chrisash

Members-

Posts

2,133 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by chrisash

-

He sure looks as happy as a turkey on Christmas eve

-

Thanks, I never considered that, stored away in the little grey cells for possible future use, (assuming any grey cells left)

-

Hi Brian I dont understand the purpose of the arrow head cutout, please can you explain

-

I find scribing a light line on the leather first and then sewing stitch by stitch is the best way, as the jump action can easily have a mind of its own lightly pulling to either side even when the jump stitch is locked down. Tricky with only one hand on the leather and the other on the wheel, as Brian states lots of practice required but as the only machine it can be forced to do most things and threads up to #138, but 138 gives only a few feet of sewing per bobbin whilst 69 gives a lot more

-

I use one of these, so you can just put a measured drop in the holes and get into small places, but each to his own https://www.google.co.uk/search?newwindow=1&source=hp&ei=Nl3bW7vDKdLgkgWK1KzgDg&btnG=Search&q=fine+detail+oiler&oq=clipart+or+Vector+drawings&gs_l=psy-ab.3...2020.21071.0.21622.27.24.0.2.2.0.88.1618.24.24.0....0...1c.1.64.psy-ab..1.25.1555.0..0j0i131k1j0i22i30k1j33i22i29i30k1j33i21k1j33i160k1.0.iKJMRD0Rj5E

-

I used to have a variety of commercial Barudan and semi pro brother embroidery machines and did the patterns myself We regularly used to use chrome and patent leather often using metallic thread on the barudan with lots of silicon spray to keep it running on leathers Always used ball point needles and on design alternated the spacing of the needle position like a small zig zag pattern to give strength to the leather then do the same with the boundary and three layers of stabilizer, stitches are far to close for leather needles, run at about 100 to 200 spm rather than the normal 800, max in my day 1000spm but even more now days, My 12 head barudan cost £44000 plus vat in the 1980's You really need a experienced designer to use on leather

-

No excuse though of not giving you a estimated delivery time when you first enquired, it's something called service

-

One area where Singer seems to help is that they have photographs of their parts in the parts lists, these can be imported into the cad software and adjusted to the correct dimension by using the data from the broken piece, but maybe replacing a worn part as worn might be a better solution as all corresponding parts are also worn , good arguments for either action. The reason i suggested the 29 was as its low speed, generally used on light leather and seems a lot of parts are no longer available for the popular No 4 series The cost of making is low compared to metal (which is coming down all the time), but few people will invest good money on making low moving steel replacements for retail Naturally its not confined to sewing machines, hobbyists have meen making them for years on different items

-

Hi Matt Go for it mate, probably not long lasting on the heavy duty ones but a low cost probably under £5 say $6 not a great problem if they just last 6-12 months (who knows) and maybe keeps the old iron working Sample enclosed

-

Just a experiment unless someone has tried before, and found it does not work I am willing to make a nylon replacement gear for say a singer 29K that is no longer available, for free including postage as a experiment to how long it would last Just need one person to supply image and full set of dimensions for the replacement both external and internal measurements and i will try to make a nylon copy, preferably something relatively small If someone has tried it before and it was not strong enough please tell me and i wont bother, but many modern machines have nylon gears that work ok if not under great pressure, hence my thoughts on the 29k especially say the small gears in the bobbin area Nothing ventured nothing gained, happy sewing

-

Dont forget Tandy, even though the UK shops are closed, there is still their online store https://www.tandyleather.eu/en/

-

Afraid your to late its already here and the price is dropping all the time as people buy the top end printers and offer the service https://all3dp.com/1/3d-metal-3d-printer-metal-3d-printing/

-

How to make a watchband with edge coating tutorial

chrisash replied to RockyAussie's topic in How Do I Do That?

Amazed by the number of steps and the time it must take to make such a perfect item Unfortunately I am restrained from trying to copy as I dont have the stainless steel egg cup -

They can be finger nail scratches, I have heard of some folk using fine cotton gloves to stop it happening

-

Those 18000k at least keeps your other half happy

-

When your skills are held back by the tools you use, its time to consider buying better tools if they are available and noticeably better Finer tools may add a tiny bit to your work but skill add far more and is far more important

-

Past posts linked into my profile ..about me

chrisash replied to RockyAussie's topic in Leatherwork Conversation

I would be interested about your history with leather, there must be a interesting story from when you started, to how you get to the fine products you make these days -

My first bag

chrisash replied to GJM's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Looks good to me, I would use it quite happily -

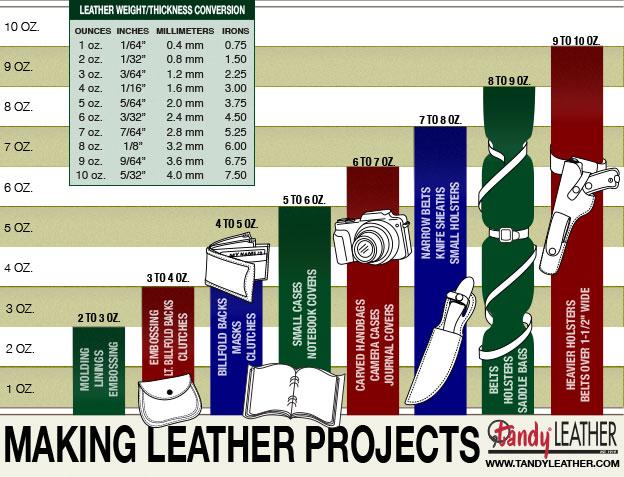

I would suggest it might be worth while looking at these two sites J Wood https://www.jwoodleathers.co.uk/natural-veg-tan-leathers/ they do a economy veg tan shoulder that is good for practice https://www.etsy.com/uk/shop/FletcherHandmade/items he offers some good prices on a different selection of cheap leathers most which may be good for bags or wallets etc Do some research on what thickness is recommended for different items

-

Leatherpro Ak-20 Leather Strap Cutter Spacers

chrisash replied to Anubis78's topic in Leather Machinery

I dont understand why you need imperial sizes when 5 min on a conversion software you would have all sizes converted from imperial to metric and 0.5 mm is quite a small adjustment size -

Maybe smooth edge paint either cold or heated up depending on the method used foe edging, to wide for creasing, just my guess

-

Brad has just published the last part of a series of four parts in making a drawing , converting it to cad, joint venture and last this one of the CAD machine making the detailed part in only 8 minutes, for those of you who have never seen modern production its worth watching, makes you think how easy to make parts no longer available

-

Unfortunately no real message to the main question of "was it worth while" and did he then use these new skills, Basic design is easy to teach, but good design unfortunately often needs flair which you cannot teach

- 17 replies