-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Adler 267-373 Vs Seiko Sth-8Bl

Gregg From Keystone Sewing replied to Ken B's topic in Leather Sewing Machines

I offer and sell both the Seiko STH-8BLD-3 and just sold my last Durkopp Adler 267 shipped from DAP America that was already sold before we got them. The best answer to your question I can give is that historically top load machines with vertical axis hooks have always been more expensive than bottom load horizontal hook machines. Across the board from mfg. to mfg. The bottom line is what you pay has a direct correlation to my cost, if you will. In some cases the margin on the higher priced machine can be less than on a less expensive machine. I can also tell you that just because a machine costs you more, it does not mean that a dealer like myself would profit more. Thinking this could maybe be a mistake. Good luck, both are really good machines and I think you'll be happy with either make and model. -

Adler 267-373 Vs Seiko Sth-8Bl

Gregg From Keystone Sewing replied to Ken B's topic in Leather Sewing Machines

Ken, Just to get the discussion started here, you seem to be asking about 30 different questions here, all going in different directions. Ironically, you seem to be answering all of your own questions as if you are putting them down on a plus/minus list. Are you able to demo both machines if possible? BTW, the formerly made by Durkopp Adler 267-373 has not been made in Germany in over ten years. It is now officially discontinued by DAP, no stock, and now is being 'replaced' with the Pfaff 1245. Hope this helps, both are good machines for what they are intended for. -

What model machine is this? If you take the hook out and things are only hitting in reverse, the next thing to check is if the feed dog is hitting the needle when you reverse feed. I would take the needle plate off so you can best see what's going on in there. Good luck!

-

441 presser feet adjustments

Gregg From Keystone Sewing replied to esantoro's topic in Leather Sewing Machines

Esantoro, These 441s were setup more or less from the factory for sewing canvas type work, not leather. Your setup is not the factory standard setup, so adjustments may have to be made. Secondly, and more importantly, just because you have a machine that shows up from Juki or any knock off company it does not mean they sent it to you with the correct settings. You could be simply coping their mistakes. Or, maybe thier settings are not ideal for your threads, materials and jobs. Nice post, thanks again for sharing. -

Just to add, 11/64-40 is a very common Singer thread pitch and dia. screw, that appears all over the place on industrial sewing machines. Every sewing guy should have something that will work here.

-

That's one heck of a setup, glad that you are happy with that. Just so that folks here know and to add to the conversation, Efka for example has on thier DC1250 and DC1550 motor control boxes an input for a external potentiometer for speed limitation, among other things, that would operate in the same way Bikemanic has it here. Not that Bikemaniac would have it any other way, but just to put that out there, and again, thanks for sharing.

-

Juki 1541S Stopped Working

Gregg From Keystone Sewing replied to cds's topic in Leather Sewing Machines

Looks like there is more service work to do on this DNU-1541S; From the image in the 1st post I copied and blew up larger, you can clearly see that the hook basket has escaped from the hook supporting plate, and has spun out out of this tab. In the second pic, this is how this bobbin case basket and hook support plate should look when properly working. -

Juki Presser Foot Question

Gregg From Keystone Sewing replied to stickandtin's topic in Leather Sewing Machines

This comes up a lot. For example, physical 5/32" OD cording is going to use a 1/4" cording foot set. -

Pfaff 1245-706 Knurled Screw

Gregg From Keystone Sewing replied to Oakley's topic in Leather Sewing Machines

Like my father would tell people, if you want to drive a BMW or Mercedes, you have to pay their prices for parts and service. It's a good thing that we can obtain parts at any cost for a 30 year old machine in some cases. By the way, $32USD sounds very reasonable when you take this thumb screw cost and compare to other Pfaff parts. Nothing surprises me at this point. I was quoted for genuine 6mm (1/4"" standard cording/welting feet over $800 dealer cost. -

Don't shoot the messenger, but direct from Durkopp Adler Pfaff America 205-370 & 267-373, no stock, discontinued model. Just thought I would put that out there as a public service announcement to you all. This is a surprise to us, as well as DAP America. Kindly note that I do not have any additional information in regards to this, and we do not have either model in stock, nor do we have access to either 205s or 267s models for sale as I type this. -DAP is using the Pfaff 1245 as replacement for the 267-373 -205-370 replaced with 969-100180 Eco/Classic

-

I hear ya, I can't find a thing in regards to this. Even the Consew 255RB-3 book, that says -3 on the cover page, and on each and every parts page...is for a 255RB, RB-1, and RB-2, NOT the -3 that uses a stitch length dial instead of the push button regulator user would press on the bed of the machine. See attached image that is on Similar to the Consew from a different machine. This examining this may help. I can poke around here to see if I have anything more I could upload.

-

Seiko Ch-2/rf Questions

Gregg From Keystone Sewing replied to Pinsplitter's topic in Leather Sewing Machines

http://keysew.com/Webpages/DemoImages/Seiko_CH_Series.pdf See attached, this will decipher what this machine started out in life as. CH-2/RF (Drop feed and walking foot / capable of differential feed) This is the machine for heavy duty sewing, which is capable of intermediate ruffling works as desired by changing the amount of upper feeding against lower feeding, in addition to usual plain sewing works synchronized upper & lower feed. *Amount of feeding ratio between upper feed and lower feed can easily be changed by pulling down the lifting lever which chained with treadling foot pedal or knee works/motor work even during sewing operation which is obtainable intermediate ruffling stitches. *Wide working space makes it easier to handle the bulky materials being sewn. *Acceptable common attachments for special stitching. *Various kinds of ruffling or open edge moccasin stitches can be performed. -

Adler 267-373 Operation Manual.

Gregg From Keystone Sewing replied to Meg Stephens's topic in Leather Sewing Machines

http://www.keysew.com/Webpages/DemoImages/Adler267ServiceBook.pdf Got you covered, Click above for Durkopp Adler 267 Service Book -

Clutch Motor Reapir Help

Gregg From Keystone Sewing replied to melliel's topic in Leather Sewing Machines

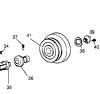

See attached, Like said before, it's almost for sure the hand wheel / bobbin winding mechanism that is the culprit. -

New Problem That I Just Cant Figure Out

Gregg From Keystone Sewing replied to cleanview's topic in Leather Sewing Machines

Am I missing something here? -

Can Anyone Identify This Screw?

Gregg From Keystone Sewing replied to rhinez0r's topic in Leather Sewing Machines

15/64-28, L=20mm Usually uses two different set screws, one with a ball point that falls onto the V ditch on top arm shaft, the other flat point that falls onto a flat spot on top arm shaft. These are common across the board for many sewing machine handwheels on many makes an models, including Singer 111W155, for an example. As said, get these from your sewing people. -

New Problem That I Just Cant Figure Out

Gregg From Keystone Sewing replied to cleanview's topic in Leather Sewing Machines

That would do it, too. Same as the bent back piece on the Juki, it just has to work, and that would help. Other models have a closed loop that I've seen. -

New Problem That I Just Cant Figure Out

Gregg From Keystone Sewing replied to cleanview's topic in Leather Sewing Machines

See image below, this is how Juki puts this thread take up stud with the bend on the end. I'm thinking this would prevent your upper thread from getting wrapped around this stud like you are showing.* *I'm not trying to knock any machine setup or sold by anyone, and I may have sold some Juki TSC-441 copies that have the same stud with no bend, not sure. Just trying to help and share here.