-

Posts

545 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by shtoink

-

If I'm not mistaken, modeling spoons fit this category, too. I guess it depends on the type of detail needing to be done, though.

-

Randomizing the tool orientation will help disguise the regular pattern that happens. In some of the narrower and curved spaces, a smaller tool with the same texture to the surface will allow you to have few restraints on tool position. This is similar to the technique you'd use to smooth out tool marks while beveling, but over a large area instead of a line. The good news is that you wouldn't need to start over, but just bash some irregularity into the backgrounded section. Just be careful not to hit too hard with a tool that has a smaller face, since it'll dig in deeper. It's all about practice and getting familiar with how the leather behaves. Proper casing can make all the difference in the world, too.

-

I'm usually pretty surprised when something similar hasn't been done yet, especially when it's as popular as this show is. I did a bit of digging and found numerous still of the astrolabe in the intro... First, the astrolabe as a whole A wiki page with some clickable thumbnails Several more close up shots on the details There was a bunch more, but it would require further weeding through the pages to find the stuff missing from the gaps. If you want to go that far with it, it'd probably be easier to snag a copy of the intro so that you can go frame by frame and transfer what you see to a sheet of paper. After that, I'd do exactly what DavidL was saying and put it on a belt. It might not be the exact thing you were asking about, but it'll get you a good start. I found another one... and another one... It looks like both of those are people trying to get more detail from the rings, too.

-

Not an acronym, but still worth an explanation. For the record, Team Fortress Class released in 1999, so I've had it a while. Also, no problems...

-

It's the copper jacket left over from a spent bullet. I don't know enough to be able to identify it, but it looks like it's from a rifle and may have been FMJ. Here are some more images... A forum page dedicated to it. Collage 1 and Collage 2 While searching, I noticed some people making jewelery from the spent rounds and selling them on Etsy. Weird...

-

I would say that maybe a temporary shift on projects might be your best bet. Sometimes, when you are having trouble getting just the right look or effect, it's best to shelve the project and work on something else until you've had time to cool off and regroup your efforts. Another thing that helps is to study items that have the look or effect you are aiming for to see how it is done. If the clean and professional minimalist look is what you are after, the first name that comes to mind is a specific member here by the name hunio. There are many more, but here are a few that I found with a quick search that are good examples of his work. Maybe you'll find some inspiration. Small Wallet Small Leather Tray Making of a Small Card Case My New iPhone Case

-

Not having any experience with the business aspect, I'll toss some ideas out for you on your other question about getting started. If you have any kind of reservations about getting into leather stuff based on some political aspect, then you could just make sure you are recycling materials for your items to sell. Cannibalizing old couches, chairs, or clothing for your source of leather can also add to the appeal, depending on your prospective buyers. I have seen booths with recycled leather goods in open air markets more than a few times and they seem to do pretty well. They'd have all sorts of bracelets, necklaces, key chain fobs, wallets, pouches, and many other things that were made from recycled stuff. Depending on where you shop, you could get items that have gone on sale or are deeply discounted to keep the costs down. Hopefully this is helpful for you.

-

I'm relieved to hear that it's not some random person who approached you with the idea. Something out of the blue like that throws up red flags and cause an overwhelming desire to flee, so that is why I mentioned it. Helping a friend out like that is a whole different thing and commendable. It might be possible to find a strong enough plastic buckle. I've never researched the topic, so I have no info on the durability, strength, or longevity of them. The reason behind the mechanic's belt idea is that there is no contact with the metal retention stud on either side. The front is covered and the back would, presumably, have a layer of pants between any skin and the stud on the backside. Here is what I mean. No affiliations with them. That was just the first place I found that had clear pictures of what I was talking about. Although, something along the lines of this or this might be pretty cool, too.

-

I might look into Grade 23 Titanium. It's specifically meant for use inside the body. It's common to find body jewelry made from it, but maybe something like that could become a buckle with a little modification. Maybe a route similar to a "mechanic's belt" to minimize skin contact might work. Those are a couple potential ideas that come to mind. If your customer claims to be allergic to even Grade 23, then you may want to pass on it based on the amount of unforeseen challenges involved along the way. I'm skeptical of the claim and wonder if it's a fools errand. I also worry that this might a potential "warranty replacement" issue for you later on if something were to cause an "allergic reaction" anyway. The last thing you need is a disgruntled customer because you couldn't do the impossible and still meet their unrealistic expectations. I'm always up for a challenge, but sometimes there's a line in the sand. This is just my personal opinion, so please keep that in perspective.

-

This is mainly an update for those of you who might be playing along at home or intend on playing along in the future. CA glue is not the glue you want to use to stick these PVC tubes together. I knew going into it that CA glue wasn't ideal for the job, but figured that it should be a reasonable glue to use. I was very wrong! The big thing is that it's a brittle glue and doesn't really do much more than sit on the surface. I should have just avoided being lazy and gotten that purple stuff meant for PVC. A quick couple swipes with the dauber, align, and wait. Then it would have become one rigid piece without the fear of accidentally knocking them apart while I figure out how to a bunch of wood and plastic parts become one solid piece. After quite a few, post accidental tube separation, choice words and phrases, I decided to set things down for a bit wait until I have the proper adhesive for PVC before I makes things worse.

-

There has been progress on this thing, I promise... With school, it just hasn't a priority. I got the axle the bearings ride on in place and placed a pair of flanged bearings on each end. It's a simple flared end type of retention for the bearings. Since the rod was brass and I wanted a low profile retaining method, it seemed to most straight forward way to do it. I ended up dropping the second set of bearings due to the risk of breaking in the area between the bearings in the images in my previous posts. I wanted to use them. but the grain of the oak I used made that too risky. I did end up shaping the top of the channels so that the whole thing dropeed into place more easily. The tubes are getting affixed to the front panel for the part that will be holding all of the punches. Some slight modifications had to be made due to an oversight on my part in the initial design. I accidentally made a couple of the plastic tubes overlap the side panels, so the next size down tubes needed to be used. It worked out in my favor, since cutting the plastic tubing revealed that the precut lengths did not yield enough sections of tubing for the number I had intended. It would have meant going back to purchase another 3 foot section for roughly 6 inches of tubing and I didn't really want that and that was the shortest the big-box hardware store sold them. There were a couple challenges along the way with the tubes. One was cutting them all with as little waste as possible and the other was getting them all the same length. While there are a ton a of different ways to go about this, and plenty that I wold have rather used over the way it ended up happening. In the end, I used a hobby razor saw and jig. Despite all the careful planning and setting up, I still ended up with crooked cuts due to a poorly designed miter. The next step was to find a way to make all these tubes stay together and get that mess to stay attached to the front panel. Looking back on that now, I should have gotten some of that purple glue meant for PVC pipes instead of a boat-load of CA glue. Still up is making the tubes part of the front panel, which is the phase I am in now. Here are a few shots on the progress and a video of the tool block motion being tested And the video...

-

If you're talking about the sanded stingray with the turquoise thread and rectangular logo in the upper left, then no... If you want an honest answer, then yes...

-

Cut out the correct shapes to assemble a dart board. On second though, maybe the darts would just bounce back out...

-

Looks like sure way to restock your repair shop with vintage parts. They even have them all nicely crated up and ready to go, too.

-

Yeah, that generally seems to be one of the biggest hurdles. I always hate that I may know what it is that I need or I'm looking for, but forgetting, or not even knowing, what it's called really makes the whole process that much harder. The moment of clarity when you go "Oh... So that what it's called..." is a pretty god feeling. Especially when you've never had anyone to ever tell you what it may have been called. I inherited the bulk of my tools and never had anyone that knew what most of them were called. I had giant box filled with "What"s this thing do? " Some stuff was clear, other stuff not so much...

-

I wear flip-flops all the time. It's become instinctual to just dodge instead of trying to catch a sharp/pointy object falling. I remember seeing my mother catch a kitchen knife with her toe, much in the same manner you described. It's like dropping buttered toast. The odds are, it'll nearly always land butter side down for a fresh coating of floor-pepper. I've had far too many close calls to count... X-acto knives and I go way back. At the age of about 8, I was allowed to use one for some unknown reason and at one point used the top of my thigh as a cutting board. It didn't take long before I had shoved it up to the hilt into my leg a few inches above my knee. Countless finger slicings later, I still have to be wary of forgetting that there's a knife in my hand when I reach to scratch my face or rub my eye. That's usually the point that I need to set things down and take a break. I've also had to implement a "No Power Tools and Alcohol" rule. I've seen far too many bad things happen after someone says, "Hey, hold my beer..." that it just seemed the right thing to do.

-

Giving Ww2 Corcoran Jump Boots A 'vintage' Look?

shtoink replied to Anticitizen's topic in How Do I Do That?

You have to pay a premium for that "worn look" on a brand new item... I remember when the grunge look was popular and the fashion industry will capitalize on anything trendy. The idea behind the grunge look was that it what was cheap, comfortable, and lended itself well to the unique weather experienced in the Pacific Northwest. Emphasis on cheap and comfortable, which translated to thrift store shopping and hand-me-downs. I recall advertisements for "Grunge Look" clothing that focused on the worn and torn clothing that had the "fresh from the mosh-pit" look, complete with fake blood and dirt stains aim directly at upper-class teens with a surplus of disposable cash. The irony of paying extra to look like a scrubby bum always amused me. I'm not saying this is the case with what you are doing, I was merely musing about my personal experiences. I understand the desire to avoid the high price tags for that "pre-worn look". I'd also argue that the Jumps would certainly outlast the designer boots by a wide margin, so you are on the right track. If you take care of your LPC's they'll take care of you... -

Could it be for scraping the hide at different points during tanning? Maybe it didn't need to be very sharp if it was scraping the flesh side during some home brew tanning.

- 5 replies

-

- antique tool

- cutting

-

(and 1 more)

Tagged with:

-

Giving Ww2 Corcoran Jump Boots A 'vintage' Look?

shtoink replied to Anticitizen's topic in How Do I Do That?

There's reliable no shortcut to putting that polish on the tow and heel caps that I know of. It's something you end up doing on a regular basis because wearing them will leave scuffs that will need to be polished out. It's skill that takes a bit of time to learn. I agree with LTC above, it's not a short explanation and generally best learned by watching and doing rather than reading. I cherished my Jumps and took great care not to screw them up when wearing them, but it always seemed inevitable that they'd need dressing up before the next inspection. They, ultimately, were passed on to the little brother of a friend who had just been accepted to jump school. I couldn't bring myself to wear them about without pant legs being cuffed and tucked in, and as civilian, now, that'd just be silly. -

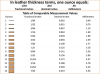

This is the chart that I remember seeing before. After some quick searching, it looks like there are a few conversion charts that might contain some errors. Hopefully using more than one source helps increase your odds...

-

I, too, had issues with the Tandy Super Skiver. I did get mine close to two years ago and the quality was complete garbage, so I can't exactly say anything concrete about what is on hand now. I was having major issues with my skiver doing any actual skiving. The biggest problem was that the blade wouldn't even sit properly due to excess material left behind from casting. That had to be ground down. The next issue was that there was a massive gap on the backside of the blade that kept getting clogged up and preventing the waste material from even leaving the tool. This required more, careful grinding. I talked to the manager about the issue as well as emailing corporate. Neither were much help, but at least the manager from my local Tandy was understanding and apologized for it. In the end, I got it working, but it took a bit of work and I really risked ending up with a chunk of garbage if it didn't go right. Not exactly reassuring and provides little incentive for a return trip to Tandy. One of the other things I tried was a course sanding drum on my Dremel, which worked really well, but kinda slow and very messy. I was able to get some insanely thin edges over a wider area. Just make sure not to breathe the leather dust if you go that route. BDAZ has the right idea with a bigger tool. Once you the hang of it, it should only take a few minutes with one of those things.

-

I second what Tree Reaper says... The issue with using tape is that it is on the surface and the dye you are applying is soaking past the surface into the leather. The typical things for a resist also soak in to about the same depth as the dyes, so that is part of the reason they work well.

-

There isn't a white dye. You need to have something that is an opaque coating to put a while color on. The only other alternative is to start out with a leather that has all the coloring bleached from it to make it white and go from there. As for making it white, you can use an acrylic or some other opaque paint. Maybe something that can be airbrushed or applied in layers so that you can have your color scheme the way you like. I know it's not exactly the news you wanted to hear, but with white, there aren't many ways around it.

-

With that setup, a vacuum bagging process might help. You could have it rested up against a smooth, flat surface for the back to keep it nice and flat. It'd also allow you to do multiple cases in a time, depending on the size of the bag you make. The vacuum won't care, it'll evacuate the air just the same. Bagging material can be cut to the size you need and as long as it's sealed properly and taken care of, it's reusable.

- 23 replies

-

I made one similar for my Dremel. Not from a drawer pull, but from a chunk of scrap Lignum Vitae from a side project for another member in here. I chucked it up in the lathe to put a hole down the center and, at the time, the drill chuck arbor in my tailstock wasn't straight. Sherline replaced it for me, but that's another story. After getting a hole into it and shoving a chunk of metal in one end so it'd be usable in the Dremel, the tiny amount of offset was exaggerated greatly once it started spinning at the lowest setting of 5000 RPM. I ended up using a round rasp end ran it up against it while spinning to help even it up and later putting it back in the lathe at a higher RPM. I'm certain the the free-hand cutting I did to cut the groove didn't help with it being eccentric either, but it ended up being functional in when finished. It's ugly as sin and I'm slightly ashamed of it, otherwise I'd post some pictures. Poor thing looks like it was a jr. high school wood shop assignment that was slapped together in the 15 minutes before it was due. Despite it's ugliness, it spins true now, burnishes an edge nicely, and taught me a few things along the way. As an added bonus, the Lignum Vitae can take a ton of heat without damage, though the same could not be said for my scrap leather I was testing on.