-

Posts

167 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gulrok

-

I'm in NJ. Specifically in a very anti-firearm area. (big city) I likely couldn't give it away if I wanted. Its a nice piece in my opinion. We just don't have the market here. Neither do we have the market for cowboy boots and a small very negatable market for holsters.

-

Putin hasn't infiltrated our Southern friends down in Georgia. https://districtleathersupply.com/collections/adhesives

-

I guarantee that's not an issue for us. Its just remembering when you switch between machines and around.

-

I'm likely in the group that doesn't do oiling enough. I wonder if there's a way to develop a little device that puts a light on when you need to oil. (So many hours of power to the motor) ... doesn't seem like it would be that hard so I'm going to take a quick look if its possible. My staff members for certain don't oil as often as needed, I know that for certain. Its likely going to be cheaper for us over the years to look into a 100$ or less than to deal with maintenance.

-

I completely agree. A 60w CO2 laser is definitely a strong starting point. Its a good balance between power and speed.

-

In theory yes. I don't know if 100% power is the peak or working rating of the laser. My tube has a 150W tube has a 150W working rating and 180W peak rating. Is 100% power peak rating or working rating - honestly no idea.That is something I could measure - with that being said, I haven't since I never go that high to begin with. The 4" lens absolutely makes that much difference. Remember the you get bad charing and cutting when your laser is out of focus.

-

Understandable, I'm not trying to be argumentative. I just want to clarify that it was I disagreed with the blanket statement in bold. As for your laser. I think you'd be personally surprised what you can accomplish. For example our laser is cutting at 26% power and 10mm/s for 12/14oz leather. You'd likely be able to hit 50-60% power on your laser by slowing it down. Definitely possible. The only reason we have the powerful laser is because of the bed size. We could easily downgrade the tube and still cut everything at the same speed but more power. Just keep your mind open to the possibilities.

-

So I don't do any handcutting or punching anymore. I've completely moved to lasering at this point. As for investment, I'm probably in the neighborhood of $17,500 USD. It wasn't the cost of the laser, but merely the upgrades, a fume extraction system (in a commercial space ,got denied venting outside, it has to be vented/purified in house). The air compressor, lines run throughout the shop... There was a lot to do to get it to cut so nicely. The laser tube in it is a 150 watt tube, it has a 60" x 40" bed on it. -- I have a 4" lens on the laser when I cut belts and 2" when I cut wallet weight stuff. I have personally found that my cuts are the cleanest with a 4" lens. I hit that wide field of depth (they say the 4" lens can cut items up to 1"). Because we have that wide field of depth the laser does not create excessive soot since I'm in that perfect cutting depth band. The closer your material is to that - the better off you are. I've cut 3/4" plywood with 'light brown' charring and no soot. My personal experience is also that leather being tanned and so tough, is harder to cut cleanly than plywood. So there is some science to it. A belt takes me... 2 or 3 minutes to cut per belt. About a minute is spent engraving our logo on the back of buckle end that wraps around to the back.

-

I don't work with natural veg. I do a lot of fire and Ems equipment and belts. The lightest thing I cut is like a chestnut (HO).

-

I posted a video....

-

I would have to disagree. See the video I just posted. I have personally found that inexperienced laser operators tend to have struggles when dealing with materials. I run test cards when I get new leather (a 6"x6") on the leather. I then pick the best settings from my test card. Depends on what thickness I cut - but I usually use my 4" lens on any belt leather. I have my laser dialed in to be able to cut 3/4" plywood without problems. I cut 1/2" plywood boxes all the time. You can wipe your hand along the edges without soot. Yes the edges have char - but it goes away with burnishing and my normal edge dying process.

-

Hey Rocky. Its 12/14 oz English Bridle from RJF leather. No top seal.

-

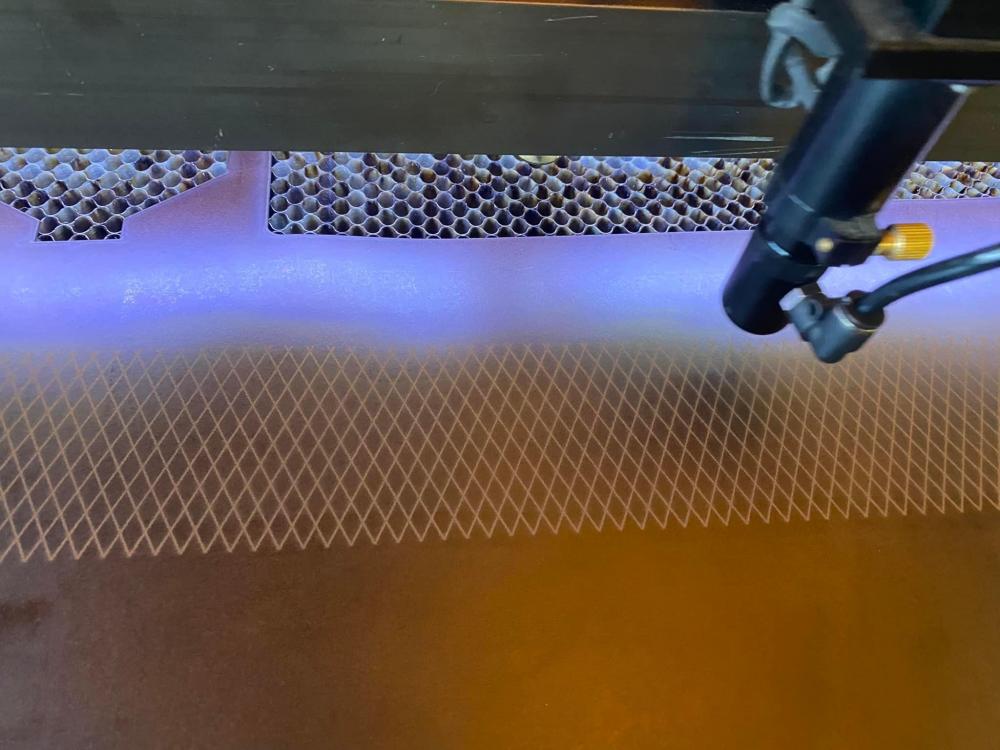

I'll get a video for you. I have belts to cut out. At the moment I'm cross hatch patterning some leather for a wallet... because why not?

-

150 W Laser here. I laser cut belts at this point in my business. Some others have good experiences. I've been able to dial in the 'char' to the point that there is no soot leftover when I pull a belt off the laser bed. You're able to wipe your hard along the edge and have a clean hand afterwords. I replaced the mirrors with higher quality mirrors. The laser head was replaced as well.

-

Only because I'm working on it right now, but laser cut boxes. Have nice plywood laser cut (baltic birch) and assembled. Then wrap the boxes.

-

My attempt to enter the machine sewing world

Gulrok replied to Tio's topic in Leather Sewing Machines

Hopefully you found a killer deal on it. I played with the Tippmann Boss for a few projects and founded out that I absolutely hated it. Your mileage may vary, and there are people who swear by those machines. So who knows. Their resale value also have a wide range. I see them from $450-$900, it really just depends. For your next machine, or if you also find that you're not into the Tippmann Boss - consider a powered machine. https://www.tolindsewmach.com/cb2500.html Is just a bit more and might be a better setup if you're looking to do more production work on a budget. -

Howdo you tell if it chrome tanned or oil tanned

Gulrok replied to Bert03241's topic in All About Leather

Yeah so oil tanned leather is just a type of chrome tanned leather finish/post processing. Its not part of the tanning process but rather post tanning / dying process that puts a bunch of oils into the leather. -

Tried A New Wallet

Gulrok replied to AzShooter's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I have a nice 4k resolution monitor - its hard to see clearly. -

Hey that's me. I do have a laser that can do it. Send me a PM with your design.

-

I use exclusively black thread because I laser cut stuff - so the thread always looks soiled. With that being said, give yourself an extra 6-8 inches of thread on each side. Your first few inches of thread will be soiled but the other stuff should be fine. That works for most people.

-

Are leather sewing machine makers lazy

Gulrok replied to chrisash's topic in Leather Sewing Machines

The reality of the matter is there is so much information available for these machines with these forums, youtube videos by al-bane and others, along with facebook groups. Tips and Tricks with Cobra Class Leather Working Equipment | Facebook Leather Machine Co Inc - YouTube Techsew Industrial Sewing Machines - YouTube HighTex Heavy sewing technology - YouTube (Cowboy) There isn't a big need for the distributors to produce lengthy videos as at this point theres so much information out there. You can get on the phone and get support quickly. I'm sure there are distributors/manufactures out there who provide a higher level of service, but you're paying for it. I own a laser cutter that costs 5-10x what these sewing machines cost. I get more support with my sewing machine than a laser cutter company so busy with orders and other customers that if there WAS an issue I would be out of production for days. If there is an issue I'm better off purchasing replacement parts myself than warranty a piece because of the time that it takes. Its an industrial machine. I could have spent another $10,000 to get someone to answer the phone faster, but I'm a crafty person and can diagnose and address issues. We just spent approximately 40,000$ on 2 Melco embroidery machines. Melco is flying people out to have a training session at our family business location. Melco has some of the support out there in the embroidery world, but you pay for it. -

Personally speaking - I cried twice. Only because I learned later on that I really needed a heavier duty machine. I bought the techsew equivalent of a cobra 26 (2750 pro). Later on I learned that the majority of the work I do is in fact 10oz or more leather and 277/207 thread. So I have a few thousand in machines now. So first we should be asking - what thread are you using and leather thickness. Make sure you're not buying something too light duty for what you're using. As far as the Juki 341 and 441 clones - they do convert into a flatbed. Its not exactly the same because if you're sewing bags then you don't have the extra run on the table to hold your bag while you sew length wise. However it is absolutely versatile and not noticeable for small leather goods. As a shop who sells a lot of goods, I'd personally buy two machines a flatbed and a cylinder arm both great for two different things. However if you can only buy one machine - definitely the cobra 26/techsew 2750/cowboy's model.

.jpg.d60258221c476480a6e073a8805645bb.jpg)