Search the Community

Showing results for tags 'industrial'.

-

What Exactly is an EPS? Cobra Steve, Leather Machine Co., explains what an EPS (Electronic Positioning System) is, and how it can help you do a better job sewing leather. Be sure to watch the video too!

-

I just bought this Singer 111w113 machine from a guy in Ohio who said his son used it for years making Corvette covers. It was serviced within the last few years and apparently runs great. Well when loading it into my truck, the guy dropped it and it hit the ground hard. He assured me it was fine, but when I got home I discovered the extent of the damage. The flywheel had broken from how it landed during the fall. I've seen replacement flywheels online, but the problem I discovered was that I couldn't adjust the stitch count, and it seemed to be stuck in its highest setting. Upon further inspection, it looks like the shaft the flywheel sits on has bent and also the threaded part has cracked. I can't figure out what this piece is called, or how to find it. I've checked some online retailers and even PDFs of original instruction manuals, but I can't find how to get a replacement for this piece. I hope someone is able to identify what I cannot. Thanks in advance!

-

Hello, i have brand new techsew 2750 with table (180$) and laser (90$) (not pictured) for sale. Paid $2,800 with shipping. I bought it as my second machine but never had a chance to use it therefore baby gotta go. I never stitched on it and it is literally brand new. Machine is located in NJ 08520, if would like to see it in person please stop by the shop. Text me or call me at 732-421-2159. if I wont pick up please leave a message. Thank you and have a great day.

- 2 replies

-

- techsew 2750

- industrial

-

(and 1 more)

Tagged with:

-

-

This has a rebuilt needle head with good regular 5 stitch per inch (you can adjust it for less). It has a new bobbin winder. It is running very smoothly and consistently. I am asking $1300 for it. It is in Aspen Colorado. I can make a crate for it and ship it for cost: shipping, time and materials. I have a balance wheel handle and hardware ordered from England. It should be here soon. It comes with 10 new bobbins and some needles, extra feet, etc. Thank you.

- 2 replies

-

- sewing machine

- boot patcher

-

(and 4 more)

Tagged with:

-

I'm pretty new to sewing. I have a consew 206RB in very good shape. The main purpose for me getting into the field is for shoe making. Before anybody goes there, I am aware that a post roller foot is the best machine for such work, but I didn't have post bed money. I bought a good machine that I could afford. I also plan to venture to other things which will require a flat bed. Anyways, the foot marks my leather. I have already read the manual and loosened the screw at the very top to relieve some pressure, which did help. But I was told that there is a screw to loosen for the outer foot and inner foot, and since I'm a rookie I really don't know which one I loosened. It's the inner or "walking foot" that leaves marks, they can easily be rubbed out of suede, but not leather. Anybody have some suggestions?? Even on tools that can rub marks out? Also, if you're interested in this machine shoot me a pm. If I can't figure out how to get this to stop marking my leather I MAY be looking to sell it to buy a machine that can. Located in Ohio. Thanks!!

- 13 replies

-

- consew206rb

- industrial

-

(and 5 more)

Tagged with:

-

make / manufacturer: Pfaff model name / number: 545 Industrial sewing machine for sale PFAFF 545 with new servo motor for SALE Craigslist add has pics and details. https://redding.craigslist.org/for/d/igo-pfaff-545-walking-foot-industrial/7216319921.html I bought this in the hopes of taking my leather working game up another notch, but I just got into nursing school and won’t have the time for it. Plus I need the money for school. I researched this a ton before purchasing it. It’s a beautiful sturdy old machine made in Germany and very well built. I updated it with a servo motor by Reliable, the Sewquiet 6000sm, which costs about 190$. This motor is well reviewed and the company gets great reviews as well, if you ever have any difficulties with it. I still have the clutch motor available also, the installation is very simple. I bought the machine and table from a store in San Francisco that was going out of business. They were using it to make canvas and leather bags. 1,400$ and I’ll deliver it anywhere in southern Oregon to the Bay Area. If you want it delivered then there’s a 500$ deposit with the rest payable on delivery. Or 1,215$ and you’ve got to come pick it up yourself with someone to help move it. It’s pretty heavy. I live near Redding. You should have some familiarity with this machine, I won’t be able to show you much about it as I just got it and haven’t had time to get to know it well. Lots of YouTube videos available. I’m not trying to make money on it, I’m just trying to get back the money I’ve put into it. So no lowballing please.

-

ABOUT ME: Hi there! I am searching for someone who might need a great INDUSTRIAL sewing machine Check this out please and see if it could be of any use... I was going to create leather belts and gun holsters in Texas, but I changed my mind once I returned to Alabama...I am an aerialist and I would like to sell my machine to invest in my dream...If you're not interested PLEASE share with someone you think may be interested. The Lord works in mysterious ways, #GodBless ABOUT THE MACHINE: The Techsew 5100 Special Edition is the ultimate sewing machine designed for a wide range of leather work projects. Light range leather work: Purses, handbags, pouches, wallets, notebook covers, vests Medium range leather work: Belts, knife sheaths, scabbards, quivers, horse blankets Heavy range leather work: Saddles, gun holsters, knife sheaths, harnesses, horse tack Additionally it is also great for non-leather work applications such as tie down straps, boat/car covers, orthopaedics, thick paper binding, parachute harnesses, tarps, vinyl, canvas, synthetics, heavy webbing and more. What makes the Techsew 5100 Special Edition so special? Techsew SmartServo-NP Needle Position Motor The Techsew SmartServo-NP is an automatic needle positioning motor which saves you tons of time and effort while sewing. This powerful and versatile motor will automatically lift the needle at the end of a seam, or automatically leave it in the bottom position. This will eliminate the need to constantly turn your handwheel to position your needle. At 1HP and 800W, The SmartServo-NP will help your machine power through thick leather at any of the 16 adjustable speed settings. Additionally, a speed reducer is used in combination with the SmartServo-NP motor for added power and speed control. This system is ideal for beginner, intermediate and expert sewers as well. ALL EXCLUSIVE TO THE TECHSEW 5100 SPECIAL EDITION! Features: Triple Feed - Walking Foot (needle feed + alternating presser feet + bottom feed) 1" Presser foot clearance Sews from 6oz all the way up to 7/8" thick 16.5" Cylinder bed Equipped with Techsew SmartServo-NP motor and speed reducer to sew at slow & controlled speeds - great for novice, intermediate and professional sewers Reverse stitch - for reinforcing stitches 12 inch heavy duty flywheel Reinforced steel pedestal style table with adjustable height (sew standing up or sitting down) Includes: Complete table with casters, SmartServo-NP motor, speed reducer,TS-28 LED lamp, TS-5 LED stitch light, TLG laser guide, swing down roller guide, flatbed table attachment, 3 pkgs of Organ diamond point needles,8 bobbins, thread lube pot, left toe foot, double toe foot, center foot, smooth blanket foot set, 1 lb. (16oz) cone of thread, oiler, instruction manual, repair tools, thread clipper. Stitch length adjustment up to 11mm (7/16") Uses thread sizes 69 to 415 Uses needle sizes 18 to 27 FREE setup & instructional DVD included! Includes Limited Lifetime Warranty and FREE technical support for the life of your machine Machine comes pre-threaded, oiled, adjusted and READY TO SEW Specifications: Needle sizes: 18 to 27 Thread sizes: 69 to 415 Presser foot clearance: 1" Sewing capacity: 6oz to 7/8" thick Cylinder bed length: 16.5" Maximum stitch length: 11mm Techsew SmartServo-NP motor: 800W, 1HP, 110V, 300 to 1800RPM, 16 speed settings with bright LED display, completely silent when idle and reduced noise during operation. The most POWERFUL servo motor in the industry.

- 6 replies

-

- leather

- sewing machine

- (and 10 more)

-

Have a chance to pick up one of these machines and cannot find any information about it. Has anyone used one? Know any leads about manual or parts? (wrote to Chandler, still waiting to hear back...)

-

I see many requests for manuals for Singer Industrial Machines. Some have gone unanswered, and some are subject to long and tedious discussion with either no satisfactory answer, or an answer hidden deeply away. Of course, there are also plenty which have been answered quickly and succinctly. By doing some research and seeking out some of those hidden answers and others less hidden, I think I have found all of those that have been asked for, as well as many others. I am not an expert, and don't claim that this is an extensive list, but it is a pretty good start for those trying to find the manuals, parts lists and service manuals. The list I have attached starts with a few of the sources which are very helpful. All of the manuals listed are free, and I suspect the list owners would appreciate it if you can send them any manuals that they are missing. So before you pay for a manual, check these lists first. I hope this is a quick answer for many of your questions about manuals. I would really appreciate any additions to this list - please add links in your responses. Singer Industrial Manuals –.pdf

- 53 replies

-

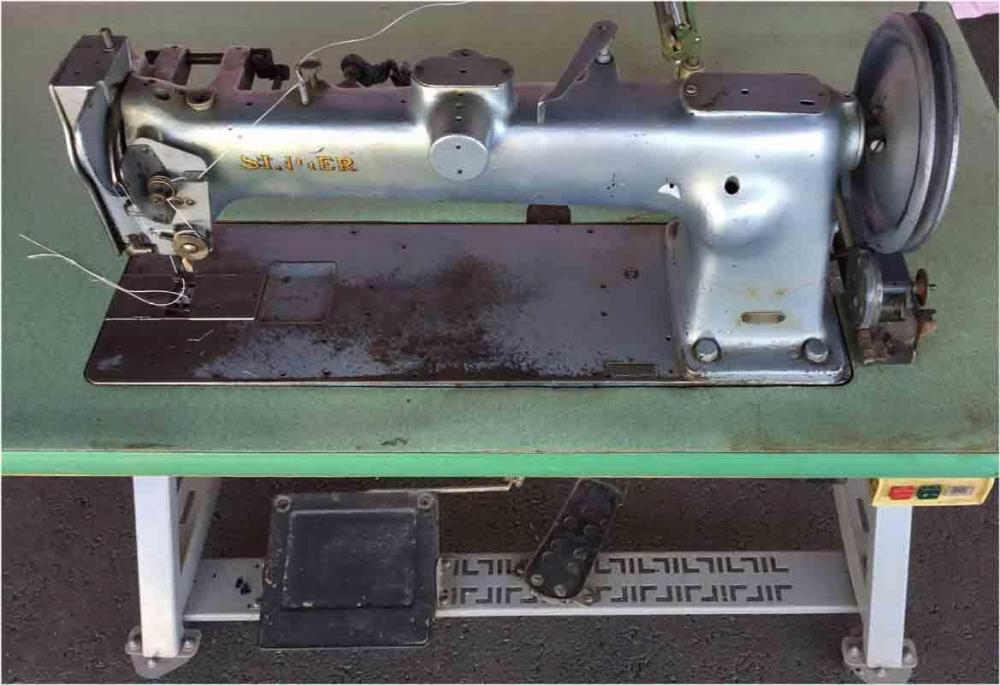

Singer 144W201 long arm industrial sewing machine. $1100 cash, local pick up only. Consider trade for Tippmann Boss with accessories and bench. -20" arm, this machine is massive and heavy -for canvas, leather, upholstery -compound feed walking foot -no reverse -straight stitch -single needle -adjustable stitch length -very large bobbins

-

Fully functional. Stitches flawlessly. Treadle replaced with clutched motor that runs fantastic. Bobbin and shuttle included. No missing parts. Has had a repair on top a long time ago. More photos available. I have owned it and been using it since around 2007 or 2008.Time to upgrade as business has improved. Seems that they go for around $1000 in less condition than this one. So, I'd like $1450 considering the condition and the motor but certainly will negotiate. Located in NW Wyoming. Reach me at wyoming.eb@gmail.com

-

- harness machine

- sewing maching

-

(and 4 more)

Tagged with:

-

Industrial Singer Sewing Machine, 44-10 - $175, Needs a Tension Spring that can easily be purchased online for a few dollars. Used for sewing leather handbags, clothing Industrial Singer Zig Zag 107W1 - $300 (photo is showing a missing plate, but I have the plate) Tables available for either machine. No motors. Pickup only in Hudson, Massachusetts Serious inquiries can email me: LeftyMonk@aol.com

-

Hi, I was looking to start sewing leather goods for accessories. Belts, wallet, holsters, etc. Having a hard time finding information on this particular model. I have attached the manual as well. Any advice or direction would be greatly appreciated. I would like to use this machine as it was out of my grandfathers building. Thanks, Brandon 96-87_107.pdf

- 1 reply

-

- industrial

- machinesewing

-

(and 2 more)

Tagged with:

-

Hey there folks, My parents have asked me to help them sell their Juki LU-1508 to help pay for medical expenses. I believe we've had this machine since early-to-mid 2000's. My folks re-upholstered our boat with it, I re-upholstered my dad's bench-seat in his toyota pickup for my senior project, and other than that it's not seen a ton of use---I'd say under 150 hrs, and most of that very light use. I don't know a ton about the machine, but it is in excellent working order and was recently serviced. There is a crack in the plastic belt-drive cover, but other than that it is in excellent cosmetic shape. My mom mentioned that they paid extra for the variable speed and to make sure that feature is noted. This machine is located in Lake Tahoe, California. My dad is currently in no shape from chemo-therapy to deal shipping this item, so it is local pickup for now. BUT: if there is no local interest, I will likely transport it down to Pasadena, CA where I can either sell it there or arrange for shipping myself. Asking $1600 PM me for more high-res photos Thanks!

- 5 replies

-

- leather

- upholstery

-

(and 1 more)

Tagged with:

-

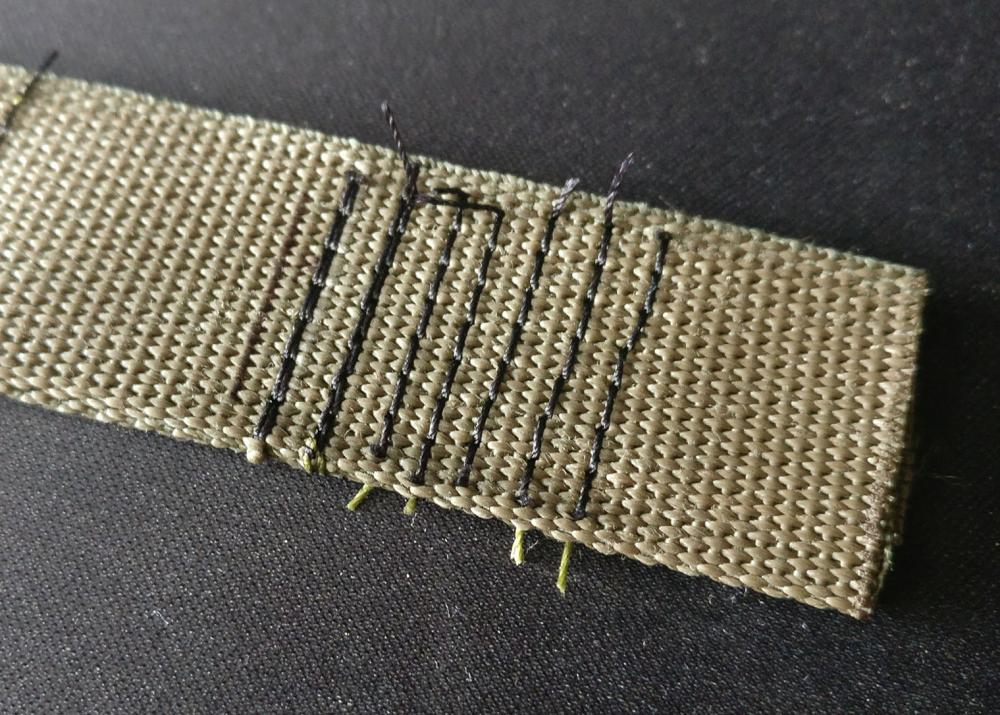

I'm trying to sew 2 layers of 1" nylon webbing and am getting the top thread showing on the bottom regardless of how tight I set the top tension; See images attached. The black thread is topside, green thread is bottom side. Both threads are size 69 bonded nylon. In the image of the bottom side I've tightened the top tension a little bit each time, until the final row where I maxed-out the tension. As you can see there is virtually no difference. I've tried two different needle types with the same results: Organ DP x 17 125/20 and Groz-beckert 110/18 RG. The organ needle is the largest one I currently have, and should be adequate for the size of thread I'm using. I'm wondering if the type of webbing I'm using requires a specific size or needle point? Things I've tried with no improvement on the bottom side stitches: Increased top tension all the way Reduced bottom tension to almost nothing Re-timed my machine Removed and cleaned the bobbin case/assembly I will also add, the tension unit is brand new, but I did take the time to calibrate it so tension engages and disengages properly with the knee lift. Images of the tension assembly attached. Is there something special about setting up this machine that I've overlooked? Any recommendations on things to try would be greatly appreciated.

- 12 replies

-

- bobbin

- industrial

-

(and 3 more)

Tagged with:

-

Hi everyone, Just a heads up for anyone looking for a walking foot industrial machine. I found a listing on Kijiji (Canada), and traveled there to pick up one of the 22 (twenty two) industrial machines that the company is selling. The price that they are asking is $200 cdn. Note: I have NO financial interest in these transactions. I'm posting the information as a potential connection for the members of these forums (who have given me much good and valuable information). So, here's the scoop: The machines are mostly Durkopp 291 walking foot units (there were also two Pfaff units there) They are 3 phase machines running at 220v (60 cycles). They require a pneumatic line to operate the foot lift, and some other functions. There are no manuals. The operators of these machines are no longer at the factory.... There is no plug on the end of the cord (snipped off, probably were hard wired into the plant's electrical system). According to Naresh (the manager who was my contact, these were all in running condition when removed from service). One of the machines I looked at was missing the bobbin top (and parts for these are EXPENSIVE!) Inspect carefully for any missing bits! I've gotten the one I purchased home and am cleaning it up and getting her going again. I'm currently waiting on a rotary phase converter ($300 US, with shipping). A harbor you know who cheapo compressor will provide air (I hope). Other pieces I've ordered: bobbins (they used preloaded bobbins), and a selection of needles. If you are interested in the machines, call or text Naresh : +1 (647) 459-0110, tell him that Marty gave you his contact info. The machines are located at: Dynasty Furniture Manufacturing, Ltd. 6830 Columbus Rd, Mississauga, ON L5T 2G1, Canada Other notes: If crossing from the US like I did, DON'T use the "Rainbow Bridge". The border guard was VERY grumpy about me using that crossing for a business related trip. He gave me a warning and said I could be fined. Nice welcome back to the US of A! The third pic is of the machine I bought, after some cleaning. Anyone who knows anything about the control modules, please let me know. Have not found anything online about those yet. The module I have says "Durkopp v720" on the front, and "Dz101" on the back. Will post this question in a more appropriate forum eventually.

- 18 replies

-

- walking foot

- industrial

-

(and 3 more)

Tagged with:

-

Hello, I need a sewing machine and I would prefer to buy a vintage industrial (or near-industrial) model over the Sailrite LSZ, which is the obvious option for a new machine. I'll be doing mostly marine canvas, upholstery and sail repair, not as much with leather but you guys seem to be the experts on this class of machine... and I will no doubt be doing some leather work as well. I need it to have a zig zag stitch. It does not need to be portable. Quiet operation, good control and simplicity/longevity are the things I value most. I would plan to replace any clutch motor with a servo motor like the Consew CSW100. I think the Consew 99 or 199 or the Pfaff 138 could fit the bill. I'm sure there are a number of other models that I should consider as well. What other vintage models and brands should I be on the lookout for? Any advice is greatly appreciated! Jack

- 1 reply

-

- zig zag

- industrial

-

(and 3 more)

Tagged with:

-

I have the opportunity to purchase a Singer 153W101 at a decent price. I found a copy of a manual for this series of machines, but have not been able to find out much information with searching about this machine. Does anyone have knowledge or experience of this machine and what it is capable of doing? I would be using it to do handbags, totes, backpacks, etc. I would also like to use it for shaving kits made with 8-9 oz leather for the sides and bottom (skived) and chap leather.

- 5 replies

-

- singer 153w101

- leather

-

(and 2 more)

Tagged with:

-

I have the opportunity to purchase a Singer 138W101 at a decent price. I found a copy of a manual for this series of machines, but have not been able to find out much information with searching about this machine. Does anyone have knowledge or experience of this machine and what it is capable of doing? I would be using it to do handbags, totes, backpacks, etc. I would also like to use it for shaving kits made with 8-9 oz leather for the sides and bottom (skived) and chap leather.

- 2 replies

-

- singer 138w101

- industrial

-

(and 2 more)

Tagged with:

-

I Just bought one.I have transported it home and will be adding new oil to clean it out before I add the oil that will stay when I operate it. How long should I run that first oil to clean it out? The oil I removed was not clear. I was told it was Synthetic Honda Motorcycle oil... There is/was a little bit of brown staining in the oil tank. The oil did not look bad but I am going the traditional route. Also, Is there anything special about these machines I should know? Any parts that regularly fail? Common problems? anything like that? I am extending the clutch actuation? arm to make it less sensitive. (Possibly a servo motor later this spring but not right away I may want a smaller pulley on the motor. I definitely want a larger hand wheel with larger pulley. Not just for speed but for my large hands. I have searched but nothing specific came back and said yeah this is bigger and fits. Also the serial # is AF677193 can anyone tell when it was made? what year? Thanks Sled

- 7 replies

-

- 241-12

- industrial

-

(and 1 more)

Tagged with:

-

Hello everyone, About a year and a half ago I got some great info from you all on a 1916 Singer 45k52 that I had picked up. That machine is working very well sewing heavy belts, holsters, knife sheaths, and small accessory bags. I love the 45k but no one makes accessories for 100 year old machines. So now I'm looking for something a little more modern and lighter weight for sewing lighter and softer leathers. I was thinking about a 206 RB but, while browsing online I found a Consew 339 RB-1. It's a 2 needle machine. Questions: 1. Can a 2 needle machine be used with just 1 needle at a time? 2. Can It sew lighter, softer leathers such as, 2oz upholstery or garment, without skipping stitches. 3. How much can it sew through/handle? For example, 2 layers of 2oz upholstery with nylon webbing sandwiched between them? How about 1 or 2 layers of 6oz veg? 4. Is there anything to watch out for with a 2 needle machine? Is it much different than a single needle? I appreciate all of the advice I got last time. It was a huge help. Hopefully someone has some good info for me on this one too.

-

I wanted to re-mount my Consew 226 walking foot sewing machine in a better table, and I had access to a replacement top. The new top didn’t have the required recess to mount the head unit, so I needed to rout one out. I started with a full-sized template of the shape I needed. Building the Template The corner diameter of the template needed to be 1-3/8”, and since I didn’t have a router bit that large, I used a Forstner bit to cut the holes. The template is made from 1/2" MDF. Then I completed the opening of the template with a router and spiral bit. A clamp-on straightedge guides the router in a straight path. Next I made removable corner inserts for the template. I’ll explain the reasoning for these little triangular pieces in a minute. They are easily made my marking the curve on some scrap, and sanding to the line. Then I cut them loose at the miter saw. These small pieces were 1-1/4” on the smaller sides, and 1-3/4” on the hypotenuse. Milling the Main Opening Then I used the template to pencil the shape of the opening on the sewing table top, and roughed it out with a jigsaw. At this point I was ready to clamp the full-sized template to the table top. The corner blocks were carpet taped in place, and I routed the opening flush with the template using a 2” long bearing-guided template bit (rout clockwise when inside a frame). Here you can see how the corner blocks protect the corners, which will eventually support the weight of the sewing machine head. Routing the Ledge Next I switched to a 3/4” long bearing-guided template bit and removed the corner blocks. Then I was able to follow the template’s radiused corners to mill a small ledge. This cut was 5/8” deep, which allows 3/8” for the lip of the sewing machine, and 1/4” for the rubber bumpers that I’ll install later. The 226 is a top loader, so I am shooting for a flush fit here. If you have a side loader like the 206rb, you might want to make the ledge slightly shallower so the bobbin access plate clears the table. Bumpers and Hinges The rubber bumpers are just some rubber mat that you can buy in bulk at the hardware store. They are tacked in place, one at each corner. Then I drilled holes in a scrap of MDF with a 1-1/2” Forstner bit. I then used that as a template to rout holes for the hinges. I could have simply used the Forstner bit to drill out the hinges, but I find the router cuts to a more consistent depth. Then excavate a little spot for the hinge mechanism. This is easily accomplished with a trim router and 1/4” spiral bit. Final Fitting The fit looks good, and the router bits cut the laminate cleanly. It took me most of a Saturday to accomplish, but it sure looks nicer than the old table. If anyone is contemplating a sewing machine table build, I found this full-sized template method with corner blocks worked quite well. I'll hang on to the template, and if I need to do it again it'll be a snap.

-

- industrial

- sewing machine

-

(and 5 more)

Tagged with:

-

I desperately need a Hook Driving Pinion Thrust Washer #224022 in a hurry

- 4 replies

-

- industrial

- singer

-

(and 1 more)

Tagged with:

-

I have a singer 300u 205 double stitcher , a singer 300w 201 double stitcher , a reece keyhole machine, 2 juki keyhole machines, several single needle lockstitch machines, a couple single needle chainstitch machines. I really need to sell! Please message me with questions

- 2 replies

-

- sewingmachine

- heavy

-

(and 8 more)

Tagged with:

.thumb.jpg.9eb503737331b368131da921c337a46a.jpg)

.thumb.jpg.1893c7cb4df5965c8440417eac06d2f2.jpg)

.thumb.jpg.3f6eb25c946a9a70023c66f72d41b52f.jpg)

.thumb.jpg.250fadede878e989b030ccd2eb78f018.jpg)

.thumb.jpg.a36f517b745a416d2c2419053fde7c53.jpg)