-

Posts

1,422 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Rockoboy

-

Hi there, I am not sure if you have seen my recent post looking for Consew parts to replace part's on my Toyota machine. Apparently there are no Toyota parts, that I need, in Australia.

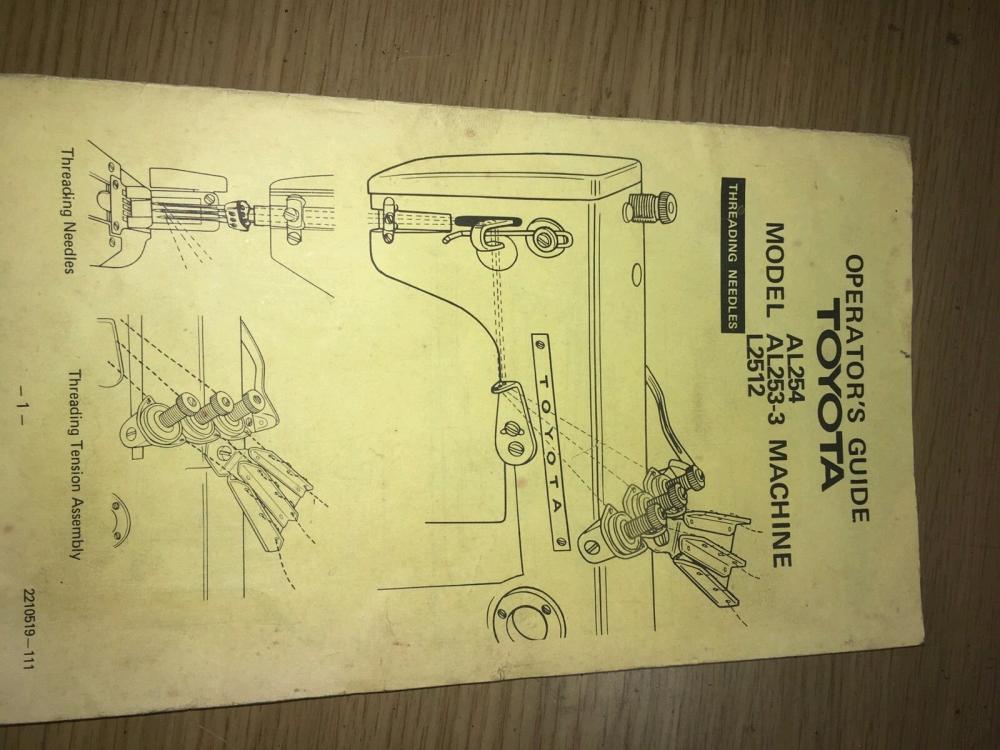

The part I need (sorry I don't have a part No.) is a take up lever for a Consew 355. I am reliably informed this part will fit right in where my Toyota DT6 AL254 has a broken part. The Toyota part No. is 2210102-021.

Kindest regards

Brian Fewson