arashikage

Members-

Posts

118 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by arashikage

-

(first post) Used Sewing machines

arashikage replied to Donkeykong's topic in Leather Sewing Machines

Most of the machines they have right now aren't really what you want. It sounds like you should look for a cylinder arm machine. You could talk to Bob at Toledo Industrial Sewing Machine. He may have a used machine that would work or can get you new. He's probably about 3 hours from you but provides great support over the phone. Or you can wait until June and attend the annual Weaver Leather consignment auction in Mt Hope and see what they have. I think about 2 - 2.5 hours or so from you. -

Weaver Leather Supply is fine. They sell their own line of tools called Master Tools. I think they make the Heritage line too. Most, if not all, of their tools are made in Mt Hope, Ohio. They can be pricey but they are usually nice tools. If you want a classic tool then I would also recommend Bruce Johnson leather tools. He has quite a few C.S.Osburne gauges for sale right now.

-

They're collectible in the since that lots of people want them for use. Doing an overhaul is fine. It won't lower the value. I wouldn't bother repainting it just focus on restoring function. I do not know of a source for new blades. You can try contacting Landis https://landisusa.com/us-en/, they may still carry them. http://www.pilgrimshoemachine.com/ or http://www.shoesystemsplus.com/ might have them too. They don't have them listed but both sites tend to carry stuff that they don't list. Worst case find a machine shop that can resurface the blade. If you get up and running smoothly you should have no problem moving it.

-

As long as the blade is sharp it's great for splitting anything just under 6" in width. It's a 6" blade but usually the outer corners don't cut as well so it's best to keep it under that. I have a Sutton splitter that I use mostly for splitting wallet backs. I occasionally use it to split scrap pieces for things like keychains and small projects. I see them go at auctions usually for $300 - $600 depending on the condition. It's worth noting that the Landis splitters should have a hollow ground blade. If you try to sharpen it keep that in mind.

-

@Ferg westwood1 is talking about a different dealer. There is a http://industrialsewingmachineman.com/ that is not Bob.

-

You never disappoint! I'm with Jeff, you would have to point out the mistakes because I can't see them. For a first one it looks fantastic! Your lines are great. The aesthetic is very balanced.

-

Need help learning this construction method please? Interlocking?

arashikage replied to ddct70cc's topic in How Do I Do That?

I finally remembered where I recently saw this! The Sept/Oct issue of "Leather Crafters and Saddles Journal" has a small tutorial on how to make this. They call it a "welted" seam. They mention it was originally referred to as a Marshall welt. You can order individual issues but I don't think they have an online option. https://leathercraftersjournal.com/product/2019-volume-29-no-5-sep-oct/ -

I looked through my copy of "Dictionary of Leather-Working Tools, c.1700-1950 and the Tools of Allied Trades" and this is not in there. I would agree with Bert, it is similar to a speedy stitcher and was most likely used in sail or canvas stitching. The fact that it can hold such a large spool would lead to believe that you could do a lot of work before needing to refill.

-

Looking good! Did you use pinking shears to make the gimping?

-

No worries. A hog bristle, also called a pig bristle is a hair from a pig or boar that gets weaved into the thread and functions as a flexible needle. Typically the hole made from the outsole stitcher is actually curved so the bristle will follow the curve. There are probably curved needles that will accommodate the large thread that would work just fine. Sorrel Notions & Findings carries pig bristles and metal bristles just to get an idea of what I'm talking about. https://sorrellnotionsandfindings.com/?s=bristles Lisa also carries the linen thread in 5 and 7 cord. https://sorrellnotionsandfindings.com/product/inseaming-thread-and-hand-wax/ She is a sponsor of this forum and happens to be one of the few vendors I know that has everything you need. And she will ship internationally. I unfortunately don't have any brand recommendation because my family uses whatever the sales person can get them at the time. If you wish to find something closer to France, look for shoe repair suppliers or shoe making suppliers and they should have what you are looking for.

-

If the bottom thread is straight the problem is top tension too loose or bobbin tension too high. Double check that the top tension is staying put after changing it. I had a machine that the threads were bad on the top tension knob and it would kick it self out.

-

You will just have to be careful that you don't over do it. The one you link to says it operates at 3500 RPM. If you use something other than fleece, that is fast enough to burn the leather and actually ruin the finish you're working on.

-

I'm not sure if French or European sizes are the same but I would probably look at a 5 or 7 cord waxed linen. If you are sewing by hand the twist of the thread won't matter. It only makes a difference in outsole machines. There are 2 main ways you can restitch it. Saddle stitch or lock stitch. Traditionally for saddle stitching soles you would need a couple hog bristles. For lock stitching you would need a jerk needle. I'm not familiar with European suppliers but either should be fairly easy to find.

-

If you want to make shoes it is best to get a post bed machine preferably one with a wheel. The machines you listed are flat beds and you will have a harder time sewing uppers. Some models to look for are the Singer 136-W101, Consew 228, Techsew 810 for example. It will be much easier to sew uppers on a post bed. Depending on what type of shoes you plan on making you will most likely be using a #69 thread (US size)/40 (Metric)/T70 (Tex). So you will want to make sure that any machine you get will handle that easily. Most of them should with no trouble. These machines are just for the uppers. You will have to stitch the sole by hand unless you have an outsole stitcher which is a completely different type of machine. Hope that helps.

-

Celtic wolf for a valet

arashikage replied to arashikage's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

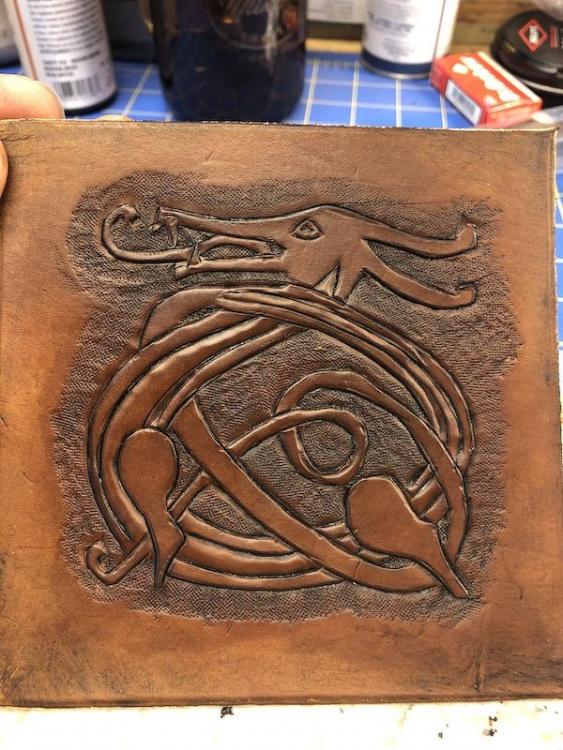

Thanks! Just to clarify not my first project, just my first tooling. I have the flat one attached to the knife. So it's pretty bulky at times. I bet it was partly how I was holding the tool. I also think I brought the background too close to the figure. I had noticed the tool marks but was getting lazy having only the tiny oval background to work with. I was concerned about making that area look mushy if I did too much around it also. That Stohlman book is still available for free. It's one of the few I haven't downloaded yet. I'll add it to my list. Thanks for the advise. I will keep this in mind on the next projects. -

Celtic wolf for a valet

arashikage replied to arashikage's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks @Northmount! I did strop the blade a lot. Probably not enough though. The leather may have been a little on the too wet side. I tried to let it come back to original color. I found that only having the large blade from Tandy made it hard for me to get into the tight curves. In hindsight I also think that there were some areas that I should have perhaps hit with a modeling spoon (not that I have one) instead of the beveler. The middle of the body for example. -

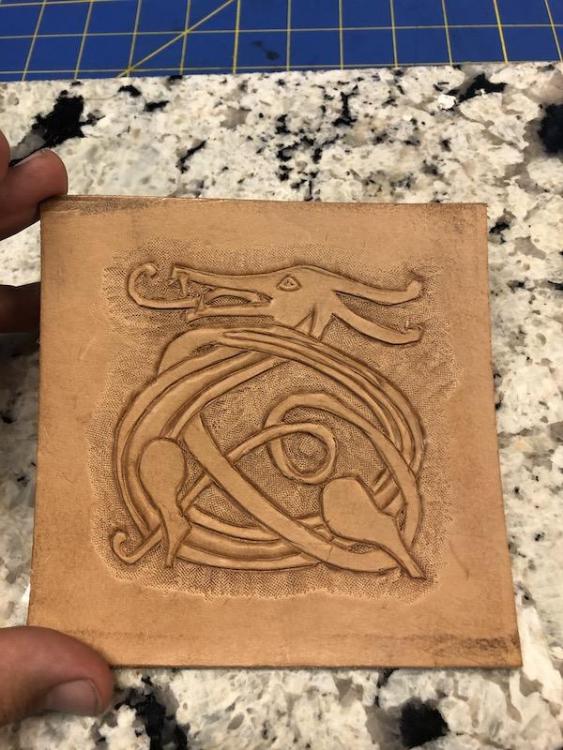

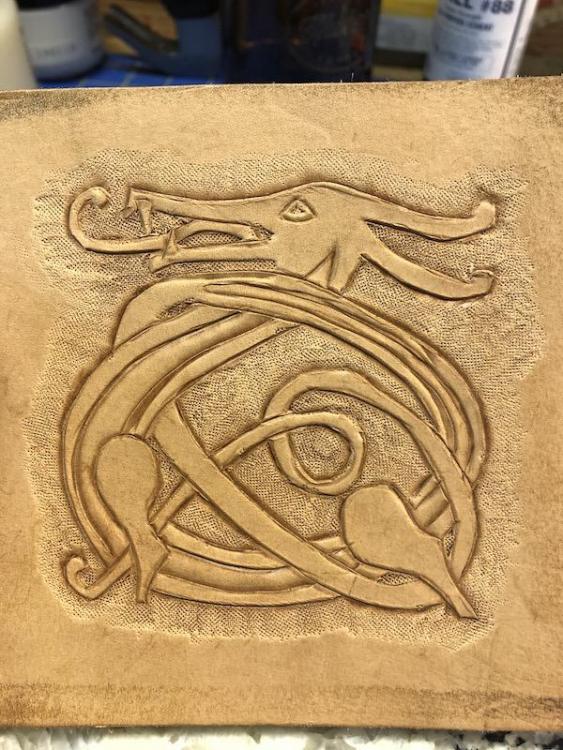

This is my first attempt at tooling. It's a split tail wolf from the the book "Learn to Draw Celtic Designs." It's an insert for a valet that will be a gift. It's about 4.5" x 4.5" Lessons Learned: Start with something simpler I need more tools, the Craftool basic 7 stamps were not enough for this I need to slow down on my tracing and cutting I need to play around with antiquing more, background didn't get as dark as I hoped Overall for my first time tooling it's not as bad as I had expected.

-

Who is your favorite hardware supplier at the moment?

arashikage replied to fighttobreathe's topic in Suppliers

Depending on what it is, I order things from Weaver Leather. Especially when they have sales. -

If you are planning on doing that much volume again, then yes, a Weaver press may be faster but you're going to be providing the power instead of a compressor. The 8 ton would definitely cut 10-11oz easier but it's still going to be a workout with that many pieces. If 300 pieces is going to be happening often then you would be better off in investing in a swing-arm hydraulic clicker press like the CB12. http://www.solar-leather.com/cb12 . They are a lot more than the Weaver 8 ton but will be a lot faster and easier.

-

I can see where France would be more likely to have big anvils. Having a much longer history of blacksmithing than the US. And I can see hammer shapes being influenced by smithing. But I would have thought that a ball peen would be pretty universal for metal working. I've never seen a welding hammer that didn't have wedge vertical. Interesting. All my French hammer experience comes from French shoe hammers. Which just happens to be my favorite hammer for leather working.

-

It is definitely a glazing iron. They are made in a variety of shapes and sizes to fit different heels and soles. This one is a step design to do the heel and sole. The big curve is for the heel and the little notch is for soles. In the pic above there is one that is heel only (1st from left) and on that is sole only (3rd from right). They are still commonly used in the bespoke and hand-made shoe world. Fun fact: these are heated with an alcohol lamp because of how clean they burn. That way it is less likely to cause soot formation on the tool and won't ruin the finish you're trying to achieve on the shoe.

-

@bcklsh Does it still have the shroud on top with the letter model? It looks like it's older than the 12 E model. Landis usually puts the letter on the base so it's easy to tell the model but clearly this does not. The fact that it doesn't have that and the only letter is on the little door. It could be a model C. If you check the plate with the serial number it should start with a letter that represents the model. @Wizcrafts do you know if Landis ever made a model C? I know of E, F, G, K, & L. If you're not familiar with the machine it will be a difficult fixer up. Does the machine at least turn if you manually move the flywheels? You could start by looking for any shoe repair shops in and around you. They will most likely have experience to at least check the machine out for you.

-

It is an eyelet and snap punch from We R Memory Keepers. They show a close up of the handle and I was able to grab the name off of it. https://www.wermemorykeepers.com/product/cad-eyeletsnap-punch/

-

Awesome! Thank you!

-

@Timbo I would be interested in the awl hafts 1 and 3.