-

Posts

319 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Vikefan

-

Sinpac How thick a leather can you sew with that Consew? I'm in Alaska.. so finding deals is pretty slim. Vikefan

-

Thanks Sinpac. I'm thinking since I'm building more and more stuff, I might just have to get me a Industrial Sewing machine. Hand-stitching takes a bit of time and work. Vikefan

-

I went back to weaver and I must say, IMO I like the richer stronger tones of the more expensive bells that I used on my project. I am hopeful that the bells stay on with the lace I used for many years. If not I guess I will have to rebuild it for the customer. Vikefan

-

KJD2121, I used a 1/2" old Osborne slot punch. That size seemed to be perfect for this style bell. Vikefan

-

As for running a file through the holes, I did not, and really didn't notice any sharpness on the one's I ran the lace through building it. Mark842 Can you send some pictures of the tools you use to rivet them to the strap? And what is the tone like on 115's? And are those bells as durable? What is as splash stamp?? I've never worked with one, and have no idea what that is. Thank you, Vikefan

-

sinpac How many and what kind of sewing machines do you have in your shop? Vikefan

-

I ran Tandy's Kodiak 5/32 lace through the mounting slots on the bells and tied a knot in each end, I figure that should be pretty durable for many years of use. I put the back on so the bell backs would not mar up her door she will be hanging this on. See attached pictures of what the back of the bells looks like, and lace run through the hole. Here is a link for where I purchased my bells. They are quality bells too! At the bottom of this link you can listen to the tone of the different sized bells. https://www.weaverleathersupply.com/catalog/item-detail/00120-cb-2/120-sleigh-bell/pr_23227 FredK, Thank you for your inputs and this was my very first sleigh bell project. I will take your advise under advisement. " You asked for it - I presume the bumps on the rear are due to the bells' mountings. I think those areas will show wear eventually. I think a third layer, sandwiched, with cutouts for the bell mountings. It need not be full width and length but skived to feather edge and glue onto the front piece then the rear piece sewn on over." The lumps are indeed the backs of the bells. I might just cut out circles of leather to put in under each bell in order for them to sit up higher and no poke through as they are doing now. I hope this lasts them a while. I just felt this would keep from marring up her door, if I left the bell backs exposed. Vikefan

-

I just made this sleigh bell door ringer for a customer (they picked the bells (by tone) and also the concho, the color and "L" carved in the top. The will be using it to train dogs to go to the restroom I am told. Please take a look and offer any pointers about my work. Thank you, Vikefan

-

Cross draw holster & cartridge belt

Vikefan replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Josh Ashman, What kind of sewing machine do you use? I'm looking at the Cowboy 3200 or maybe the Techsew 2750 (plain). Great work! Very Clean. Vikefan -

1st belt

Vikefan replied to GnewVFL's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice belt... My recommendation would be to skive down the backside of your belt Buckle end so tapers down in leather thickness, instead of being thick leather on the back. I also prefer large snaps or possibly Chicago Screws, so you and change out buckles if so inclined. Vikefan -

Two New Estwing Hatchet Sheaths

Vikefan replied to Vikefan's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Outfitr, Thank you.. There is a welt on both of them (Plenty thick for the blade), but I didn't take pictures of the blade side edges. My customer asked me to cut the belt slots, as I usually sew on a separate belt loop as well. He said most of the time the hatchet will be packed in a backpack, then maybe strapped on short short times. I based this design off of pictures of the original Estwing Hatchet Sheaths, especially for the Belt loop position and slots. Vikefan -

Two New Estwing Hatchet Sheaths

Vikefan replied to Vikefan's topic in Gun Holsters, Rifle Slings and Knife Sheathes

No lining...The original sheaths weren't lined either. -

Custom Bowie and Sheath

Vikefan replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Awesome Knife Sheath design.. Convertible style! Great job! Vikefan -

Latest Bowie and Sheath

Vikefan replied to dougfergy's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Hi, You are your own worst critique... I think you did a fabulous job on that sheath and should be proud of your accomplishment! I think it looks great! I like the color and the overall design. You thought things out.... Rock on my friend! Vikefan -

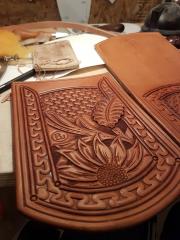

Western Tooled Case Thing

Vikefan replied to AlexOstacchini's topic in Satchels, Luggage and Briefcases

Darn... I wish I could dot that well on floral carving... Great job! Vikefan -

Recent Projects

Vikefan replied to stormcrow's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Wow! Makes my work look like it was done by a child... I love the product you are turning out! Well done! Vikefan -

Knife sheath

Vikefan replied to Bayou Bengal's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I think it looks Great! I love the colors, and that blade is awesome! Congrats! Vikefan -

pancake sheath Pancake sheath for my pocket knife

Vikefan replied to Riem's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I don't know... I think it looks really nice to me! Stitching is even and looks great! Keep in mind, we are all artists.. and have our own interpretations on the designs we come up with. I like it! It looks functional and very professional. Vikefan -

Knife sheath with snake skin inlay

Vikefan replied to pitersek's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Awesome! Kudos on that Project! I am in awe, seriously! Great Job!! I have a cobra skin, I can maybe try to do something along those similar lines.. WOW!!! Simply Beautiful! Vikefan -

I like that stamp! Vikefan

-

-

Dougfergy, No, not really. I dyed it with Angelas Gold dye, letting it dry, then I put two coats of neatsfoot oil on it, then after it dried two days I decided to coat the middle stamped section with Fiebings Antique Brown stain, wiping off the excess. After that dried well I put on two coats of Angelas acrylic Finisher (Satin) drying after each coat. That's pretty much all I did. Sometimes you might have to go back and re-stamp, to get the depth you need, I had to do that on a good portion of the stamping I did on this sheath. I don't know why, but I did. Hope this helps, Vikefan