-

Posts

5,252 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

Western Style Heel Bar Buckle in 1.75"

Dwight replied to harimau777's topic in Hardware and Accessories

And you can take a look at this guy's offerings: after I posted above, . . . I got curious, . . . found this one. On the left side, . . . pick the heel bar buckle offering. https://www.buckleguy.com/heel-bar-buckles/ May God bless, Dwight -

Western Style Heel Bar Buckle in 1.75"

Dwight replied to harimau777's topic in Hardware and Accessories

My friend, you will have a tough time on that one. In my 73 years, . . . not sure I ever did see one, . . . but then again I could be wrong. One thing you can do, that will (if anything will) make a difference, . . . put your search in quotes "heel bar buckle" , . . . and try different search engines. There are a dozen or so out there ready to help you, . . . and each one has it's own way of doing things. I normally use Google Chrome . . . but Firefox is my secondary, . . . and Edge is the next one. You also want to try Ebay, . . . lots of times I have found stuff there that I could not find else where. Good luck, . . . May God bless, Dwight -

Has anyone tried Un-doing saddle stitching?

Dwight replied to KingsCountyLeather's topic in Sewing Leather

Hand saddle stitching is one reason I have a very sharp knife that will get down between the layers of leather. May God bless, Dwight -

Best Finish for Belts

Dwight replied to steelhawk's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

If you define the word "better" as cheaper, . . . yes there are. If you define it as a finish that will give your customer a better product, . . . you will probably have to get up real early in the morning, and stay up real late at night to do that. For the double layer belts I make, . . . I would not even think of putting anything else on there except maybe Mop and Glow, . . . all the others are much softer finishes, will scratch easier, will look much uglier, much quicker, . . . and not give your customer as good a product. The only reason I don't use M&G is I did a cost analysis for my business, . . . Resolene is cheaper for me to use, . . . and easier. May God bless, Dwight -

Using A Press To Mold Holsters?

Dwight replied to hestes's topic in Gun Holsters, Rifle Slings and Knife Sheathes

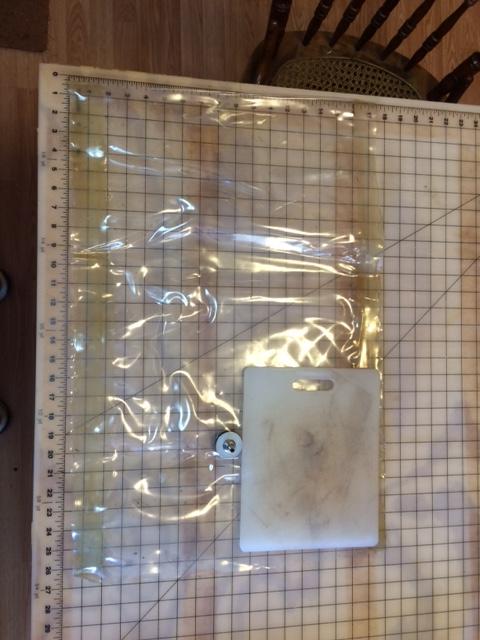

My setup cost me $99 for the pump, . . . couple bucks for the hose, . . . $10 for the vinyl at Joann's fabric, . . . and $15 for the vacuum nozzle that goes thru the bag. I've used the same bag now for at least 6 years. All I did was buy a piece of Joann's heavy duty clear vinyl, . . . about 24 inches wide, . . . 45 long, . . . contact cemented the edges to make a bag, . . . installed the nozzle, . . . and have never really had any problems. I gave up the press idea when I started getting so many of the plastic fantastic firearms, . . . figured one of these days the press would collapse the thing, . . . and I would be stuck buying him a new weapon. Can't happen with a vacuum setup. This is my vacuum bag, . . . and my sealing setup, . . . I use the little board to keep the back of the holster straight, . . . without it, . . . it all collapses into a ball. May God bless, Dwight -

Clintock asked for a pattern for a Ruger 9mm, . . . and since it had been a long time since I had made one, . . . I had to make the pattern again. Figured while I was at it, . . . might as well make a holster for it, . . . as I don't have one. Here is the finished product from the pattern on another thread in here. And for tearghost, . . . this is the typical product I produce with my vacuum forming process. I don't get serious about the outlining and detailing, . . . prefer the simple look. May God bless, Dwight

-

chapelstone, . . . if you have a buddy that has one, . . . borrow his before you go into the trouble of making one, . . . or heaven forbid the price of buying one. I've got a couple of them, . . . and if I could get my money and effort back that I've got in them, . . . I'd do it in a NY minute. You have to carry something small and/or lightweight, . . . no 1911, . . . no Python, . . . not even a Glock 19. AND, . . . it is pretty easy to spot a vest carrier, . . . they also have a habit of standing out on the LEO radar, . . . if there is a reason for them to be watching. But good luck, . . . lots of people do like them, . . . and they do work out for some folks, . . . I'm just not one of them. May God bless, Dwight

-

Ruger 9mm semi-auto pancake

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

No problem tearghost, . . . just do one thing for sure. When you buy your vacuum pump, . . . make sure you get a bottle of vacuum pump oil for it. I used to be in the HVAC game, . . . and we always had to add oil to them every so often, . . . yours should have a little window in one end of it, . . . keep that window half full is the way most of them go, . . . check your mfg book to be sure. You can flat burn it up if it runs out of oil, . . . and it takes special oil. Holler if you have any other questions or concerns. May God bless, Dwight -

Use very thin and pre dyed leather, . . . make sure you also line it with some satin like material. Leather vests that are made from heavier leather get really hot, . . . really quick. Make your gun pocket between the two pieces, . . . and toward the outside piece, . . . glue in a piece of Tandy's bag stiffener, . . . you can then put velcro on it, . . . and velcro attach any type of holster you choose. May God bless, Dwight

-

Ruger 9mm semi-auto pancake

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

What would you like to know, tearghost, . . . ??? It is basically a $99.00 vacuum pump from Harbor Freight, . . . a piece of plastic hose from the hardware store, . . . I bought a piece of thick clear vinyl from Joann Fabric store and made a bag out of it by contact cementing the edges. I place the holster on a white plastic cutting board to keep it flat, . . . turn on the vacuum pump and let it do it's work. The tricky part to find is the inlet fitting to get you into the bag with the hose. This might work, . . . it is different from mine, . . . but looks promising: https://www.ebay.com/itm/Vacuum-Bagging-Fitting-Port-Adapter-Chuck-w-Locking-Nut-Sealer-Washer-Brass-SS/391876111610?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m1438.l2649 The other tricky part is sealing the bag, . . . you can basically roll it over a 1/2 inch piece of tubing, . . . then put a clamp on on the tubing, . . . don't take much. Once the bag gets stuck to itself, . . . it seals pretty good. Let me know if you have any other questions. May God bless, Dwight -

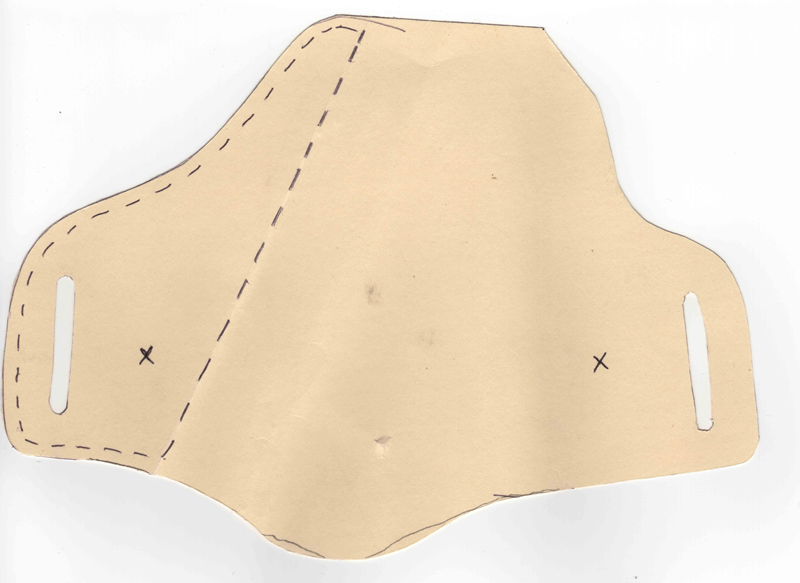

Got a request from Clintock for a pattern for a P90 Ruger 9mm semi-auto pancake holster. The gun is better known as a "brick" because when you get done pumping out the bullets, . . . you can always throw the gun at the perp, . . . and if you hit him in the head, . . . it's darn near as good as shooting him. Anyway, . . . down and dirty, . . . pancake pattern, . . . flat backed pancake, . . . to me the most comfortable. If you use these patterns, look on both pieces for two little "X" marks. Print the patterns so that when you get done, there is exactly 6 inches between the X marks on each pattern, and they should be sized correctly for the pattern. I cut out both pieces so the inside of my pancake holsters is the flesh side of the leather. Position them as in the sewn together picture, . . . soak the thing and form it. You can see I used my vacuum forming bag, . . . love the way it does the work for my thumbs and fingers. Hang it up to dry, . . . position it correctly, . . . contact cement it, . . . and sew the trailing edge.' Your holster is ready for finishing. Have fun, may God bless, Dwight Drag files here to attach, or choose files... Max total size 1.46MB Insert other media Uploaded Images ruger 9mm p80 pancake inside piece small.jpg 165 kb · Done ruger 9mm p80 pancake outside piece small.jpg 187 kb · Done

-

Actually, . . . a one piece (google " image: roman armor " ) is better overall, . . . you just have to make sure you roll out the neck and arm holes, . . . and make them big enough for his arms to move in any direction and not get chaffed. Riveting them together makes a piece that will be almost no different from the one piece, . . . other than it is a lot more labor. If you make the layered (known as segmentata ), . . . it is a LOT MORE WORK, . . . but it is THE most flexible. The leather version a lot of folks make, . . . the pieces are long enough to go completely around the person, . . . and are laced together from the top of one piece, . . . down to the top of the next piece, . . . and they overlap enough so that the cords are well covered by the lower piece. This allows it to flex up and down, . . .but still protects the person. It is then laced together in the front, . . . similar to lacing up a pair of work boots. THAT is the design of the most successful soldier's armor the romans used. Have fun, . . . good luck, . . . May God bless, Dwight

-

Just a shout out and a thank you to the Tandy leather store in Columbus, Ohio. They ran out of their advertised specials very early on black friday, . . . and had to substitute. Corporate gave them the green light, . . . and I got a 22+ sf 8/9 hide out the door for $90. It did have a minor flaw in it, . . . but all things considered, . . . I would have had to have paid darn near double that price the tuesday before Thanksgiving, . . . and I just wanted to give credit where credit is due, . . . Tandy Leather on Morse Rd. Columbus, Ohio. Even got to chat with a good friend who used to be the manager, Scott, . . . we compared open heart surgeries. May God bless, Dwight

-

I learned a long time ago, . . . from a fellow who wore 36 inch waist jeans, . . . and I made him a 36 inch belt. ALWAYS measure their belt. Come to find out . . . they had stretched to the point he needed a 41 inch belt. SO: make the individual take off the belt they are wearing when they order their new one. Measure from just inside the outermost part of the buckle, . . . to the hole he / she used today, . . . and you should not go wrong. I always add 3 holes each way from that measurement, . . . so they have room to expand and contract . . . people have a habit of doing that. The one exception to this rule I ever found, . . . measured a guy up for a 53 inch long western belt. By the time he came back to get it 6 weeks later, . . . he needed a 56 inch belt. Anyway this system itself has never let me down, . . . people have. May God bless, Dwight

-

JC Javelle, . . . and Clintock, . . . PM me with full email addresses, . . . I'll send you some information. The shoulder holster of this type I make is very comfortable, but takes a WHILE to get done. Don't be in a hurry. It also is a muzzle pointing down, . . . I will not make or supply patterns for horizontal or armpit pointing shoulder holsters, . . . personal rule. It needs to be made out of back leather at worst, . . . double shoulder leather preferably. It carries the option for one or two (preferably) magazines carried on the off side. May God bless, Dwight

-

Try this one: https://www.ebay.com/itm/387-1C-Rubber-Natural-Gum-1-In-Thick-12-x-36-In/381935295108?hash=item58ed1e1a84:g:70EAAOSwIFtaDzVf May God bless, Dwight

-

I liked the other one much better......... May God bless, Dwight

-

SHOULDER HOLSTER HELP

Dwight replied to Dave Richardson's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Sorry Dave, . . . can't help you because I don't know what he does. Can you share that pattern, . . . better idea of what YOU want??? I make several different types of shoulder holsters, . . . and they tend to have different straps, . . . and it becomes a personal preference thing more than anything else. Send me a PM, . . . we're not too far from each other, . . . maybe create a NEW one........lol May God bless, Dwight -

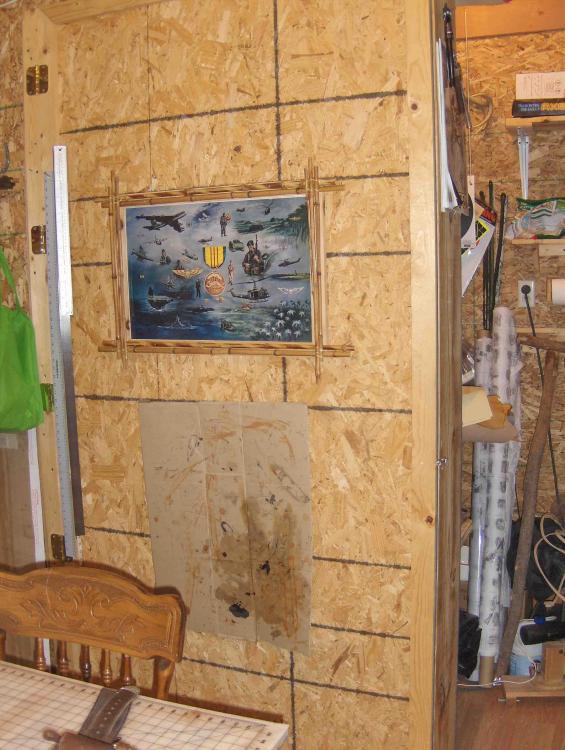

No problem. The first picture is the outside of the door, hinged on the left, opens on the right, 8 ft 1/2 inch tall . The second picture shows the side of the "vault" made of 2 x 12 boards. Third picture shows the hangars and how they hinge back and forth from the left side. The last picture shows the stuff hanging. Really pretty simple, . . . truth is, I think I spent more time worrying and fretting over what I would do that the time it took to get it done once I figured it out. One of my old gripes was having to struggle with rounded leather, . . . this way it becomes pretty flat, pretty quick, . . . makes life easier. May God bless, Dwight

-

Ruben, I have a pair of these I've had for over 10 years now, . . . and while at times I'll fail to set every thing up right, . . . if I do my part, . . . these never fail me. https://www.ebay.com/itm/Snap-Pliers-Set-Canvas-Marine-Heavy-Duty-Fabric-Button-Fastener-Installation/352192247767?hash=item52004b37d7:g:JXYAAOSwvTpaA2V9&vxp=mtr May God bless, Dwight

- 11 replies

-

- leather tools

- press

-

(and 2 more)

Tagged with:

-

Gary, . . . I'm thinking you could come awful close to duplicating that in veggie tan, . . . if you took one of those 3 or 4 inch paint rollers, . . . and stuck a sandpaper roller on the outside of it, . . . got your leather all cased up real good, . . . rolled her back and forth a couple times. I'd think it should come out fairly close. Only thing I can think of at the moment if you can't find the original. May God bless, Dwight

-

A piece of thick walled 1/2 inch by 1/2 inch angle iron, . . . laid at the top or the bottom of your line, . . . will suffice in most cases to keep you lined up. Keep masking tape on it so no rust transfers (and don't even think aluminum, it's far worse), . . . or a piece of 1/2 inch flat stock maybe 2 inches wide. Put a mark on it on the edge of the piece so you can check it from time to time to make sure it is not slowly running out on you. Cheap, and effective, . . . both ways. May God bless, Dwight

-

Help me pick a couple of guns

Dwight replied to SouthernCross's topic in Gun Holsters, Rifle Slings and Knife Sheathes

1911. S&W Shield, and Glock 19 are my biggest sellers. The Shield has been heavily promoted around here, . . . lots of people packin' em. You can do pocket holsters, clip on, IWB, and pancake on them. But you can hardly go wrong with a 1911, . . . lots of people like me that are willing to carry the anchor. May God bless, Dwight -

Looking for some help with a pattern

Dwight replied to LoneWolf1973's topic in Patterns and Templates

Once you have the basic bi-fold cut out and ready, . . . take another piece of 5/6 leather, . . . make it the size that will cover one end of the bi-fold, . . . outline the badge on the leather, . . . and cut it out. On the next layer down, . . . punch two holes for the pin on the back of the badge. Cement and stitch or lace as you please, . . . but that is how I make mine. AND, I won't start on one until I know for certain the size and shape of the badge. Like was said above, there are just too many different variations. May God bless, Dwight