-

Posts

5,999 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by fredk

-

Wow! you have an order form? and you give people choices as well

-

US spelling = coloring, vs British spelling = colouring

-

Reinforcing: Leather case to carry a motorcycle battery

fredk replied to Littlef's topic in How Do I Do That?

The OP can tell us, but nearly all modern motorcycle batteries are totally sealed for life. Thus they don't spill acid when a motorcycle goes topside I would put two straps around the case in a + shape with the ends of one making your carrying strap I used to have a case of this sort for carrying extremely heavy dry cell batteries and a very large condenser for a portable camera flash unit. The gubbins for inside weighed about 6 lbs. The case was about 8 inches by 4 inches and 6 inches tall. Very thick leather, 3 straps around the body and a separate carrying strap held on by loops and D rings on the back -

yup, dun that two Colin turned out Golin, Andy became Amdy, left out a T in Kitty, spelt Gemma Jemma

-

. . . . . when you stamp something to find you've done it up side down?

-

How to answer the question "How much is it?"

fredk replied to Leatherinspire's topic in Marketing and Advertising

Difference in culture; here buyers like a wee bit of banter as they deal, sometimes with a wee bit of bargaining to boot. If you (I/me) just blurt out the price I'll lose the customer because to them that is just a hard sell and they don't like it We like chat, banter. We can string out one comment about the weather for a whole afternoon -

How to answer the question "How much is it?"

fredk replied to Leatherinspire's topic in Marketing and Advertising

I string the customer along; How much is it? Not sure, I really don't sell those If you did, how much would it be? Dunno. I'll have to work it out. (pause), mmmm, probably about £xy . You can buy real cheap versions made in China for much less. But mine are quality leather. Hand made Proper leather? Will you make me one? Yeah, I reckon I could. It'll take me a while though. I'm a slow worker Can you have it ready for (choose a month)? What?! THIS year! mmmm. . . . I think I can and so on. . . . . -

The Trend of Leather that Scuffs easily.

fredk replied to SpruceMoose's topic in Leatherwork Conversation

We sound like the 'Four Yorkshiremen' -

Has this been 'spoken' for? If still available I'm interested in it Possibly, Airmail letter to UK

-

The Trend of Leather that Scuffs easily.

fredk replied to SpruceMoose's topic in Leatherwork Conversation

I do. We brought all ours from US to UK. A few people here wore galoshes but not many. They seemed to soon fall out of fashion. Sometimes just called 'over-shoes' here I do. Not as often or as high a shine as when I was in RAF. But about every 2nd or 3rd day they get a good cleaning and polishing, maybe every day in a bad wet winter. We don't get snow here Same. And I did my boys school shoes every night. 3 boys x 2 pairs each. I did them to RAF standard shine This, is very true -

you guys know this sort of thing is already available right? I just bought two tubes, one of blue and one of black. I'm going to try them as fillers on edges of made items, rather like a thick edge paint. If they work I'll get other colours Its a vinyl repair paste for repairing scratches or splits in leather, especially furniture or car upholstery. I first used it about 35 years ago to repair splits on my Cadillac dash-top. I bought a kit from a company called 'Eastwoods' of USA who specialised in supplies for refurbishing US cars, With that kit you got special sheets of plastic which you pressed onto the paste as it set. The sheets had common surface textures so you could match your dash top's texture. The stuff worked ok, it wasn't the best but at about $10 for the set was a lot less than $500 Cadillac wanted for a new dash top panel shipped to me. photo example of tubes of paste; the colours can be mixed, just like paint

-

This evening I just spotted that Le Prevo has replacement tubes for the rotary hole punch http://www.leprevo.co.uk/hole-punches.htm

-

When I procrastinate for so long I either miss a deadline or nearly so Been putting off making a quiver for #1 fav dottir so long I just realised she needs it in two weeks time. I'm a slow worker

-

They look most excellent I've not known anyone use a 'tally book' for almost 50 years

-

Looks kinda like a cross between Darth Vader and a samurai Line up the pieces just as you have them. Glue them together and then to a piece of board painted off-white

-

If you are insistent on doing this; buy a new rotary hole punch of reasonable quality and take the punch tubes out of that and put into the old one You'll be ending up with a 'Triggers Broom' though

-

With a guess at the problem; sew a 3/4 inch or more strip to the long edge of both the front & rear covers. Don't try to match them in, make them different but complimentary to the main work

-

The stitch groove need not be cut into the leather but can be pressed in

-

I bought a 'Boss' To answer some questions, in order in which I think of them 1. Speed; I like to work at a speed I like, not at the speed a machine wants me to. I've converted my Singer 99K to manual 2. Time of use; I live in a small flat/apartment, surrounded by others. Families in those frequently change. Currently above and to my left are families with very young children. I need to work quietly. Late at night they can even hear a an electric drill or my washing machine. I can use the Boss at 2am if I want to 3. Size; I have the Boss bolted on to an extension to a desk. It has a 'foot print' of about 15 x 10 inches, smaller than my Singer 99K. Any of the powered machines I considered were much larger. And many need their own work table. I simply do not have the room 4. Power; Any powered machine I considered did not use UK electric. On top of the main price I would have had to pay a minimum of £300 extra to get it converted over. Also, power cuts, (outages ? to you) whilst neither common nor frequent, they do happen. No worries with the Boss. I used to do craft shows, so if I want to I can pack the Boss and take it along. No worries if the show is outside in a field or an old castle somewhere, I don't need power, just a table and some clamps or ~ I've considered getting a piece of tree trunk and drilling it for using coach-screws to hold the Boss 5. Use; I do not sew belts I make. I make smaller items using thick-ish leather. Thus it doesn't take long to do anything, At the moment I just use mine to make holes for saddle-stitching by hand 5a. Use (#2); you set your powered machine to 4 spi and zip along. But what if some of the holes/stitching don't fall just where you want them? With a manual machine you can adjust where the holes will be easier by seeing them come up more slowly. Yes you can do the same on a powered machine but not just as easily 6. Exercise?! Its not your hand, its the muscle in your upper arm (bicep?) which gets exercised! Its what one gets used to. Such upper arms exercises are no stranger to me. Sore & tired? Just take a short break. After a few sessions your time sewing lengthens and the time for breaks shortens 7. A 'Boss'; will hold its value more readily that powered machines. Any 2nd hand powered machines I considered all needed attention, ie work to make them work. I got a comprehensive new Boss outfit for less than the price of one of those very used and broken powered machines here. Good powered machines will hold their value as well but good used are hard to find. A new machine with guarantee is better than a used machine with none imo

-

Most excellently done They remind me of the bestest Viking or Medieval work of this type

-

Like it, I did the same, but over a table top. I got very high on the fumes from cleaning it up.

-

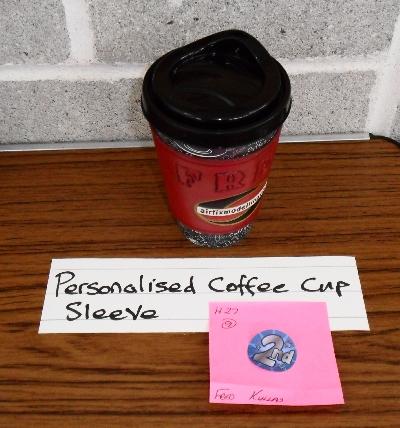

Some photos; my items on the display table. 10 items. 4 of mine in current use, 2 old items and 4 newly made items In traditional reverse order; 3rd Place, a Novelty Knitting Belt Pouch. I had some of the parts for this ready cut and in a plastic box for several years so I got stuck in and made it. Its actually terrible, worse than it looks! That sewing is really ragged In 2nd Place, my currently in use Coffee Cup Cuff (or Sleeve) And in 1st Place, a copy of a Medieval Girdle (Belt) Pouch. I made this maybe 14 or 16 years ago. I put it into this event just to make up numbers. I got the design from 'Purses in Pieces' by Olaf Goubitz. #3 son used to wear it when we played at medieval things, thus the turned up corner on the flap As far as I know, this was the overall winner. A child's 'push' car. Its big. About 6 ft long. Its like a 1/2 scale version of my Austin 7 Ulster my Austin 7 I got to the venue early to set up and didn't see much of the other entries, actually I only saw a couple. I planned to go back well before the show closed to view the other entries but I was delayed and saw nothing. The show officially closed at 4.30. I arrived at 3 and only my stuff and a few other entries were left, and they were packing up. Everyone else had taken their items shortly after 2.30, the official time that entries could be removed. This happens at a lot of shows and events here; people take their items or close their stalls early. Why? My #1 and I do a toy car fair twice a year. The toy fair starts at 4.30 / 5pm. It closes at 8pm. All the other traders are packed and gone by 7pm. We stay on till the very end and we get good sales in that hour. One time #1 took in over £100 just in that hour. People came to buy and spend and we sold I've started planning for next year! Watch this pace. Same time, Same Channel. I'll be back after a word from my sponsors I now have a reputation to up-hold

-

We all need to find a really good sealer for our dyed leather items My Resolene, Astonish (my local version of Mop & Glo) and water does a very good job of sealing. But its not 100%. A few years ago I made some items for members of a club I'm in. I dyed and sealed. I tested how good the seal was. I put items in plain water, dish washing water, water with clothes cleaning powder in it, I tried strong alcohol, vinegar, Lemon juice, wiped the items over with a rag soaked in acetone, and with cellulose thinners. I even tried hydrochloric acid. No dye came off. A month after I'd given the items away one member happened to mention that his 2 year old grandson had chewed his item and his mouth had turned red from the dye. I never thought of trying a child's saliva in my tests! back on target; to the OP. You may have done right. Mop & Glow is an acrylic varnish. Resolene is an acrylic sealer. Your dye was most likely a water based acrylic as well. M&G is more aggressive. It can dissolve itself and other weaker acrylics. When I use those same products I dip dye, but I use a paint brush to put the sealer on. I keep the item flat and I flood the sealer on. Although the sealer might be dissolving the dye a bit its not going any where and dries back into the leather. I put on several coats this way, but I/you need to be careful not to put on too many coats as the M&G varnish will start to give a hard finish that will show cracking on a belt Another thing you can do is to change to oil based dyes. Neither the Resolene nor the M&G can or will dissolve that

-

I'm not sure I understand your problem Its many years since I found that Resolene doesn't really seal dyed leather. Originally mine did but newer stock of it never really did much I switched to a mix of Resolene and my local version of 'M&G' and water. Don't ask proportions, I just poured some of each into a bottle. But I still got some dye coming off in the first two dips My latest version is to add some dye into the mix. Thus I have, green mix, blue, red, tan, walnut etc as well as the standard Black Resolene. Now if I get dye coming off I don't see it, , but the coloured sealer adds extra colour to the item plus seals it