kgg

Contributing Member-

Posts

3,343 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

I would definitely use my drill press not as a drill but just as a press. I would simply install a hole chisel in the head. For me it would be easier on the arms and with a simple alignment fence on the bed of the drill press the holes would always be aligned with the outside edge of the leather. Since you can set the downward travel of the head and the height of the bed you would get consistent chisel penetration. The only thing is going around corners you may have to change to a single or double tooth chisel. You could also use a press similar to the: i) Amazon at $169 CA which I don't think would give constant alignment of your holes as the head can swivel around the support arm and it would be only a single purpose machine. ( www.amazon.ca/dp/B07TBKGFBW/ref=sspa_dk_detail_2?pd_rd_i=B07TBKGFBW&pd_rd_w=ov56M&pf_rd_p=8e308614-8b7b-45e9-9526-75d8e163854c&pd_rd_wg=vxfZ1&pf_rd_r=RZBGPHJ7K41F0NFTQT3C&pd_rd_r=a1ccbbd1-5dbd-4acb-9e8c-e50e934d47a5&s=kitchen&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUExVEhZNzlUWElUMUlOJmVuY3J5cHRlZElkPUEwNDUyMTMzM0tKWDNVNVBOTDdXNyZlbmNyeXB0ZWRBZElkPUEwNzgyNDM2M05IOUlCMEtINVoxUSZ3aWRnZXROYW1lPXNwX2RldGFpbCZhY3Rpb249Y2xpY2tSZWRpcmVjdCZkb05vdExvZ0NsaWNrPXRydWU&th=1 ) ii) Tandy's Craftool pro hand press ( www.youtube.com/watch?v=SKWkyJg510g ) My attitude would be use whatever works best, gives constant results with equipment that hopefully has more then just one function. kgg

-

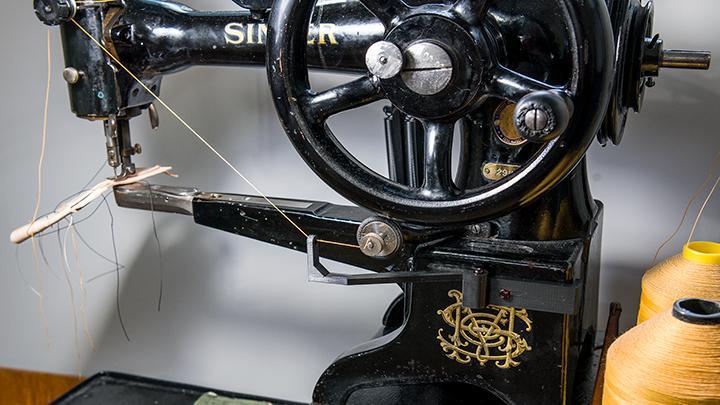

I think it is a 45w-53. It is one of oddities of being a left handed sewing machine made for left handed users as indicated by the thread tensioners, thread path, the location of the pressor foot being on the inside and the tilt of the foot drive peddle.If you got a better picture of the oval nameplate it would be easier to confirm. kgg

- 5 replies

-

- singer double stitch

- singer29-4

-

(and 1 more)

Tagged with:

-

Big Barb - The Consew! (255 RB2 - I think!)

kgg replied to suzelle's topic in Leather Sewing Machines

For all those who want to try and use a pulley to reduce speed on their machine here is a easy online calculator for both single and multiple pulley configurations: https://www.blocklayer.com/pulley-belt.aspx kgg -

You never mentioned what the purchase price was. The best case would be too get a quote for re manufacturing / repairing / installation labor of the damaged part and subtract that from the purchase price. Worst case is the value it would bring as scrape metal. kgg

-

What I see: First photo of the turn. i) If you started your seam from left to right: your got 3 stitches that were long then two longer stitches then one medium length then nine short stitches then it started go go all over the place until you basically got back on track on the straight run on the seam on the right hand side ii) If you started your seam from right to left: nice straight stitches of uniformed length and then they begin to go all over the place as you enter the turn before finally starting to straighten out. Second photo of the turn: i) At the point of your stitches where they are going off the pressor foot impressions are not visible like of those where the stitches are good. The thread tension appears to setup nicely. I am guessing the problem lines in: i) The amount of pressor foot tension where it is not holding the leather down with the necessary tension to allow for slight turning deviations as you start and work through the turn. ii) Using a right hand side pressor foot versus a left hand side pressor foot. iii) The stitch length adjuster is able to move ever so slightly up and down which maybe caused by the stitch length locking surface isn't machined perfectly to the stitch length indicator surface. Are you using the same pressor foot configuration as the one shown in the video?? kgg

-

Consew 206-RB4 oiling mechanism and sewing speed?

kgg replied to sojourner999's topic in Leather Sewing Machines

There are few reasons that I know of: i) Sometimes people just like the look of the larger thread on the top side where the addition strength of the top thread wasn't necessary. ii) The machine wasn't designed for V138 top and in the bobbin sewing but you can cheat sometimes if you use a smaller bobbin thread as it is easier to haul up the smaller V92 thread through the larger size hole created by the larger needle required for V138. iii) Their is misinformation out on the web that you should use one size smaller thread in the bobbin then that of the top thread. v) You can get more thread on the bobbin to reduce bobbin changes. vi) Worn or damaged parts that create tension issues. kgg -

Consew 206-RB4 oiling mechanism and sewing speed?

kgg replied to sojourner999's topic in Leather Sewing Machines

Glad they helped. A little cleanup and she should be good to go. Best of Luck, kgg -

Consew 206-RB4 oiling mechanism and sewing speed?

kgg replied to sojourner999's topic in Leather Sewing Machines

This may help, I don't see a pump. https://usermanual.wiki/ACE-EASTMAN-PDF/Consew206Rb4PartsBook.1436973753 khh -

Tension setting for sewing multiple layers in one pass

kgg replied to palvim's topic in Leather Sewing Machines

What size of thread and needle combination are you using? kgg -

I like the video and hope you have good luck with the contest. kgg

- 7 replies

-

- contest

- small business

-

(and 1 more)

Tagged with:

-

Really like how you revamped the singer base to accept the motor and reducer. kgg

-

I like the way you set the Boss lower so you could create a table top surface for it. kgg

-

The prices during these times are all over the place. In Ontario, Canada private sales for an original Juki LU-563 with a clutch motor people are asking between $500 ($390 US) to $1000 ($780 US). Before Christmas Juki LU-563 machines in private sales were lasting a weekend before being sold now some are still listed after three weeks. I did sell my PFAFF last summer for $500 ($390 US) with a clutch motor in good physical and mechanical condition and happy to get that for it but it took a few months to get rid of it as PFAFF's aren't very popular. Me, at $800 US I would probably pass on that machine to find an original Juki LU-563 and not a rebadged Juki LU-563 or seriously consider buying a new Juki DNU-1541S for about $1800 US. kgg

-

What I understand: JUKI 1) Juki LU-562 there two models (one with and one without reverse) 2) Juki LU-563 there were three models ( one with reverse; one without reverse; one with reverse and 10mm stitch length a LU-563-3) 3) Juki LU-562 and LU-563 use the same needle system and could accommodate needle sizes from #18 for v69 thread to #23 for v138 thread for both the top and bobbin thread 4) Juki LU-562 and LU-563 had a pressor foot lift of 4mm by hand and 10mm by knee lift 5) Juki LU-562 and LU-563 had a 7mm max stitch length except the LU-563-3 that had a 10mm max stitch length 6) Juki LU-562 had a 3000 spm rating while the LU-563 and LU-563-3 had a lower rating of 2500spm 7) Juki LU-562 had a small bobbin 8) Juki LU-563 and LU-563-3 had a large bobbin with automatic lubricating Reliable 1) Reliable MSK-1245 is a clone made in either China or Taiwan of the the PFAFF 1245 not an Alder. I think the Chandsew is a rebadged Juki LU-562 or LU-563 (I think made in Japan) sort of what Landis did on some machines. If it has a big bobbin it is a Juki LU-563. If I had to choose between the two I would go with the Chandsew. I had a PFAFF 1245 and got rid of it as parts were expensive, had a small bobbin, didn't like how you had to move the stitch level to get it into reverse and generally disliked the machine. With that said I am basing that on both machines being in good operating condition. kgg

-

Nicely done. kgg

-

I also looked and came to the same conclusion. kgg

-

This is a high speed needle feed machine made for fabric and the max size needle is a #18 needle for a max size thread of V69. For me the major downfall with any machine having electronics is the electronics as I like to to keep my machines very basic mechanical machines. If the electronics goes out it is going to be expensive to repair, if you can get the parts. This machine is missing the pressor foot, needle feed dog, cover plate and probably more. To me the price is way over priced for a fixer upper that will not do leather. kgg

-

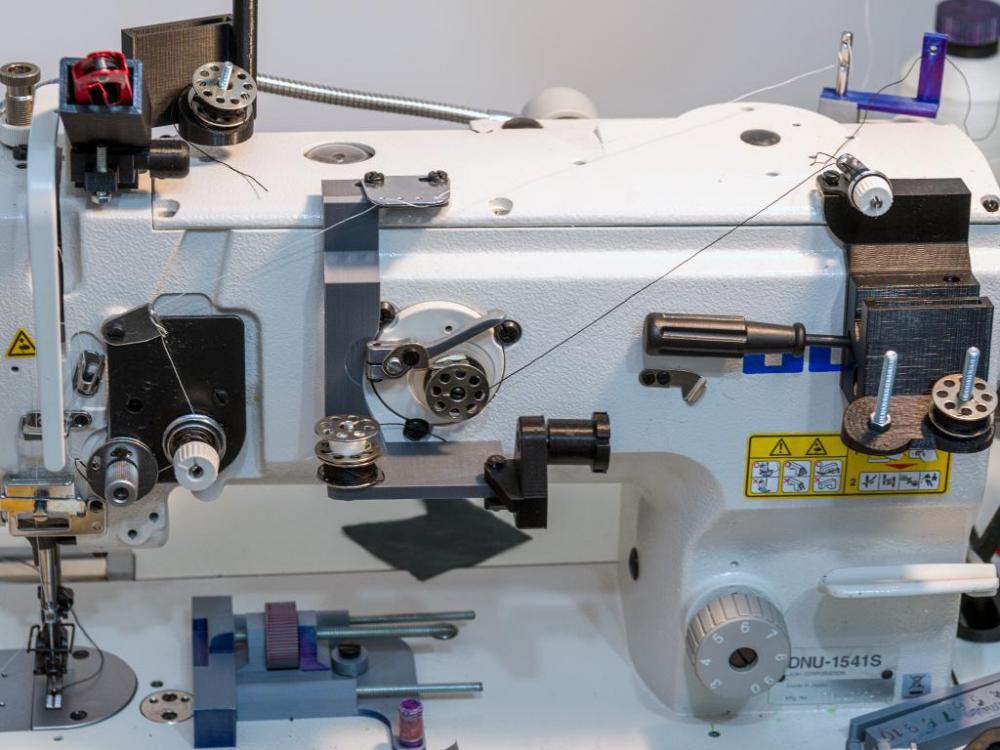

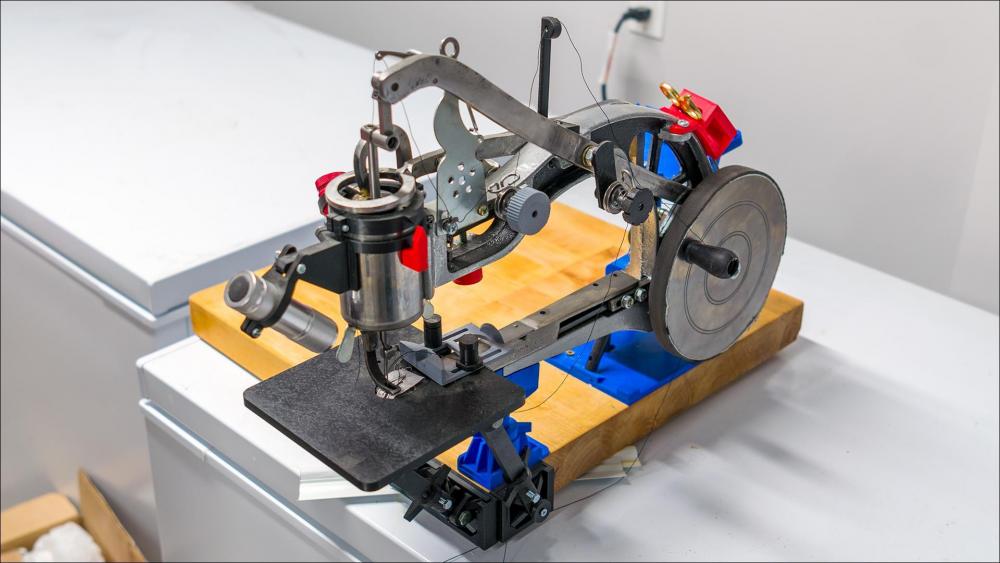

It is 3d printed as well as the adjustable support legs and the table attachments for it. My machines except for the Tinkers Delight live in the bedroom across from me. Those are some, not all, of the accessories / attachments that I have designed and 3D printed for my machines just to make life a little easier. My main consideration for any accessories / attachments is that there are no additional holes needed to be drilled into the table top or sewing machine. What I have shown in the photo's are: i) Kobe LS-1341 clone: turn table style binder tape dispenser with ball bear race; binder tape guides; micro table attachment to allow for the use of standard flat bed binders / edge guide; top mounted swivel bobbin/ snip holder; lower swivel bobbin / snip holder; hands free bobbin thread cutter with needle / bobbin caddy ii) Juki DNU-1541S: top mounted swivel bobbin & snip holder; lower swivel bobbin & snip holder; hands free bobbin thread cutter with needle / bobbin caddy; caddy for tools / needle / bobbins iii) Chinese Patcher a Tinkers Delight: adjustable double light caddy (front gray led light and far side red led light); pressor foot position indicator (red arrow); Red colored rear mounted scissor holder; Blue colored rear mounted 1lb bobbin thread holder; Blue colored rear mounted top thread holder; Black colored 6" drop down adjustable table top; Blue colored adjustable height nose support (prevents any forward tipping of the machines arm); Blue colored machine mounting base iv) 1949 Singer 29k-71 swing away bobbin thread guide ( replaces your finger so you can wind a bobbin as you go ); double 1lb spool holder; double spool thread guide; double thread guide for top and bobbin thread. kgg

-

The Kobe is a LS-1341 Clone, Juki DNU-1541S, Chinese Patcher (Tinkers Delight), Singer 29K-71 (1949) my Juki 1181n is setup similar to the 1541S

-

Patching a strap for yourself is at your own risk but doing it for someone else to be used in a commercial application like for a tow truck driver you could very well open yourself up to being liable should anything happen to a strap that you fixed up. The Singer 20U is a high speed drop feed machine made for light weight fabric and isn't really suited for much more. The machine was made to handle light weight threads and maxing out at V69 and a #18 needle much like your domestic sewing machines. kgg

-

I agree. My expectation of a new anything particularly a sewing machine is that it works out of the box except for minor adjustments, thread tension type stuff. Unless it is a Chinese Patcher which is a "tinkers delight" or a used machine I expect it to sew properly in forward and reverse for the needles sizes and thread sizes it is rated for. Yes, I can do some of my own repairs but not everyone wants or should be a sewing machine mechanic. If a machine requires 4 or 5 hours of adjustments before it sews properly what does that say about the initial quality control at the manufacturing level. Like the old saying "you get what you pay for" the difference that separates dealers is the level of service they can provide. I do like brand name equipment and Juki has never disappointed me, yes they are more expensive but the quality difference can be great and noticeable. I have test rode a few clones and I do admit some were good while others I would put them in the "sounded like a bucket of bolts banging around" category. kgg

-

I believe Nikos69 bought a Techsew 2750 from him about 2 years ago. You may want to drop him a PM and see what his experience was like. Also you could do a search on this forum for ---- "industrial sewing machine man”---. You should come up with something. The last two new machines I bought were a Juki and a Juki clone. I got them fresh off the boat so to speak, packages unopened. Saved the check over / setup fee. The Juki sewed perfectly out of the box while the clone needed a couple of small adjustments. kgg

-

Just a little food for thought since most everyone is cost conscious. I figured I'd see what the cost of a Singer 29k back 100 years would have cost versus the average hourly and yearly wage. What I found sort of surprised me. 1) Average 1922 hourly wage $0.35 Average yearly wage $728 for 52 weeks of work based on a 40 hour work week. Average cost of a Singer 29K was $60 which works out to about 4.28 weeks of salaried work. 2) Average 2021 hourly wage $26.78 Average yearly wage $54,630 CAD for 52 weeks of work 3) If the Singer 29K was being still made what could we expect it to cost? 4.28 weeks of work X 26.78 hourly wage X 40 hour work week = $4,584.74 CAD In Canada the cost of a new overseas 29K clone ranges in price from $1079 and $3600 while a brand name Claes Model 30 costs about $7000. kgg