-

Posts

4,828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dikman

-

Welcome to the forum. Have you read this -

-

That looks great! The leather has a texture to the colour, it should age well.

-

The last thing I'd be doing is trying to use inkjet inks on leather! It will probably act like dye and get into the leather. My experience with such ink is that it's not colourfast and it runs when wetted with anything. I'm curious about your laser printing process too. I dabbled with it for making printed circuit boards many years ago so would like to know how you did it.

-

Trying to make a wrangler/rough rider holster.

dikman replied to Frankster's topic in How Do I Do That?

Frankster, there are many youtube vids showing how to make holsters, including making the pattern. It's not that difficult, once you understand the basics. That's exactly what happened to me! I couldn't get the holsters I wanted (many in the US wouldn't ship to Oz ), so a few years and many $$ later........ -

Jesse James's rig

dikman replied to Brushpopper's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice work. Regarding the money belt, there are many examples in Packing Iron. The buckle end of the belt is not usually sewn, to make it easier to get the money (including notes) in and out. The tongue of the belt is passed through the slot and then the buckle, this closes the open end of the belt. -

22 Plinking Pouch

dikman replied to Brokenolmarine's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That turned out very nice, and the very detailed explanation will doubtless prove useful to others. Box-stitching is tedious and can be nerve-wracking, as well as time-consuming. Unfortunately there is no easy way around it, but it's a satisfying feeling to be able to do. -

22 Plinking Pouch

dikman replied to Brokenolmarine's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I forgot the instructions. Ammo box instr..pdf -

22 Plinking Pouch

dikman replied to Brokenolmarine's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Here's something you might find interesting, the patterns for an 1841 Army ammo pouch. It's very similar to what your making. I made one but haven't got a photo of it (no carving or stamping, just plain as per the originals). Ammo box.pdf -

Don't forget that gearbox oil is generally used in enclosed sealed gearboxes so the gears are essentially running in an oil bath. It doesn't matter if it gets flung off as it is constantly replaced on the gear surfaces. Unlike sewing machine gearboxes.

- 28 replies

-

- grease

- industrial sewing machine

-

(and 1 more)

Tagged with:

-

Ordinarily I would agree, but in this case the piston assembly is shielded from the motor by a "bulkhead", for want of a better term, and while the head gets hot it's nowhere near as hot as the area of the casing that's above the motor coils. I've taken temperature readings to try and localise the main source of the heat. The fan on top keeps the cylinder head noticeably cooler, the motor only slightly so. It's just poor design of the motor housing. Fred, thanks for that, lots of interesting stuff to look through there!

-

Oil-less piston. Like I said, it's a known issue with these little compressors, but having said that there are no reported failures because of it (probably because they're rarely used continuously, it's not as if they're spraying a car). The heat comes from the motor, not so much from the piston/cylinder head. I toyed with the idea of completely stripping it to drill out more holes for better circulation but couldn't be bothered as it will work fine like it is. Another possibility is to fit a small air tank to it, like my other one - maybe one day? I'm still annoyed that I can't fit the pistol-grip airbrush to the cordless compressor.

-

Bladegrinder, there's nothing wrong with your stitching, it's just your oblong holes, they don't fit properly.

-

Update: The bowl on the airbrush was a bit small so I found some larger capacity bowls on Ali-express, however it was only a few dollars more to buy a complete pistol-grip airbrush with the bowls, so I did. I felt this type of airbrush would be more comfortable to use with the compressor hanging underneath. Great idea, unfortunately the thread size on the compressor isn't like anything else I've got and the gun won't fit!! Bugger. Looking on gumtree (local ebay) I came across an airbrush and compressor for $50, so grabbed that. I figured I could leave that in the shed with the airbrush. It works well, and the pistol-grip airbrush fits so that's good. A couple of problems became apparent, however - it runs bloody hot and moisture is an issue. After 10 mins use (continuous) the case is almost too hot to touch (approx. 40*C at its hottest part), a common issue with these compressors. So I fitted a couple of fans. It still gets hot (poor air circulation inside) but considering it normally won't be in continuous use, more like start-stop, this should be fine. It has a water trap on the regulator but with continuous use water still builds up in the hose, so I've ordered some small water filters that attach to the airbrush end of the hose. Again, with start-stop use it should be fine. I now have eight assorted airbrushes!! Do you think I may have a problem?

-

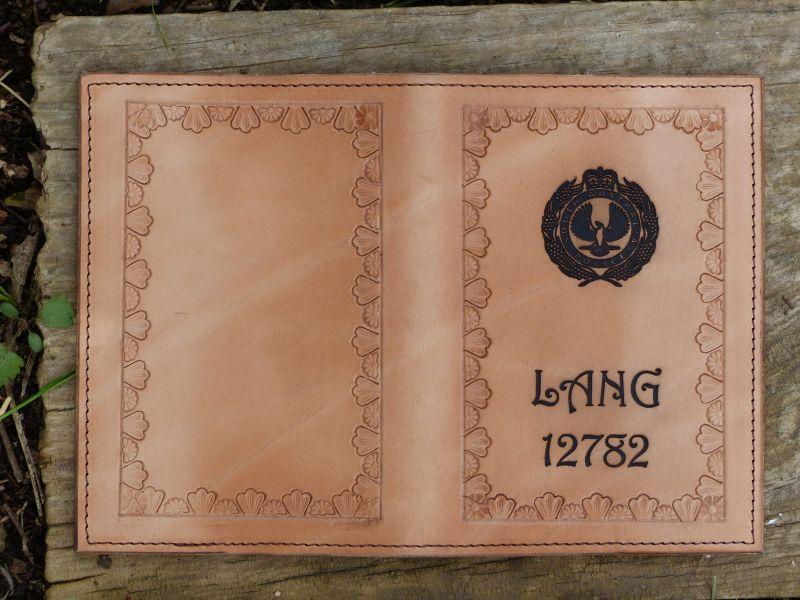

I have a couple but they were taken before I gave it the sun treatment. You can see a slight "colour" variation in the leather, this disappeared after being left in the sun. I didn't think to take a photo afterwards. It's nothing special, as such, about 4"x6" and is designed for their pocket size notebooks. It will be handled a lot so should age very quickly.

-

310 to Yuma, Hand of God

dikman replied to Bawarrior's topic in Gun Holsters, Rifle Slings and Knife Sheathes

From what I've seen it doesn't look too much like the original (for one thing yours is obviously for a longer barrel so the patterning is different). Having said that, and ignoring the Hand of God reference, you've done a bloody good job!! Lots of time-consuming detail work there, and a very nice colour. I'm impressed. -

I made a notebook cover for a graduating police office and everything about it was pretty much left up to me. I had used a small laser thingy to burn the official police logo into it and felt that most dyes were likely to be too dark against the black etching, but I didn't like the "natural" colour (too light), so I gave it a coat of neatsfoot oil and left it in the sun for a couple of days (in Summer). It came out with a beautiful rich lightish brown colour. The girl I was making it for was stoked!

-

Interesting idea. I see where you're coming from but if you get it that hard then stropping probably won't have any effect? Still, I think you should try it as we will all learn something.

-

There have been a few posts about making dyes, I have made walnut dye from walnut husks, but it's a long process. As Ed said, vinegaroon is a great one for dying things black, although it's more of a dark-grey/black, looks really nice. If you have sunny days battlemunky's idea works well, the UV darkens it slightly to a rich golden brown.

-

Dipping my toe into sewing; Advice requested

dikman replied to Sam83's topic in Leather Sewing Machines

That's great news, Sam. It's much better being able to see and, if possible use, a machine before buying it. Hopefully through this forum you'll have a pretty good idea of questions to ask when you eventually visit the place.- 45 replies

-

- sewing machine

- newbie

-

(and 1 more)

Tagged with:

-

I had to look to find out what the heck a "Pulaski" is. Nice neat job, as for the bungee cord it's a simple effective solution without messing around with buckles. Once it loses its bungeeness it will be simple, and cheap, to replace.

-

Dipping my toe into sewing; Advice requested

dikman replied to Sam83's topic in Leather Sewing Machines

Sam, you mentioned possibly a 441 clone, these are heavy duty machines and likely to be too much for what you intend sewing. With RockyAussies modified needle plate and feed dog they will go down to #138 thread but anything lighter than that could be problematic (one of the issues will be finding small enough needles for lighter thread). Something with 1/2" max. under the feet might be a better fit?- 45 replies

-

- sewing machine

- newbie

-

(and 1 more)

Tagged with:

-

My first carved holster.

dikman replied to dikman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you for the kind words, Bert, but my effort is pretty mediocre compared to what others are doing on here. I have a long way to go yet. -

Dipping my toe into sewing; Advice requested

dikman replied to Sam83's topic in Leather Sewing Machines

I might as well chime in. The "famous" Chinese shoe patcher is often known as a tinker's delight! They can be a useful machine but will likely require a bit of work to make it run smoothly. My suggestion, in your situation, is no. Importing from China, naturally I have no idea about the ease/difficulty in importing large items where you are but I considered importing a 441 clone head into Australia. While there are any number of dealers on Ali-express/Ali-baba who were happy to sell me a unit (at some good prices) it was a nightmare trying to work out how to do it, at every turn there were additional costs required here (shipping, port forwarding, brokers fees, import taxes plus some I've forgotten). The cost worked out the same as buying locally, which I did. Hopefully it won't be as bad for you (here we have taxes on taxes!!) but be thorough in your research. As for the Typical brand I came across it during my searching and it appeared to be a good brand. Good luck, and I hope it works out for you.- 45 replies

-

- sewing machine

- newbie

-

(and 1 more)

Tagged with:

-

My first carved holster.

dikman replied to dikman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Steve, you're quite right, the reactions from people who have seen it range from impressed to awestruck!! The fact that holsters are uncommon here, let alone carved ones, probably has more to do with it than the quality of the workmanship. You're right in that to be period correct the belt loop should be sewn as a separate piece on the back, however for my needs I needed the holster to sit a bit lower, to make it easier to clear the holster when drawing an 8" barrel. Your idea of stitching the loop before gluing the liner had already occurred to me as it would be much neater than this effort. With the folded drop loop the loop part of the liner would have to be glued first, folded over and stitched to the holster and then the rest of the liner glued to the holster. It would be do-able but a bit tricky if the holster is formed with a curve first, but I think it's the way to go I'm still working on the design for the next two, I just scrapped the first drawing as it just didn't look right. Did you post any pics of your holsters?