-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

May the torque be with you.

-

What type of Servo Motor and Reducer for a Consew 230?

Uwe replied to MaryGladys's topic in Leather Sewing Machines

The very common, cheapest (around $110ish shipped on Ebay) and actually pretty good servo motors go by various names, usually something like Family Sew 550 or FESM 550, etc. They all come from the same factory, it seems. They are being sold by a bunch of distributors. It's a good, basic choice that should be a huge improvement over your current clutch motor with its apparently defective clutch. This servo motor has a simple dial that allows you to limit top speed down to about 400-500 RPM usable speed. This motor should be a direct swap for the clutch motor without requiring any modifications of the table or motor mount points. Depending on pulley sizes, this should get you into the 3-10 stitches per second range at the low end with good low speed control. Fancier servo motors that cost about twice as much ($200 or so) often have a digital control box with a bunch of buttons to navigate a cryptic menu to adjust how the motor works. Some of these fancier motors also allow adding a Needle Positioning System (NPS), sometimes called Electronic Position System (EPS), which makes the needle stop in the UP or DOWN position whenever you let go of the pedal. NPS is nice to have for some high volume, fast production applications, but it makes the whole installation more complex. It doesn't sound like this is something you'd want/need. Same bottom speeds of about 3-10 stitches per second. Speed reducer pulleys are surprisingly expensive at around $150 and slow things down by a factor of two or three ( about 1-3 stitches per second instead of 3-9). They can also be a real pain to install, depending on your machine and table setup. The speed reduction may not be worth an extra $150. Servo motor speed ratings are deceptive when they state "0-3,600 RPM", making you think you can smoothly accelerate from 0 to 3,600 RPM. What they really should say is "0 RPM, and then 300-3,600 RPM". They jump from 0 to 300, there is no smooth ramping of speed between 0 and 300. One new 1,100 watt servo motor sold by SewPro USA for about $200 plus shipping has a significantly lower usable starting speed of 100 RPM. The motor is not yet on the website, you'd have to call and ask for it. The slower starting speed gives you the same effect as a speed reducer pulley, but without the extra cost and pain of installation. I've used these motors for a few installations and really like them. A needle position sensor is available for an extra $25 with a nice, simple Up/Down button on the control box. You can turn the NPS function off via a menu setting (other NPS systems can not be easily turned off, which can be real problem/pain). Alas, sewing too slow can actually cause problems with your machine, since it has an oil pump that only works properly when running at high speeds. You'd have to run it at full speed every so often to keep things lubricated properly.- 28 replies

-

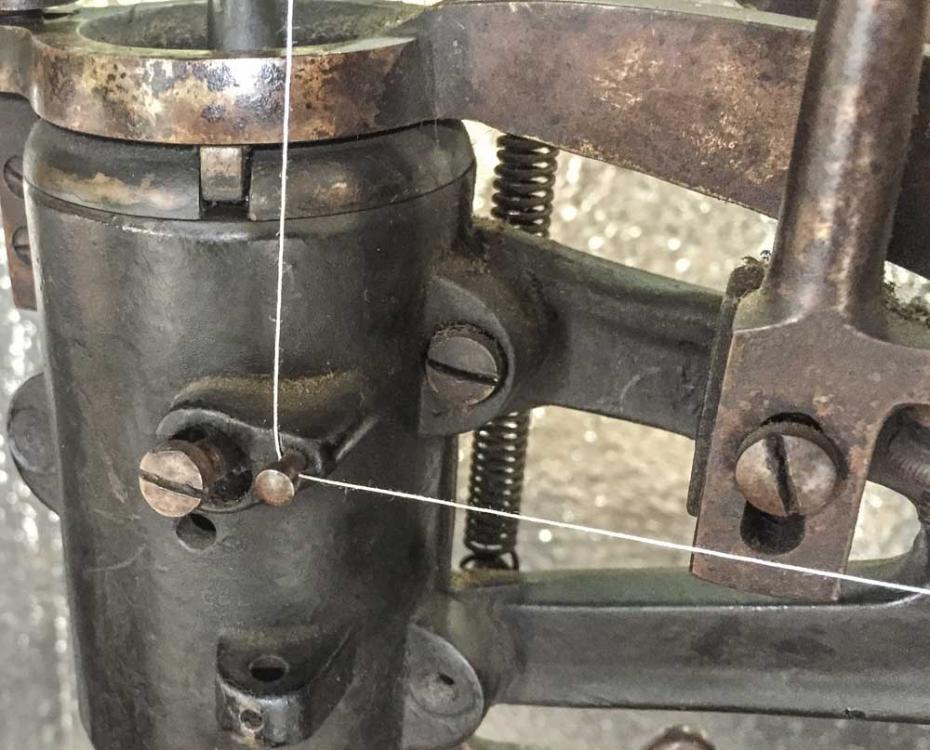

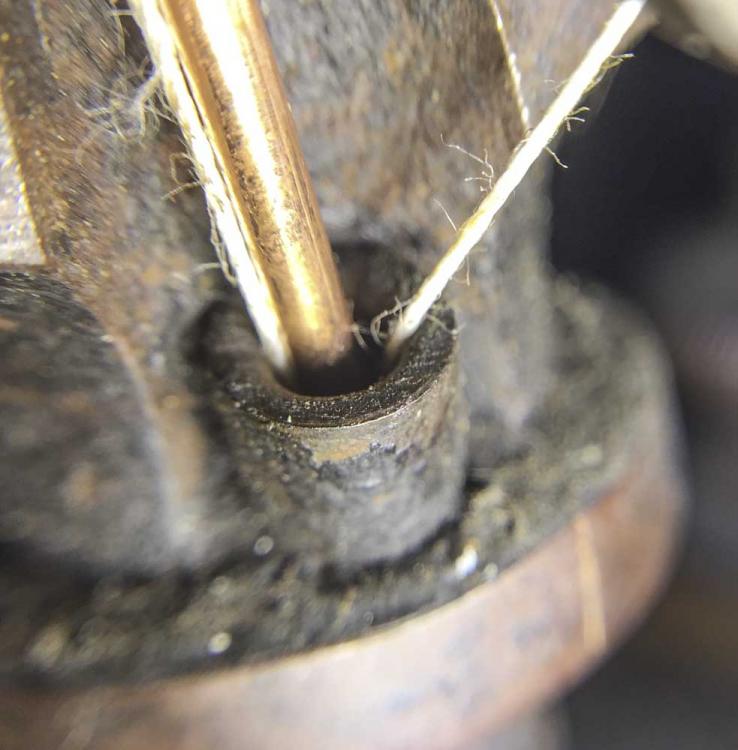

For threading, here's how I would do it for the top. You'll need the long piece of notched metal wire. I made my own from a welding wire rod by filing a notch at one end to hold the thread as I'm pushing it down the chute inside the needle bar. My machine is missing the little lubricant cup that is shown in that Ebay listing I referenced above. Sadly, my machine is also missing the shuttle hook, so I can't do any test sewing right now or show that threading detail.

-

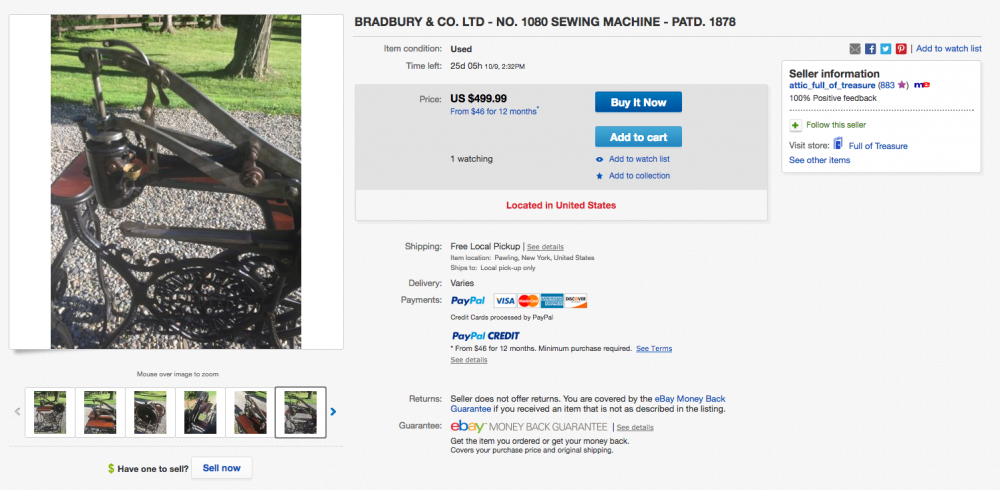

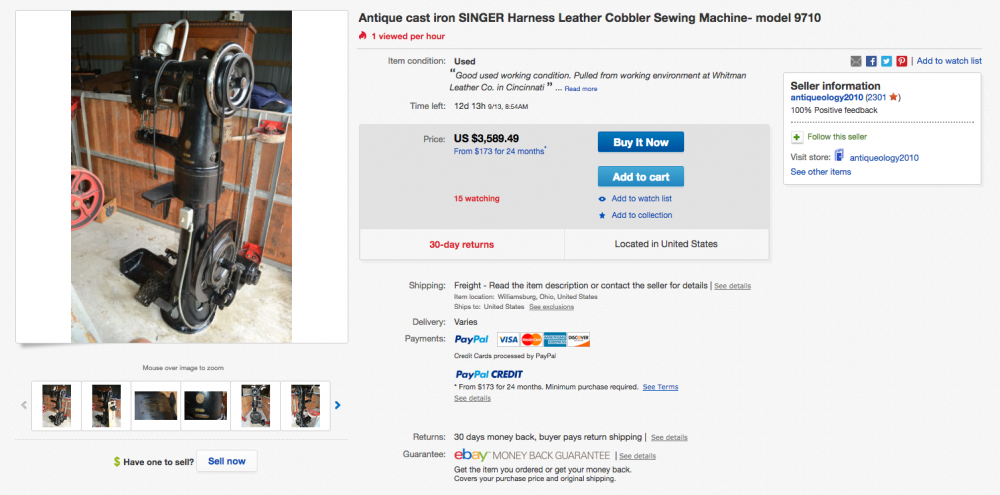

For a rough price reference, this Ebay listing is the only thing I've seen so far that comes close to my machine: http://r.ebay.com/hWCERT

-

I came across this Bradbury manual yesterday: http://www.sewmuse.co.uk/bradbury/bradbury a1 repairer threading.htm It's the closest thing yet to a manual for our machines, I think. It has threading instructions but the picture doesn not show details very well. In any case you'll need to use one of those long wire tools with a tiny notch at one end to grab the thread and push it down the center of the needle bar. I'll try it out when I get a chance. My machine turns over nicely, but I'll have to find a bobbin to do some test threading and sewing.

-

I don't think we have it quite nailed down yet. The body casting of ours has more of an I-Beam cross section, whereas most of the machines we've considered so far have a round or oval main casting cross section. The lower front arm on our machine also goes to the top of the head, not into the center. Apparently there's a mind-boggling variety of manufacturers that made these machines. Christoph Schiffmann in Germany has the most extensive collection I've seen so far. I had no idea there were so many copies of this design by so many manufacturers! It's almost like the hundreds of long-defunct U.S. Auto companies that were all tried their hand at making variations of the same car design and didn't survive past the second decade of last century. From Schiffmann list: The Adler 27 has a similar body casting, but the lower front arm is not right: The C. Schmidt & Hengstenberg has the correct front lower arm that curves up to the top of the swivel head - very few machine have that design detail. Alas, the body casting has a rounded cross section, not I-beam like. Maybe I'll contact Herr Schiffman to see if he can identify the precise model of ours.

-

31-15 Roller Foot Conversion--parts don't add up!

Uwe replied to oxeyenyc's topic in Leather Sewing Machines

I would hope the castings are the same but I don't know for sure, sorry. Of the 31 class I've only seen a 31-15 in real life so far. Singer does not include the body of the machine in their 31 class parts diagrams. But even if it's the same basic 31 class body casting, the different subclasses may vary subtly in how they are machined and/or have holes drilled in different sizes and locations. -

31-15 Roller Foot Conversion--parts don't add up!

Uwe replied to oxeyenyc's topic in Leather Sewing Machines

The "it seems" part makes it less of an absolute statement. Perhaps I should have used "intended" instead of "designed." What I meant was that in the SInger 31 class of machines, the 31-15 subclass was not originally configured with roller feet and no roller foot options were listed in the parts book. The 31-17 subclass on the other hand is configured with roller feet and drop feed and the 31-18 subclass has roller feet and roller feed. I suspect there's more to the 31-17 subclass than just the different roller foot. Yes, you can swap feet/parts and sometimes it works and sometimes it doesn't. In this case it kind of didn't at first. If Singer had a specific roller foot in mind to be used with the 31-15, they probably would have included it in the list of optional parts. Instead they seemed (<- see what I did there?) to say that if you want a roller foot machine, you should use the 31-17 or 31-18 subclass instead, which were designed/intended for roller feet. -

Well, I have no idea what it is, but I do hope we collectively figure it out, because I happen to have one almost exactly like it. Yours is in nicer condition, it appears. On mine, the picture of the factory on the handwheel is from a different angle, too.

-

I'm not sure a double needle machine is a good starter machine. Most beginners have a hard enough time keeping a single hook system adjusted and working properly. With a double needle & hook machine roughly twice as many things can and will go wrong. Also, for three-dimensional bags (as opposed to flat pieces like wallets and belts, etc. ) most folks end up wanting a cylinder arm or post bed machine. In the $700 range, I'd recommend looking for a Juki LU-562 or similar single needle flatbed machine instead of your double needle candidate. Also, instead of a double needle machine, consider doubling your budget and looking for a used Juki LS-341 or similar cylinder arm machine. The pain and suffering caused by an ill-suited first machine has its price, too. I always recommend a modern servo motor to beginners. Personally I find them much less intimidating and MUCH easier to control at slow speeds. For about the price of a speed reducer pulley ($150), you can also buy a decent servo motor that often doesn't need a speed reducer pulley at all. Sewing leather, especially bags, really benefits from being able to sew very slowly and very precisely, at least initially until you get the hang of it.

-

Does the manual not describe how to perform initial setup of the machine and how to adjust the table height? The machine must come with some kind of documentation. Bob at Toledo Industrial Sewing Machines is your contact, since you likely bought the machine from him. Give him a chance to earn his customer service brownie points. If you want people other than Bob to chime in, we'll need some pictures at the very least. We really have no way of knowing what your table looks like or if it is similar to others we've seen. Some table stands have internal gas cylinders designed to balance the weight of the machine. If the cylinder is compressed with no machine on top and you loosen the knob, it may pop up and put hole in your ceiling or forehead. All I can recommend is be absolutely certain that you can securely and safely install the machine head on the table before you ever pick it up - have a plan and a plan B. It may take half your foot off and likely self-destruct in the process if it falls off.

-

Parts for old Singer Industrial sewing machines - where?

Uwe replied to customizer's topic in Leather Sewing Machines

I find it hard to justify spending much effort to track down a single screw or two when you can buy a complete new 6028 hook for about $20 on Ebay. Even if you want to continue using your original singer hook to keep things original, the screws and other bits from the aftermarket hook should fit. -

Parts for old Singer Industrial sewing machines - where?

Uwe replied to customizer's topic in Leather Sewing Machines

Very cool photo ,Thomas! That is the first time I've seen that outer feed drive wheel of the Singer 18-3, which is a very interesting and different feed transport solution. I always wonder if they made those left-handed machines for actual left-handed operators or if there is some other reason for the left-handed design. I happen to have some (maybe a lot - not really sure yet) Singer 45K parts, mostly used, some new. Nearly all of them are still hiding in dozens of unorganized parts cabinets/drawers I acquired recently. I put some Singer 45K open frame shuttle hooks (91774 or DD1OP) and Singer 45K Feed Dog Carrier frame (91160) on Ebay. You may not need those, but I thought I'd mention it. Good luck with your restoration! You appear to be doing a very nice and thorough job. I'm looking forward to seeing some before/after pictures and perhaps some video snippets of the machines in action. -

Please forgive us if we come across harsh, but we don't answer questions that sound a lot like "How do I get this stuck knife drawer open?" with a simple "Press down on the safety latch and pull on the handle."

-

I'll rephrase that: Don't trust the person who installed the belt to do things properly. Read the manual and do it yourself.

-

So how did the belt get on the machine if you didn't install it and Bob shipped the machine with the hand wheel removed?

-

Need Advice Buying Sewing Machine for Shoes Upper

Uwe replied to EarleneAgripina's topic in Leather Sewing Machines

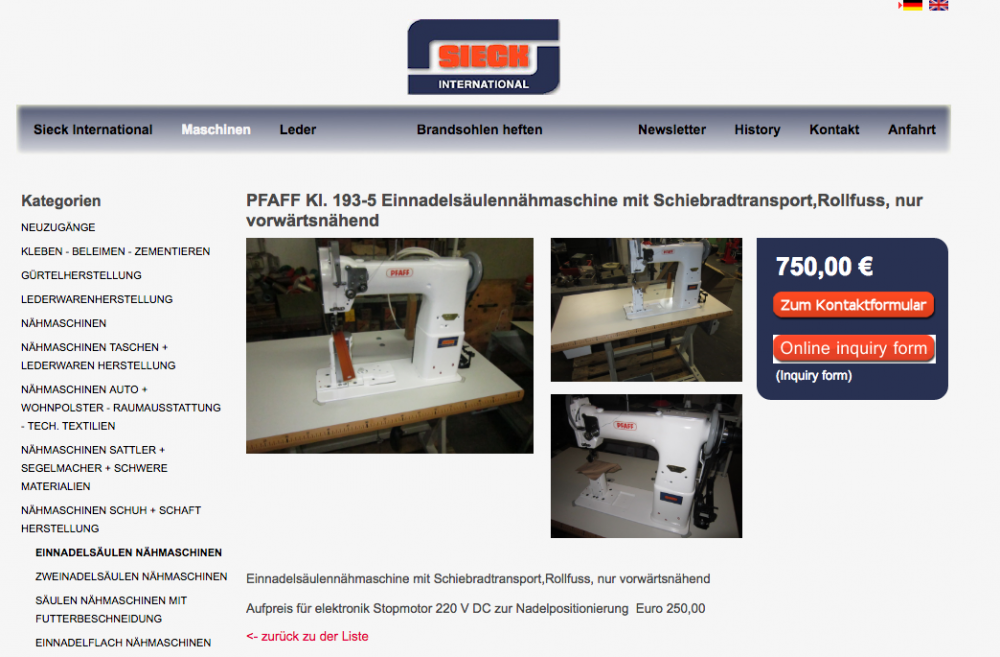

I wouldn't recommend starting with a Singer 29K unless you've used them before and know they will work for you. Save up (or borrow) enough money to buy the machine you really need. Otherwise you'll spend a great deal of effort, time, and money buying shipping and figuring out machines that will not work for you in the long run. Sieck also has some cheaper post bed machines like this Pfaff 193 post bed on their shoe making machine page. It's seem like a MUCH better starting point than a Singer 29K for shoe production.- 8 replies

-

- sewing machine

- machine

-

(and 4 more)

Tagged with:

-

I'd try calling the Coats folks directly to find out where you can buy their products: http://www.coats.com/index.asp?pageid=37&country=usa

-

A few things: You gotta tell us what you have. Pictures always help. My crystal ball showing me your motor installation is all foggy today. If you can't figure out the belt tension mechanism on your setup by looking at it, perhaps it's not such a great idea to start taking things apart. Whoever sold this thing to you probably has a phone and an interest in keeping you happy. If you don't trust that person to assemble things properly, perhaps not such a good source for purchases. I'd advise against taking things apart just to check whether they were properly installed in the first place. Quite often you introduce new problems unless you really know what you're doing. I'm not sure why you feel this is an important first thing to do before commissioning the machine. There are perhaps a dozen of grooved rods and bars with set screws. Do you plan to check all of them?

-

Servo motor mounts usually have a pivot point and some way to adjust how taught/loose the belt is. You can loosen the belt via the motor mount and then you can remove the belt. If you have a speed reducer pulley, that may need to be loosened as well.

-

Seiko STH-8BLD-3 reverse/tacking question

Uwe replied to anvilring's topic in Leather Sewing Machines

I'm not positive but I believe that adjustment screw/mechanism allows matching the amplitude of the needle bar rocker frame movement to the feed dog movement. It makes sure the needle's position remains fixed inside the feed dog hole as they both move front to back. If the amplitudes don't match, there will be relative movement of the needle inside feed dog hole as they move. -

Seiko STH-8BLD-3 reverse/tacking question

Uwe replied to anvilring's topic in Leather Sewing Machines

Since your machine doesn't really behave at all the way it should in reverse, you're either using it wrong or something may be way out of adjustment, loose or broken. The Seiko STH-8BLD-3 manual will get you going on the right path. I highly recommend reading it carefully - it's one of the better manuals out there. First thing to make sure is that you don't turn the hand wheel backwards to make the reverse stitches - that's just not how it works but you would be in plentyful company if you tried that. Second thing to make sure is that the reverse lever has normal range of motion (isn't catching on anything) and that you depress the reverse lever all the way down and hold it there while sewing in reverse. Third thing to make sure is that you don't make any changes or loosen screws unless you really understand what they do. That screw in your picture is NOT where you adjust the reverse stitch length balance. Chapter 8-13 on page 23 of the manual shows how to adjust stitch length balance. -

By coincidence, I came across a Pfaff 3334 subclass booklet in my stash of manuals yesterday. It won't help with fixing the the thread cutting knifes, but it relates to the machine in question. I scanned it in and made a text searchable PDF. It's surprisingly hard to turn scanned booklet spreads into a normal sequence of PDF pages! http://docs.uwe.net/Pfaff 3334 Subclass Patterns Reading.pdf (for reading online) http://docs.uwe.net/Pfaff 3334 Subclass Patterns booklet printing.pdf (For printing the booklet: print duplex on letter size paper, fold in half and staple)

- 6 replies

-

- pfaff 3334 bar

- bar-tack

-

(and 3 more)

Tagged with:

-

Not complaining, just documenting facts. The seller may need the money to pay off the medical bills for back injuries sustained while trying to move the monster.

- 16 replies

-

- saddles

- antique equipment

- (and 7 more)

-

- 16 replies

-

- saddles

- antique equipment

- (and 7 more)