-

Posts

3,014 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by electrathon

-

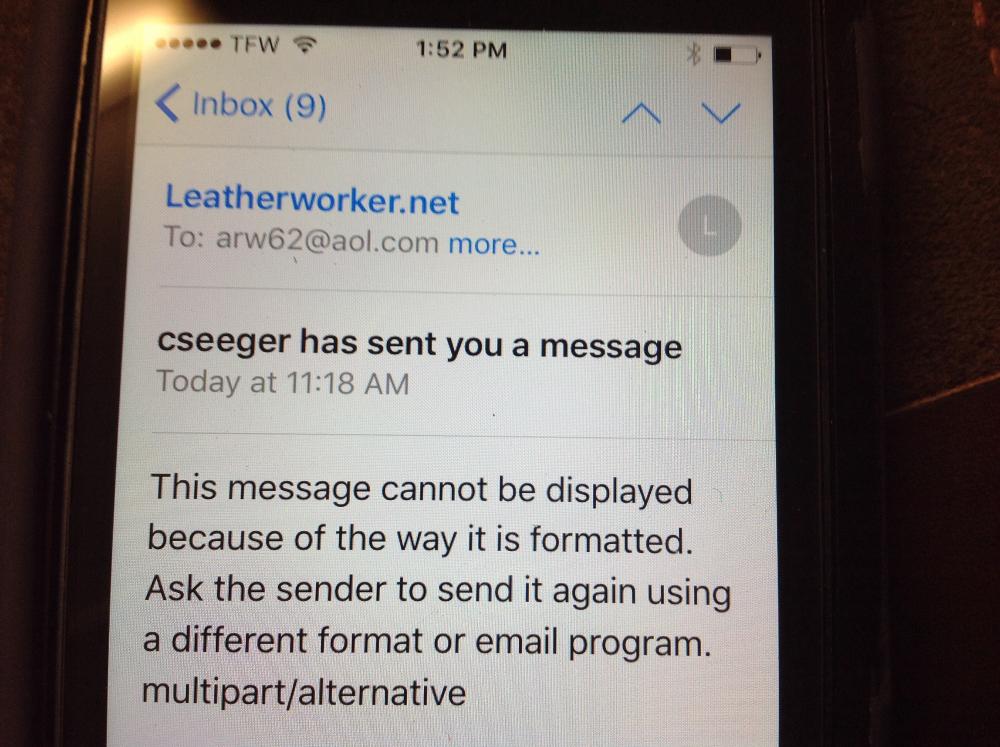

I don't know if it matters, the ipad is a 3, the iphone is a 5c

-

I have a pic of it the other way but it keeps saying "there was a problem uploading the file"

-

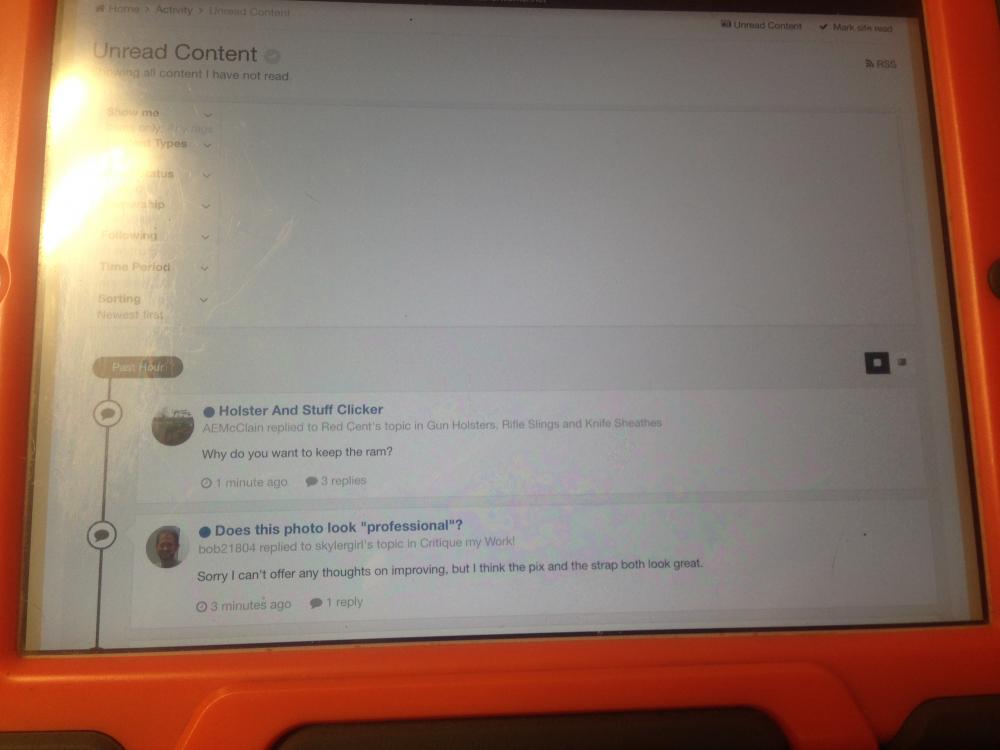

Another issue. I have to have the iPad upright instead of sideways or a big blank box covers the top half of the screen.

-

-

Agreed on the faster part, the other software was slow from day one, this scoots along better. Today is the first time accessing it from a PC, and my positive comments relate to the PC. From my IPAD, I hope the configuration bugs get worked out.

-

Finally Cracked the Shoe Code

electrathon replied to Reegesc's topic in Shoes, Boots, Sandals and Moccassins

I am most interested in the forming of the toe box. I am assuming they are not lasted.- 10 replies

-

- chukka boot

- chukka

-

(and 2 more)

Tagged with:

-

Finally Cracked the Shoe Code

electrathon replied to Reegesc's topic in Shoes, Boots, Sandals and Moccassins

Nice. I like this style of shoe.- 10 replies

-

- chukka boot

- chukka

-

(and 2 more)

Tagged with:

-

Any laser shop can cut you one. They cut the pattern on a piece of Delrin, leaving the lines and removing everything else about 1/16" down. Leaves a bunch of raised lines.

-

Is it dry in the photo? Often times it will drastically change color as it dries. what I would do is take the remainder of your dye and dilute it about 20% with alcohol. Put the dye in a flat pan. Dip your piece in and submerge it, don't be slow, keep it moving. This only takes a few seconds. Remove the piece and pat it dry with an old towel. Lay it flat, every little while pat it again, do not rub. When it is almost dry oil it with a light coat of oil. Let it dry for a day. Coat with wyo-sheen, antique with fiebings antique, clean up the antique with tan-kote. Try this process on a scrap first.

-

I would use a wax shoe sealer. Like sno-seal or similar (there are a lot of them out there).

-

Have to second Ron's Tools.

-

http://shop3992.hstatic.dk/upload_dir/shop/waterstain-farve.png I am fully aware that there are different brands of paint or dye on the market, of varying qualities. My comment revolved around the fact that waterstain (the common product that most leatherworkers know as a waterbased stain) is labeled by the manufacture as a dye. I believe I even saw the new Tandy label the other day and it is listed as a dye on it too. As to penetration, no water based product will suck into the leather like a solvent based product will, very true. Bottom line is that eco flo waterstain is totally and completely a water based dye. Even the manufacture says it is.

-

Machine For Sewing Sneaker Midsole?

electrathon replied to Daniel G's topic in Leather Sewing Machines

Short of spending lots on a real machine I would use a jerk needle (a needle off a hook and awl machine). About my last choice for sewing anything would be a speedy stitcher. -

How To Set A Rivet In A Tight Space

electrathon replied to AndersenLeather's topic in How Do I Do That?

Grind off the outside edges of the tool. As an alternative, use a drift punch instead of the hammer. It will let you get into the tight area. grinding the correct tool is the best idea though. -

Removing Ballpoint Pen Mark From Vegtan

electrathon replied to Erystawi's topic in How Do I Do That?

If you are using brown Fiebings dye on your projects it will remove red ball point pen marks. You can mark all over it and it will just disappear. -

Sharpening A Splitter Blade - Am I Doing This Right?

electrathon replied to rhinez0r's topic in Sharpen it!

When sharpening, the purpose of a finer stone is to remove the scratches of the courser stone. Stay with the course stone till you get an edge, then move to the next stone to improve the edge. For a splitter I use wet dry sandpaper spray glued to a piece of glass. Wet the paper with water and simple green, about 50/50 mix. Using two hands work the blade on a circular motion, keeping the cutting edge pressed down. Color the edge with a black sharpie to see where you are removing material and if the blade is warped (every blade I have sharpened was warped at least some). This can take some time. -

Tandys Printable Tracing Sheets. Whats The Best Type Of Printer?

electrathon replied to Jarednem's topic in How Do I Do That?

I never trace twice. The books say to use tracing paper because they were wrote 60 years ago before there were copy machines. Start exactly how you now do. Print on paper. Put your cased leather on your table, wrap it with seran wrap. Place the paper on it that has a pattern printed on it. Tape it all so it doesn't move. Trace the image (red pens are awesome, you will never miss a line). Toss the used pattern. If you need another pattern simply hit print. Way cheaper, faster and works better.- 13 replies

-

- printable tracing sheets

- printer

-

(and 2 more)

Tagged with:

-

Tandys Printable Tracing Sheets. Whats The Best Type Of Printer?

electrathon replied to Jarednem's topic in How Do I Do That?

While I have never used them (I do not understand why you do not just use paper), in general ink jet printers do not print well on plastic. A laser prints well on plastic.- 13 replies

-

- printable tracing sheets

- printer

-

(and 2 more)

Tagged with:

-

Cutting Leather With Laser Questions

electrathon replied to pillpusher's topic in Leatherwork Conversation

I thought this same thing I understand that the only reason why the old timers did things the old way was because they did not have the tools that we now have. -

Not sure where you are located but that switch design is very common. The trouble is there are a huge number of variations, all giving a new part number but most of which cam be used interchangeably. Such as extra terminals, shorter or longer terminals, built in lever, etc. A Google search and lots of calls will get you answers. I have a very similar switch on a car I own (very small run electric car) and was told I would have to buy thousands of them to get one. I talked the guy into looking on the shelf and he found some that had shorter terminals. For $35 I got ten of them (minimum order). My car now works again. To fix the plastic use epoxy and re-drill the holes.

-

The coloring looks very nice. The sharpener is set way to high in the sheath. It will be drawn almost never compared to the knife itself, it will interfere with that. Also the sharpener looks like it will pull straight up easily without unsnapping, a recipe for loosing it. The retaining strap on the sharpener is also backwards, they should be placed so that brush and forward movement will not open it. Did you make the knife? I like the handle colors. A pic of it drawn would be nice.

-

To start with let me say it is a huge learning curve. My suggestion is to take a class at Bonnie and Wills down in Ashland. They are one of the only shoe schools in the nation that teaches real shoes. Classes are $1900 If I remember correctly. Also in a few months there is going to be a shoe symposium in Ashland. You would not learn enough to make shoes there but you would be exposed to some of the top shoe makers in the world.

-

She is a one person store, so possible life is in the way. Normally good to work with.