kgg

Contributing Member-

Posts

3,343 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

I figured the OP was going to replicate the drawer and to get a more accurate measurements I would provide them in mm. To convert metric into imperial just divide my measurements by 25.4. kgg

-

Ender 3 new motherboard 4.2.7 problems adjusting z height

kgg replied to chrisash's topic in 3D Printers and Lasers

I think the problem is that your firmware isn't compatible and will need to be updated. I would check www.reddit.com and see if there is a forum for the Ender 3. I know there is one for the Ender 5. This link may help with setting the Z, (3dprintscape.com/guide-to-install-a-bltouch-on-a-creality-32-bit-mainboard/) I do have a question why did you decided to try and upgrade to a 32 bit board? kgg -

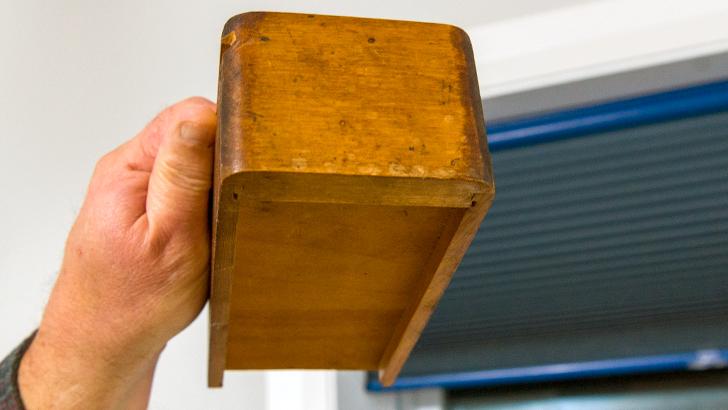

This is the small plain face drawer in my 1949 Singer 29k 71 case iron base. The tracks that are attached to the base for the drawer I painted black to match the rest of the base. Dimensions of the drawer: A) The length i) front to back, outside to outside, is: 205.34mm ii) inside length is 177.33 mm iii) thickness of back is: 8.13mm iv) thickness of front is: 19.88mm The width, i) side to side, outside dimension is: 97.03mm ii) side to side, inside dimension is: 80.09mm iii) thickness of sides are: 8.47mm C) The height, i) front and sides are: 70.43mm ii) back of drawer is: 56.87mm D) The bottom i) bottom of the drawer is 177.33mm x 84.33mm x 2.23mm thick and slides into a track cut in the sides E) The track i) Track for sliding in and out of drawer are 7.92mm wide, 3.45mm deep and are down 9.2mm from the top of the sides kgg

-

I think the best of the three is the Juki LU-1508HN but the price is going to be much higher, probably north of $4000 US. I would place the 1508HN closer to your Class 3 capabilities which may prove to be to much machine for lighter items. To give you an example of how different classes of machines work with material Sewing Gold has a good set of videos on youtube. They show the end result with three Juki's dnu-1541s, du-1181n and ddl-8700 sewing the same light, medium and heavy fabric. I would class the 1541S as a good compound feed upholstery type machine, 1181n a walking foot machine and the 8700 as a garment machine. I wouldn't count out the Juki DNU-1541S (~$1800 US) for your sewing needs, it maybe a good fit for your needs. I still would advise you to check out a dealer with a sample of your items and then make a decision. Also another option maybe changing the needle plate and feed dog if it will work on your Class 3 like what was recently discuss here under the topic " A liitle change to make a BIG differance on Cowboy sewing machines By RockyAussie, October 30 in Leather Sewing Machines " kgg

-

Will my sewing machine work well with leather?

kgg replied to Warhauk's topic in Leatherwork Conversation

I do have one of these. Usually it will sew and could get you out of pinch but don't fool yourself in assuming you are going to get great results. The quality of these machines are at best on the poorer end of the scale. Yes they do have their place like all machines but I would not recommend this type of machine for anyone as an only machine or a beginners machine as it may prove to be too frustrating. These are what I would consider a true tinkers machine and it was fun tricking it out but it cann't hold a candle to a my Singer 29k's. kgg -

machines on craigslist: what can handle 12oz net thickness?

kgg replied to berninicaco3's topic in Leather Sewing Machines

Having a sewing machine demo'd by the owner and they can't get it running right is a real red flag for me. Why is the owner wanting to sell it???? Problems not being mentioned??? To me if an owner can't get their own machine running right then the machine is worth little more then it's scrap value or at least a drastic drop in price to help cover possible repairs. The clutch motor is another red flag as to how fast the machine was operated at prior to the new servo motor being installed. Typical speed on those clutch motors is either 1725 or 3450. Any speed reduction??? The servo motor control panel indicated it was running at 1600 rpm but what was the actual rpm's the machine was run at. Any speed reduction? Most of the Singers Patchers shouldn't be run at much more then 500 rpm's but the Alder maybe different. Another option that may fit your needs if space is a real concern are the portable walking foot sewing machine's like Sailrite Ultrafeed and Reliable Barracuda, to name a couple. kgg -

Chris is pretty good and glad you got it to where you feel comfortable sewing. kgg

-

machines on craigslist: what can handle 12oz net thickness?

kgg replied to berninicaco3's topic in Leather Sewing Machines

It wouldn't be my first choice. The parts are probably going to be to be expensive should it require any. I stay away from Alder and Pfaff machines for two reasons replacement parts and accessories are much more expensive then other manufacturers in my location and the machines are difficult to sell. I also stay away from any machine with build in electronic functions as I like to keep my machines as simple and cost effective as possible. I would check the availability and cost of replacement parts for the Alder in your area. kgg -

machines on craigslist: what can handle 12oz net thickness?

kgg replied to berninicaco3's topic in Leather Sewing Machines

You can't go wrong with a Juki as they are what a lot of the clones copied and parts / accessories are readily available. That said all lot will depend on how the machine has been cared for. If any of those machines were used in a commercial setting they probably are being sold for a reason. The Juki DNU- 1541S will do the upholstery work but as for shoes, boots etc being sewn to soles you will need a heavier weight machine. Upholstery class machines can handle about 3/8" thick material or less depending on the material. I would check / look for leads with the local sewing machine dealers, repair shops, shoe repair shops as well as places that do tack repairs like horse riding / polo clubs and companies that do upholstery work. kgg -

Nice work. kgg

-

Which model number. Do you have any history of the machine? Yes but it also depends on the model, work history and just not the age. The max stitch length of my 1949 Singer 29k 71 was manufacturer spec'd at 7 to 15 per inch. My 1998 Singer 29k71 is probably similar. Sewing 9 mm of veg tan is effortless but I have not sewn over the 9mm thickness myself. There are two end plates that came with the 29k each marked for the size of needles that plate could accept for the range of needles. The range of needles it can handle are from #11 to #24 needle. The 29k machines if complete will have a hand wheel which can be used on either the pulley end or the side drive. Parts for the Singer 29k 70, 29k 71, 29k 72 are still readily available and fairly inexpensive but the older models can be a challenge for some parts. This is an example of a what I think is a nice running 1949 Singer 29k71: https://leatherworker.net/forum/topic/97429-singer-29k-71-all-cleaned-up/?tab=comments#comment-661772 This is an example of a what I think is a nice running 1998 Singer 29k71: https://leatherworker.net/forum/topic/97594-how-singer-29ks-should-operate/?tab=comments#comment-662317 This is an example of how quiet a 1998 Singer 29k71 should be and this machine is louder and not quite a smooth as the 1949 Singer 29K71: https://odysee.com/@SingerSewing:0/singer:a This maybe something you can compare with the one you are interested in. The main question is this the right machine for putting soles on, I don't know. kgg

-

Good repurposing of an old drill. kgg

-

I would checkout this video as it adjusts a set screw behind the small horizontal plate that adds or releases tension on the up and down movement of the rear pressor foot shaft. May help in reducing the jerky movement. The video is called "Techsew 4100 Trouble shoot" Link: youtube.com/watch?v=NHswdukpWog&t=600s kgg

-

I do find it odd that a lot of the heavy duty machines say their machines can take a #18 to XX needle or V69 to XXX thread but you can't readily get them. kgg

-

I can't be of any help other then check with a cobbler that does replacement soles cut from either used car tires or the sheets of retreads rubber used to retread tires. kgg

-

I would still check with Aaron Martin in western Ontario as they do cater to the horse and tack people and mybe able to source them. kgg

-

I would try: i) Cowboy Dealer ii) Aaron Martin in western Ontario as they maybe able to order ------ aaronmartin.com/product.php?cat_id=996&catview=20&submit=View ---- they list Schmetz in a 160 (#23) iii) Cutex Sewing ------ cutexsewingsupplies.com/products/100-organ-7x3-dyx3-794-sewing-machine-needles-singer-consew-highlead?variant=32221430415413 --- they list Organ in a 120 (#19) iv) Amazon ---------- amazon.com/7X3-Sewing-Machine-Needles-Highlead/dp/B01FGZ22X6?th=1--- they list Organ in a 120 (#19) kgg

-

Thank you. Give it a go, you got nothing to loss. The only problem maybe the length of usable shaft which could be extended with inside threaded shaft extenders or similar shaft extenders. kgg

-

Thank you. The thread on the both sides of the the machine shaft are your standard SAE 5/8" - 11 just that the right side has your standard right hand thread twist and the other side is a left hand thread twist (commonly known as bastard thread). There is a silver color nut for the side with the regular thread and a dull sort of yellowish nut for the other. Also the machine did come with two 8" cotton polishing pads. kgg

-

Not sure yet and the heat maybe the down fall but over the next day or so I am going to give it a go on a half round sheath that I have be playing with so we'll see. kgg

-

I agree, just got to figure out what sizes of grooves that will get used the most. I think I am going to use some good old fashion Canadian ironwood (eastern hophornbeam ) which is the hardest wood in Canada and I have a lot of it. kgg

-

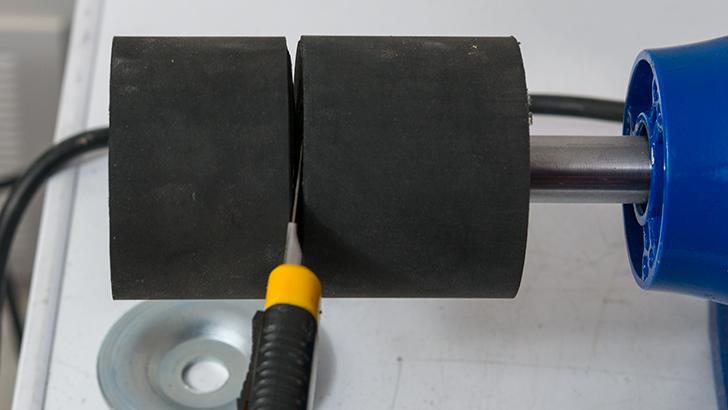

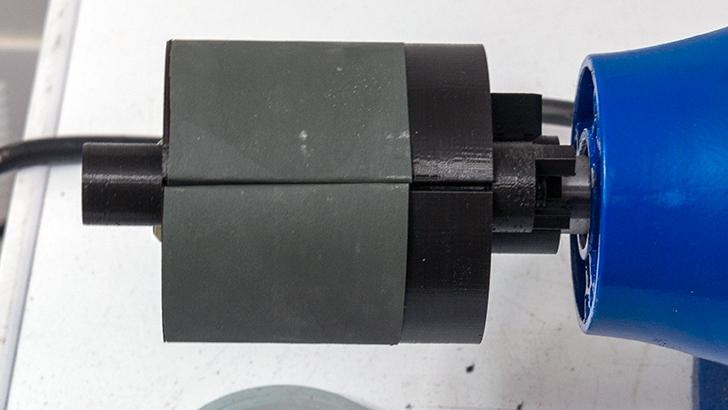

I was looking to step-up from the inexpensive rotary tool attachment to a more professional setup. Sticker / spec shock would be an under statement as anything I would consider decent was about $750 plus shipping with adjustable speed control but only with 1/2" or less diameter shafts and amp ratings of 5 or less. After much looking and pondering I settled on a 8" buffing / polishing bench machine made in Taiwan from Princess Auto (Photo 1) as it pretty well covered off what I was looking for: i) 3/4" main shaft cut down to 5/8" (Photo 2) ii) CSA approved iii) 7 amp rating iv) adjustable speed control from 2000 - 3450 rpm. The price was $130, tax in, and all I had to do was purchase a burnisher ($75 tax in and delivered) and re-drill the 1/2" hole with a 11/16" bit. The next thing was to figure out the sanding wheel side. I chose to go with a 3" x 4 1/2" sanding sleeve which I could have in hindsight gone with a 2" diameter sleeve. This required me to get a 4 1/2" rubber sanding drum ($30 tax in and delivered) and 3" x 4 1/2" sanding discs ($28.50 tax in and delivered). Then I had to re-drill the 1/2" hole with a 5/8" bit and cut it roughly to the usable 5/8" section of the shaft. To cut the rubber sanding drum I stuck it on the shaft and with the machine running I used a utility knife to cut it to the proper length (Photo 3). This did work but the drawback was there was a lot of the sanding disc unsupported about 77mm (Photo 4). The piece I am holding is just too tighten or loosen the spacer in place / removal (Photo 5). To this point the cost is $263.50 for something that can do the job but... The sanding disc side of the machine was begging to get modified so I 3D some stuff: 1. A spacer which fills the unsupported and allows the use of the full sleeve (4 1/2 long x 3 inch diameter) rather then just 37 mm of the supported surface. 2. A 3.15 inch long x 3 inch diameter sander wheel for using standard sheets of sandpaper (Photo 6). This was a scrap piece of 1000 grit sandpaper I had handy just to show how it wraps around the drum. This way I can have a better range of available sanding grits and get three pieces of sandpaper out of a sheet. It's also cheaper as a sanding sleeve costs about $8 each whereas a 3 pack of the expensive 3M sandpaper sheets are about $8 and I get 9 pieces so it costs about a dollar per. I did like the principal that the Just Wood burnisher in the UK uses to attach the sandpaper to the drum but I figured I could build a better mouse trap. My thought on the Just Wood as I see it is once you cut the sandpaper sheets too the proper width along the length of the sandpaper sheet you have to trim the length by about 10mm and the sandpaper is being held in place by a hollow flatten pin that is dependent on a friction fit in a oblong hole. 3. A 4.25 inch long x 3 inch diameter burnisher with 1- 15mm, 1-10mm, 1-8mm, 2- 6mm and 1-4mm concave slots. This does work but if I like it I probably will use it as a guide and turn it in wood (Photo 7). The cost of PLA filament about $30. Total Cost including about $30 in PLA filament is $293.50. So far no problems like flying bits and pieces, fractures or catastrophic failures when run at full bore. Any and all comments are welcomed.

-

I don't think of it as so much as pushback but on this side of the pond, at least where I am, the cost of those items would be much greater then the £30 ($50 CAD) you paid. The taper bearing alone would be probably be £30 ($50 CAD) or more depending on the size and to get a decent pulley the cost would be £60 ($100) or more. Not everyone feels comfortable in modifying their machine so for a little more money it is easier just to order a speed reducer setup and belt that is mounted under the table mount. If the machine is used and or the motor is older I would recommend replacing the motor with a newer servo motor. Then if the speed still needs to be further reduced add a under-the-table speed reducer setup. kgg

-

It still is, with Imperial easier to access for a lot of items like nuts, bolts, drill bits, pulley's etc. kgg