mike02130

Members-

Posts

513 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by mike02130

-

My experience is that the bigger the table the more junk gets stored on top and in the way. I made a tool well like the woodworking benches have to store tools and what not level with or below the bench surface. Basically a tray attached to the bench. Drawers and shelves are pretty convenient. I would have dedicated drawers for leather panels and one for my patterns.

-

Shoulders or sides? Cutting table or work table or both? You ought to know best what your needs are. Do you mean depth(front to back)? Five feet with out more information.

-

https://www.tatraleather.com/shop

-

https://hashimotoindustry.com/en/customer_cat/tochigi_leather/page/2/

-

I read somewhere (maybe Horween?) that horse leather comes from Canada and Europe (UK?) and is a byproduct of the food industry. Americans don't eat horses.

-

How thick are the slots ? Are you planning on skiving them down by hand? I would use .8 mm goat skin.

-

https://www.rmleathersupply.com/collections/view-all-leather/products/luigi-carnevali-olso-reinforcement?variant=13992321974381

-

How thick is your leather? He's using 1.2mm for the pockets. How wide and thin is your skive? Looks like it may be too narrow(?).

-

You ought to have a water separator on your compressor.

-

I know nothing about horse tack but a chicago screw has a bit of bulk to it--I think(?). If you recess it then the leather may be too thin. Why not a hand peened copper rivet. One side will be flush.

-

https://www.dickblick.com/products/alvin-cutting-mats/ Better than others.

-

Cool build. I'm interested in your clamping gizmo. Can you explain and show how it is done? Thanks.

-

https://www.ebay.com/itm/Vintage-Leather-REIN-ROUNDER-Vise-Mount-9-Hole-Vintage-Leather-Tool-T105/124506712698?hash=item1cfd2daa7a:g:KqAAAOSw6DBf7FpH

-

Yeah that MB limit is obnoxious. I email the picture to myself then save it and then post it seems to shrink the MBs for some reason. I'm sure there are easier ways?

-

Recent Kitchen Leather Projects

mike02130 replied to Woodshed's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If you have a cast iron pan you can make a handle cover. -

My very first project

mike02130 replied to Loudcherokee's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Do not buy leather from Amazon (seems expensive to me). Your leather is chrome tanned and will not burnish. I suggest you stick to veg tanned shoulders. There are a lot of discount leather stores that sell undyed leather but most of it is hit and miss. I suppose it's okay for practice and proto types. I've had good success with Zack White. If you can afford quality dyed leather I suggest Rocky Mountain Leather or District leather supply, both offer free skiving. Between the two all your leather needs will be covered. I suggest you put the round knife aside for now and concentrate on improving your skills. A round knife is a specialized tool and takes some practice to get to the point of proficiency. It is a popular knife with the UK crowd and in the USA it is used mainly by holster and saddle and tack makers. I have a couple that I use mainly for cutting large double shoulders and belt work. I know of no new knife in the USA that is worth a damn under $200 plus. One can get a good used carbon steel round knife off of eBay for under fifty bucks. You also need to be more than proficient at sharpening to maintain the knife. A green cutting mat is not recommended with a round knife because it creates a lot of drag on the knife. I use HDPE as a cutting surface. Ritza is a quality thread and has it's purposes but I do not recommend it for wallets. It is a flat thread and the colors are solid and look unnatural. For serious work I believe you are better off with something in the .45 mm range. Brands such as Vinymo and Meisi polyester are popular with high-end products. You are not ready for linen thread. Rocky Mountain leather carries a brand called Twist. It is a braided thread but does not lay as nicely as the others but it is good quality and they offer free shipping. District Leather carries Vinymo (size #5). It doesn't seem like much difference between .6 mm and .45 but when compared side by side it is quite noticeable. One mm thread is quite large. Your 3 mm irons are too small. What do you plan on making with such a large thread? I see no need for a stitch groover unless you are making saddles or holsters and the like. When saddle stitching in a groove the stitching lays straight rather than getting the angle that is so indicative of saddle stitching. Sticks are not good for gluing, you want something that is flexible. The two shops I mentioned sell glue spreaders. For you now punching ought to be done from the inside of the wallet. You missed stitching over a few card pockets because you punched from the outside. I wet my edges and sand, repeat and repeat again using finer grit paper then Tokonole and burnish with a wood slicker. Maybe again, and maybe again again. I prefer paraffin wax over bee's wax. I believe it gives a better looking edge than bee's and is easier to use. Finish burnishing with a canvas or jeans cloth. What is this Japanese knife you speak of? If it is the ubiquitous cheap red handled Chinese knife from Amazon throw it away right now. Rocky mountain has a good one that is real for $60. The Japanese knives are great for both skiving, chopping and cutting. If I were to only have one knife, that is what I would choose. To get an idea of various knives side by side see https://leatherworker.net/forum/topic/91489-a-few-leather-knives/?tab=comments#comment-626814 -

My very first project

mike02130 replied to Loudcherokee's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

It may help if you tell us what you did wrong rather than what is wrong. Your cuts look wonky and stich line is not equally spaced from the edge. I suggest you cut your outer piece to size and cut the outsides of your pockets oversized by an 1/8" and glue it all together. Place it slot side down and using the back as a guide trim the overlapping pockets. This will give you clean even cuts all around. Get rid of the stitch groover and use a wing divider to scribe a stitch line. I use contact cement and a small glue paddle rather than a brush and only use a little bit. If you are using veg tanned it ought to burnish. If the leather is chrome tanned it won't burnish. No overlap on the slots. The thread looks big and chunky, use smaller and better thread. Hammer down your stitches. When asking for advice it would behoove you to be more specific of the tools and materials used. It will assist us to help you and won't waste our time. What are you using to punch the holes and size, what brand, type and size thread are you using and what type and weight leather are you using, how are you burnishing? Which side are you punching from? -

"haha" is code for China. I'm guessing another reason may be that a lot of college children are taking up leather work. Look at the Reddit boards and they're wandering everywhere. A lot make cosplay items like bracers and armor and the like. I see arm bracers and leggings that have six buckles each--24 total. I blame the Klingons.

-

It is Regad, not Regard. I suggest the one RML sells. Works for me. https://www.rmleathersupply.com/collections/machines/products/rocky-mountain-summit-x2-electric-creasing-and-edging-machine?variant=33109259255917

-

BTW, If you were to buy only one book, this is the one to buy. It will teach you luxury goods and she provides patterns. https://www.rmleathersupply.com/products/leatherwork-school-book-techniques-for-making-hand-stitched-leather-goods-pattern-download?_pos=1&_sid=1af776371&_ss=r

-

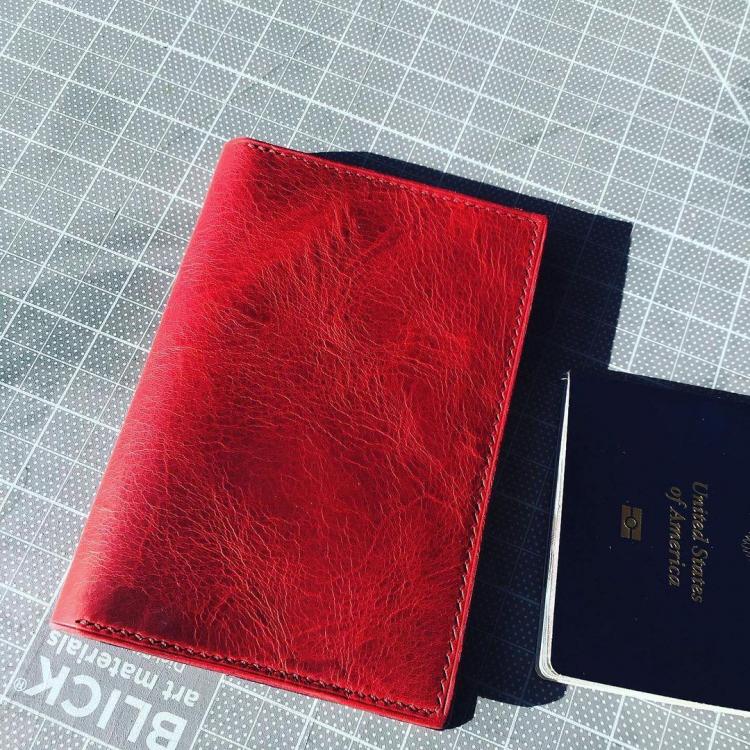

After tools you need to learn some basics. Saddle stitching, saddle stitching and more saddle stitching. Right now--today--go buy some cheap irons from Amazon. You will also need a non steel mallet, a wing divider and a utility knife, glue and a straight edge. Go to Rocky Mountain leather and spend some money on a nice piece of 3 oz Buttero leather, some small John James' needles and a spool of their "Twist" brand polyester thread at .45 mm. Make a stitching pony. The Buttero is 22 bucks a square foot. Expensive but that will be the caliber of leather you will be using. Get a feel for it and appreciate the quality. Cut some strips and glue and scribe, punch and sew. Show us your stitching and we'll help you improve on that. Times a wasting. I think we--at least I--have done all that we could for you. Show some initiative. The ball is in your court. Decide if you are going to run or fumble. I suggest you start out making something basic such as a card holder with your left over Buttero or something like a passport/notebook cover such as below. https://www.rmleathersupply.com/collections/view-all-leather/products/buttero-veg-tanned-leather-3oz-1-2mm-made-in-italy https://www.rmleathersupply.com/collections/thread-sewing/products/john-james-saddlers-harness-needles-sz-4-2-0-00-000-25-pack?variant=711082135 https://www.rmleathersupply.com/collections/thread-sewing/products/twist-polybraid-premium-braided-polyester-thread-buy-5-get-6th-free

-

Your head must be spinning.

-

I make handbags and wallets. If you are going high-end luxury you really ought to be using Italian or French cow and goat (chevre) leather in sizes ranging from .05 mm to 2 mm. Wallets and small goods use a 3.0-3.38 iron. A 2.7 iron is good for watch straps but you could get by with 3.0. If you are making your own patterns a 3.0 iron makes it easier to do the math on the layout. "Pricking irons" such as Vergez Blanchard are old school and are not used by many since the advent of irons such as KS Blades, Sinabroks and others. I've used Sinabroks and Amy Roke and they are more for pricking or going through thinner leather. Do you really want a true pricking iron and then use an awl to go through hundreds of holes on a handbag? Sinabroks are highly polished but dull. They need to be sharpened. Their handles are round and uncomfortable. The teeth are square across making it more difficult to center on a scribed stitching line. KS have teeth that are not as dull as the Sinabroks and need some touching up and polishing. The tips are slightly round allowing then to register in the center of the scribed line and penetrating the leather easier. I own four sets of the KS irons. Kevin Lee's irons get rave reviews and have a more traditional look and are sharp and polished and are made to go through layers of leather. His is about the only product from China I would recommend. Shipping is expensive and there may be a long wait time. High-end makers say they are the best bang for your buck. Any of these two iron sets are going to cost around $200. Using the above irons and making wallets and watch straps and other flat goods an awl may not be necessary. If you make handbags with gussets an awl is necessary. Really, every leather worker ought to have an awl. I have a few and choose to use different ones in different situations or according to my whims. A Vergez Blanchard awl I like very much. The cost is around $22. and needs quite a bit of work to polish. A better awl that's ready to use and is more suited to the above irons and high-end work is a Palosanto flat awl. You will need an edger, too. With that you are looking at around the $300 neighborhood. Those three items will be your most important and most used tools. Do not skimp. All the recommendations from the other posters above are good. You need to figure out your needs and desires. If you buy cheap tools it is easier monetarily and psychologically to upgrade to more expensive tools. Buy middle priced tools and that makes it more difficult. Many people new to leather work get excited in the beginning and get a raging boner thinking about doing the craft. Once started they realize that it is much more difficult and expensive than they thought. I see that this is your first post-- don't be one of those people and make sure at some point to thank all the posters that have taken their time out to help you out.

-

Exactly what Tugadude said. That wallet is a solid 3/4" folded and empty.