-

Posts

833 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by CaptQuirk

-

Lacing Sizes And Lacing Hole Sizes

CaptQuirk replied to mtrain17's topic in Leatherwork Conversation

Sorry to dredge up the dead, but I am getting to a point where I could try lacing. I got some 3mm flat lace, only to discover that my chisel is 2mm. I wish I knew about waxing the lace first, it might have made it easier. Anyways, I just got a 1 prong 3mm chisel, and would like to know whether horizontal or diagonal slits are better? Would 1/8" spacing from the edge and between the slits still apply? -

I have been diluting the Fiebing's with water, and using a large ziplock, pour the dye into the bag, throw the leather in, shake it up. After a couple seconds, you should have decent coverage. Lay the leather flat on some newspaper, so that it dries evenly.

-

These are the cartridge straps I make, using belt scraps. I don't care for stitching the loops, so I weave it in and out through slots. They clip to belt loops, or many other options... but I found out that you don't want to hang it from the front belt loops. When you get to walking, the strap starts swinging back and forth. It isn't pleasant when you have a full strap of ammo slapping you in the privates.

-

I'm having the same problem, and that is using the Tandy waxed nylon thread. In some cases, I have hit the seam with a little saddle soap, and it sometimes cleans it up. I am so tempted to try hitting it with a cotton swab dipped in bleach.

-

I just loop the thread through the needle twice. It seems to hold ok, but sometimes it causes the needle to stick. Using the "Large Eye needle for blind old fools" doesn't help that either.

-

I can honestly say, my leather requests haven't been as funky as when I was doing web design. Had one lady, wanted her site to look like the card she designed. Problem there is, her card looked like Don Ho threw up on it. Another customer wanted a website for his Real Estate company. As I would make changes to the site, he and his wife would print out the page. I could never get them to understand that the monitor displayed the actual wide format, and the printer would cut off whatever didn't fit in the portrait format. Now days, I get sideways requests. A lady tracked me down, to do a knife sheath. This knife was special to her, yet she couldn't find it. Could I make a bracelet for her, while she finds the knife? I told her that when she found the knife, I'd do both at the same time, saving time and shipping. Never heard back from her. Another fella had a belt he needed some extra holes for. He had also cut off the end, and was worried about it fraying. I go to look at it, and it is a cheap plastic belt that he had bought at a thrift store for a quarter. I told him to go back to the thrift store, and buy a belt that fit.

-

First try at a full flap holster

CaptQuirk replied to Jake907's topic in Gun Holsters, Rifle Slings and Knife Sheathes

This is a small example, of a semi closed toe. Normally the hole is just a little larger.- 32 replies

-

- rough out

- .44 redhawk

-

(and 1 more)

Tagged with:

-

First try at a full flap holster

CaptQuirk replied to Jake907's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Instead of leaving the toe open, close all but a small pencil sized hole near the muzzle. This keeps most stuff from going in, but allows the other stuff to fall out.- 32 replies

-

- rough out

- .44 redhawk

-

(and 1 more)

Tagged with:

-

Right hand or Left hand

CaptQuirk replied to seabee's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I'm pretty compulsive about making sure the client knows which hand, what position the holster sits. Just for fun, I also ask when they order slings, whether it is for the right or left shoulder. But, I have one or two guys that wear more than one gun, and have a favored side for that particular pistol. -

First try at a full flap holster

CaptQuirk replied to Jake907's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That is a good job on a flap holster. I would have done two things differently, because of the size and weight of the gun... First, either heavier leather, or lining it. 8-9oz should be fine, but, heavier wouldn't hurt either. Second, make the belt loop just a bit wider, to keep it from seesawing on your belt. All in all, a bang up job Sir.- 32 replies

-

- rough out

- .44 redhawk

-

(and 1 more)

Tagged with:

-

Latest Rifle Sling

CaptQuirk replied to georgiapine85's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice work, I like the color too. Did you freehand that Buck, or was it a craftaid? I've had a few folks ask me for slings, after one person asked for a thumbhole sling, padded, and non-slip. They are a pain! You get a lot of calls for these?- 3 replies

-

- rifle sling

- deer

-

(and 1 more)

Tagged with:

-

I'd swear I tried to order from them once, but there was something that stopped me from being able to. Been using Zack White in N.C. for the past several orders, and been mostly happy.

-

Since I come from the old school of graphics and design, I have several compasses. I use them instead of the dividers that I don't have. The lead leaves a mark you can see, and even leaves a shallow depression for the stitching, but comes off pretty easy with saddle soap or oxallic acid.

-

My quick draw knife sheath pattern

CaptQuirk replied to builderofstuff's topic in Patterns and Templates

@garypl-The blade actually doesn't come in contact with the rivets, as they pinch the leather tight. At least, it shouldn't touch the rivets.- 15 replies

-

- quick draw

- knife sheath

-

(and 1 more)

Tagged with:

-

That is an interesting border. Is that an inverted meandering stamp?

-

My quick draw knife sheath pattern

CaptQuirk replied to builderofstuff's topic in Patterns and Templates

@garypl- The tip of the knife goes in at a downward angle, through a tunnel that is between the 2 sets of rivets. Once the blade is in the tunnel, as you push the handle into the case, the leverage folds the blade back. It does not close all the way, because the front set of rivets.- 15 replies

-

- quick draw

- knife sheath

-

(and 1 more)

Tagged with:

-

Buck Knife Sheath

CaptQuirk replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks as good as always. How did you do the welt on this one? -

-

Thanks Guys, for replying to my Hijack. The guy is apparently never happy with anything, or so I've been told. Thanks Dave, for referring him to me. Anyways, I would have to remove a strip of .22 cartridge loops to split the back. He would not go for that. So, I just wanted to stretch it enough in the front and try to center the buckle somewhat, without moving the holster too much. Not to mention, it just looks goofy with 15" of tongue.

-

@Dwight-I am so glad this thread popped up! *HIJACK!* I have a fella with a Bianchi belt that doesn't fit anymore. When he said he had bought a belt at TSC, and wanted to "cut off a hunk, and rivet it to the tongue", I should have let him. Instead, I carefully removed the original tongue, made a copy adding 3" to the middle of it. I also added 3" to the belt flap under the buckle, at the request of the owner. Keep in mind, this is exactly what he asked for, 3" pieces both ends. I even got the color fairly close to whatever faded out brown it is. It didn't work. First, the buckle had shifted to the left a few inches. I tried to explain why it did, and got just blank stares. He spent a couple minutes fighting with buckle, trying to fit the fat square pin on the buckle, into a round hole in the tongue. That was my fault, in not making the hole larger, but I was able to buckle it with little effort, and knew the hole was going to stretch some. Lastly, the end of the tongue did not reach all the way to where the buckle strap started. So now, he wants the tongue longer, and thicker, even though the leather I used was a good 1-2oz heavier than the original. What I want to do now, is extend the tongue 3 more inches, and extend the buckle piece 3". The belt was a size 36", and needs to be a size 42". That just doesn't sound right though.

-

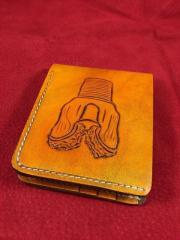

That is a very clean looking finished project. Almost looks machined.

- 21 replies

-

- sheridan carving

- wallet

-

(and 1 more)

Tagged with: