kgg

Contributing Member-

Posts

3,343 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

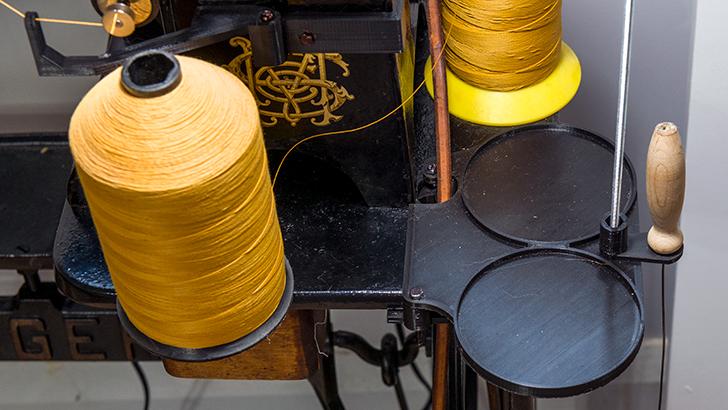

-

I have made some 3D printed upgrades to my 1949 Singer 29k-71 which can be used on other versions of the Singer 29K as well as other machines like the Consew 29, Cowboy CB29, Cobra 29, Techsew 2900 to name a few. The upgrade requirements: i) Simple ii) No holes to be drilled or tapped into either the sewing machine or the cobbler base. iii) Installed / removed in under 5 minutes with no special tools. 1) Photo 6 is a view from the pulley wheel side showing a Double 1 pound spool thread stand and threading rod holder mounted to the cobblers base (Photo 5). The top thread stand guides can be positioned and locked in place as needed. The height from the cobbler base to the thread guide holes is 2 and 3/8 the height of the thread spools. The threads then leaves the thread stand guides and goes to another double thread guide to keep the threads separated and keep the thread angle down. This double thread guide replaced the original 4 oz spool pin. Both threads then go to under the lever in the oil pot and exit through the two holes in the end of the oil pot. The inside thread then carries on as the top thread to the top thread tensioner and to the needle. the outside thread carries on to the darning tensioner to be utilized for the bobbin thread. All the instructions I have read or viewed for winding a bobbin either with the hand wheel on the front or the side want you to wrap the thread around the bobbin and guide the thread onto the bobbin. Which to me seemed OK but there had to be a better way that gave a more consistent winding of the thread onto the bobbin and allowed me to wind a bobbin while sewing. To accomplish this I used the Darning Tensioner was used to give consistent, adjustable tension as I don't darn and haven't really figured out what the advantage it would provide over the top Thread Tension for darning. If someone can explain this I would really like to know as I can't seemed to find any information in the 29K manuals. The next step was to make a guide that would replicate my fingers position and properly guide it onto the bobbin (Photo 4). The guide when not in use folds back against the machine. For those that use the hand wheel mounted to the main drive shaft I do have a simple design just haven't 3D printed it yet. 2) Photo 3 is a view from the front showing the top thread path to the head and the bobbin thread path to the bobbin being threaded. All comments greatly appreciated. kgg

-

You can't go wrong with a Juki. When you decide to sell it you will probably have an easier time and at a high price then a similar clone. kgg

-

You didn't mention what are you planning on sewing as there maybe other options that maybe better suited for want you want to sew. In the manual operated machines there are only three options I know of and all three can handle up to 3/4" thick: Weaver Cub (~$1800 US) rated max thread V346, Cowboy Outlaw (~$1400) rated max thread V346 and maybe V415 and the Tippmann Boss (~$1000) rated max thread V415. kgg

-

I would first recommend a Juki LS -1341 if you can afford the price of a new one about $3500 CAD and you don't need a 441 class machine. The Cowboy and the Cobra you noted are in the 441 class machines while the Techsew 2750 and the Juki 1341 are in the 1341 class of machines. So you need to figure out if you need / want to sew 7/8" thick or 1/2" thick stuff, what needle system is needed, the max thread size thread for the top and in bobbin for the machine you want to use in your stuff. In the 441 class machines the cost effective way is with a clone as the Juki TSC-441 is just to expensive, north of $9000. In the 1341 class machines if your budget doesn't allow for a new Juki then a used Juki LS-1341 from a dealer in the Toronto area can be had for about $1500 complete with table and servo motor. If you want a new clone that can be purchased and serviced in the Toronto area then I would recommend the KOBE LS-1341 (Japan Sewing Machine -- Chris at (905) 764-0100) which is a Juki LS-1341 clone just an awful lot more cost effective. I actually went to get a new Juki LS-1341 and wound up giving the Kobe a try about a year ago based on the cost difference with the full intent of selling it and getting a new Juki LS-1341 if it couldn't / didn't work out but so far no problems. The downside of the clones on the average is ease of resale and resale value when compared to comparable Juki's. Buy Once, Cry Once kgg

-

The machine does appear to be in good shape. The badge may say Tokyo, Japan but I would check with a Consew dealer or call Consew to confirm as to where it is manufactured. Juki even has some machines that are now made in China. A couple of other things you need to check for that machine are: The max needle size will it take. The max thread size for the top thread. The max thread size in the bobbin, some machines can not take the same thread size in the bobbin as the top thread. What would be a similar Juki model. Is it a clone of the Juki DNU-1541S or the LU-1508 N. In the upholstery class of machines they max out at 3/8" sewing thickness depending on material and thread size. For what you have described as wanting to sew I think a Juki DNU-1541S should be quite capable of handling it. The cost of a new Juki DNU-1541S, table and servo motor is probably in the range of $1800 US. Clones are usually cheaper. Buy Once, Cry Once. kgg

-

Servo motor from Dürkopp Adler with very low speed.

kgg replied to Gymnast's topic in Leather Sewing Machines

That is a amazing slow speed but for the average joe the cost of the motor I think would be out of reach and to complicated for most hobbyists. I use the old fashion plain jane "brush" motors on all of my machines easy to repair and cost effective. I also don't have speed reducers installed on any of my machines. My attitude is two fold: I follow "KISS" so no computer /electronic stuff to screw up as I have enough user errors to contend with as it is, "me". If I have to use a speed reducer to get added torque to gain punching power I am using the wrong machine. The Sairite Workhorse servo manual may help ( www.manualslib.com/manual/1644613/Sailrite-Fabricator.html ) as it is a copy of the Reliable servo motor. kgg -

Smart decision. kgg

-

Smart decision. kgg

-

Good point. kgg

-

I do like the pedestal style bases so much more space. On my Kobe LS-1341 (clone of Juki 341) the center of the base of the machine hangs over the table top by very small amount. I think a good style of base for a cylinder machine would be like those old case iron cobbler bases that were used for the Singer 29K. When I can find another case iron cobbler base I am going revamp/modify it so I can mount the LS-1341 and servo on it. kgg

-

I agree try and get the bobbin case and thread or anything else that may be there from the previous owners use out. If you can slowly hand-wheel the needle up and down chances are the safety clutch (hook drive) has disengaged and needs to be reset from the under side of the machine once you get the bobbin and tangled thread out. There is a pin that needs to be pushed back in and you need to turn the hand wheel in the reverse direction until you hear it snap back in place. The procedure is on page 18 of the PFAFF 245 / 1245 Instruction Manual for the old German casing. kgg

-

Great video showing the difference in table function but most importantly table construction / strength. Also the bag is damn nice. kgg

-

Thank you. This machine is on a out-the-door journey as I really don't need a second Singer 29K-71. kgg

-

I have the 550 watt brushed motors with a the speed limiter dial and pot on a two Juki flatbeds (DNU -1541S, Juki DU-1181N) and also a cylinder bed KOBE clone of the Juki LS-1341. None off my machines have a speed reducer pulley installed. The brand / label on these motors are KOBE which is similar to all the other brush servo motor brands. I think they probably are using the same design or coming from the same manufacturer and then branded / labeled XXXX. I do have another new spare 550 watt servo branded / labeled Rex and you can't tell them apart. If you are planning on the Sailrite or Reliable with the standard domestic motor on them I would suggest installing the larger pulley wheel which Sailrite calls the Monster wheel. Sailrite does have a replacement motor called the Worker B which is just a straight swap out that should give you much better torque and speed control but a bit pricey. kgg

-

I have a couple of Singer 29k-71's one a 1949 with the case iron cobber base and the another from Landis a 1998 version that has a 52 to 1 helper geared motor. I did a short video using the 1998 Singer 29k-71 and plan on doing another of the 1949. Hopefully, someone may find it helpful if they are planning on purchasing a used machine or even a new clone of the Singer 29K. It is very easy to say a machine should sound / operate this way or that but I hope the video will provide a good base line. These machines were flushed and oiled using my redneck oil. The link to the video is https://odysee.com/@SingerSewing:0/singer:a Comments always welcomed. kgg

-

Thank you both. kgg

-

I am looking for a basic no frills motor driven machine that can handle V346 thread. What ever happened to the basic GA5-1 and GA5-5 machines? They seemed to be popular six or seven years ago. Were they discontinued because of problems? kgg

-

I think the CowBoy CB105 / 2500 / 3200 are threaded similar to the Adler 105. kgg

-

That is a really nice restoration. kgg

-

You didn't mention the colors you would like. Two things that can make your project, needles and thread. Buy brand names for both. Needles: V69 thread minimum size 16 V92 thread minimum size 19 V138 thread minimum size 22 Thread: The brand of thread that has never failed me is American & Efird ( www.amefird.com ) which is made in both Canada and the USA. These guys have put some engineering effort into designing their threads. For the type of thread and specifications go to ( www.amefird.com/products-brands/industrial-sewing-thread/ ) and select Fiber type or Application too see which thread specification meets your needs. For colors go to their color card section ( www.amefird.com/color/color-cards/ ) for that type of thread. In Canada it can be purchased directly and I assume it would be the same in the USA. Their threads are not cheap but definitely beats not having to deal with the frustration and eventual throwing out of a spool of cheap stuff because of inconsistencies or quality. I think they supply thread in 1 lb sizes not in 8 oz spools which maybe a downside for some. kgg

-

Interesting disclaimer. I guess you would never put it on something like a old Singer 29k patcher with the old case iron hand wheel installed on the end of the main shaft. The Sailrite Monster wheel weights about 7 pounds versus their PRO Balance Wheel is roughly the same size but made of aluminum. This leads me to think run on caused by flywheel momentum maybe a problem with these sorts of motor designs. I couldn't find the same sort of disclaimer for the Reliable 6000 motor. I run on my machines 550 watt brushed motors with a the speed limiter dial and pot and so far have not had a problem. kgg

-

I am glad you are enjoying your new machine. Something to keep in mind with the stitch length is it will change slightly (more stitches per inch) as the thickness of material increases. kgg

-

This one even shocked me, $2500 for a Singer Featherweight 222. Kijiji ad in Ontario, Canada ( www.kijiji.ca/v-art-collectibles/ottawa/singer-featherweight-222/1588802786 ) kgg

-

Nice simple straight forward useful solution. kgg

-

That is great news. kgg