-

Posts

1,431 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Stetson912

-

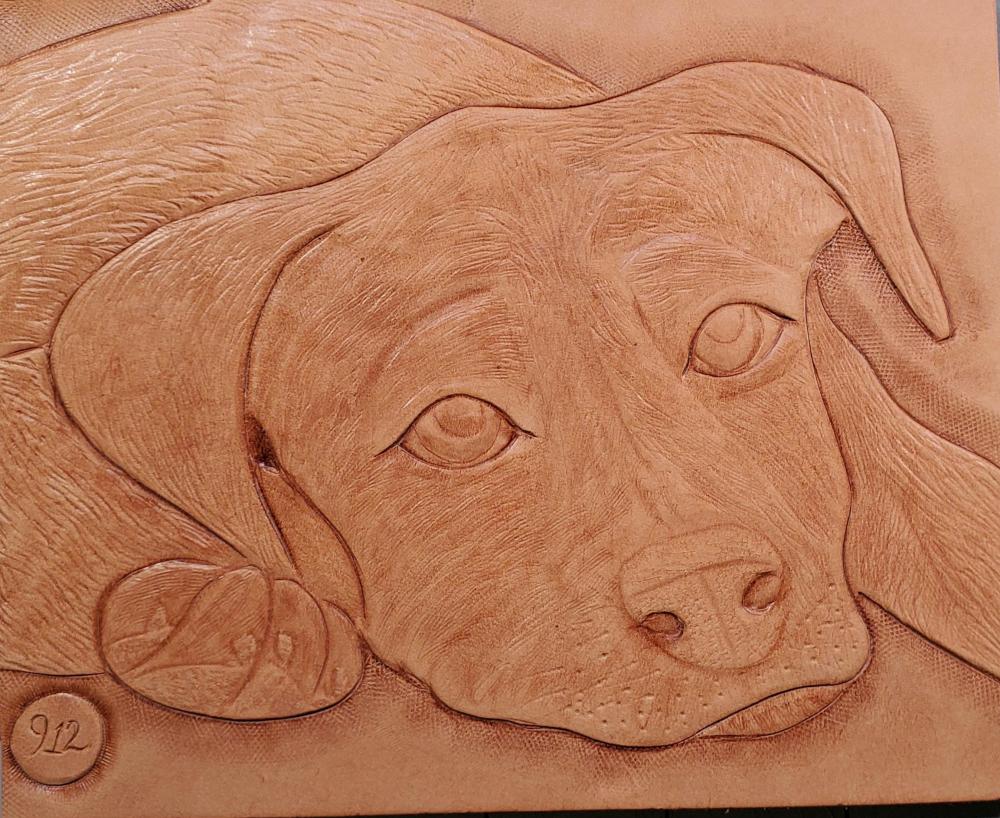

I've been trying more figure carving lately. This was my sister's dog. I had a cute photo of her and thought I would try it out. I need to work on the hair texture and some other shaping but not bad.

-

The nose except for nostrils, top of head and bottom of ear i dont think should be cut. The eye isn't quite right either. Eyes can be tough. You want to start deeper in the corners and fade your cut to nothing in the middle of each eye lid. Start in the corner and do half the top fading to nothing then do the other side. Repeat for the bottom. You should have 4 cuts total for the eye. Bevel the eye the same way, deep in the corners fade to light in center top and bottom. A modeling spoon can help smooth out beveling as well

-

Sheath for Spoonmakers's Adze

Stetson912 replied to Woodshed's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well, you kn ok w how to cover your adze... hehehehe Looks great in all seriousness -

I'm sure there could be, it would be nice to have a section dedicated to it where people could go to trade

-

Definitely find me on there. I'm always down to trade. Ill be making some more sometime haha It really is. "Leather artists trading cards"on Facebook if you are interested

-

Thanks

-

He is indeed. Apparently it isn't a new thing, but the group really brought it to life. Personally I haven't heard of it before. He is on there, rex goblet, I've seen Peter main, and a lot of other great artists. Definitely get in that group. And look me up 912 leathercraft

-

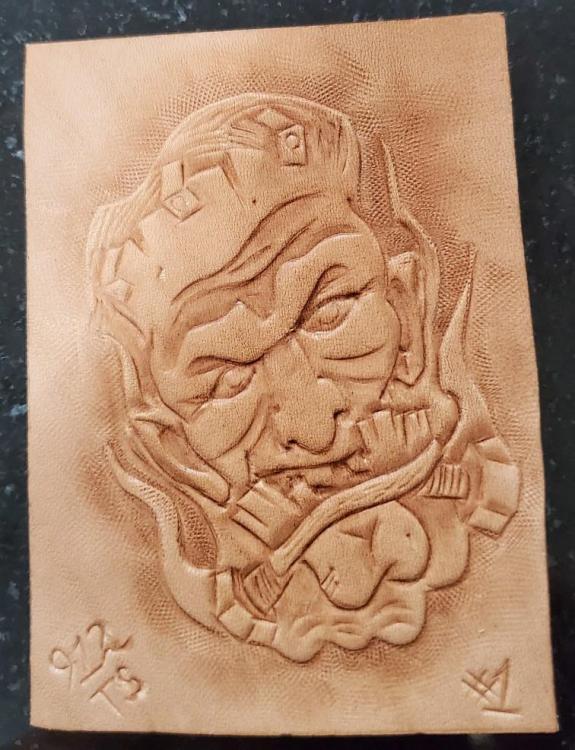

Jim linnell has a group on Facebook called leather artists trading cards. The way it works is you make up a card with tooling or stamping or whatever you want. Recommended size is 2.5 x 3.5 inches from 4/5oz (but this isn't a required dimension or size). The idea is to keep them relatively small. Once you have one for trade, you can post it saying it's up for grabs or you can ask a specific artist to trade. Final communication is done through pm on Facebook usually then you just send your card to the other person and they send you one of theirs. There are a lot of great people there already and some incredible work being traded. People even have their kids making and trading them which I think is awesome. And, beginners and experts are encouraged to trade with each other. Skill doesn't really matter, its about the community and keeping the craft alive and exciting. The cards make it real easy to collect other artists work too.

-

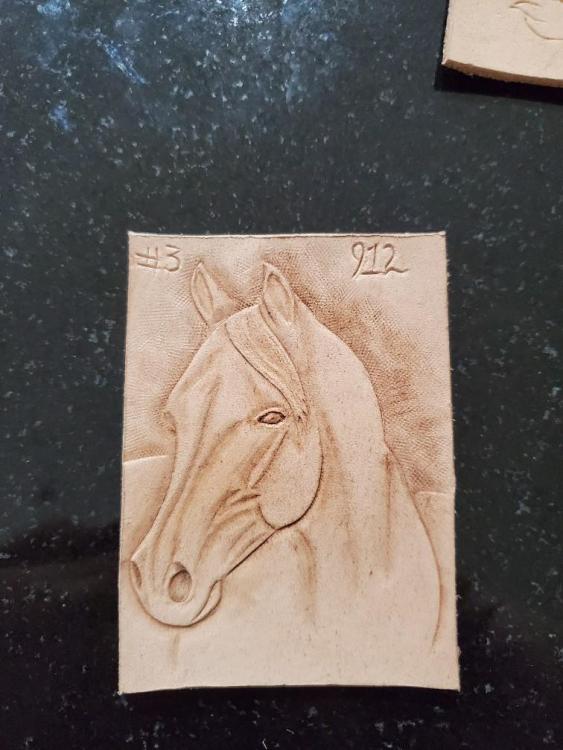

Thanks again haha I traded frankenstein and the horse with people in France and UK. I colored them (albeit not very well) but they came out ok

-

Do you mean stitching the corners or making the turned edge meet nicely when you turn it? For the first, a small round hole instead of angled hole will help stitches lie better. And i like to start in the corners and pick towards the middle. So my stitching lies perfect in the corner. Unless I round my corners, then it doesn't much matter. For the turning, you simply clip the corner off. Then when you turn the edge they line up nicely . Hope my silly drawing makes sense.

-

Roper Wallet

Stetson912 replied to DustinSmith's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice design -

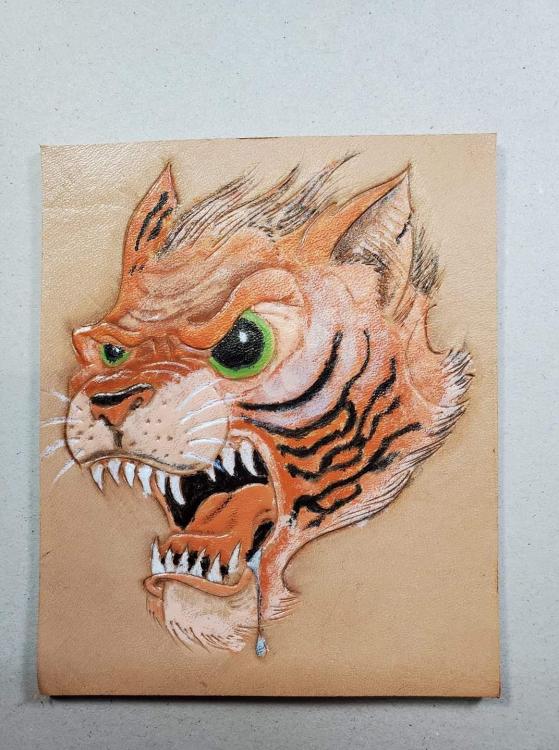

Thanks. All are on 'cards' 2.5 x 3.5 inches i colored some of them. Traded most of them haha

-

I did. They are real cheap acrylics though. I do want to unvest in good paints like angelus now. I only jad a few basic colors to use too, black white red yellow green and a blue so, getting a good orange was a bit tough for me hahaha

-

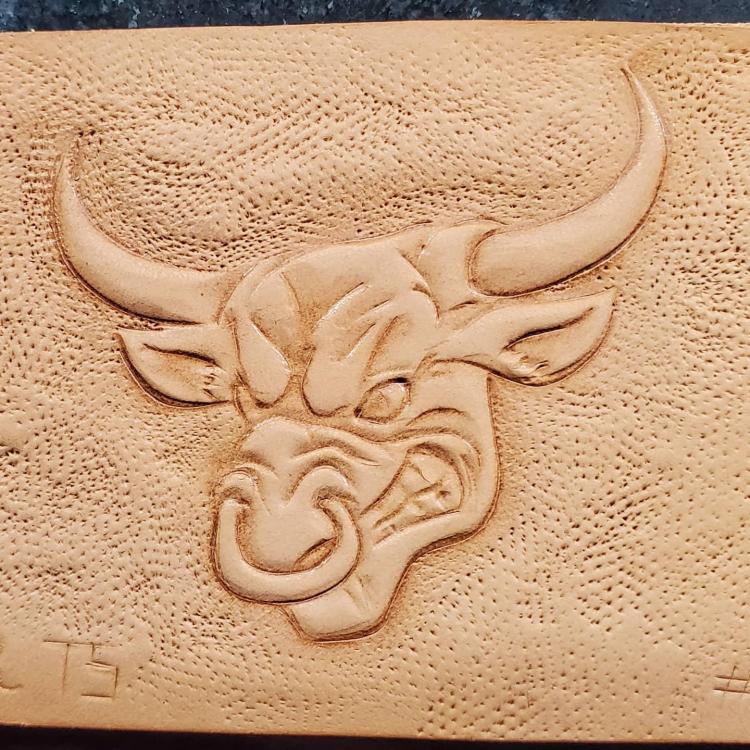

Thanks. But the design is borrowed haha one i found a while back and rediscovered the other day

-

I tried painting again. It came out alright I think. I need better paint haha... oh, and a clue as to what I'm doing would help too.

-

These are some small cards I tooled up recently. Just thought I'd share them here along with my other outlets.

-

There are a lot of ways to do it. Dustin loftis and Don gonzales draw in pencil straight to the leather. I cant do that. For me it depends. Usually I get velum or thick tracing paper to trace what I want to tool. Then I cover my cased piece in plastic wrap and then trace the pattern on the leather with a stylus. The plastic wrap keeps the tracing from getting damp and tearing and curling. Sometimes I print something to size on regular printer paper. Then I use clear shipping tape and the both sides trying to minimize tape overlap. Then I can just set that on the cased leather and trace.

-

Hmm, this is tricky. The problem I forsee is that the collar will inevitably need to be larger than the quiver. This is due to the leathwr thickness. The collar will end up being larger by the thickness of itself and the quiver leather thickness. You might be ok using a thin leather that would stretch better. Since it is decorative, I'd recommend 2/3 oz. However, if you are to use thicker leather you'll have to figure the dimensions of the collar. If it were me, I would have my 3.5 inch dowel, wrap my quiver leather around it, then wrap my collar leather around that. This gives you the proper length for the collar. For gluing, I believe you would need to glue on a curve so the quiver and collar match up (again because the collar will be wider) then stitch. It won't be flat exactly but it won't be a complete cylinder either. Dwights method is far simpler, but I do feel it depends on what type and thickness leather your collar will be made from. And honestly. I would try dwights method first (on scrap) due to its ease of execution.

-

This was my concern too. Not just that but you could make people think you're reaching for your gun rather than your phone. Just knowing how people are, you might get into some trouble with that. Never know these days

-

Matched Pair for J Frame S&W

Stetson912 replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice work as usual Josh. Would you explain those two screw spacer dealies for me? Are they spacers or for tension? I don't think I've seen them used before in leather. -

Playing around a little

Stetson912 replied to Alric77's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Sometimes he discounts them. Just a thought was all there are a lot of classes I want to get haha. It does add up quick -

Playing around a little

Stetson912 replied to Alric77's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That is very interesting. Especially on a holster. I like the.leaf stiffener too. I've never used horse wither, is it hard to work with? @battlemunky just something I remember seeing (I haven't taken or actually seen the lesson personally) but jim linnells elktracks studio has a lesson teaching how to do wood grain. Search elktracks studio and it'll bring up his site. I imagine its done mostly with a swivel knofe and modeling spoon but I can't really say. Just something I thought you may be interested in -

Sounds like a plan. I wanted to make some matters too out of some bolts. So, that's another idea I have. Just thinking of textures for that. I like your handle too, came out great