-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Singer Industrial Sewing Machine Screws

Gregg From Keystone Sewing replied to shoepatcher's topic in Leather Sewing Machines

Glenn, That list was about as good or better than I ever really needed, what information missing is it that you're looking for? -

Singer Industrial Sewing Machine Screws

Gregg From Keystone Sewing replied to shoepatcher's topic in Leather Sewing Machines

Here is, by far, the most comprehensive list if Singer screws with part numbers, images, thread pitch and dia. KeystoneMasterPagesScrews.pdf -

Singer Industrial Sewing Machine Screws

Gregg From Keystone Sewing replied to shoepatcher's topic in Leather Sewing Machines

Now I'm interested. I guess you have to find what model machine would take a #1 screw, right? I've never seen screws with single digit part numbers, only double, but again, that why we're looking I guess? -

How to Connect a Quick Rotan setup

Gregg From Keystone Sewing replied to jegenes's topic in Leather Sewing Machines

We have all three; 110V Single phase, 220V Single phase, and 220V three phase. Used to be every factory machine was 220V three phase, now everyone want's 110V single phase and the new Efka motors DC1550AB321 and DC1280AB620A only come available in 220V single phase.- 21 replies

-

- quick rotan

- eps

-

(and 2 more)

Tagged with:

-

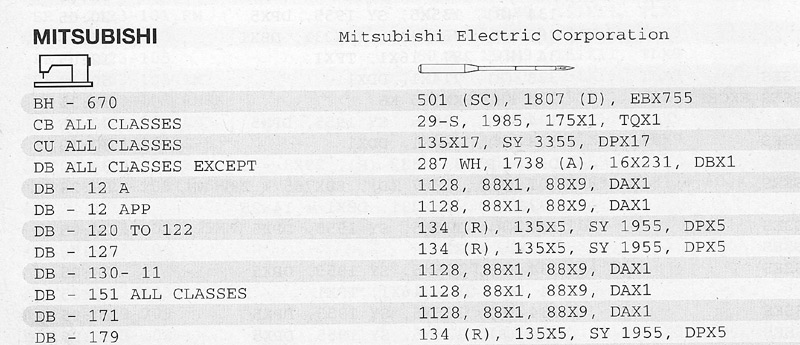

Needle system for Mitsubishi DB-130

Gregg From Keystone Sewing replied to DrmCa's topic in Leather Sewing Machines

And DAX1 is same needle as 88X1, also known as SY1315, 1128 in case people were wondering what these numbers are. All designate same actual needle. -

Anyone Have Experience With Juki 1508 Nh

Gregg From Keystone Sewing replied to Roy2k's topic in Leather Sewing Machines

See attached, section 7 Needle-to-hook timing. LU-1500N Engineers Manual.pdf -

112W139 thread twist

Gregg From Keystone Sewing replied to Cheval's topic in Leather Sewing Machines

See attached, this will help people understand a bit more where Left or Z twist or Right, or S twist is commonly used. Usually, if the thread is bonded well, this is not critical, but if you are trying to max out the performance, this is one more thing we can look at. The_special_application_needle_SAN_12.pdf -

Needle system for Mitsubishi DB-130

Gregg From Keystone Sewing replied to DrmCa's topic in Leather Sewing Machines

Agreed, but this also may be why the needle bar height is already messed up. Many needle bars, especially older ones, have two lines near the bottom below the bar; one is for bottom dead center on the bottom, the top is to raise up for hook timing. But I don't know. -

Needle system for Mitsubishi DB-130

Gregg From Keystone Sewing replied to DrmCa's topic in Leather Sewing Machines

DrmCa, The information that I have is that 88X1 is the correct system, not 16X257. 88X1 is much shorter side by side with a 16X257. -

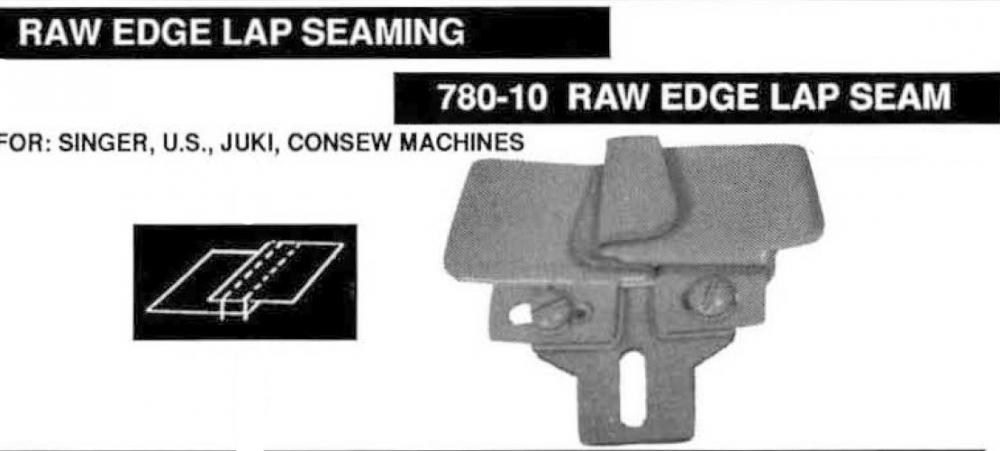

Roller guide for a Consew 1206RB

Gregg From Keystone Sewing replied to lb61906's topic in Leather Sewing Machines

If you can drill and tap some M6X1 or 1/4-20 holes into cast iron, how many do you want? I don't have this model on hand, can you take a picture of where it would mount nearby, next the the hand lever for presser foot lifter? -

I've been through this many times. It's not a crime to hype, promote, sell, advertise, or provide only the good selling points of equipment offered. A good sales person or team is supposed to do this, and it's their job. The problem I have is when people wind up surprised that the backyard go-cart with lawnmower engine they purchased is not the Maserati that they were told to expected to own. You have to explain the limitations. 1st thing I do when offering a machine of this type is to qualify the customer by sitting them down on an industrial or asking them about their existing equipment to give a fair comparison. This way the customer knows what it is they are getting and what to expect from the equipment. If you are in production, machines of this type are great for on site job repairs, small jobs and the like. They have a place in life, but are not going to replace a production quality canvas or sail making machine. One guy who bought a machine of this type told be he lived on a house boat and cannot afford the space of an industrial. Boom, perfect fit. Right machine for the right customer.

-

Servo squeaky when hand turning

Gregg From Keystone Sewing replied to Cheval's topic in Leather Sewing Machines

Like Wiz was saying, the Family FESM-550S motor has a mechanical brake. If you want to be able to free wheel the handwheel without the break engaged, push down on the foot treadle before the motor starts to move under its own power. From what it sounds like, your clutch break is working the way it is supposed to, unless it is making noise when it comes to a stop under normal sewing conditions. -

Juki 1541s Clone Bobbin Case Comparison

Gregg From Keystone Sewing replied to Foiler's topic in Leather Sewing Machines

Sorry for any confusion, yes, this is what I was specifically referring to. The concept of the bobbin case opening lever is to help allow for heavier thread to more easily pass through the hook position finger, also known as a hook supporting plate. See attached pdf that I made up showing this area of the machine that I'm talking about, thanks. Juki DNU-1541S Hook Supporting plate install and adjusting.pdf -

Juki 1541s Clone Bobbin Case Comparison

Gregg From Keystone Sewing replied to Foiler's topic in Leather Sewing Machines

Juki DNU-1541, and DNU-1541S both use different hooks, and the same bobbin case. The Econosew, even if it has a safety clutch, does not have a bobbin case opening lever, like the Juki S model does. Not a problem, in my opinion, but would indicate that they may be using a different hook and bobbin case? Also, why not contact EconoSew in regards to this, I'm sure they are eager to help. They love selling parts, too. -

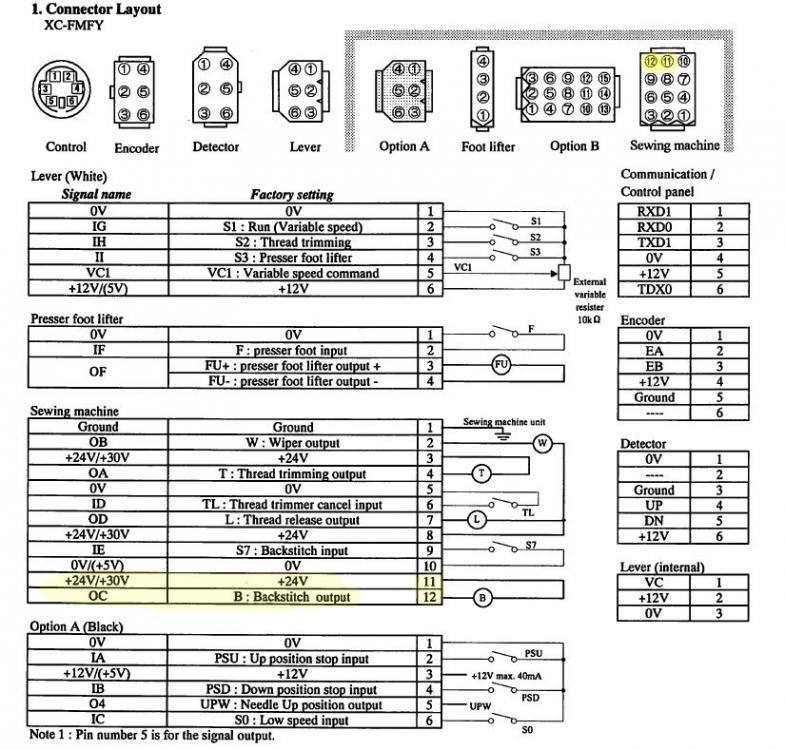

Need Help with Mitsubishi Control

Gregg From Keystone Sewing replied to JSM's topic in Leather Sewing Machines

I've done this before myself and maybe this is where you are at as well; Check to make sure you have the solenoid connected to the correct pins. See attached, it's easy to confuse the Foot Lift OUTPUT with the INPUT.- 7 replies

-

- adler

- mitsubishi

-

(and 2 more)

Tagged with:

-

Need Help with Mitsubishi Control

Gregg From Keystone Sewing replied to JSM's topic in Leather Sewing Machines

I work a lot more with Efka motors, but I also do a bit with the Mitsubishi as well Sean at Electronic Services is very good, we use them as well. I know that you know the signal is working, but I normally would do a signal test anyway to make sure the foot lift is working, and connected to the correct output. Page 83 in the instruction manual does this. To set the parameters at the end of the seam (they call it after thread trimming), check out function settings for FUM and FU on page 47. Check page 49 as well, function setting FL to make sure this is enabled for full heel back foot lift. Last, on page 50, check the S3L setting for half heel back foot lift while in seam (they call this light heel back here). As I glance over this, many of these setting are set to OFF at time of delivery. Mitsubishi Limiservo X B Series With Control Box Instruction Manual- 7 replies

-

- adler

- mitsubishi

-

(and 2 more)

Tagged with:

-

Singer 111W153 & table resto project

Gregg From Keystone Sewing replied to Sugarkryptonite's topic in Leather Sewing Machines

How the heck did I miss all of this action? Great thread, thanks for sharing. Love this.