-

Posts

391 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by SARK9

-

Like several other *standards*, the contents and specifications are licensed by the body that generates the information. See: https://www.asme.org/codes-standards/find-codes-standards/b30-9-slings No idea if it has the complete construction details that would be of interest in this discussion, but this is most likely why there is not much authoritative info on the web. I've encountered similar gate keepers when looking up the specs on V-belt pulley dimensions. -DC

-

Most of the programmable functions are controlled by a low voltage solenoid or small air cylinder. You can delete the controller and replace the motor with a "servo" of your choice, and use a dedicated switch to actuate foot lift/reverse levers etc. You need to find the voltages required etc. Some of the electrical wizards here can probably provide model specific hints. -DC

-

One other thing to check, if you haven't already, is the bobbin case opener adjustment...if too tight they bind a bit. -DC

- 6 replies

-

- friction

- resistance

-

(and 2 more)

Tagged with:

-

I believe the 211U566A uses the large "U" bobbin and may be a Japanese model. The 211G266 is German made and uses the smaller "G" style bobbin. I'd go with the U model if its suitable for your projects. -DC

-

Looking for cylinder arm for leatherbag making. Necchi 840-100

SARK9 replied to luxuryluke's topic in Leather Sewing Machines

The 134 system is a common needle I use on a couple of fabric-type machines....The "R" designation indicates ROUND POINT style. It comes in other points for leather etc. My Singer 20U33 and Pfaff 481 both use this system. Some of the other confusing systems can be seen in the photo attached: -DC -

How to attach a binder to a Singer 111W155?

SARK9 replied to Willie0's topic in Leather Sewing Machines

Yes and Yes. I think this is the budget set that has all the parts in one go: https://www.ebay.com/itm/162817911154 Quality wasn't too bad, but it did require a tiny bit of fitting. -DC -

How to attach a binder to a Singer 111W155?

SARK9 replied to Willie0's topic in Leather Sewing Machines

I've been using a bobbin cover to mount and switch the various binders I use for quite some time....These top-load machines make it very convenient to lock the binders in the position needed to perfectly run the different material/binder combinations, and retain those settings without wasting any time or material to resume work every time you change binders. Simply switch out to another pre-adjusted cover plate/binder combo, or back to a plain cover plate as needed. I shop-make my own plates from mild steel in batches. Machine shown is an old 111W152 someone discarded, resurrected as a dedicated binder. If you don't install a binder needle plate and foot set on these walking foot machines, you may chase your tail for an epoch or so trying to get decent results. DISCLAIMER: I only use this setup on heavy fabrics needing various inside curves, and I mostly use the double fold styles with my own bias tapes. I can't find the odd colors needed in any purchased tapes or webbing. -DC -

There is another side of that particular coin....many of the aftermarket presser feet are made to "about here" tolerances and occasionally require adjustment of the foot height to function correctly. The center (smaller) presser foot should trap the material you are sewing against the feed dog and move rearward in UNISON with the needle and feed dog. While this is not quite as positive as a 4-motion or elliptical feed dog motion, its not all that bad when adjusted correctly. Adjusting a two-motion feed dog is sort of not designed into the mechanism in many machines....the design assumes a certain protrusion through a certain thickness of the needle plate, but it has to NOT interfere with the material which the outer foot traps and holds when the center foot lifts and resets the presser foot to the forward position for a new stitch. If you remove the needle and cycle the machine by hand with a sample of the material you are having problems with under the foot, see if the foot has the material firmly trapped against the feed dog, to the point it is difficult to move or slip from under the foot. If you run it thru the whole cycle and the center foot allows slippage or does NOT feed it in time with the feed dogs, you probably need the check the adjustment of your presser feet. I'm not sure how your machine adjusts, but many of the walking foot types have you cycle the machine until the needle just touches the material you are sewing, then loosen a link on the upper feed bar assembly and let the feet "snap" into the correct position (for the height of your feet) and the material thickness you are sewing. Your mileage may vary, but that is how several of my machines compensate for the pair of presser foot lengths being a tad wrong. -DC

-

It could be just the picture, but every moving part I see in that shot looks dirty and dry. It could be holding out for a cleaning and re-oiling. -DC

-

The picture does show it has a walking foot, after all. -DC

-

Superior Sewing Machine & Supply has an illustrated parts list for the YU-360-22, which shows it is an upper-and-lower feed single needle machine with no evidence of a walking foot mechanism. The parts list catalogs a reverse lever and associated hardware, but the pictures of the machine body don't seem to show it. I didn't find a spec sheet to see its capacities. -DC

-

I second Greg's curiosity- what aspects of its performance do you find superior? -DC

-

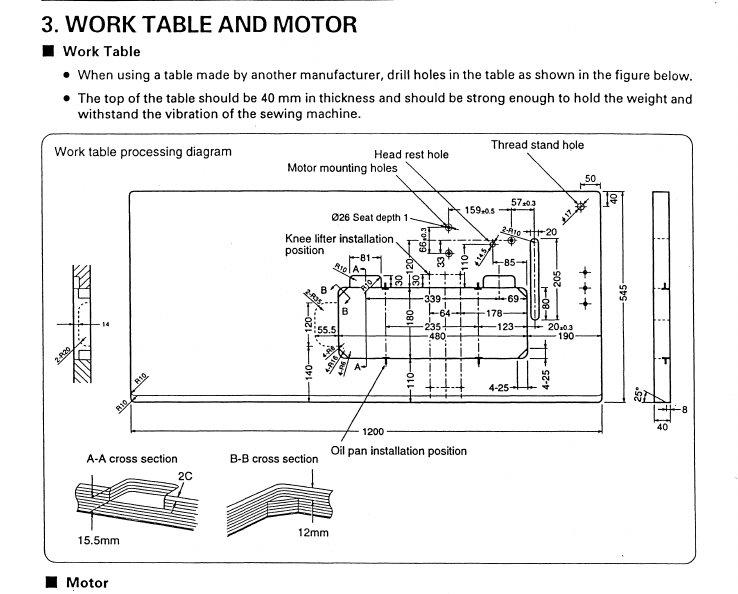

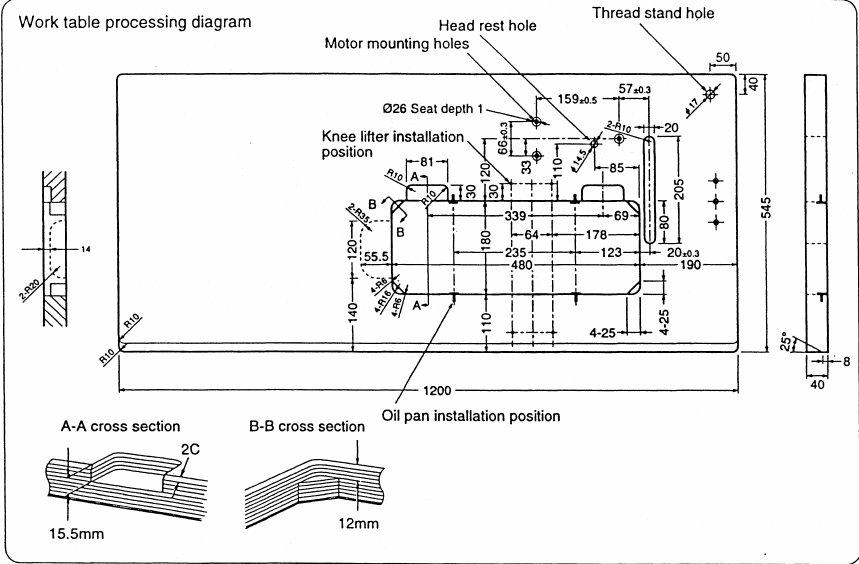

I didn't want all the particle board dust settling onto the residual sticky coolant film all over the VMC cabinet and getting washed down into the coolant system, so I used a water jet to cut out an aluminum plate router template for the various cutouts I use and cut the actual table holes with a portable router. If you use a "porter-cable style" base guide on the router, remember to adjust the dimensions to accommodate the guide and cutter diameter. The hinge pad dimensions are variable depending on if you use the ones on hand or if you buy new, ditto the rubber corner support inserts, so some edits to your DWG/DXF file may be needed. Having your own template on hand allows you to pop a machine into any "table of opportunity" you may encounter in your travels or inlet anything you make yourself. The LU-563 is a great machine and there are a zillion DIY speed reducer designs in the wild you can add to the mix later. -DC

-

My Pfaff 481 (flatbed) uses the very common 134R needles.....also called DPx5 or 135x5. My Singer 20U33 uses the same needle. -DC

-

Sounds like yet another possible case of Cork Brake Shoe Rubbing, *if* you are using one of the speed dial graphite brushed "servo" motors. The brake could be engaging while the motor is still having voltage applied at a very slow speed. -DC

-

Singer 16K SV 11 - I could not resist

SARK9 replied to Constabulary's topic in Leather Sewing Machines

Singer model 78's....since we are in olden machines. -DC -

If you will compare the casting of your machine to a Consew 206RB-4, I think you will see some some pretty unique similarities. https://www.ebay.com/p/Consew-206rb-4-Walking-Foot-Big-Bobbin-110v-Leather-Industrial-Sewing-Machine/1458135144 I bet the slide plate for almost any of the later 206* models will fit it: (#18032) https://www.ebay.com/itm/Slide-Plate-Complete-for-Seiko-Consew-Walking-Foot-Sewing-Machine-206RB/123780802949?hash=item1cd1e92985:g:2XQAAOSw64Nck86C -DC

-

JUKI 563 thread snagging on bobbin case

SARK9 replied to matcanada's topic in Leather Sewing Machines

On the subject of aftermarket parts with wild variations in tolerances, the underside of the needleplate, where the groove which prevents the bobbin case from rotating is located, also deserves a look. I've had to increase the width slightly and ease/reshape sharp edges to allow the thread to pass smoothly without random binding or erratic tension. Also, if your hook timing is slightly retarded, you may get a momentary high tension on the needle thread as it slides across the top going around the bobbin case. This might tend to allow the thread to pop into that groove over the bobbin tension spring and wreck things. Slightly too much hook advance is less risky, within reason, and worth a try if you hear "snapping" noises as the stitches form. As far as the cheap and variable aftermarket bobbins leaving too much gap, I submit that the "sideless" prewound bobbins leave one hell of a gap as they are unwound and used up without issue in many commercial applications. I personally only use them with certain common colors in *G* style bobbins on a Singer 111W152 which is dedicated as a binding machine, so who knows. The sideless bobbins are very uniformly wound and hold a bit more thread. As far as the anti-backlash spring goes, the speeds most often used for meticulous stitching are so slow that I have to wonder if it is another solution for which no problem exists, but they are cheap, so *whatever*. As we used to say in the shooting sports, if you think it helps, it helps. -DC -

The presser foot situation for this style of machine is pretty grim....I went through something similar looking for a foot selection to fit my Seiko SK-6 not long ago. There are several machines reported to use the same foot style found on the 45K*....with a selection for the jump foot and the drop feed, which do not interchange. Mine is a simple drop feed, so that is all I really looked at. I saw the "plain foot" and found it useless for my application, as none of the available feet I ever found were able to be used with an edge guide very close to the needle. I believe that commonly seen ebay foot was made for a "GA5-1" type of 45Kish asian generic knock off, and supposedly fits the drop-feed 45K and Singer 132K6 type machines. I "heard" the Adler 105 stuff interchanges to some degree, but I have none here to verify that. I tried to find a wheel presser that would fit the 132K6/SK-6, but couldn't run a source down to the point of actually buying it, owing to the horrific translations and naming conventions on the popular "Asian" web sites. I ended up buying one from a well known dealer stateside, and received the single worst piece of overpriced Chinese rubbish I have ever held in my hand to date. Lesson learned. I resorted to just making my own feet, as I have with several other sewing-related items. I HAVE bought some decent quality hinged split-toe feet for the SK-6 from random suppliers off alibabba, they are drop-feed only, but aren't much lower in quality than the original Seiko foot which came with my machine. I'm working on a wheel presser as time allows. Current selection pictured below: -DC

- 18 replies

-

The bed slide plates have a right and left design. The RH plate has a relieved area on its underside to allow clearance for the thread to pass over the bobbin assembly. See if the other plate has this relief on the underside, and swap them if so. Closer inspection shows you DO have the correct RH plate. Sorry. You'll need to check the assembly of the hook to bobbin basket group of components to make sure they are assembled correctly. -DC

-

The decimal inch, divided into a million parts, was so simple before the political expedience of the metric overlords. No really, decimal is decimal. This is the penalty we all must endure as a concession for preferring Greenwich for the location of the Prime Meridian. The real fun begins when we start trying to get us peasants to relate to SI time, and reveal the rubbish one must endure when attempting to name these new *units of time* something which can successfully describe a naturally variable seasonal cycle. 10 month year vs. lunar cycle, etc. Nature is so inconvenient. I find myself armed with the numbers .03937 and 25.4 in the calculator memory and go on down the road. *ON TOPIC NOTE:* The Consew motors have a shaft diameter of 15mm., or 0.59055", which 19/32nds (0.59375")approximates for all practical sewing needs. Pedants can take full advantage of the "decimal sized" reamers offered by most industrial supply houses. I make all my own pulleys to suit, and lathe bore them with miniature boring bars. Concentricity, you know. -DC

-

Sorry if it has been mentioned, but this style of machine (with the vertical axis bobbin) pretty much requires that you hold on to the thread tails when you begin stitching for two or three stitches. Just hold back on the loose threads as you begin, and see if that helps with the bobbin tangles. -DC

-

I've bought 2 of them in the last 18 mos or so. I'll have to check the receipts to see which was the Consew, and which was the generic "Rex". I know you do NOT want the one character display version. I surfed around until I saw the picture of what was being offered, taking note of the display. -DC

-

First, congrats on the 206RB-4 deal, that is a nice looking machine. To add a dissonant note, on the subject of "push button" servos, I must say that I have used nothing BUT the Consew servers for a number of years. These "push-button" servos all seem to be "branded" to suit and essentially made under the same roof, as far as appearance goes. The Consew branded servo has undergone quite an evolution since I got my first one, with enough minor AND major changes to merit a revision number, yet all of the later models are still called "CSM-1000". Here is a quick snapshot of the variations that I personally have bought, which is probably not all inclusive. All but the CM were advertised by various vendors as Consew CSM-1000. I still use 3 of the CM-1000's with the optical gradient speed controller, and I've had 2 others which left with the machine I installed them on. None gave me any problems, but you did need to do some mods on the controls for the best results. All the other CSM-1000 types seem to use a Hall effect sensor, which tends to start more abruptly. The latest ones I've purchased that have 4 buttons and a 4 character display seem to be better in that regard. For my use, the lowest initial-on speed seen with almost any of these is not sufficiently into the motor's power band to use on heavy materials as installed. I only use direct drive pulleys on machines sewing moderate fabric and set the RPM to the max rated speed of the individual machine, which some of these motors can easily exceed. All of the machines which see thicker material like my Juki 563, Consew 206RB-5, Seiko SK-6, and the Mitsubishi cylinder arm have speed reducer pulleys fitted. I've yet to have one of these motors "go bad" myself. All of the clutch motors which came with any machines I bought in used condition have been discarded as scrap. I don't do repetitive piecework in a garment factory, and I really find the buzzing and the various "personalities" of these 40lb. watermellon sized relics pretty annoying. If I need 3000SPM, I get it easily. The garment factories still in business have been retiring clutch motors with various new machines using REAL servo type motors with electronic clutches and other automated pneumatic or solenoid actuated functions since forever, and lately, with the direct drive electronic motor very similar to the retail push-button servo in many ways. -DC

.jpg.d60258221c476480a6e073a8805645bb.jpg)