Search the Community

Showing results for tags 'skiving'.

-

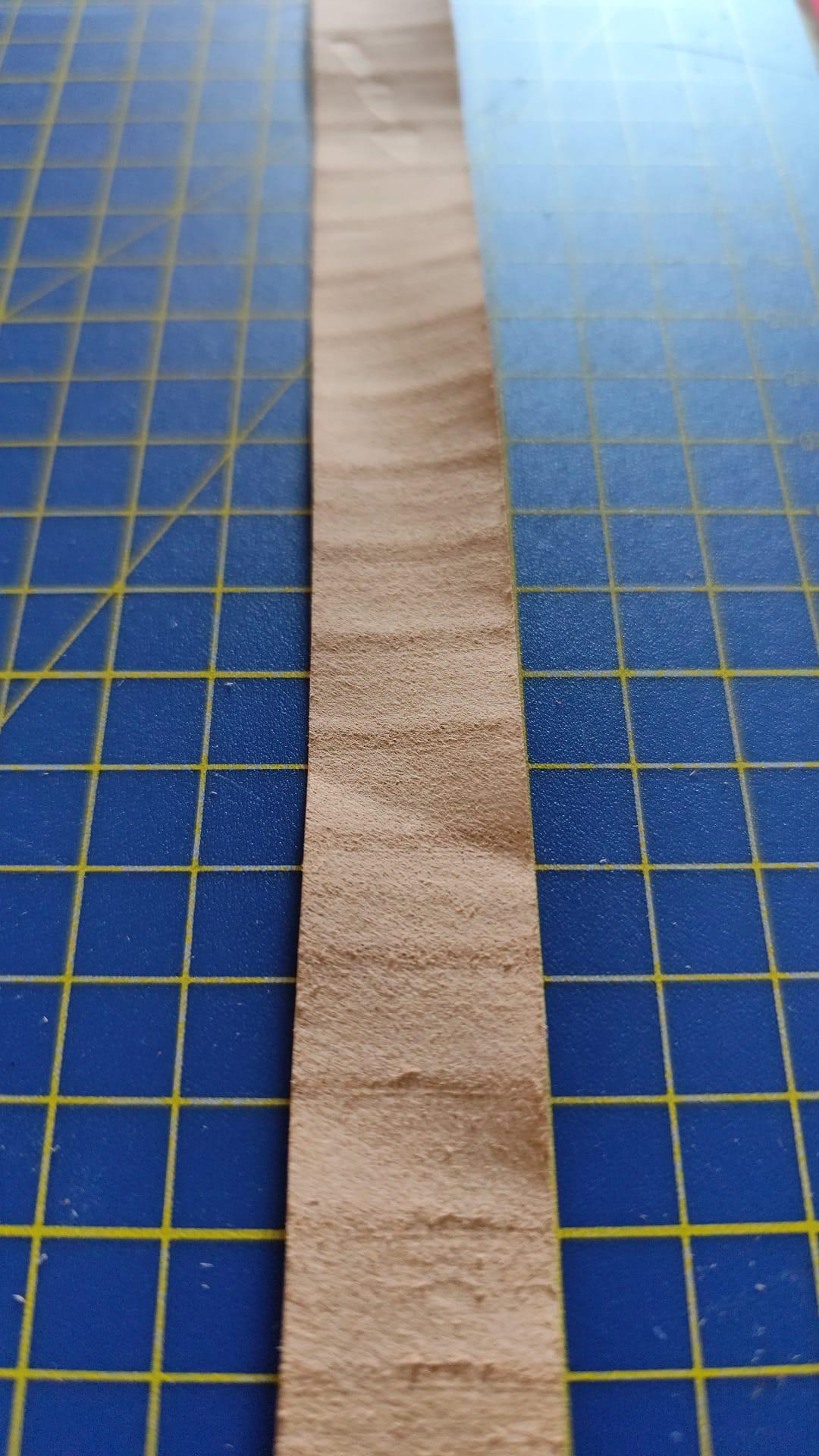

Hello everyone, I recently bought my first skiving machine, it's a used machine, a Sagitta SC75A (for which I'm also looking for the manual) I'm new to skiving so I'm asking you if you've encountered problems like mine and could you explain to me how I can solve them? The big problem is that it flakes unevenly with a wavy pattern, not smooth as it should be. Thank you Ps, I'm attaching a photo to help you understand the problem. It's a 2cm wide and very long strip of leather, stripped from 1mm to 0.5mm.

-

Just wanted to share a tip with anyone out there having issues with skiving by hand. We all know the potato peeler safety skife is useful, and a lot of us dad using it. It takes a bit of practice to perfect. I fell I've mastered the art of the skife knife since I work with one thickness, and thin down straps for example. 25-30" of skiving can be stressful trying to get out even. Which is where I have a tip to share. I was in my shop planing a couple boards down to even thickness for a welcome sign I made. It got me thinking, why can't I use my hand plane on leather? Nobody says you can, but there's nothing saying you can't either. So I took my small plane, I refer to it as a finger plane but it's a bit larger than those. Changed the edge geometry a bit and starting playing around with some scrap leather to see what happens. Spent some time figuring out how far to set the blade depth. Fine tuned over a few projects, kept extremely sharp (as all blades should be) Well, this little plane has changed the skife game, for me anyway. Here's a pic of the plane and what it does with leather. You can see how fine of a cut it makes, just barely skimming the high points on the buckle side of this belt blank (more on that to come on that) Anyway, it works and it's a cheap alternative to help reduce some skife anxiety. You can pick these up for like $10.

-

When we moved to Israel, I took some of my leather tools but not all of them. Unfortunately you can’t buy a skiving knife here (not that I loved the Osborne skiving knife I had in the U.S.) Big Stacks Small Workshop suggested using a razor blade scraper. Fine as it goes, but not much stability. And it doesn’t work well for straight 90 degree cuts. Viktor George had the answer. On one of his Tips videos, he shows some skiving knives he made from carbon steel putty knives that he bought second hand. I found some new high carbon steel knives at a hardware store that focuses on contractors. Now it was time to get to work! Using a set of cheap diamond-on-steel sharpening stones from Amazon, I sharpened one side only, starting with 400 grit, until I had a wire edge. Then onto 600 grit, then 1,000 and 1,200. After that, my trusty chef’s steel and the rough-side strop with green rouge. Total sharpening time: about 2 hours. The result was great! It skives, trims & makes vertical cuts. I’d post a picture but frankly it looks just like a putty knife with an edge on one side.

-

For whatever reason, I always have horrible luck when skiving projects. The skiver seems to occasionally "catch," resulting in severe gouging. I suspect this may be due to my skiver (a Tandy SuperSkiver.) Would a well-stropped woodworking plane produce a more even skive?

-

I live in Vancouver BC where the cost of renting space has gotten so bad I have to close my studio Here are the machines I have for sale, if anyone lives nearby it might be worth a trip! All prices are in CAD$ Leather Machine Co. Cobra class 4 premium. $3500 Various feet and needle plates, drop down guide, custom flat top table attachment, and complete vibrating binder setup! Servo motor and speed reducer and table included. Leather Machine Co. Cobra NP-4 Skiving machine $1300 various attachments, table and servo included. Pfaff 335 cylinder arm. $1500 Servo motor with needle positioner. Currently mounted on custom table but I will include the original table. Gemsy 335 copy $1000 works great! It's set up with a custom flatbed sewing attachment but i will include all accersories for binding as well. Has servo motor with needle positioner but you will need a table top to mount it on. Will include the custom table it's currently mounted on as well. Photos: vancouver.craigslist.org/van/for/d/vancouver-industrial-sewing-machines/7723026253.html

-

Whenever I try to skive the edges on belts, I get really inconsistent results. Some areas end up skived very deeply, others barely at all. This causes them to look very unprofessional, especially once I apply Edge-Kote. How do you go about getting a consistent skiving depth? Please don't answer with "get a skiving machine"; that's out of my price range.

-

I'm moving out of state and downsizing my workshop space. The machine is located in Chicago, IL and is NOT available for shipping. It has been a great machine to use and quite frankly did not get used enough. This machine ALONE costs $2,395 new from Techsew, EXCLUDING shipping. I have a video that I can share of me skiving with it. Includes stand and vacuum suction device with sealed scrap bin for easy waste removal. BONUS - I installed a rubber roller instead of the more coarse standard roller and am including an extra rubber roller. I am also including an extra roller presser foot for softer leathers. Features: Precision designed for simple and smooth operation Built in blade sharpener, adjustable skiving width, adjustable skiving speed, equipped with power stand and variable speed 550W Servo motor, 1200 RPM Rotating Speed, skives light to medium leather up to 8oz, and up to 2" skiving width.

- 4 replies

-

- leather skiving

- skiving

- (and 5 more)

-

Made this holster with turtle tail. Had to do quite a bit of fleshing to get maximum use from it. 6 sq inches of useable leather is hard to stretch. A 1” belt sander w/120 grit and a feel for what you’re doing and you can make use of the rock hard 1/2” thick outer edges. Turtle puts off more dust than any other leather I’ve used so it’s best done outside. It takes more work than other exotics, but it’s definitely an attention getter. Sewing it together was easy peazy on the 29k except in one area where I could’ve skived it thinner, but the China patcher handled that like it should’ve. Customer loves it and that’s all that matters. Be great to make a costume out of, And what I’ve been told they’re tasty too. I dunno about that, but I’ll eat anything with gravy…

-

-

- skiving machine

- skiving

-

(and 1 more)

Tagged with:

-

Hello all, i have a variety of tools for sale since I will be closing down my leather tool business. Just some of the tools I have for sale are the following; a vintage set of tools put together from odds and ends for 85$ which contains -Vintage C.S. Osborne head knife -vintage coarse grit sharpening stone -bisonette no.0 -vintage Vergez Blanchard plough knife -vintage Japanese euro style paring knife - Auto Awl Then a pair of Pricking Irons both 9 SPI For 65$ one is a vintage J.Dixon slimline iron and the second is a handmade iron by an ex Joseph Dixon Employee has visible grinding and file work on teeth. then for sale I have the following items -vintage C.S. Osborne head knife 38$ (bottom knife on picture -vintage Theo Harrington round knife rare 70$(2nd knife from bottom) -Japanese style skiving knife made from D2 steel has heavy marking from shape being grinded down 50$ -Vintage C.S. Osborne round knife 45$ (2nd from top) - Vintage C.S. Osborne round knife 45$ (top) I have also a very large selection of Wrose, Gomph round knives and other pricking irons and rose wood handle awls. I am willing to accept the best offers on these tools and as an incentive to those who buy I will offer free sharpening to a razor edge and I’ll give some high grade polishing/sharpening compound that we produced in our workshop I ship internationally from my location which is Belgium and I accept payments only through PayPal for which I can provide invoices too. If you have any questions please do ask I’ll be happy to answer!

- 10 replies

-

Here are some videos of skiving with a new roller foot and some of the advantages this roller foot is capable of. Having worked with many various leather types over the years including glazed finished crocodile I found it necessary to have a skiving foot that did not scrape the top surface and allowed leather to go through more smoothly with less friction than the normal supplied feet can give. I made up my first roller foot by cutting down a spare normal foot and making a brass roller to fit onto it. This roller has almost never come off the machine ever since except for the occasional polish and oiling. Steve or on this forum member Singermania kindly provided me a couple of manufactured roller feet to try out. The long one interested me the most as I could see a few applications it could be good for. Unfortunately this foot did not fit straight onto either my Fortuna or FAV skiving machines and some modifications were needed but in the end I think well worth the trouble. The first 2 videos are all about the foot modifications and the last is a bit long but shows me trialling out some skiving operations. I hope these are of some help to any of you that are trying to master their skiving machines. Regards Brian

-

Houston, Texas Metro Area Hello. I am selling my Thor RE-T801 skiving machine. The machine was purchased December of 2019. Used only twice. 110v Servo Motor. I do have original receipt of purchase. Works well.

-

Just a few knives. Various shapes of Japanese knives. A few "Aogami" super blue steel Japanese knives made by Mr. Okada in Japan, an RML "Shirogami" white steel and a Palosanto D-2 steel knife. L'indispensible with Chartermade D-2 blade, a couple of Doldoki D-2 skiving knives, some Erick Anton Berg clicker knives from Sweden, a couple of unmarked head knives and a few other miscellaneous knives.

- 6 replies

-

- knife

- japanese leather knife

-

(and 2 more)

Tagged with:

-

First I have to say i'm no expert, I am a self-taught hobbyist. Not that it matters in this tutorial, the purpose is to get a nice result, and this is a nice result. (In my opinion) There is of course more than one way to skin a cat (of course not literally in this context) but if we are talking literally there is more than one way to skive a cow (in my example I use a vegetable tanned cow skin. So this is how I do it and it works for me. What do you need, except your card pocket you plan to skive? 1. A sharp knife, it doesn't have to be something expensive, you can get a good result with a skiving knife for a couple of usd/euro. But if you can afford it, I would recommend a knife with decent steel. A really cheap knife will have a bad edge retention and you will have to sharpen it constantly. I use a Kyoshin Elle. https://www.goodsjapan.com/kyoshin-elle-japanese-leathercraft-utility-skiver-beveller-leather-knife-angled/a-20860 2. Should you skive with the bevel down or the flat side down? I'm right handed and use the knife I just linked. And I prefer to skive with the bevel down, then I get a "fulcrum point" to angle my knife on. 3. Push or saw? I prefer to saw through the edge in multiple passes. So let's start. 1. Scribe a line where you want to skive. (I filled my line with a pen so you can see better) 2. Make a first light skive (sawing motion) from right (the corner) to left. And keep doing a couple of skives until you skived the edge. Let's say your leather is 1mm thick and now it's around half of the thickness (0.5mm) and you want it thinner, you can wait with this until you skived the "pocket ear" (because it will be easier to see with a clean edge) 3. Do the same on the "pocket ear" to stop the leather from sliding away you can use your left hand to hold it down with a glue spreader at a low angle (I'm right handed so I skived with my right hand) 4. If you need to skive more to get your edge thinner, you can do it know. And the finished result.

-

As promised here are some photos of the Ellegi/Atom GL12 skiving machine I bought and the start of the modifications I want to make. The machine was owned by an older couple closing their shoe making shop and was in great condition. The model I bought has two motors: 1 for the vacuum and 1 clutch motor that runs the blade and feed wheel. The feeding speed was much too fast for my use. As I only paid about 200 euro for it I decided I would try to make the feed wheel independent of the blade. I also wanted to be able to finely control the feed speed, for example being able to very slowly feed the leather in and then gradually increase the speed as I skive. I researched every way possible to add a third motor for the feed wheel. There are three ways you can do this (that I can think of): 1. a direct drive servo directly behind the feed wheel as found in some new machines; 2. a motor underneath the feed pulley on the right of the machine; and 3, a motor on the top of the table behind the feed pulley, again on the right of the machine. Option 1 is far beyond most people's abilities, at lest mine! I tried very hard to make option 2 work but could not. My table has upper cross supports, a lower belt guard and a middle sheet metal "wall" between the operator and clutch motor. The only way I might have made this work was to replace the clutch motor with a small servo. I am too cheap to do this! The clutch motor works great so I want to use that for the blade as long as I can. That left me with option number 3 which is what I went with. I found a new Jake JK-513A servo motor for about $105 from a dealer 5 minutes from where I live. This was cheaper and easier than buying a DC or servo motor, the power supplies, controller etc. It is 550W which is much more power than I need, but the price was right. I recommend a motor where the motor, foot controller and power supply are separate. Without that I could not have done this. My table has so many under supports that I need this flexibility. I removed the belt from the main shaft that goes to the feed pulley. I then mount this motor directly behind it on the table top. It took a little bit of playing with the placement of the motor, the foot controller and power supply and it works! Not elegant, but it is doing what I want The feed is now controlled by the foot pedal and servo speed controller and the blade runs continuously. I have used a machine that had a separate clutch for the feed wheel. This offers even better control than that in my very limited experience! If you have space under your table that would be a better option. Here is someone on Instagram who has done this: Here are some photos. I will post some more when I get a chance. I need to cut a slot in the machine belt cover, mount the belt cover on the motor and buy a few parts for the machine. Hope this helps! -Adam

- 18 replies

-

- skiving machine

- skiving

-

(and 1 more)

Tagged with:

-

Hi All Anybody ever skive Buffalo leather? I understand it may be a bit of a challenge. I have a client that would like to replace the seats and backs of an outdoor chair set and I'm thinking that Buffalo would be a good choice for him but I would need to skive it along the edges so it could be folded back and the edge finished stitched. I normally use a Landis 5 in 1 skiver for everything. Silverd

-

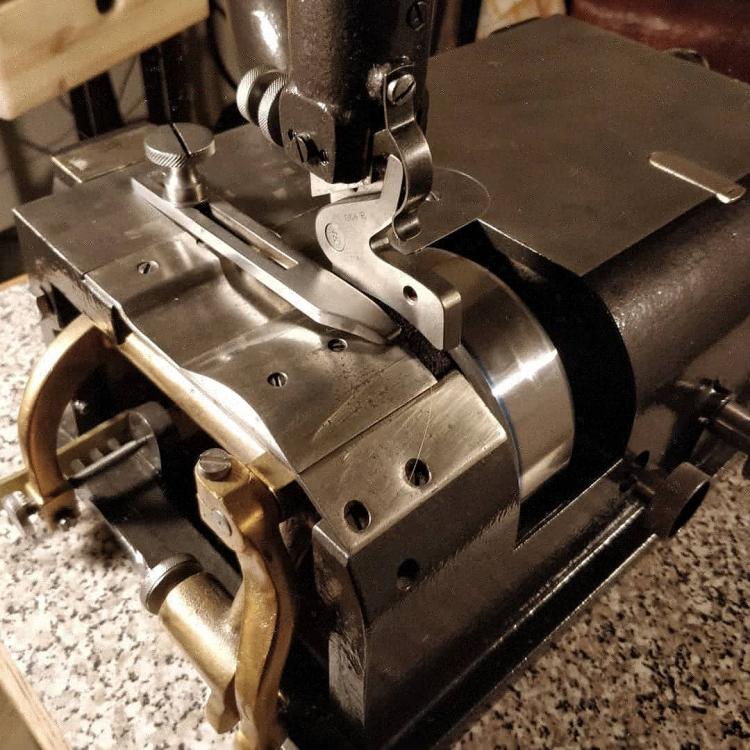

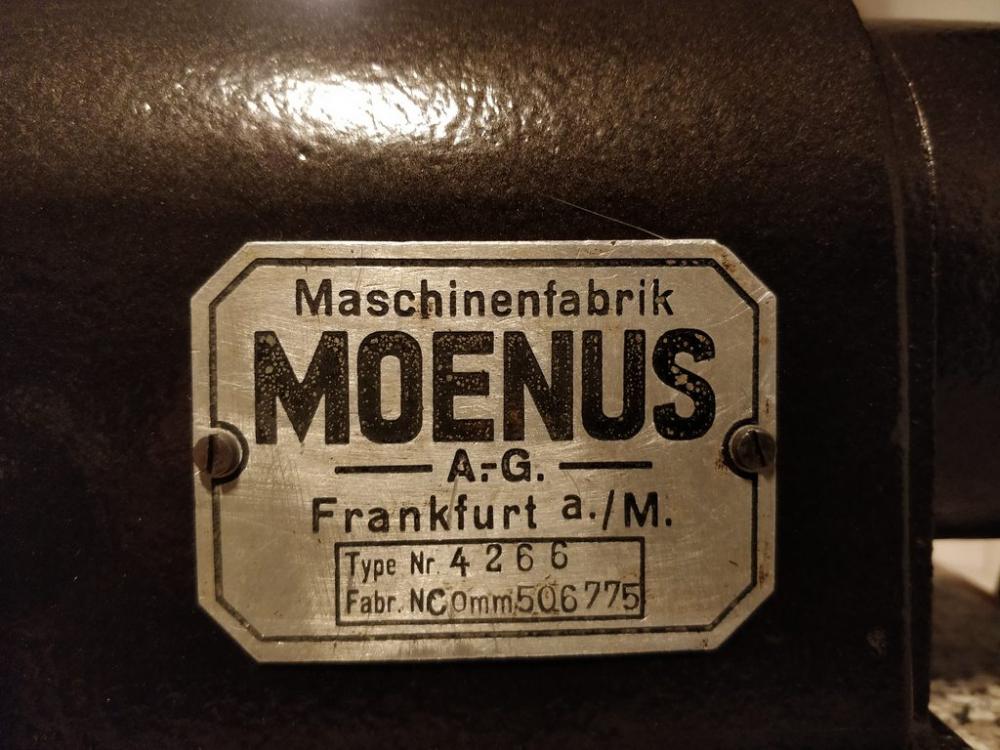

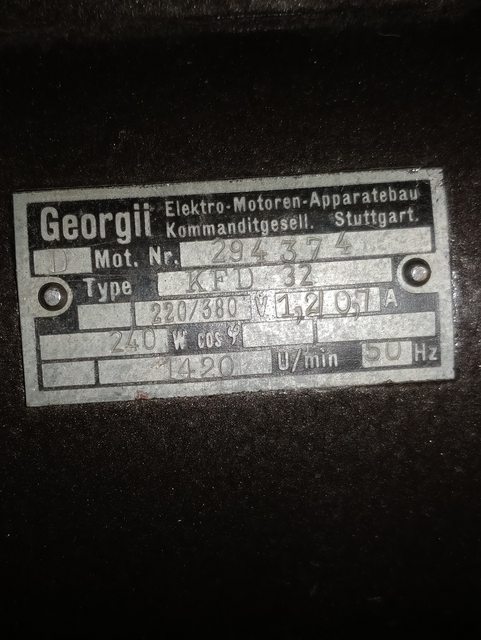

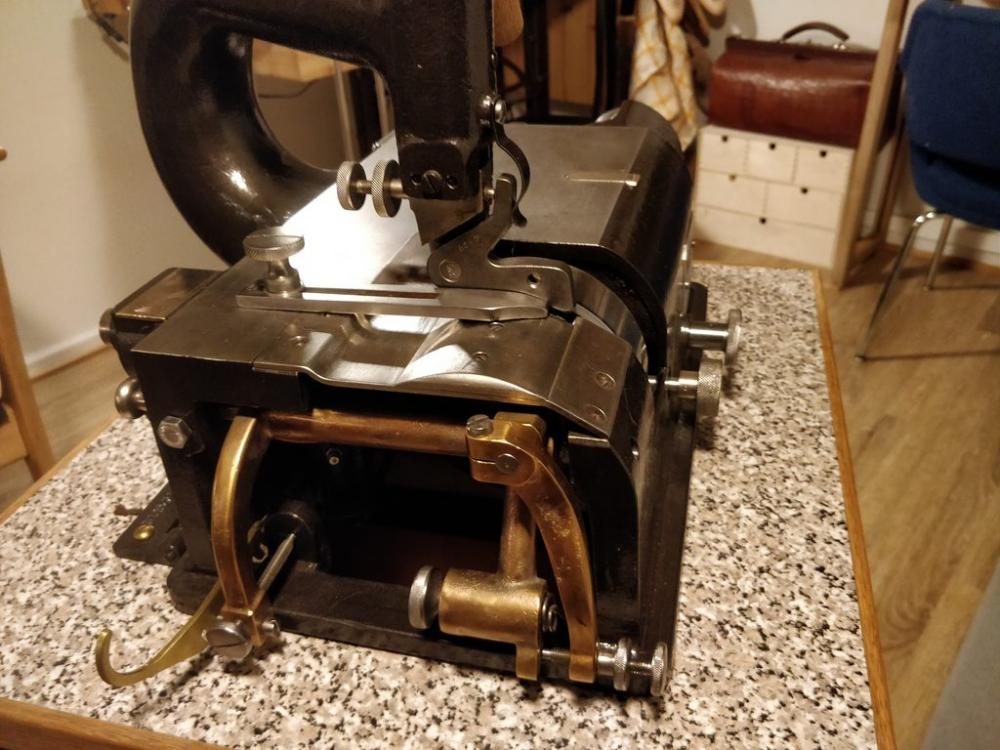

Hello! First post on these forums! I make shoes and boots as a hobby and recently acquired a skiving machine. It's an old machine branded "Moenus". I can't find much information on the company, but I know the company is German and has been around for awhile (I'm not sure if they are still in business). The machine was rebuilt by a machinist and machine enthusiast who dabbles with leather work every now and then. He had replaced all the bearings in the machine and in the motor and repainted both. Judging from the underside of the machine, the colour matches the original paint. I looks like he had even machined some new parts for it, and the machine has a new Fortuna bell knife on it. What I like the most about the machine is the small custom table he had built for it. It has little wheels and even little retractable handles, so it takes up very little space and is easy to move around. As for now, I work in a corner of my small apartment so having a full size skiving machine with a large table was not an option (well, I wouldn't mind but my wife might). My first thought was that it's a re-branded Fortuna, but I have no way of telling for sure. Just from looking at it closely, I can tell that it must be at least 40-50 years old, but I can't find any dates or information on how to read the serial number. It has the original power switch which is made of bakelite. Bakelite hasn't really been used since the 50's as far as I know. The motor is a German one branded "Georgii Kobold" and seems to be original. The motor is set up as 3-phase 380v, but I only have single phase 230v available in my apartment. I might try setting it up with a capacitor (the motor sign says its 220/380v so it should be possible, although it might lose too much power). If I have to use another motor, I think I'll set it up with a continuously running knife and pedal feed on the feed wheel (either with a servo motor or a normal one with scr/pwm power modulation). Making shoe uppers means skiving small curved pieces that require a lot of precision so a slow feed is desirable. I paid 300 euros for the machine which is roughly $345. The price seemed fair considering it's a rebuilt machine, but confirmation on that would be nice, haha. My question is; does anyone have any information on Moenus or this particular machine? I'd love to know how old the machine is. Also, input on dealing with the motor is greatly appreciated. I've included photos of the machine.

-

Who has extensive experience with the Craftool Pro Splitter? I want to try my hand at a couple rolled edge wallets but I do not want bulk. I have some Old World Bellies that are about 1.1-1.2mm thick and I'd like to take them down to a fairly consistent 0.8mm (which is still thicker than some of the leather in my Bosca wallets). My Splitter is inbound so I haven't had a chance to play with it yet. So my real questions are, how thin have you been able to go? And, how little have you been able to successfully peel from your stock? Half of a millimeter? Obviously the blade edge matters and milage may vary, I just want to know if anyone has been successful in this area. Thanks, Joel

-

Hi everyone. As practice, I was trying to hand skive 1.2-1.4mm leather in preparation for my project which calls for skiving about 1.0mm. I was using a Tandy Super Skiver and well, it sucked. No matter how delicate of a touch that I tried, my cuts were vastly uneven and it pretty much ripped and tore up the edges. Absolutely no uniformity in the cuts. I’m sure some operator fault is there. Skiving is a skill until itself especially with thinner leather. I have to ask; is there a better knife/tool to learn on like a very sharp, straight or slanted skiving knife or even a round knife? I don’t mind putting the time in to practice but if it’s a better knife choice thing, I would rather practice with that Any insights, tips or suggestions would be appreciated! Thanks! William

- 23 replies

-

- skiving

- skiving knife

-

(and 1 more)

Tagged with:

-

I know that skiving strap ends seems like a simple thing, but what I'm unsure of is where exactly are you supposed to start the skive? I hear so many differing opinions on the proper technique, and I would love to hear from those who are experienced with this. So for a buckle end, some people recommend to skive down the leather only at the very end, so that the part that actually is folded around the buckle is full thickness. This doesn't make sense to me, since skiving is meant to reduce thickness, and the folded part is the thickest part by far. Others recommend starting the skive where the leather is folded, and skiving down to say 6oz, if you have a 12oz strap. But this doesn't make sense to me either, because if the strap is 12oz, and you skive the fold and everything toward the end to 6oz, then its folded over to become 18oz. So wouldn't it be stronger to start the skive before the fold, and skive toward the end, at an even thickness of 9oz? Then you would have two pieces of 9oz leather sewn together, rather than 1 piece of 12oz and one piece of 6oz. This seems like it would be stronger, no? So why do we always see people skive down only one side of the leather to say that's being folded over to say 6oz and leave the other side full thickness, instead of skiving both sides to 9oz? So experienced strap makers, what is the proper way? Thanks in advance

-

Not sure if this question should go in the machinery section or technique. If I cut a 1 foot square of 2mm leather and skive a half inch along one side it will come out as I intended. Then if I turn the leather to skive the opposite side with the exact same settings the second side may barely skive at all. does this have something to do with the grain of the leather? If so, how do I correct this without readjusting the skiving depth for each side? Thanks

-

Close to getting a skiving machine and trying to learn what I can.. Can you all help me understand the different types of presser feet for the basic single motor skiving machines out there? I see most of them come with a 2" non-rolling foot, but I've seen images of other types of skiving presser available. What types of results do these variations yield? Wondering which I should look for and add to my want list. Thanks for the help!!

-

Hi! I'm going crazy here! I have a 1000/3000 whetstone and stropping block. I have two Japanese skiving knives. I can get my knives sharp on stone. Then I strop..then test..still sharp. But, when I pass the knife a few times through my 3.5 oz chrome leather (on top of treated granite..and tried glass) the knives dull! I've tried not stripping...and my sharpness still doesn't last. I can't possible have to sharpen throughout the day..I must not be doing something right. Any tips from anyone? Thanks!

- 37 replies

-

- sharpening

- japanese knives

-

(and 1 more)

Tagged with:

-

Hi All, My name is Sonya and I'm new to this site and forum. The company that I work for just purchased a FAV AV2 Skiver. We have messed up the original settings on the machine and now I am unable to skive. Originally when we bought the machine it was skiving great. However, when we started using different types of leather, we had to adjust the feed roller, foot pedal etc. Since making these accommodations for the different leathers, we are unable to feed the leather through as well as it's not skiving. When I do get the blade to engage to skive, it eats the leather. Any help would be greatly appreciated! Thank you, Sonya

-

Looking for someone to skive several pieces down to 3 oz.

.thumb.jpg.327685d8c1787fa894323fed9a6b2dac.jpg)