-

Posts

1,806 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Matt S

-

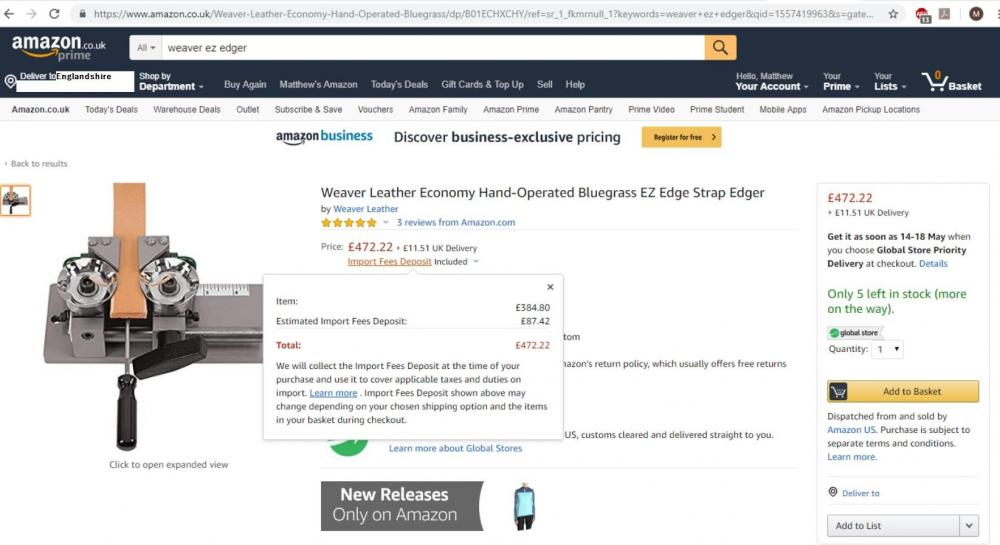

EBuystuff calls it their Global Shipping Program, and the seller ships to their national distribution node (paying domestic shipping). eBay sorts out customs and international shipping (having calculated things at checkout and the customer having already paid all relevant charges). Amazon calls it Global Store I think: Looks about the correct amount of largess going to the government, so HMRC is happy. No valuation delays at customs so they're happy. Courier doesn't have a bunch of packages hanging round or have to collect payment from the customer so they're happy. And the customer doesn't have their package delayed or have to pay a handling fee so they're happy. Not sure if it'll help you in your situation Mike but there it is.

-

Yep, this. I have a harness stitcher that's 50-50 about picking up a loop without material but 100% with leather under the foot. It's probably the stiff black poly thread I use.

-

Several couriers are offering an option to calculate and pay the various import charges before shipment -- something I've seen on eBay and Amazon. I wonder if this is how Tandy are doing it, and either working the average costs into the prices for each country or simply absorbing them from their profit margin.

-

Most expensive leather? buckskin? What is it like?

Matt S replied to JC2019's topic in Leatherwork Conversation

It's brain tanned (or maybe tawed) deerskin, smoked and heavily staked by hand. I felt a sample about 10 years ago. Very soft, like a really nice suede. I know that some people sell some every now and then but not aware of any commercial manufacture. Google would be your best bet if you wanted to buy a hide. Perhaps look at primitive skills discussion groups. -

Sorry fella, our Stupidity Factory is 3 years ahead of yours! https://www.bbc.co.uk/news/uk-37080682

-

This isn't just a Facebook thing. Look at the ongoing Youtube monetisation/content debacle, the looming UK national porn filter, and the EU's Article 13. Blunt rules, crudely forged by ignoramuses that are applied inconsistently by uncaring bots and third-world clickfarms. These are killing or will kill the internet. Rules intended to do good (improve ad revenue, avoid tabloid headlines, protect copyright trolls holders or children from shock horror seeing naked people "accidentally"). In the OP's case I suspect that Facebook doesn't/didn't intend to ban leather -- it's just a poorly worded rule that picked up on your use of croc. Human review was probably done by some underpaid worker in a third world cubicle farm where the personal consequences of an over-harsh decision are zero and the consequences of an overly generous decision are severe.

-

how to change the length of the stitches

Matt S replied to Chamod's topic in Leather Sewing Machines

The safety clutch is like an over-pressure valve. If you get a needle crash, timing slippage or thread jam so tough that it prevents the "business end" parts (needle, hook, feed dog etc.) from moving but the "back end" parts (balance wheel, top shaft, bottom shaft etc.) keep trying to drive them, something will break before you notice and take your foot off the gas. Hopefully that'll be something cheap like the needle but it could be something expensive like the hook. The safety clutch protects parts from breaking and you from having sharp pieces of metal flying around near your eyes and fingers. In the event that there's excessive torque on the bottom shaft it simply disengages the bottom shaft from the belt sprocket which drives it, reducing or preventing any damage. Fix the fault, hold in the button and turn the balance wheel backwards until it pops back into place. (Then test your timing as it's possible to reset the clutch 180 degrees out of time...) Your blade looks like a side trimming knife, which is useful in certain production situations. Imagine sewing a soft lining into the upper of a shoe. Clicking the lining to exactly the shape of the upper will require a fiddly and slow glue-up and the edge might be uneven. However if you cut the lining oversize you can glue it quicker and trim after sewing. Now if you put the trimming blade on the sewing machine, next to the needle, you will trim it as you go which will be faster (cheaper). -

I'd cut the "fitting" off then epoxy onto the top part of a chicago screw or speedy rivet.

-

Lister diesel engines, Webley revolvers, Land Rovers, the English Electric Lightning, cylinder bed Singer 45ks... there's a long list.

-

Hmm, a collection of unnecessarily complex forgings and castings that form a machine that performs a simple task. Every part is ungainly and badly proportioned but together, while certainly not pretty, it has a certain gawky beauty. Looks British to me.

-

Well that's about typical for modern journalism -- a copy pasted press release filtered through the publication's political bias and minimal basic background research conducted.

-

Andrew, there are plenty of water based dyes around, both traditional and modern. However the vast majority of leather dyes are still alcohol based and I am not aware of any oil based ones -- contrary to popular misconception Fiebings Pro Oil dye is not and never has been oil based, and they have recently changed that name to avoid this misconception in future.

-

SEIKO - What kind of sewing machine is this?

Matt S replied to Seom's topic in Leather Sewing Machines

That's clutch motors for you. If you can/are happy feathering the clutch and slowing it with your right hand on the wheel, do that. Otherwise spend £100 on a servo motor.- 29 replies

-

- seiko

- sewingmachine

-

(and 2 more)

Tagged with:

-

What is the singer equivalent to the Juki 441?

Matt S replied to DavidMillsSaddlery's topic in Leather Sewing Machines

Well the 45K fits dead in that gap... but if you want something with more bells and whistles you might have to look at Adler, Seiko or Juki. I'm jealous of your 97-10! -

Sole stitcher that’ll do double row stitching!

Matt S replied to DavidMillsSaddlery's topic in Leather Sewing Machines

The distance between each stitch line visibly varies in that photo. Looks like it's a "do it twice" job to me too. -

What is the singer equivalent to the Juki 441?

Matt S replied to DavidMillsSaddlery's topic in Leather Sewing Machines

I am aware of no machines equivalent to the Juki 441, apart from the Seiko CH series and the Adler 969, which will be similar or higher price than a real Juki 441. Singer 45Ks are great machines but a couple of generations of technology behind the 441, and a smaller capacity besides. Most models had a feed but it was almost always drop-feed only. Some later models had a non-driven snapping "walking" foot in addition to the feed dog. Most models did not have reverse. In cylinder-bed format there most common subclass was the 45K21 -- drop-feed, fixed foot, no reverse. Same machine with a wheel presser was the 45K25. Sews maybe a half inch thickness with max thread thickness around v346/TKT8/5-cord. CB2500/GA-5 is a current-production machine directly descended from the 45K: https://www.tolindsewmach.com/cb2500.html. Singer stopped manufacturing industrials in the late 60s or early 70s I think and started rebadging Seikos and Adlers. Adler had been cloning the 45K as the klasse 4 (flat-bed) and 5 (cylinder-bed), stopping only when the factory got flattened by the USAAF and RAF. Post-war they brought out the 104 and 105, gradually improving the design with new technologies like reverse as standard and more positive feed systems. Klasse 204 and 205 came out to supercede the 104 and 105 in the late 1980s (around the same time as Juki brought out their 441) and production only stopped a few years ago. -

Skiving without a skiving knife? And Splitting with minimal tools?

Matt S replied to JC2019's topic in Leather Tools

The traditional Japanese skiving knife looks like a wide-bladed paring chisel so there's a good starting point. I used to use a 10a scalpel for small skiving, and have had some success using the wider type of snap-off utility knife. Bookbinders have used spokeshaves to thin panels for a long time, though I think that use of the skill is declining since the band-knife splitter has come into more widespread use. @hwinbermuda would be worth contacting about that. I think that "heavier" leather trades used to use spokeshaves and such to level out and thin hides in the past but again that died out once tanneries acquired large splitters. Oh and @RockyAussie has pictures of a belt sander he's modified to make a splitter/lap skiver of sorts. -

Looks like blue steel oxide (from tempering). It's odd, I've been running a seiko lcw8 for six months now and never experienced backlash, despite having no anti backlash spring. I run it hard (>2000SPM) and it has huge U type bobbins. Is it because it's a vertical axis hook? Used to get backlash all the time when I was running horizontal axis machines.

-

Looking at the UK site (which will be a whole nother kettle o fish soon) the prices look much better. Shame about the severely reduced offerings but non-moving inventory is just a millstone around a company's neck. Hopefully they will continue with bringing out newer, more relevant offerings. I have a business account and everything's still working for me.

-

Anyone ever do an apprenticeship? Was it worth it?

Matt S replied to JC2019's topic in Leatherwork Conversation

Apprenticeships in most of the world tend to involve the apprentice working full time alongside experienced professionals for several years. There are often formal exams and certificates throughout. The apprentice is paid commensurate with their experience and skill, and adds value to the master's business by doing a lot of the drudge work, and even taking on some of the teaching of less experienced apprentices. Here in the UK there are typically three different "apprenticeship routes" to leatherwork: saddler, harness maker and cordwainer. Each takes about three years of full time education. -

I split bridle (a medium-hard veg tan) all the time with my 12" Fortuna, though admittedly that's mostly belt strips and wallet parts. Done a few bag panels from bridle at 12"+ before (on a ratty old 18" Camoga). There's a lot of variables on these machines and perhaps your friend's simply wasn't setup for that sort of job. In what way did it struggle? I've never used a 12"+ fixed-knife but used to run a 7" crank. It's apples and oranges but the Fortuna is more accurate, repeatable, versatile, leaves a better finish on both sides and generally is far less trouble. Blade sharpening is far less trouble too, since there's a built-in grinder. It's perhaps worth pointing out that a new basic 12" band-knife splitter is a 5-digit price whereas those big Chinese fixed-knife splitters like the Cowboy 8020 are, I think, in the low 4-digits.

-

I... see...

-

I can believe that. My (very early) Fortuna skiver came with a big pile of paperwork including an invoice from Fortuna/SAS UK. Looks like the previous owner spent more for a couple dozen spare parts than I paid for the entire machine 10 years later -- and I didn't exactly pay beer money. I've bought generic skiver parts from the usual online suspects and they tend to work, though sometimes need a little fettling. If you can stand the wait for it to arrive on the slow boat from China the savings are significant.

-

What Exactly Is An "eps" (Electronic Positioning System)?

Matt S replied to Johanna's topic in Leather Sewing Machines

No reason why not. I have one on my Seiko LCW-8, which is an updated version of the 153w. Biggest problem will be in fingering out how to fabricobble the sensor onto those machines. They were built well before such things were common. The sensor attaches to the handwheel by a little hub that's supplied in the kit. You unscrew the screw that holds the handwheel in place. The kit comes with a couple longer screws in common threads, so you screw the hub onto the handwheel through the hole left by the screw. There's some L-shaped screws which thread into a hole next to the handwheel, which prevent the sensor body from rotating. If these screws don't fit your machines you'll have to get out the calipers and start getting creative.