DieselTech

Members-

Posts

1,726 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DieselTech

-

What type of Edge beveler do you use?

DieselTech replied to Yukonrookie's topic in How Do I Do That?

Yep built diesel engines & worked on diesel trucks for 25-30years. 20 of them years for Caterpillar. Yes I like 4 or 5mm stitch spacing on my leather projects. I bought the weaver brand diamond stitching chisels cause they were priced right. KS Blade diamond chisels are super nice, but they are over $300 for a set. -

Can you show us a pic of the leather you are using? Mulesaw might have already mentioned it, but chrome tan & oil tan leather will not take & hold a stamp impression

-

What type of Edge beveler do you use?

DieselTech replied to Yukonrookie's topic in How Do I Do That?

I use 4&5mm diamond chisels from weaver. I was planning on buying some KS Blade diamond chisels, but I haven't yet. They are expensive. -

Lmao i am getting weak!!!

-

Holy Bat Azz Robin!!! This thing is fn heavy. Came in a wooden crate! Going have to file a worksman comp claim!!!

-

What type of Edge beveler do you use?

DieselTech replied to Yukonrookie's topic in How Do I Do That?

@Yukonrookie you might also check out: Rons Tools he makes a bunch of different styles of edge bevelers. He makes nice stuff.. -

What type of Edge beveler do you use?

DieselTech replied to Yukonrookie's topic in How Do I Do That?

Sorry for not replying sooner. I know you asked me this earlier on this. I'll try my best to show you & explain. Here is a #3 Palosanto edger on 10-12oz brown Latigo leather. As you can see in the pics it kinda cuts like a 45° angle. But if you sand the edges lightly it will give it a nice rounded edge. Here is some pics with "No Sanding" on the edge. I just beveled it & took some pics. -

Thanks. So did you have clicker cutting dies made or brass embossing stamps? Weaver about 6 months ago or so, opened a shop for custom cutting dies for clicker presses. Or they got hammer type cutting dies. Here is what they will be making cutting dies for. Vertical & horizontal wallet card pockets.

-

Well guys & gals I decided to try Weavers Custom Die Shop to make 4 wallet card pocket dies. Has anybody else tried them? I set my patterns off this morning for the dies I want made. I got a rough quote of $75/die. So we will see.

-

What are you actually wanting? Dimensions for the pedestal stand? Did you get the speed reducer pulley & bracket? Thanks.

-

I was told every time you have the throat plate off. You got to adjust it so the feed dog don't contact the sides of the throat plate. I think you just need to readjust your throat plate. Also leave the throat plate a touch loose & cycle your machine by hand to help align it. Then hold the throat plate as you snug the screws.

-

Help me identify a "new to me" consew

DieselTech replied to RickPleasant's topic in Leather Sewing Machines

That machine has seen a lot of sewing. Great old machine thou. -

Need help with Adler 167 Maschine fixing bobbin bar

DieselTech replied to Karlluis's topic in Leather Sewing Machines

- 9 replies

-

- leathermashine

- adler

-

(and 5 more)

Tagged with:

-

Need help with Adler 167 Maschine fixing bobbin bar

DieselTech replied to Karlluis's topic in Leather Sewing Machines

I got 1 question. When you turn the hand wheel? Does the connecting belt on the right side turn with the hand wheel? I am no sewing machine mechanic. But I am Diesel technician. Thanks.- 9 replies

-

- leathermashine

- adler

-

(and 5 more)

Tagged with:

-

Seeking Input on Sheath Design

DieselTech replied to rktaylor's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I know you do exceptionally nice stuff. It is hard to make a recommendation without the knife in my hand. If that makes any sense. But I am curious what others might recommend. -

Seeking Input on Sheath Design

DieselTech replied to rktaylor's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Are them knives what they refer to as a chore knife? RK you make some nice stuff! If it were me & these were chore/work knives to be used around the farm/ranch. I would make sheaths a bit longer & wet form more around the handle. So the knife sits a bit deeper in the sheath for more retention. They look great to me as is. -

Ok thanks. I looked on his sight & ordered a couple of his pattern books yesterday. I will have to go back & look at his digital downloads. Thanks. Much appreciated.

-

Went looking for a Landis Splitter, came home with a...???

DieselTech replied to LMullins's topic in Leather Machinery

Thanks. Yes if you get time & can post a few more pics, that would be great. I would not mind seeing what the chewed/chipped up gears look like. Keep me in mind when & if you decide to move it down the road. P.M me. Thanks. -

-

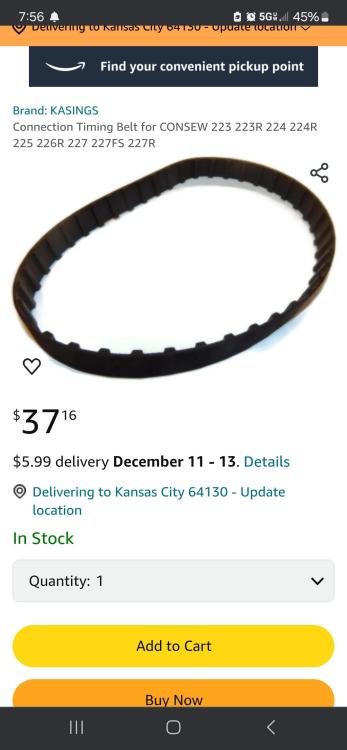

Would that be the timing belt possibly?

-

Thanksgiving Recovery, Black Dye Rubbing Off Belt

DieselTech replied to AlamoJoe2002's topic in How Do I Do That?

Do you think it is something about the black dye with rub off? It seems like it is a re-occurring question asked on here & it always seems to be black. Or do you think it is more to do with how it was applied? -

Looks nice! I looked today for a pattern/line art of the feathers & arrow belt. Is that by chance a digital pattern? Or is this your artwork? Thanks.

-

Thanksgiving Recovery, Black Dye Rubbing Off Belt

DieselTech replied to AlamoJoe2002's topic in How Do I Do That?

I am wondering if you possibly got too much neats foot oil in the belt. Usually 24-48 hours is sufficient for the neatsfoot oil to distribute thru the belt. I would wipe it down with a rag & acetone & then let it dry completely. Then check it for dye rub off. Others may have a better solution. -

Can you post a pick or 2. I always like seeing the classic old tools/machines. Thanks.

-

Looks nice! That's is going to be a awesome belt.