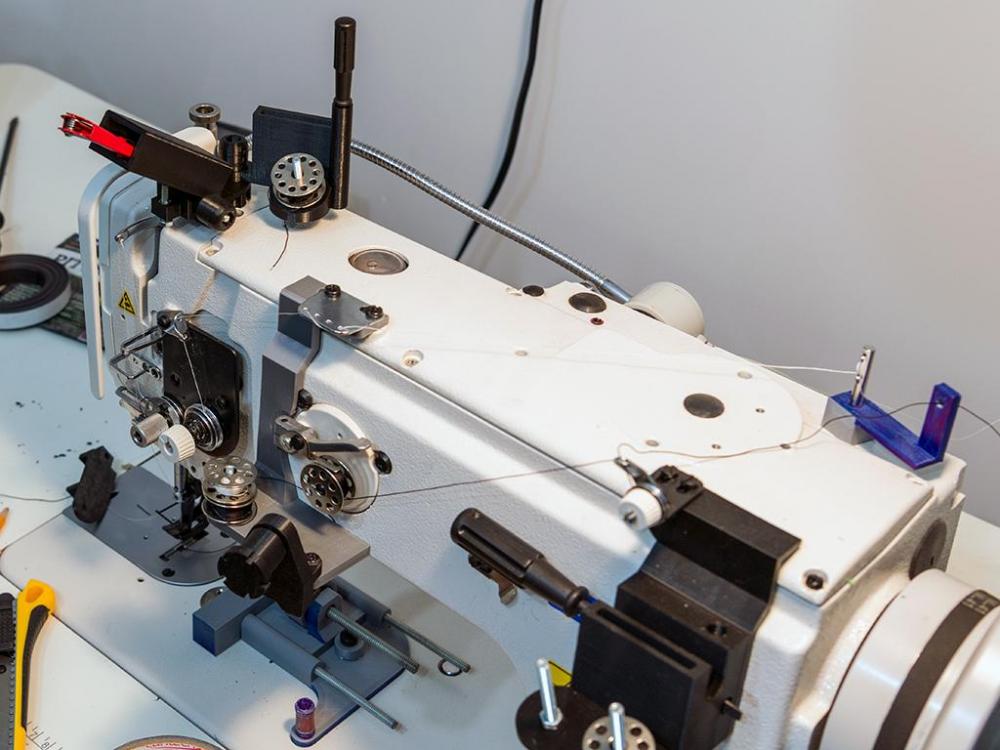

The in the catalogue photos there are two major differences from my Juki DN1541S other then the accessories I installed for my needs. i) the bobbin on mine is accessed by sliding the bobbin access plate to the left and sliding the bobbin horizontally in the bobbin case vs the double plate in the above catalogue photos where the bobbin is in the vertical position like the 1508 or the older 563. ii) the top thread tension assembly in the above catalogue photos is a multi tensioner system found on the 1508 versus the single tensioner system on my Juki DNU-1541S kgg

-

They don't look like my Juki DNU-1541S. kgg

-

The thread sizes you are using if my conversion is correct are: Belts: thread size 15/3 or even 10/3 if possible These Tkt numbers converted to the "V" size would be V 207 for 15/3 and V 277 for 10/3. Bags: with thread size 20/3 This Tkt number converted to the "V" size would be V 138. Wallets: with thread size 30/3 or even 40 These Tkt numbers converted to the "V" size would be V 92 for 30/3 and V 69 for 40. Personally I would probably look for a heavier duty machine then the DNU-1541/X55245 machine if most of your work involves using Tkt 10/3 ( V277) thread top and bottom. You maybe need to look at having two machines, one for the Tkt 10/3 ( V277) projects and one for the rest. kgg

-

Tension disks on Consew 99 not opening when foot lifted

kgg replied to Chelan's topic in Leather Sewing Machines

To get nice stitches particularly with the Sunbrella material which will depend on the denier, you will need at least 3 layers or more. I found it acted more like ripstop from a sewing perspective and getting the bottom stitch up into the material can be a chore. kgg -

Tension disks on Consew 99 not opening when foot lifted

kgg replied to Chelan's topic in Leather Sewing Machines

This maybe as simple as the nut on the tension disc is screwed in tight so the coiled tension spring is putting to much force on the discs. Try backing the nut off and see if the discs become slack when the pressor foot is locked in the up position. They could also be seized together from lack of use. It maybe that the rod that pushes the apart is damaged or worn out. A photo of the tensioner may also help. kgg -

Pulling my hair out over tension issues with Consew 206rb

kgg replied to Lokahi's topic in Leather Sewing Machines

I looked at your photo's and I would suggest a couple of things to try that may or may not work. i) remove thread from your needle back to the vertical guide just before the tensioning discs. ii) lock the pressor foot in upper position and retread. This will release tension on the two discs. The discs now should be slack and movable. Rethread as you did before. Now you will assured the thread is in as far as it can go between the tensioner discs as possible. iii) when you have threaded the needle unlock the pressor foot from the up position. Test drive and see if that makes a difference. If not the discs may have a thread path worn in them. So I would turn the very first guide from the vertical position to a horizontal position and thread like a Juki 1541 which has the first guide in the horizontal position. This would change the position of the thread through the discs. kgg -

The one arm bandits have their place but as some of us become a little older with a few more physical limitations motorized equipment offers a much more enjoyable solution. You didn't mention what type of things you are presently hand sewing now or want to sew. With that info someone can offer viable motorized solutions as to machines and accessories, new and used as well as brand name or clone machines. A motorized machine will definitely take the stress and strain off your dominate hand. kgg

-

Maybe to help reduce your time in creating stitching holes if you modified a multi hole Stitching Chisel to fit in the chuck of a drill press. Then just use the lever to press the Stitching Chisel down through the leather that way every hole would be identically spaced. By the way I do like the snake skin insert.

-

Yes. That is the correct location for the vertical guide pin. Your main thread has to be threaded through this before going to the horizontal guide that is located just above the bobbin winder. I would recommend you have your top thread come from the top arm of the spool stand for your top thread directly vertical pin. When threading this vertical pin with your top thread it will cross over the large round dial for adjusting the amount of lift for the pressor foot and walking foot. So that the top thread doesn't touch the top of the dial you thread this pin by going into the bottom hole first and out of the top hole. The hole in the top arm of the spool holder for guiding your top thread ideally will be as close to being horizontally level and create a straight line from the horizontal guide to the top arm guide hole.This may pose a problem with the type of spool holder you are using. So you can wind a bobbin while happily sewing along you could replace the 2 hole pin with a 4 hole vertical pin or do something similar to my solution or just have your bobbin thread come directly from the top arm guide hole directly into the bobbin thread guide. My take on this is that it holds the top thread for a split second acting as a damper so the thread doesn't go slack or to tight in the cycling of the top thread arm and reduce unwanted thread movement at the needle. Some other machines don't use this at all while others particularly in the 341 class use a felt pad inserted in the guide just below the take up level to achieve the dampening effect. The spring loaded flat piece system is also used with some 2 needle systems to help keep the two threads separated during the sewing cycle with one thread being on each side of the screw. I have used my 1541S both with and without the flat wiper. I found not much if any benefit when using V69 or V92 but a difference with black V138. Just my two cents worth kgg

-

Yes, looking at the video your thread is being snagged. This is one of the reasons why I do not use the cheap spool tree that seems to come with all new machines these days. I noticed you don't have the vertical guide pin installed between the horizontal guide just above the bobbin winder and the thread spool stand which may contribute to the problem as the thread entry angle is to steep. The vertical pin helps maintain a slight thread tension from the spool. I would suggest: i) install the vertical thread guide ii) lower the thread spool holder down to as low as you can so it basically on the top of the table iii) readjust the top thread guide arm down which will help reduce the angle iv) check the spool of thread for a manufacturing defect in how the thread was wound onto that spool or a thread defect. It maybe just simpler to replace it with the other spool of thread and see if it occurs on that spool of thread as well. What I do is try and get the thread to make as straight a horizontal line ( Photo K-3 ) as possible between the horizontal guide which on the 1541S is just above the bobbin winder, the first vertical thread post pin (which your machine doesn't have installed) and the thread guide hole just above the spools. Keeping a straight line means the thread spool is moved to the far right rear corner of the table. The purple thing in my photo (K-3) is a thread guide that just slips over the original vertical pin and is just used as a simple guide for the bobbin thread. The less angles either horizontally or vertically the thread has to make before the horizontal guide (which on the 1541S is just above the bobbin winder) gives a more constant top thread tension. I don't use the thread spool stands that came with my machines, don't even take them out of the packaging, they all pose more problems then they are worth. I didn't have a good photo of the spool stand on my 1541S so Photo K19 is a thread spool stand on a Kobe 1341 which maintains this straight horizontal thread path. kgg

-

The thread you are using are a great brands so the thread shouldn't be the problem. As a note in Canada and I am going to assume in the US A&E stopped selling and producing the 8 oz spools about 3 years or so ago. When this happens how much thread is left on the bobbin? You should start out with a 80% full bobbin and work down. Winding to bobbin to only 50% or less may cause inconsistent thread tension within the bobbin and allowing the thread to basically unravel within the bobbin. Any chance of a photo of the bobbin filled with the amount of thread you normally wind unto it. A & E on their 1 lb spools date their thread (upper right corner) on the label affixed to the underside of the spool not sure about the 8oz size. kgg

-

The 8 oz size thread spools can be a challenge at the best of times. There are many factors at play with thread both in spool and bobbin. Some of the issues are: 1) Poor thread consistency along the length of thread on the spool. Cheap Chinese thread. 2) Spring back more noticeable on the smaller spools where the thread comes off the top of the thread spool looking like a coil spring which can create thread spring back and unraveling of a portion of the spool. Cheap Chinese thread, old thread that has developed a memory and darker colors like black being the worst. 3) Bobbin thread will very quickly develop a coil memory and as the bobbin gets closer to the end of the thread on the bobbin it looks and acts like a coil spring. Cheap Chinese thread, old thread that has developed a memory, darker colors like black being the worst and being left to long a time on the bobbin. Bobbins should be filled to about 80 percent capacity and filled relatively close to the time you need to use them. 4) Bobbins of poor quality both in dimensional and weight quality. Some can be so bad as not fitting properly on the winder causing the bobbin to be filled inconsistently and actually wobble when placed in the bobbin holder. Cheap Chinese. kgg

-

I would first decide on what size of thread you need / plan on using. The 335 class machines usually are rated at V69 (Tkt 40) thread which is basically the top end thread size for domestic weight thread. I would advise a class 341 or 1341 class machine as they would give a broader thread range of up to V138 (Tkt 20) for top and in the bobbin. However others can advise on what type of machine like a post bed maybe best suited for your needs in making leather slippers. kgg

-

The Thor Machine is similar to the Juki 1541 S but has Two extra thread tensioners (the top one with the + and - sign on it and the one located at the 9 o'clock position) which shouldn't matter, just a little more balancing needed. The tensioner system is like the the Juki 1508. I would remove the sponge in the vertical thread guide and move it up further with a very slightly tilt about the 12:30 o'clock position just to give a little extra angle on the thread going into the take-up lever. Some Juki's and clones in the 341 class have a felt pad that is inserted in the horizontal guide just below the take-up lever which I suspect the tech wanted you to insert the sponge into not the vertical guide as shown in your photo. The Juki 1541 S and 1508, according to the Juki manual, has the thread leave that horizontal guide and go through the next guide on the "Right" side of the screw. This noted in the sufficiently noted in both Juki manuals for the threading diagram. I suspect that you need to thread your machine like a Juki 1508 not the 1541. I see you are using a spool thread sock on the 8 oz threads. I would try not using them as they can give inconsistent thread tension and may not be perfect and catch / snag thread. Also I would try and lower the top arm and spool holder down so the thread doesn't have such a steep angle entering the first horizontal guide. I find the best angle is when the thread enters the first horizontal guide almost horizontally. kgg

-

Any chance of a photo's showing the tread path from the spool to the eye of the needle. Also the distance from the bottom of the spool to the thread hole just above the spool of thread should be approximately 2.5 times the height of spool of thread. Are you using a 1 lb spool of thread or 8 oz? Is the thread a brand name or a Chinese brand thread? kgg

-

I have two of the machines you mentioned, the 1181N and the 1541S. The 1181n is a walking foot machine and is quite happy doing items up to about 4mm or so thick while the 1541S is much happier at above 3mm and is a compound feed machine. The 1181N is rated at V138 which mine handles 138 top and in the bobbin quite nicely ( as per Juki website). The 1508NH is rated at V207 and even more heavier duty and with a larger throat then the 1541 S and there is even one that is heavier again the LU-2800 series. The 1181n covers off what the 1541 S doesn't in thin material. The 1541 S can sew thin stuff but you have too really dumb it down to do a nice job otherwise it has a tendency to tear it up. The needles for the 1181n (max size 23 ) are the same series as the 1541 S ( max size 24) and the 1508 ( max size 25) being 135 x 17 for material and 135 x 16 for leather also the bobbins are the same for the 1181N, 1541 S and the 1508. I would suggest visiting a Juki dealer with your stuff, the size of thread you are going to use and test the various machines to see which will suit your needs best. Buy Once, Cry Once kgg

-

First I have to say I love my 3d printers and put a lot of hours / filament through them. They can do some amazing stuff and are great for inexpensive prototyping / small scale runs. Yes you can purchase Chinese 3d printers for under $400 but i) not everyone can quickly learn or has the want to learn a CAD/ Slicer program irregardless of the 3d printer cost ii) the life expectancy of the inexpensive 3d printers before having a rebuild or replacement is very low when compared to the more expensive reliable 3d printers ( plus $1500) and iii) sometimes it is just simpler and faster to use basic materials and tools for simple items. For me it would be quicker to take a common material like wood or HDPE and some basic carpentry tools to make a flat template as compared to 3d printing the same template. kgg

-

The best material I can suggest that you could use basic cutting tools like a saw/ drill /sander would be HDPE (High Density Poly Ethylene) in at least 1/4 ", it cuts just like wood and you can sand the edges like wood. Any smaller then 1/4" thick and you will get warping. It is available in sizes up to 4 ft x 8 ft in various thickness.

-

Where do fellow canucks buy saddle hardware other than

kgg replied to plinkercases's topic in Saddle Supplies, Tools & Trees

Maybe try Aaron Martin Harness Ltd. ( aaronmartin.com ) located at 4445 Posey Line RR#1, Wallenstein, ON N0B 2S0, Canada. I have bought some rivets from them and the price was reasonable with quick shipping. kgg -

There isn't really enough detail in your photo's to determine if the left and right sides of the zipper are correctly installed. The following video may help you to determine this. The video outlines in good detail a metal zipper, the teeth, the direction of the teeth and how the two sides should mesh together with the slider. Hope this helps, kgg

-

This is for general info mainly for Canadians like myself looking to buy 135x16 or 17 needles. Finding needles at a good price in Ontario and probably the rest of Canada can be a chore either in pricing, duties or shipping time. I had to buy some needles this week as I was down to a couple of size #23 needles. Another member I was emailing with suggested a company called Wawak (wawak.com) which I never had heard of. They carry four brands of needles but I only use the Schmetz brand of needles in my machines and I usually get a pretty good price from a Canadian supplier. To get 100 Schmetz needles of 135x 17 in size 22 and 23 it would have been approximately $140 CAD with shipping and taxes. When I phone, toll free, Wawak I could get 100 Schmetz needles of 135x 17 in size 22 and 24 as well as 200 needles in size 23 needles for approximately $128 CAD with taxes and shipping was free. Works out to $0.32 CAD per needle vs $0.70 CAD. I placed the order with Wawk on Monday afternoon and received the order by UPS today before noon. I am impressed with their shipping as the package came directly from Conklin, NY USA. So I figured I would pass on the info for future reference. kgg