-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

servo motor Servo motor with syncro and speed reducer

DonInReno replied to Reacher10's topic in Leather Sewing Machines

Sailrite should have a cogged pulley that will work - they use it on the industrial servo in their catalog. At least as of a few years ago the cogged servo drive pulley was available separately. The XL timing belts are all 1/5” in pitch, but do vary in width. There are 1/4” wide, 5/16”, and 3/8”. You will also see metric sizes, but they are the same belts, just listed in metric widths. You’ll be ordering the belt based on the number of teeth, the width and also what it’s made from - specialty belt suppliers will have half a dozen different constructions, but most sold on eBay or Amazon are ordinary black rubber. -

TOTALLY BUMMED OUT!! CANT GET A COBRA Class 26!

DonInReno replied to KennethLee's topic in Leather Sewing Machines

I hope you get that Cobra! I’ve long been impressed with the brand loyalty with Cobra (and CB) and regardless if it’s better or not than any other brand there’s nothing better than saving up for something that excites you! -

Reliable Barracuda and its look a likes

DonInReno replied to Trouthunter's topic in Leather Sewing Machines

There is good news and bad news.... The good news is that many of clones of this type of machine share the design and parts interchange for the most part. More than a few of these machines list 92 weight thread as a max, but 138 is commonly used with little more than resetting the hook to needle clearance, adjusting bobbin tension. Sailrite has most replacement parts and a good online manual - like I said this is a generic design without a lot of difference between companies, although Sailrite machines do have some upgraded parts. These are very compact - essentially the size and weight of an old domestic machine. Another plus is there is minimal learning curve if you’ve only used domestic machines - essentially this is a domestic with a walking foot. The bad news is these aren't very durable and while there is a walking foot, the design lacks a needle that travels back with the material like most industrial walking foot machines do. The lack of needle feed makes stitches in heavy material much less consistent than a true triple feed. If you were to place a triple feed industrial (singer 111w155, Juki lu-562, etc.) next to the Baracuda it would be quite clear it’s not much more than a domestic machine with a walking foot. Industrials are over twice the weight and every part is beefier and designed for day in and out factory work. All three of the domestic machines below are out of the 1960s - it’s a well proven domestic design copied by many makers - you’ll find 95% of the baracuda’s parts are identical in size and design to these. I was looking at few machines of this vintage at a thrift store out of curiosity and actually bought one to compare it to my Baracuda clone...from the underside it would be impossible tell the difference between the walking foot and nonwalking foot. I had one and gave it to a family member who didn’t have room for an industrial and honestly probably only uses it to hem jeans. I warned them that if they are interested in heavy sewing this little machine would be quickly outgrown. I warn people to stay away from this type of machine, but they look like a winning combination on the surface and the intimidation factor of a true industrial scares many into buying them. Edit: I forgot add, any clones with standard size handwheels need to be upgraded to the much larger “monster wheel” or it won’t hardly sew thick material, even though these all have that cute little speed reducer. -

PFAFF 1245 - adjustments sequence

DonInReno replied to vblouindemers's topic in Leather Sewing Machines

Assuming every moving part has a drop of oil on it....literally every place two metal surfaces meet...even if you have oil reservoirs and wicks that are supposed to keep parts oiled add oil manually to everything that moves. Troubleshooting always starts with the easiest most basic things. You might look carefully at the walking foots presser bar to make sure it’s straight and not binding slightly in its bushing as it’s going up. If that’s ok I’d look for binding in the linkages that operate the presser bar. There may be something simple that doesn’t require anything other than a very slight adjustment, something may be cracked, or bent, or whatnot. With a strong light and looking very closely, wiggle everything related to the presser bar in question....then crank it until it starts to bind and wiggle everything again and you might feel what’s binding. Look closely at parts to make sure there’s clearance - slide a strip of paper between parts if you can’t actually see the clearance gap. If nothing looks obvious by this point check the presser foot spring very closely for binding - springs can bind in strange ways at times - clean it and lightly oil. -

Sounds like that works out quite well - you drive through a lot of good picking spots. That’s a nice part of Oregon you’re in....the old growth forests nearby are quite amazing to hike through. The places I seem to travel to to see family are like sewing machine deserts - industrials are few and far between. It’s nice to get out of town for a day drive if a machine isn’t farther south than Stockton, farther north than Chico, and maybe west to north bay if it’s something really interesting. The machines I regret not buying these past few years for my personal collection have all been a two day round trip to get and work just got in the way. Lol

-

Now that’s a decent price - heck I’d buy it if it were nearby.

-

Did you get the Adler from near Los Angeles about a month ago? It looks great. When I first saw the description and price I was convinced it’s worth picking up, but then the location was a deal breaker since we couldn’t get away for two days. Both are very nice indeed.

-

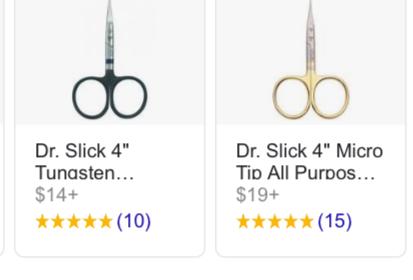

The tungsten scissors for Kevlar and micro tips for everything else. Dr slick makes a dozen different models of fly tying scissors, but these are my favorites for sewing - great quality and the prices aren’t bad.

-

If you keep looking you can buy one that actually works for that price. You may spend 50 hours getting a rusty machine moving again only to find out it’s so worn it won’t sew.

-

I use wd40 to clean and regular sewing machine oil for lubrication. I’ve cleaned really greasy machines that I intended to refinish with cheap carburetor cleaner, which is mostly acetone and will bubble paint, but it dries quick and doesn’t leave a smell. Many people use nothing other than sewing machine oil - bought by the quart or gallon it’s not all that expensive. Toothbrush-size brushes in nylon for painted surfaces, brass for most metal, and stainless steel for rust. Qtips reach little spots, and forceps holding paper towels or cloth scraps reach larger hidden areas well. Having said that, most industrials don’t need a deep cleaning - simply wipe off what you can with a rag and over oil it a bit and anything that needs to get flushed out of moving parts will.

-

There’s very little online about sewing heavy straps and safety harnesses - I’m guessing nobody wants to be sued for suggesting something that later fails for any number of reasons and kills someone - there’s no upside to sharing such things. I still think it’s really interesting and would love to know what industrial strap makers use as far as rules and regulations. Im guessing anything for sale to the general public designed for lifting or pulling has to have a rated load capacity, based on actual destructive testing of a test piece with the webbing, stitch pattern and thread. Materials have to be traceable back to the company that certifies its strength rating - that’s common in a wide range of industries. This article is primarily aimed at sail makers, but it’s an informative read for anyone sewing load bearing webbing. https://www.sailrite.com/How-to-Sew-Webbing-Loops

-

One thing that doesn’t get mentioned in thread guides and marketing info is that the size of thread matters down the road when most of the thread’s strength has been lost - bigger is better for longevity. The shops that sew boat covers are well versed in how long the various threads hold up in years of direct sun - I can’t remember what discussion group they hang out in, but their conversations were quite interesting.

-

How and what you choose to do when bobbin thread runs out depends on the situation and personal preferences. You’ll see many thread racks with space for a few spools of each color and matching bobbins so it’s convent, quick and efficient. I’m not sewing for profit, and space is somewhat limited so I only have a few prefilled bobbins in the most used thread colors/sizes. With time you’ll get a better feel for when the bobbin thread will run out and plan accordingly, but it catches us all, or a thread will break. How you deal with restarts depends on how important looks are - for the most part I pick the end of the thread through the bottom for a few stitches back, tie it, and start from there. Instead of a backtack on the new start I might pull the top thread through the backside and hand tie it. With canvas and thread color matching the fabric I normally just backtack over the end and continue on. Unlike domestic thread, bonded nylon is pretty slick so you’ll have to develop a feel for what it will take to keep the stitch intact over the long term. I’m a fly tyer so it seems natural to put a small dot of thread cement, super glue or something on any hand tied knots or questionable short tacks. Lol Edit: I also use a stand alone bobbin winder and only wind one when the other is empty - always using the bobbin winder as the machine sews meant I always had an extra full bobbin.

-

Roller feet are kind of fun to use on an old machine. Often the roller is sold with a needle plate and feed dog to match, but as long as your existing feed dog has good contact under the roller it will work just fine. Keep in mind most feed dogs for these machines are for light weight sewing and have smaller teeth - heck many feed dogs described for heavy sewing aren’t very aggressive, so look carefully before buying. The flip side to large teeth is they are more likely to mark up leather. The pre-WW2 feed dog on my old singer doesn’t have sharp teeth, but rather large pyramids - I have no idea what it was designed for, but it works quite well with a roller.

-

For the kinds of webbing belts you’re talking about most that I’ve been around are sewn with 138, but it’s very much a design decision. Some webbing with smooth textures might look better with 92 if you are after a sleek look, but I’d still start with 138. When I see webbing sewn with 92 the first thing that comes to mind is they are trying to save money or their machine won’t sew 138. Once you have a big machine you’ll find some webbing looks better with thread larger than 138. Needles are pretty straight forward - use ball nose for fabric or webbing since you don’t want to cut the fibers. There are some good looking cobra-type buckles out there!

-

While you don’t have a walking foot machine, setting the hook and needle is very similar. Check out all Uve’s videos, but this one explains the relationship between hook, needle gap, and needle height you’re looking for. Moving the needle bar up or down is a pretty simple matter of loosening a screw and moving the bar a little.

-

Beginning to look for a sewing machine.

DonInReno replied to mcmuck's topic in Leather Sewing Machines

There are websites that allow you to search all of Craigslist that can turn up some used machines once in a while, but geographically you’re in a tough spot. The Rocky Mountain states just don’t have a lot of big leather machines floating around. Covid also seems to have had an effect on used machines - people are doing more at home and in many places only a fraction of machines are popping up. On the other hand there are some really good deals as people get in financial binds and they need cash pretty quick, but you need to be close by with cash in hand. To be honest, the for sale section here is pretty good, but it’s hit or miss for your area and good deals sell fast. Don’t overlook eBay - machines there are few and far between, but they do come up and sell fast. eBay is somewhat safe, but if the machine is listed as not working and it shows up a pile of junk, you don’t have a lot of room to get your money back. Beware of anything that seems flakey - don’t put any money down to ‘hold’ a machine. The scammers list leather sewing machines from time to time, so be careful. Personally I wouldn’t buy a machine that has to be shipped unless through a dealer or eBay - there’s too many ways to get screwed. I also look at google images - once in a while a used machine on an out of the way place like auction site will show up there, but it’s a big time waster. Overall, you should be checking twice a day at as many places as possible. -

It’s always exciting when someone gets a new machine - you’ll find all sorts of uses for it. Many people will set their machines up for the longer needles in order to have a common needle for walking foot machines as well as any needle feed machines such as your consew. If the style of needle you like is available in the shorter needles, such as the ones you’ve purchased, there’s no benefit going with the longer ones since this is your only machine. The length of the needle won’t change the maximum thickness of material that will fit under the presser foot. With these twin needle machines you don’t have to use it with two needles. Also, many different stitching widths are available and often come as a set including presser foot, needle clamp, feed dog and needle plate. The hooks would also need to be adjusted for the different needle spacing, but it’s not a hugely difficult process once you get the hang of it. Personally I like the same size thread top and bottom unless there is a tangible visual benefit to the different sizes. Keep in mind that your machine and needle feed Singer/Juki/Seiko machines that look similar are also very similar internally so if you don’t find an answer in a Consew manual, it might still be easy to find in other places. My Singer leaks oil like crazy from the upper oil reservoir so leaving a piece of cloth under the presser foot when not being used helps keep the oil from puddling when not being used.

-

Is there a chance you’re moving the material too fast with hand pressure and deflecting the needle enough that the hook point is snagging the thread? The more dull the hook point the more likely this will happen.

-

Help with possible Chandler 167 373 purchase

DonInReno replied to Don Ayres's topic in Leather Sewing Machines

Someone who knows specifics will chime in, but it’s a solid walking foot machine with good reputation. At that price you have little risk in buying it, since you’ll be able to get your money out of it fairly easily - what else in life can you use as much as you want and turn around and get all your money back? Mr. Dyer did a nice video on one: -

The speed reducer gets my vote. It triples the torque at low speed, which is a huge plus in addition to the reduction in speed.

-

Very cool additions!