nylonRigging

Members-

Posts

477 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

Singer 111w155 - edge binder

nylonRigging replied to MackProvisions's topic in Leather Sewing Machines

You going to have to drill and Tap for best mounting results on the R-side slide plates. you will be guaranteed also to take it off, and re-drill and tap again, to fine-tune it's position . But if screw it up or not happy, is no biggie , because L and R-side slide plates are easy to get and cheep for the old singers . Start by trimming/notching the R-side of presser foot toe, to get a good starter point for the binders position . also dremel trim off flush, the underside of the bolt sticking threw . so plate will slide in and out , and also not to interfere with the bobbins movement . When you get Binder into working position, tight into presser foot Notch you cut . You will probably also cut/shorted the length of the material push Bar that tails off the exit of the binders Throat . and also might have to trim the bottom some to make sure it clean and not tagging the feed dogs on their up-lift movement . . -

Techsew 5100 Binding attachment?

nylonRigging replied to Runzeigrun's topic in Leather Sewing Machines

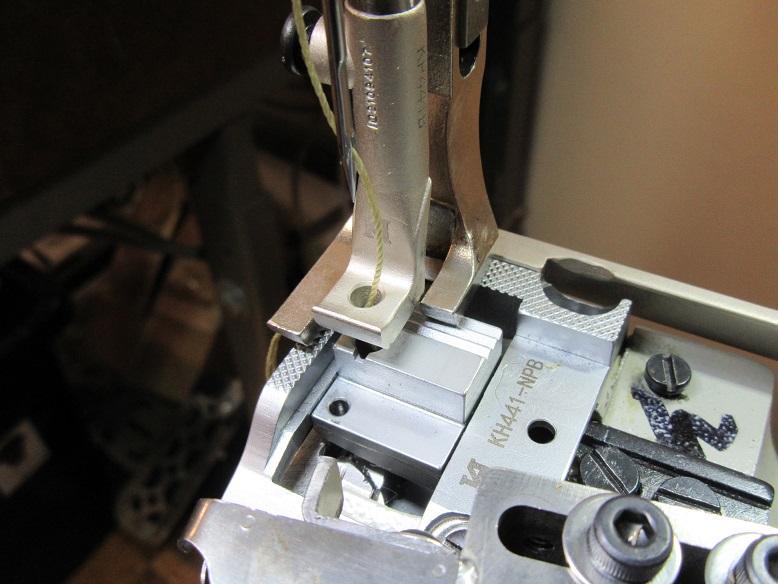

You say your doing/Binding Canvas fabric . What is the thickness of the material you are feeding into that 441 Binder ? also what size thread you using on that canvas ? Can you post a Pic, of the 'bunching' problem you get ? . did you buy the feet offered/supplied by KH on their 441 setup ? . or, did you cut/trim your own for the Binder ? the feet set-up is a fine point to complement the binder system and end result, also the angle that your feeding the material through the binders throat will change your results . Also for your learning technique with a synchronized binder and compound feed and feed/turn rhythm . slow the machine down on the radius and make a conscience effort to only feed-turn the material, on the needles down stroke, when the needles foot is down, with the outer feet off . That KH 441 machine and binder set-up is a brute for Binding, and you maybe able to get far better results with a smaller/lighter cylinder bed or flat-bed machine and binder set-up . for me sewing.. ( example Fabric ) .. On that 441 Binder set-up . I have a couple small outside corners on a closing flap of a bag that I regularly do . that is 'smallest ' I do on that machine and binder for ( thickness ) of material when Binding around radius lid and closing flap .. Is binding threw .. 2-sides of 1" type-ll nylon binding . 1 piece of webbing . 3 pieces of 1-k denier . and 3/8" foam . I have the machine dumb down with nylon #138 . That is NOT Even Close to workload that size of machine and binder can do and handle . It's nature is big tension, thick thread cord, big needle and thick material . . working with Good quality Binding tape material is a must , but I got to take a different view of binding material than RockAussie . Not that you can not turn a nice radius with gross grain , but I find that I prefer binding with a bias and herringbone weave over the gross grain when turning tighter radius. . -

Singer 111 going out of time consistently

nylonRigging replied to Sugarkryptonite's topic in Leather Sewing Machines

from older thread here . - KeystoneMasterPagesScrews.pdf - -

the sound is normal . I kind of prefer the 1st stitch crawl slow on the 1st stroke of the stitching . you need to find a down-load of the manual anyway to see all the setting choices .. but ( imho ) , I would just leave that program set the way it is . It is always nice to see the needle slowly plunge exactly where you want it, before it takes off on the run . .

-

Is that an action that is just programed in ? . I have a servo drive that giving the 1st stitch a , slow lagging RPM stroke , is an option that you can choose . .

-

How to attach a binder to a Singer 111W155?

nylonRigging replied to Willie0's topic in Leather Sewing Machines

If your talking about the Pic. on the 3rd Post down from top, on this page , poster Feb 6 2017 , made by ( gregg keystone sewing ) . ? . it is binder and Bracket, made by Tennessee Attachment Co. . He listed Part# in the post also . I have had that exact set-up once from TA, and if you prefer to go in that style direction for a swing-arm setup . it is a Heavy Duty and top notch hardware, along with their Solder work with the head/throat of the binder . . -

Bobbin thread usage calculator?

nylonRigging replied to Sugarkryptonite's topic in Leather Sewing Machines

And In a Ideal World , Both bobbins on my double-needles would always end-up empty, exactly same every time. ...LOL . -

Bobbin thread usage calculator?

nylonRigging replied to Sugarkryptonite's topic in Leather Sewing Machines

Your Question in your Post, ..." I was wondering if anyone knew how much I could sew with 1 bobbin on 5 SPI with this machine ". 'On average' How many 20ft. runs can you get from one bobbin of thread ? . your question revolves around ' knowing how many yards is on your full Bobbin ' . Then What Uwe, is saying .. figure out how many inches length, you can sew with a yard of Bobbin thread . Then 'know' how many yards are on a Bobbin your filling . Your question is something I never ever thought about finding , so out of curiosity I put a Yard ( 36") of bobbin thread in a 111 to see ? . with t70/69 , and 5 spi . with having a 2 inch of loose thread tail , I sewed about ( 28.5 ) inches of stitch length , for 36" of bobbin thread . . -

Bobbin thread usage calculator?

nylonRigging replied to Sugarkryptonite's topic in Leather Sewing Machines

How many 20 Ft. runs you sew with a bobbin of thread, ? . with sewing stitch run, 5 spi , ??? What size of thread ? are you rolling onto a Bobbin ? , How full do you wind your Bobbins ? , How long length of thread tails, do you pull to cut at the end of each stitch run ? . -

Mercury 280 ls table and Mercury m337 head

nylonRigging replied to TEG's topic in Leather Sewing Machines

I am assuming that both flatbed machines have a ' Knee lift ' for press foot raise up/down ? The one machine that does not have a hand lever lift, for presser foot . Is it missing ? . Or was Head, never produced with on ? You could always find the machine model that Mercury cloned that particular model from, and find if it ever had a hand lift lever . Or find parts #'s if it did, and add those parts, to your Mercury head . - hey ?? also in your website profile you write ..." interested in sewing Human skin products ". are you Jame Gumb, aka/buffalo bill ? “ It puts the lotion in the basket, or it gets the hose again ” ....LOL . -

I have/use that Post Artisan model . Only job I use it for, is for bottom of bag seams I running right now . You get 2 bobbin size choices also in that 4618 from Artisan, or others selling . If you go the M-bobbin , just remember the feed end of Post is a tad larger in size , because it has to accommodate the larger bobbin assembly . That Duel-feed Post is a real smooth feeder, It has a small amount of Needle-feed motion in it also . also/no Reverse, but (for me) that is no biggie. The Artisan 4618 is same as the Cowboy 8810 , that Wiz posted link on . that Postbed body/sew mechanics is a real popular cloned model sold by several . Don't know where your US Area zip-code Is ? I heard that Artisan sell quite a few of those Postbeds to Leather Class down in Cal. area. . If you living in Cali. I would keep looking in used Craiglist for people dumping them when they get bored with their newfound hobby , If looking for a used Buy on the Artisan 4618 , I never seen used Artisan Post-bed around here . Seen a used Pfaff Post, dual drive last week in the craiglist , but it went pretty quick . Used .. Pfaff is another way to go if looking for used, and they are solid with several Post model choices, but Pfaff is a little spendy-$ on the OEM parts if needing . --- If you looking to buy New, Just call Artisan and talk to 'Chester' and ask if they have one in-stock . About a month ago, I called them and asked about 'time-line' on their next order for machines . Was told they are making up an order for machines for the end of Dec. or 1st end of January . So right now would be good to get on their list if wanting one. .

-

Edge guide screw holes on a flatbed

nylonRigging replied to DrmCa's topic in Leather Sewing Machines

You saying .."40 TPI " . . I just checked on a Mitzu. DB on the factory tapped holes on it's bed top . I threaded-in some ( 6-40 ) and they threaded in and bottomed out holding firm . But they did feel a little tiny sloppy when I was threading them in . Cast metal Heads are kind of soft easy to drill/tap . So I cant tell if it just a sloppy Tap work at factory ? . . Or it is some proprietary Thread size/pitch, that Mitsubishi used, that is real close to 6-40 ? . -

Mitsubishi DB stitch length acting up when using reverse

nylonRigging replied to DrmCa's topic in Leather Sewing Machines

Backside Pin notches probably just worn pretty bad on the backside of your Dial knob . Does not take that much pressure of the spring/pin to keep it from turning . I would just get ta new turn dial . People man handle and force the turning of the Stitch-length Dial . It wears out the backside of the Dal . Always push down little bit on the Reverse Lever, to release pressure on that Dial spring/pin , so it turns smooth easy when changing stitch length's . . -

-

I think they/Artisan only put speed reduction pulley w/servo drive, on their heavier duty machines . The drive servo and pulley reduction on my heavy Artisan Cylinder Bed, is a torque brute . - No , on the Artisan model 2618-1B . the pic is Drive on one of there dual drive Post Beds machines . but relevant because ( IMHO ) this Post Bed not heavy duty Artisan industrial machine, and this Servo Drive is probably same Servo used with their current lighter weight machines . - Have no complaints yet , they have pretty good customer service also, easy to contact and talk over phone . Have a crapload of hours on their 441 clone , and only had their Post Bed about a year . Both machines are pretty solid workers . And that is my biggest interest in any machine I buy .. It Has to be Dependable runner, or it going back out the door . Tables are set-up right and tight, and are good plywood/Lam. tops , ( No cheep Press board tops ) . Have other machines, Singer, Consew, Mitsu, Juki ...etc. ( my ) main reasons for going with them/Artisan, is their competitively priced . W. Coast US established, with me up North in W. Oregon . They don't take your payment till the machine is shipped . Good CS . and Trucking/Shipping has been under 200-$ usd up North to Oregon for me. .

-

I have 2 Artisan machines . in-house set-up . 'one with' reducer , and one 'without' speed reducer . When buying the Artisan machine with the spec's. that read 'without reducer' . That was also the 1st question I had, before I bought this last machine from them . So I called them and they reassured me that it not needed . . All I can say is that I have Zero Complaints with their drive motors they brand and install that have No reducer . programmable, and It adjustable to go as slow as you choose . I was pleasantly surprised that Low torque power is there also . So here is 2 Pic's. of the Drive 'without reducer' . pulley off the drive is a smaller 50mm Diam. . I don't know the Servo manufacture that Artisan put there brand on but they seem to make good choice on there servo purchase . - - -

-

IMHO .. that not looking to bad at all . I don't see any rust or pitting . as long as it not froze with old varnished oil ? . Just looks like it was neglected on any cleaning . Me .. I would just blow it all out with Air Hose, and then manual oil All friction points , taking my time and rotating the hand wheel . Then string it up, and turn-ON the motor drive . Run it for hour or so sewing lightweight scraps, then get a good feel for what you got going on mechanically . I would just lay a small towel in the bottom of the oil drip-pan , Then after you over-oil the whole machine, you can clean the drip-pan out latter. After blowing it all out with Air . If it tight rolling and sticking with rotating hand wheel . I would pump some hot air to it with Hair Dryer on Hot . or a heat gun set on 'low heat' . That will loosen all the old oil and lint and get all rolling smooth . .

-

craiglist is going to be a hit and miss for finding good clean cylinder bed in reasonable driving distance . If you wanting brand name, and will hold a better resale value over time . the Juki 1341 that ( kgg ) mentioned is ...Great . . You are living in NorCal. . if you do end-up buying new clone import . 'for Me' .. I would just contact Artisan Sew in Bay area Cal. , call and ask 'what is in stock' . You can get into walk compound feed, medium duty cylinder setup for 1800-$ to 2300 . along with consew/juki/singer... I run a couple of Artisan setups on cylinder and post machines , they run solid, and setup with a quality servo drive . Have good customer service . Shipping for me from bay area up to Portland trucking hub for me to pick it up, was about 190-$ last time I brought one up here . So you shipping closer in-state would probably far less-$ . .

-

Those, 3-prong/spur T-bolts . If you buying more than a few, . It is pretty cheep price and fast shipping from ' MonsterBolts ' . they have their website. and also sell of off ebay or Amazon . Last bags of, 1/4"x20 - 7/16" , were 16-$ shipped, for bags of 100 . .

-

The kwan Hing raised feed dog/needle plate fit pretty smooth easy, was really nothing that was off on fit and finish . Their feed dog change-out was just like any other feed dog on that model machine . - -

-

Pfaff 1245 bobbin shuttle won’t spin

nylonRigging replied to Nims8582's topic in Leather Sewing Machines

1st post ? .. 1st sewing machine ? .. You got a few things going on there ? . People on the forum could ( guess ? ) explain any number of possible different 'cause of problem' scenarios for you to pick and choose from . but .. Your already saying that your way over your head, lacking mechanical knowledge for the machine diagnosis and repair . Don't Punish Yourself . Fix it fast and correctly the 1st time , find/hire a Tech. to assess the problem and do what is needed . . edit add: Where do you live ? unless you are isolated area away from civilization ...LOL , and repair Tech. is impossible to find or you drive to his location . Get a factory model schematics parts diagram, then off the list of problem/fix possibilities you collect here . Start studying and take your time in finding and fixing the problems . . -

Are Zig-Zag machines exceptionally hard to find?

nylonRigging replied to williaty's topic in Leather Sewing Machines

The zigZags do pop-up here off and on regularly , and Speak of the Devil ... LOL.HAhahaha . and 1st thing I see when I clik on the Craiglist to take a quick browse .. and I see what you Jonesing For . A nice clean little ( 107w5 ) ... . . But it killing me a little to, as that machine model was the very 1st machine I bought to learn to sew . https://portland.craigslist.org/clk/for/d/vancouver-singer-industrial-sewing/7393692542.html . EDIT ADD : Craiglist will tease you.. cant beat it .. Just noticed this popup today .. If you in the N.W. , ( OR. WA. area ?? ) IF wanting a good buy on a , 40" Longarm ? Singer 144W302 compound feed . This machine Head is just begging for a fresh new table set-up . Looks priced to move @ 1500-$ .. or Best Offer . https://seattle.craigslist.org/see/bfs/d/port-hadlock-singer-144w302-long-arm/7390184967.html . -

Opinions on these feed dogs + plate

nylonRigging replied to AbelJojua's topic in Leather Sewing Machines

( IMHO ) .. just start with the small fine tooth and smallest needle hole plate , then can easy move up larger, if you cant get the results you want . the dogs, plates, feet ..etc. are all pretty cheap cost anyway for that set-up . So no biggie on owning multiple Feed sets . I think if you play around for one day with sewing sample pieces of thin/lightweight materials . You probably make the fine fabric dogs work great on the Feed with your choice of press foot, pressure, and tension . ( same type yours ) . I use the largest/heavy feed dogs/needle plate on similar set-up on one of my bottom feeds , but I tuned it to thump threw thick and heavy with a, size# 20 and 22 needle and t-70/#69 . I would not use that combo if I sewing light and thin material, and it for sure be crappy results . . -

Opinions on these feed dogs + plate

nylonRigging replied to AbelJojua's topic in Leather Sewing Machines

Why ,.. Med. or Large feed dog and plate ---> If you sewing light/thin ? A 'smaller' size needle hole on the fine-tooth plate . You will get far less pucker, getting punched/shoved threw hole around the needle . .