LatigoAmigo

Contributing Member-

Posts

1,012 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by LatigoAmigo

-

I have some experience cutting leather with a 100-watt CO2 laser. I tried cutting some Delrin, but it was a beast to cut on my machine, it took several passes at high power, and the edges weren't "square", possibly due to the conical shape of the laser beam and the related heat that the many passes produced. If you were to ask for my advice, and I know you aren't, I would say to join a "maker space" and test your materials before you put out any money for a laser.

- 8 replies

-

- custom stamp

- uhmw

-

(and 2 more)

Tagged with:

-

I would consider using something like Montana Pitch-Blend All Natural Leather Dressing, then I would (using a dryer rack) place the treated leather in our clothes dryer for 10-20 minutes. This is the best way I've found to treat and warm leather.

-

Anyone using Laser Cutters at home for pattern making?

LatigoAmigo replied to bermudahwin's topic in Leatherwork Conversation

I've had some luck cutting acrylic and plywood, but only very thin plywood and only certain acrylics. My particular machine does not do "fine" engraving, but some units can do very refined work, and even cut at varying depths. To get the leather to lay flat on the cutting bed, I adhere the leather to stencil board. This stencil board, or oilboard, is available at some art stores, and is a thin, but rigid, cardboard that comes in 24 x 36 inch sheets. Its durability would work as a template, and it is very reasonably priced compared to acrylic or plywood. -

Anyone using Laser Cutters at home for pattern making?

LatigoAmigo replied to bermudahwin's topic in Leatherwork Conversation

I use a laser for cutting and engraving all of my leatherwork. The homemade CO2 100-watt laser will easily cut leather (have only cut up to 8 oz.), and after some fine-tuning have been very happy with the results. I don't know if this kind of machine is available where you are, but the parts are imported from China, and are available through dealers here in the states. The laser leaves some smoke residue on the leather, which can pose a problem on some softer, lighter leathers, but can usually be cleaned off with a damp cloth (I don't cut veg-tan leathers). There are threads on this site that discuss this issue. Here is my latest piece as an example of what can be done... -

Too bad. Not knowing what type of leather you have, maybe you could clean it up with what they call a Magic Eraser. That is a sponge put out by Mr. Clean. You add water to the eraser and rub it over the surface of the leather. It will pick up excess residue but can leave the leather with a somewhat "flat" look (again, not knowing what kind of leather you have), to which you might want to apply a conditioner.

-

You may not be interested, but there are various ways to gain access to Photoshop and Lightroom at a reasonable price. This link shows several options. Check the Students and Teachers section for discounted student pricing. https://www.adobe.com/creativecloud/plans.html

-

What to use for stiffener - bonded leather or splits?

LatigoAmigo replied to terryHHI's topic in How Do I Do That?

I have had success using a heavy mesh style interfacing along with "HeatnBond UltraHold Iron-On Adhesive." For me it has worked better than spray on adhesive, which tends to be both messy and uneven. -

I have successfully used HeatnBond UltraHold Iron-On Adhesive (ordered from Amazon) to glue fabric to leather. You iron the fabric onto the back of the leather. There will be no bleed-through.

-

When you scan images, you can save them in various file formats. The file extension ".jpeg" (or .jpg), the file format for Joint Photographic Experts Group, has been around a long time (in computer years) and should be around for many more. Some of the file extensions mentioned above are designed for very specific applications and find themselves outdated.

-

Is there a font for Ivan Alphabet stamp set 8132-00

LatigoAmigo replied to RockyAussie's topic in How Do I Do That?

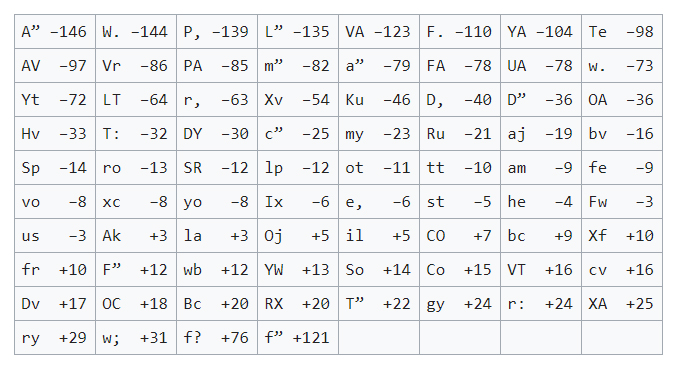

The amount of shaving needed will vary depending on the letter pairings. This table demonstrates the kerning attributes of various letter pairs, where you can see, for example, that VA uses different spacing (-123 / tighter) than VT (+16 / looser). Hope you find this helpful. -

From an early age, Bruce Grant has been my inspiration.

-

Just type "Sussex" into the search box on the home page and you should find a few folks from your locale.

-

I think Ohio Travel Bag has what you are looking for: https://ohiotravelbag.com/c-1951/1-14in+quick+release+latch+solid+brass

-

You might try Maine Thread Company, they carry turquoise waxed cord in assorted weights. https://www.mainethread.com/index.php/waxed-polycord/product/155-turquoise-waxed-cord

-

Help how to download pics from Android phone

LatigoAmigo replied to Bawarrior's topic in Member Gallery

When I email a photo on my IPhone, a dialogue box pops up, allowing me to scale the image to a smaller size. So if you are using an IPhone, it looks like you can shrink the photos by simply sending them to yourself, so there is no need for an app. -

My wife silkscreens onto wet clay, so I'm sure you can silkscreen images onto leather in the same manner.

-

40W Chinese Laser - Engrave and Cut Leather - Discuss

LatigoAmigo replied to Billy Hell's topic in 3D Printers and Lasers

Sounds fantastic. What software do you design with? -

I've seen quite a few backpack patterns available on this site: http://www.leathercraftpattern.com/index.php?route=common/home

-

Here is another possible source, 250 lids for $28.95: https://www.amazon.com/Mann-Lake-CN160-250-Pack-Container/dp/B00B8L5JUG/ref=sr_1_2?ie=UTF8&qid=1534534014&sr=8-2&keywords=yellow+flip+top+lid

- 6 replies

-

- dye lids

- flip top lid

-

(and 1 more)

Tagged with:

-

The deal is only as good as what you make with it, or what you can re-sell it for... but it looks pretty good from here.

-

Short of removing the rivets and re-riveting the Velcro in place, you might consider stitching small pieces of Velcro between the rivets. Using very light weight cream colored thread. It wouldn't have very many stitches, like 3 or 4, just enough to tack down the Velcro.

-

I have several Horween hides with backs like that, just part of the tanning process, probably when the hide is stretched out over something with a mesh pattern, like a screen.

-

Dwight, you are a saint to provide us all with such specific steps to success. For a "drying box" I have found that using the "sweater rack" in our gas clothes dryer works very well.

.thumb.jpg.d1295788ecc4d49414e70da153d96874.jpg)