-

Posts

5,805 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

good luck with that! I know you want to avoid pulling the top shaft. But I´m not sure if it really is worth the effort and at he end not sure if it will work / last at all.

-

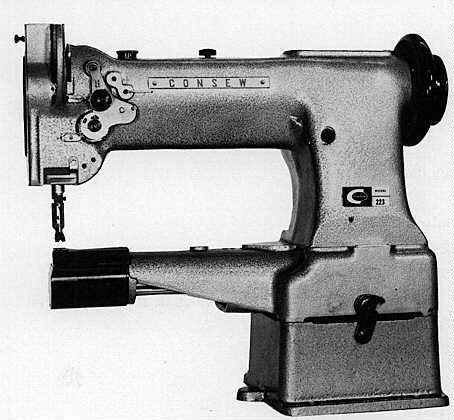

Seems the 223 came with 2 different stitch length mechanisms - one just as used on the Singer 153 (old type) and one with a stitch length / reverse lever (later type). I would open the top lid and check what inside there and find out which type of stitch length mechanism is inside the machine. But I think you are right seems someone "cobbled together" 2 different machines (see lever marks on pics 2 + hand wheel with coarse thread seems to be from the 1st type) - or - it is a custom build / modified machine but I cannot tell from your pictures. I just looked for pictures:

-

A clutch motor 1425 rpm or upgrade to servo?

Constabulary replied to Badem's topic in Leather Sewing Machines

Buy a servo motor + maybe later a speed reducer or DIY one! You will not regret it. Value of a used clutch motor? Almost nothing because no one really wants them - maybe 25 - 30€ if you find a buyer. College sewing is blowing out their NOS clutch motors for 28GBP with wires and switch. -

I would go with a e-commerce shop software like "Modified e-commerce Shop Software" - its free - you only need the web space and have to adapt it to your needs. https://www.modified-shop.org/ Not sure if they have an "english branch" but it has lots of templates you can choose from and you can check out some templates designs at their demo shop site: https://www.modified-shop.org/demoshops EDIT: or check MAGENTO: https://en.wikipedia.org/wiki/Magento https://magento.com

-

its a 29K71 clone with minor differences - not Singer made but probably better made than you other (29 clone?)

-

30-5 is a small hook high lift / long needle 30-3 is the large hook short needle variant. There you have it - 29K71 sewing approx. 12mm material with sz. 15 metric thread with 140 needle - okay I´m cheating for approx 0.5mm

-

I would buy the 29K71 mainly because of the parts situation. I´m owner of a restored 29k71 and have restores several other 29K models and Adler 30. The 29K71 is technically advanced and you have more options for making adjustments. The 29K71 can sew with a lower foot pressure whereas the Adler always has a certain and quite hight foot pressure due to the leaf spring. The 29K71 has a helical presser foot spring you can tune the foot pressure a lot better. Regarding high lift - belief it or not my 29K71 can sew 10-12mm thick materials - it just depends on the settings. This is no sorcery and I have not modified parts. I hoverer never sew materials this thick "in real life" but it is possible. The thing is you have to play a little bit with the position of some parts. I think Singer never explained well enough what their late model patchers are capable for. I can post a quick 29K71 Video showing how thick it can sew if someone wants me to.

-

Picture tell more than 1000 words...

-

No matter the machine - you usually can but as you said sometimes it requires to bring the hook tip closer to the needle - meaning you probably have to move the hook saddle toward the needle. Just try it it will not hurt.

-

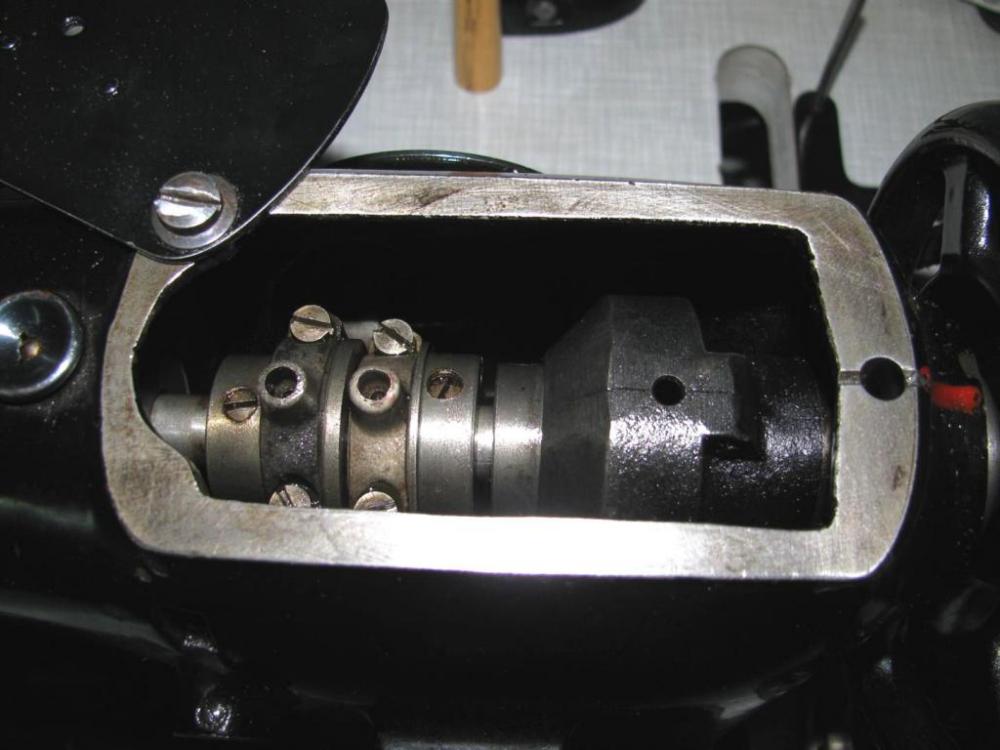

It is also possible that you have a dedicated binding machine - as far as I recall you can tell the difference by opening the top lid near the hand wheel, There usually is missing the 2nd drive rod which is controlling the up and down movement of the feed dog. If the rod is missing your feed to only moves back and forth. You also can tell when you look on the underside. there is not drive rod attached to the upper rod. Hope you know what I mean - I have to look for pictures.... Edit: see pictures - I think you will notice the difference. Not sure if you have a binding machine but pictures tell the difference.

-

Since I have an interest in sewing machines I came across 2 or 3 of these motors they all didn't work properly and I figured it really was a waste of time an money trying to repair them (BTW I had no luck). When they run - great - keep em running - if they do not run just scrap them and buy a servo motor. It´s is a nice idea to "revitalize" old motors to save resources, avoid waste and to save money and so forth - I absolutely agree - but honestly if you invest more than $25 (not speaking of your time) it is not worth it. And you don´t know how long they will "survive". I have tried several types motors and setups but the best solution for me (yet) is a servo motor + speed reducer. Lot´s of control, lots of torque (if needed) and you have energy. My 2 cents. EDIT: check the timing belt of your Adler 67 - if it is brownish and brittle / has cracks - do not buy it - changing the timing belt on an Adler 67 class is a real pain. I did it once and and don´t want to do it again.

- 9 replies

-

- steppermotor

- variostop

-

(and 3 more)

Tagged with:

-

my plate is not an original 132K plate - I have modified a 96K table because the plate was so nice and vintage (original Singer actually). The peg I´m using came form a different machine and I´m using the original hole of the former 96K setup cause I don´t wanted to drill new holes into this nice old plate. I´ll post some pictures later. I´ll send you an PM bcs. of the drip pan.

- 9 replies

-

- seiko sk*

- singer 132k*

-

(and 2 more)

Tagged with:

-

Looks like drop feed variant w/o jump foot - then the machine takes the same presser feet as the Singer 45K / GA5-1. BTW - do you need an oil drip pan & bobbin winder?

- 9 replies

-

- seiko sk*

- singer 132k*

-

(and 2 more)

Tagged with:

-

don´t know who typed it - must be decades old. I once found it in a lot of manuals I bought. You may need the "old" parts list (with old Pfaff parts numbers) to understand what parts they mean. I have an old 145 parts list but its too big to attach - if you need it send me a PM so I can forward it by Email.

-

She’s broke....Singer 111w155 parts needed

Constabulary replied to Glaciersew's topic in Leather Sewing Machines

sometimes its helpful to show a picture of the part because most people do not know the long Singer nomenclatures and parts number by heart and I´m sure just very few will check the parts lists - if at all. You for sure have to check with a dealer for this part - maybe Keystone Sewing Machines in PA or Toledo Sewing Machines in OH can help you with this. -

Consequently 225 cylinder arm?

Constabulary replied to Madmax500000's topic in Leather Sewing Machines

Rather a Consew 227 - maybe seller mistyped... -

What adler is this 30-1, 30-5, 30-7?

Constabulary replied to Gunengraver's topic in Leather Sewing Machines

30-1 most likely - small hook short needle. You can tell from the position of the arm lever pivot pin that it has a short needle (pivot point on the right = Adler 30-7 / 30-5, pivot point on the left Adler 30-1 / 30-3) plus it has no raised housing and and on the last picture you see a pice of the hook - its a small hook. 30-1 small hook, short needle 30-3 large hook, short needle 30-5 small hook, long needle 30-7 large hook, long needle It´s a light greenish hammertone paint. BTW - foot lift lever is broken off, needle plate holes are very worn. -

I don´t think the shaft is stainless steel. I haven´t pulled a top shaft yet and cannot support here but you at least have to remove all gears and all parts attached to the top shaft. I have a disassembling / assembling instruction for the Pfaff 145 - maybe it helps you a bit - the head is "quite" similar. I have sent you the parts lists I have - I hope they help a bit. Dismantling Pfaff 145.PDF

-

Damn - thats bullshit! Shipping a sewing machine from an "unexperienced" seller (in terms of shipping) is a 50/50 risk . I would always remove the hand wheel form the machine when shipping it or support the machine with styrofoam the way the hand wheel is free. And you at least need 1.5" styrofoam on each side (more is better) of the machine + it has to be packed real tight! I have a parts list for a "new and old" 193. I´ll send them by email. Pfaff once changed their parts numbers - what I have observed is that the old part number is part of the new part number meaning they added some digits as prefix and some digits as suffix. The old number of the arm shaft is 10002 - the new number is 91-0100 002-05 College Sewing seems to have the shaft - seems this is the one but better check with them: https://www.college-sewing.co.uk/store/9101000205000-ARM-SHAFT-GENUINE-PFAFF German dealers might be cheaper but my experience is (ordered Pfaff parts once and requested prices from 10-12 different dealers) that CS necessarily is NOT the most expensive. Prices from German dealers varied by more than 100%.

-

regrading shuttle carrier: #1 is Singer 82117 for 29K71 / K73 #2 is Singer 8605 for 29K1, K3, K4 and the like They could fit but the screw holes tell a different story - pretty obvious, right? But this is just what I have and what I can compare and I don´t know if there have been other differences over the years... I don´t know the whole Singer patcher (and parts) story, I just scratched the surface. Let me check some measures again... EDIT: okay - checked another 8605 shuttle carrier I have - the holes are approx the same as with the 82117 - approx 7mm from the rim to the center of the hole Seems the 8605 I have shown in the picture above is modified (for what ever reason). But still - if I had a worn out patcher like yours I would not spend time an money - sorry to say that!

-

Do not expect that any of the parts from College (Sewing) will fit for the century old patchers gear box - neither pinions, nor racks are the same - different size and different teeth pattern - the parts do not work! You remove the parts from the underside. There is a plate that covers the gear box and serves as a bushing for the 2 pinions. To give you a rough idea how the different pinions look #1 is for 29K1 - 29K33 (approx) #2 is for 29K51 - 29K56 (approx) #3 is for 29K60 - 2973 (approx) #1 is what you need and #3 is what the Chinese 29K71-29K73 clones have and you get from College sewing. Shuttle carriers look the same but have screw holes in different positions. Honestly - rip apart you patcher and look for a better one and keep some spare parts. It´s just not worth the time and money when a century old patcher is as badly worn as yours is. Sad but true. If you want to give it a try go ahead but don´t expect too much. When a gearbox is worn out like yours guess how the condition of all the rollers and and cams are (machine 4 different rollers and 3 cams) - not to mention all the other parts

-

Help! I'm reaching the end of my tether!

Constabulary replied to Cymro29k3's topic in Leather Sewing Machines

Well, you can do a rain dance and wait until the pin is rusted away or you hammer it out Of course you have to hammer it out - its a pin! When the needle is in the material and it starts feeding you don´t have many options - the pulley cam is controlling the needle bar and if you want to solve this you have to reposition the cam (that's what I would try) Unfortunately no one knows what the previous owner did with this machine so we all can only guess (just wrong cam position or installed different cam... we all do not know). If you drive out the pin be careful the pin is tapered it will go out only one way (as Carlosveiga mentioned already) . One end of the pin is smaller than the other end - maybe hard to tell now since you have painted the machine already. Usually you do it the other way around - make the machine work and then paint it. I can´t help more - I explained the cam / needle bar position in an earlier post so it´s up to you if you give it a try or not. No one said it will be easy - a century old machine is not an easy task if parts are gummed or rusted in place and the paint doesn´t make it easier. We all can only give you our opinions... At the end it´s your machinate and you have to decide what you do or don´t do. You can try it or you leave the machine as is as a more or less decorative boat anchor. Good luck. -

Help! I'm reaching the end of my tether!

Constabulary replied to Cymro29k3's topic in Leather Sewing Machines

I still would guess (as I said in my earlier post - see below) that someone actually did a repair but put on the cam / pulley the wrong way (turned by 180°). Please check my earlier post. -

If you consider the machine just as tools I would keep with white one (Asian made clone of the Singer 29K72 / K73 ) because parts are available, the other one looks live a very early 29K1 - 29K4 or the like - probably a century old and very few pats are available or just used parts for ridicules high prices. Keep in mind that the presser feet of these machines will leave marks on the top side of the leather - this is probably not what you want. I don´t think a patcher machine is the right machine for your work - they are designed as repair machines.

-

Help! I'm reaching the end of my tether!

Constabulary replied to Cymro29k3's topic in Leather Sewing Machines

the foot lift lever is an early "push down" lever - modern lever do not fit. I only have seen this once - let me check if I find more pictures... you can ask a welder if he could weld a piece of metal on it to endlong the lever. EDIT: I once restored a 29K3 with push down lever. This it how it looks when correctly installed - sorry no other picture I recall it was a bit odd to install it but I do not recall what the problem was. So it could well be that your lever is the correct one - just broken.