-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Some years ago I was in about the same situation when I was hunting for a Singer 34K NB: https://leatherworker.net/forum/topic/66729-singer-needle-bar-i-could-use-some-help/ The REX here is a clone of the Singer 16-188. NB in the Class 16-188 parts list is # 4264 so this should work: https://www.ebay.com/itm/292096957975 You may find it from other dealers too. EDIT: And don`t forget the needle bar clamp. I would also order some needle plate screws and 1 or 2 new check springs or a complete tension unit, 1 or 2 bobbin cases and a new CB hook just to have spares on hand when needed. The parts are not really expensive.

-

Diagnosing an issue w/ Singer 29-4

Constabulary replied to Teradee's topic in Leather Sewing Machines

You mean the top shaft? Then no cause you have a pinned cam on either side of the shaft. If it causes mechanical issues (but I do not think so) I would add a very thin washer but removing one of the cams (in worst case) can cause more issues cause the pins are tapered and sometimes they are super tight. -

@RC65 Yeees, weeeeeelll.... I heard of those people I have a 212G141 as well, I´m not using it much but it is good to have. I converted my into a split needle machine. https://leatherworker.net/forum/topic/80209-singer-212-112-double-needle-converting-into-split-needle/

-

Diagnosing an issue w/ Singer 29-4

Constabulary replied to Teradee's topic in Leather Sewing Machines

Slow running machines with a "rather simple" mechanical system can use heavier oil IMO. It will not kill the machine. I would not use heavier oil on domestic sewing machines but patchers with their big cams, rollers racks and pinions are tough! Some folks even put grease on the cams and it will not hurt but will be messy with the years. Sticky grease can make the machines run a bit more silent and sometimes compensates wear on parts. -

Old Singer machines suitable for leatherworking?

Constabulary replied to Redbeeerd's topic in Leather Sewing Machines

To be honest - for 40 bucks I would buy this machine in a heartbeat. You do not need a treadle to run it. The short arm patchers are great for mounting on a board and hand crank them. It seems to be a 29K51 and the outer condition seems to be very good. Patchers are very versatile (I have the later 29K71) but as WIZ said they are not really machines for producing things. Anyway - great useful machines especially at that price. Just from the picture looks like the nuts for the tension units are missing (still available) and I´m not sure about the bobbin winder. The critical parts on this machine are the pinions in the gear box, they are special (fine teeth) and they are obsolete but considering the outer condition I would assume the pinions are still good cause the machine does not show much outer wear. If it was me I would buy it. -

Old Singer machines suitable for leatherworking?

Constabulary replied to Redbeeerd's topic in Leather Sewing Machines

"Old Singers" can means everything and nothing . Singer made hundreds of different industrial and domestic machines and made dozens of leather sewing machines for different kind of leather work. I`m using vintage Singer sewing machines only (nothing else). So it depends on what kind of leather products you want to make and what Singer sewing machine models you are talking about. If you mean the small domestic machine with treadle base - well you may be able to sew some garment type leather with them with thin thread but sewing belts, boots, holsters or bridles is not possible. Maybe this thread helps to narrow downs what type of machine could suit your needs -

Diagnosing an issue w/ Singer 29-4

Constabulary replied to Teradee's topic in Leather Sewing Machines

Keep in mind that the 29-4 are more than 100 yrs old and parts can be worn or even worn off. Not sure if I got you right but I´d check it you have some sideways play on the top shaft. If there is play and you have a load change on the inner cam (the one on the top shaft you see through the window on the rear) you may hear a clacking sound (most likely its the cam pulley banging slightly against the casting). First thing I would try is oiling all the cams and rollers and the shaft bushings with an heavier oil like motor oil f.i.. -

I´d look for a Pfaff double needle post bed machine manual. F.i. Pfaff 1294 - scroll down here for a instruction manual download link: https://www.pfaff-industrial.com/en/portfolio/sewing-machines/post-bed/pfaff-1294

-

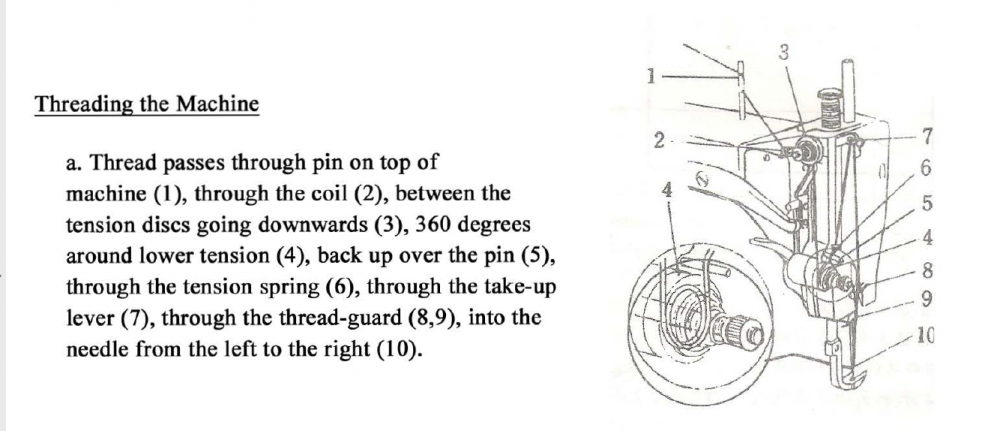

I can´t see anything wrong in the pictures. But to me the tension spring on the lower tension unit looks kinda weak (not sure though). See picture of my tension unit. The wire of the beehive spring on my tension unit is approx 1.8mm in diameter (have to check to be sure). All guessing but maybe worth checking: Are you wrapping the thread around the tension pulley / wheel? Meaning thread comes from the top tension then wrap completely it around the pulley? This is from a GA-5 Manual but the circled picture shows it quite good. Are you sure all parts of the lower tension unit are present? I looks like this: Also - please check the 2 discs / washers in the tension. They should have a flat side in the center hole. That ensures they do not rotate when the pulley spins. If the flat side it rounded (happens with the time) and they rotate you have less friction between the components and that can cause less tension on the thread. See picture:

-

Is it a needle feed machine? How do the bobbins look like? What is the max. stitch length and max. foot lift? I would like to see a video how this thing works!!!!

-

All pins on this machine are tapered. This pin would go out back to front just as the large pin on the lever arm. The 2 mentioned pins usually go out with a few gentle hammer strikes. There is nothing on this machine that requires drilling or grinding for removing / replacing parts. Ask Bob if he has a new pin. Parts # is 8589 BTW - in one of your earlier threads on this machine KGG linked a manual with parts list with good part diagrams for the 29K7x series which is not the exact same machine but it is a very good manual and the majority of parts remained the same (just minor differences).

-

FEDEX did the packaging or the sender? Packaging usually is up to the sender. Packing up sewing machines is often underestimated. It requires a serious good packaging and a lot more than just a heavy carton and some foam flakes or bubble foil. It´s easy to blame the shipping Co. but from my experience 99% of the time the mistake is in the poor packaging which (as I said) is often underestimated. Heavy and bulky items like sewing machine require a different packaging than f.i. a cell phone or an electric drill. Logistics today is not the that postman carries 1 package from A to B and takes care of it all the time. Shipping starts with proper packaging and that is up to the sender. Proper packaging require that a box can be dropped from 1 meter (at least) without damaging the goods inside the box (some Co. even say 2 meters afaik).... I could continue. BTW - I do not work for any shipping co but I have shipped packages around the world in all possible sizes and weights. Most likely the top shaft is bent. You can try to bend it back but you most likely will never be 100% straight again. You could ask a professional to do that but it most likely will costs more than the machine (incl. disassembling and reassembling, timing...) The screw on the end of the shaft is for adjusting the horizontal play and the further you turn it it the more the hand wheel pushes against the machine casting. So remove that screw and remove the 2 set screws and if the hand wheel is seized / gummed on the shaft you may need a larger gear puller for removing the hand wheel.

- 11 replies

-

- parts needed

- wobble in balance wheel

-

(and 2 more)

Tagged with:

-

I quote myself and please post pictures of your lower tension unit please

-

@Sham Post pictures of your threaded machine please. When you have tightened the top tension and you still have loops on the bottom I would assume too much bottom thread tension or maybe a too weak top tension spring. But I only can guess w/o knowing your machine.

-

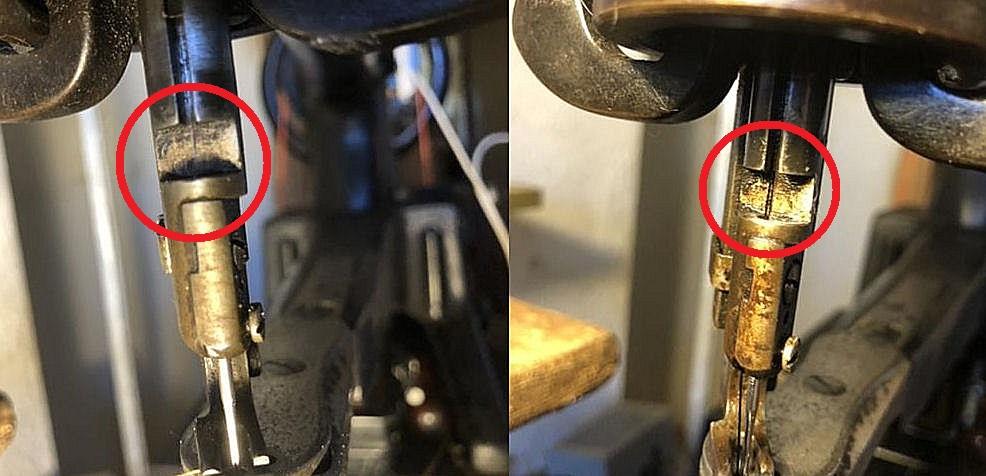

For what ever reason the depth of the worn in grove looks significantly different on your pictures. One like almost no grove and the other looks quite deep. If the grove is not too deep it will not bother (as it seems to be on the left picture). Anyway you can file if down as long as you do not go too deep cause that may create an edge / burr in the thread path and could damage the thread when thread slides over the edge. If it is as deep as it looks on the right picture I would file down the grove and install a new spring. Springs should be available from most industrial sewing machine dealers. Part # is 8656 The spring is held by 2 very tiny screws Part # is S133D or SS133 Even when the screws are there I would order new screws. They are tiny with very fine threading and when you drop them they are gone (guess how I know). Make sure you are using a proper screw driver and do not damage the screw heads. If the screw wont come off / are seized I would heat the screws with a little gas blow torch... Important hint from WIZ: BTW - filling the grove with epoxy or lead makes no sense cause the threading wire will wear it out soon.

-

The paddle spring is missing on the needle bar and as it seems you have a deep grove in it. You can file it out up to a certain degree. This is how it should look

-

Normal - nothing unusual. You have thread slack on all sewing machines (as far as I know) when the needle bar is in the lower position before it rises and is forming the thread loop. However - thread slack can cause problems on the Singer 29K or Adler 30 when the paddle spring on the needle bar is worn / has a worn in grove (caused by thread and / or the threading wire).

-

However - you may be able to sell the treadle base locally cause they are sometimes missing. They work for Adler 30 and Singer 29K machines too. It may require drilling some mounting holes but they will work. Some even buy these stands for garden decoration for putting flower pots on them or what ever. Taking the machine apart and selling the parts may be an option too. You may brake even or probably maybe make a small profit. If you are able to ship the parts overseas I may know someone who (probably) could be interested in the parts. But I´m sure he is reading here too.

-

You have to edit your text, it is almost impossible to read. the machine appears to be some sort of early CLAES RPX (very similar to Mod. 200) but seems the machine has "not been loved" very much. Bobbin winder and tension unit are missing and the spring on the needle bar is not original - as far as I can tell from the pictures. If it sews then good - if not you may need a 2nd machine for parts. I love restoring vintage machines as long as they are in a "certain" shape but IMO yours is not worth putting money in this machine. You will have a hard time finding the missing parts, it most likely easier to find a 2nd machine in better shape.

-

Faithless - Insomnia First seen at the Hurricane Festival in 1999 and then 2001 - an unforgettable act! Insomnia is one of my favorite lifetime songs since then though it entirely is not my style of music but that particular song plus the festivals experience back then made unforgettable for me. Maxi Jazz died yesterday at the age of 65 - RIP!

-

The screw is a stop screw for the stitch length lever. It basically has 2 functions 1. limiting the forward stitch length (longer or shorter) and 2. limiting the reverse stitch length (longer or shorter) the way that you have a reverse stitch length equal to the forward stitch length for locking the seam start and end. The machine will sew but you will not be able to adjust an equal forward and reverse stitch length. You can try to put stitch length marks on the machine body but that IMO does not make sense on the long view and is not very precise. You can try to tap a new larger thread and insert a screw BUT you only have 1 try. When the threading is a little offset you will not be able to adjust a matching forward and reverse stitch length anymore and the forward and reverse function then IMO is useless. If it was me I would NOT do it.

-

Singer sewing machine 132K6 top thread problems

Constabulary replied to Mapleseeker's topic in Leather Sewing Machines

Not sure if and what manual you have but the best 132K6 manual you can download here. Make sure timing is correct (see linked manual) and the spring of the bobbin case / hook retainer is touching the bobbin case just ever so slightly cause the thread will be slide between the spring and bobbin case. Also make sure there is no burr in the thread path and the bulge on the retainer spring tip is smooth. -

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

The screw is replaced already. It was the most unimportant screw on the whole machine. It just holds the oil pot in place. I was just super surprised that it split up like this. Manufacturing error - I will check with Dürkopp if I still wave warranty. When the "planets" are aligned like this and the needle is set as mentioned above the machine is correctly timed and sews well. -

Looking at the video I would guess either the inner foot bar or the needle bar are bent (needle bar I guess). Why? Cause both bars go up and down in the needle bar rock frame and therefore both bars are in a fixed positioning to each other. So the distance is not adjustable. But I only can guess....

-

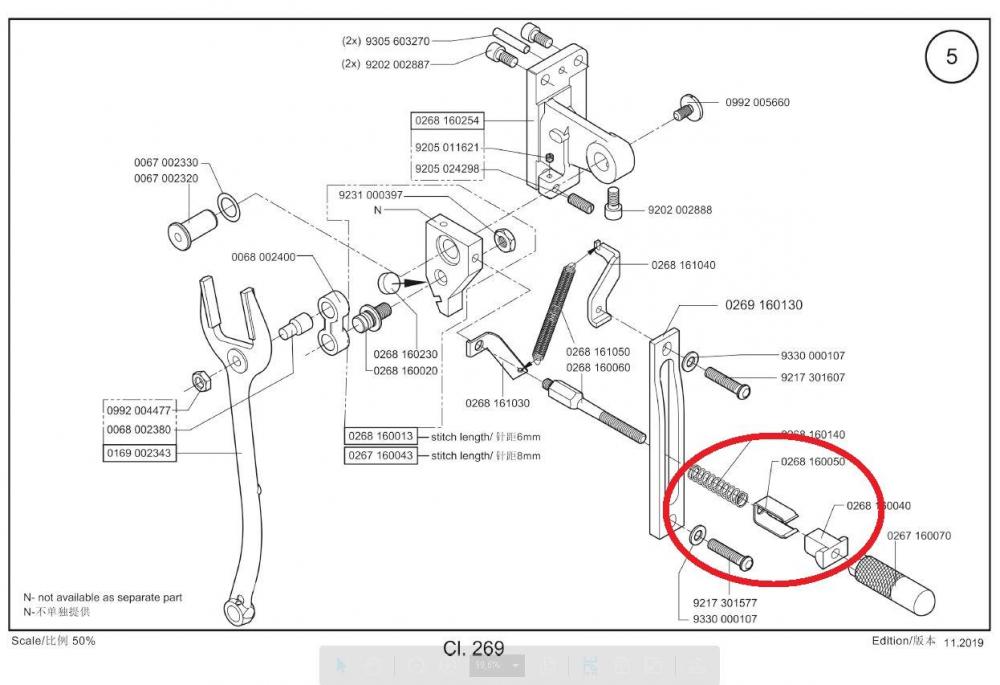

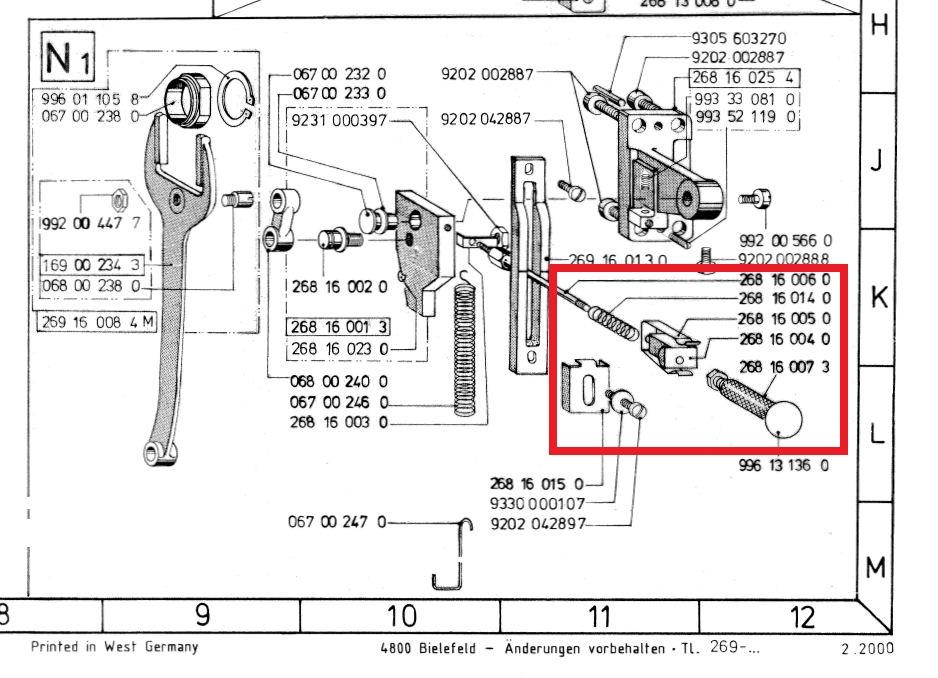

I´m not an Adler expert but when I look at your picture and cross check the parts list of a 269 - I would guess your stitch length adjuster is not correctly assembled. Just a guess.... Cross checked the older parts list as well: You may also check the orientation of part # 268 16 004 0 - you (maybe) have to rotate it by 180° but I do not know the design of this part but f.i. on certain on Pfaff machines the orientation of this part matters!