Search the Community

Showing results for tags 'dies'.

-

Hello! I've been researching all the leather cutting options for a while now. So I am new at leathercrafting but I would like to find a way to make perfect cuts so I could make good products. I have very little space - 1.5x1.5 sq.m. and I need a little machine for that purpose. The options I researched are as follows: Laser To use a laser for cutting skin, it is necessary that the laser has a power of at least 10 watts. Mandatory should be added air assist to get less skin burns, encloser, as well as perfect ventilation. My space is easy open air area and I would not have problem with ventilating. Lasers that would work for me are the following: Wainlux K8 - That would be the best option due to size and portability. The big downside is the working area /130x130 mm maximum/; Longer Ray5 10 W - may the best option for me. Ortur LM3 Laser Ortur LM3 LE Laser Engraving & Cutting Machine Atomstack X12 Pro Atomstack P9 M50 xTool M1 10W - best quality. May be the first laser and also with blade for cutting. CNC with drag knife - looks good but very big and loudly. Not compatible for me. Cricut Maker 3 & Cameo 5 - both look amazing. They can cut leather but I don`t know. i would like to know your opinion about that those two. Sizzix - I find on amazon "superdant" store. There cutting dies for leather which work with sizzix - 1/2/3/4 . But that`s it. I don`t know if they can make it custom patterns and I have doubts for the quality. Clicker press - I think that would be the best option for me to buy low cost clicker press. I was looking that ones by vevor: 1/2/3 . I have problem with their weight - around 30-40 kg. I was looking for a smaller by zonesun like that ones: 1/2/3 - but I would by a machine for 120-200 $ and pay 200 $ shipping .... Arbor press - looks good for 50-100 $ I could buy an arbor press 1 or 2 tons. But than I have to order a base and the only good option I found is that one - link . The cost is 120 $ without taxes and shipping so no thanks. I would like to start with wallets and small stuff - no bigger than a medium bag. I try to cut by hand but the finish is not good enough for me. I don`t like it and got frustrated. I'm already seriously confused about which path to choose to start with. I ask for your opinion.

-

I recently acquired a D.B. Die Works No. 39 kick press. It is currently without a stand. Before I go ahead and build my own stand for it, do any of you out there have the original stand for this kick press for sale? Also, can you suggest a good source to purchase dies for this machine? I will be looking for dies for Line 20 and Line 24 snaps. I appreciate any help I can get. Thanks!

- 4 replies

-

- dbdieworks

- kickpress

-

(and 3 more)

Tagged with:

-

I came across an older saddle that had the pinking Edged rossettes. Does anyone know of where to get them or the die? I need sizes 2" and 1 1/4".

- 2 replies

-

- restoration

- dies

-

(and 1 more)

Tagged with:

-

-

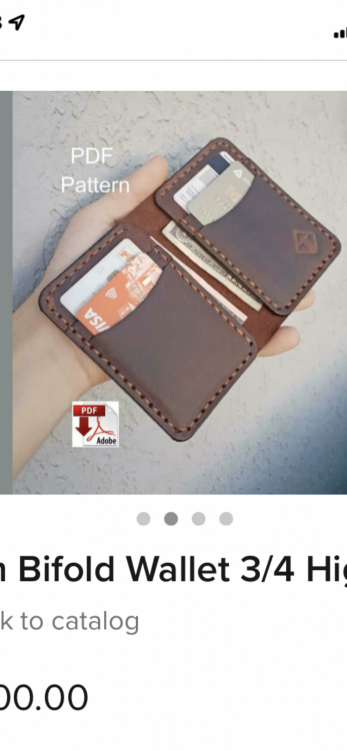

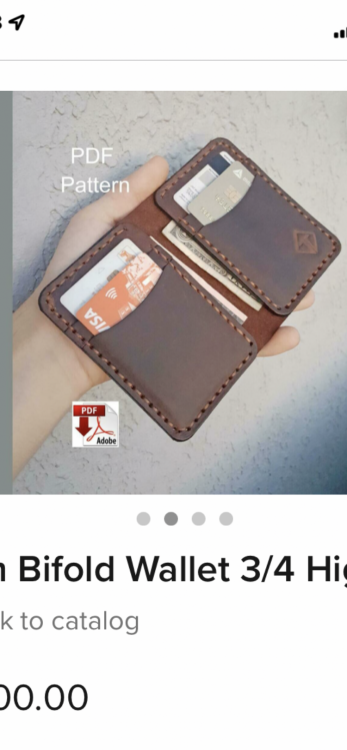

I have a new Int’l Die small bifold wallet cutting die for sale. The company was closing and kept sending me the wrong kit (3 damned times). The kit is made with 3/4 inch rule, there are 4 pieces and never used! $120 for the set, $20 shipping, plus tax if you use a credit card or debit card. No I will not send samples (ruins the “never used” status) . Price is non-negotiable! Contact me by here, DM, or call 980-621-5851 I block weirdos

-

I have a new Int’l Die small bifold wallet cutting die for sale. The company was closing and kept sending me the wrong kit (3 damned times). The kit is made with 3/4 inch rule, there are 4 pieces and never used! $120 for the set, $20 shipping, plus tax if you use a credit card or debit card. No I will not send samples (ruins the “never used” status) . Price is non-negotiable! Contact me by here, DM, or call 980-621-5851 I block weirdos

-

From my shop that closed in 2015. Good sharp Weaver-made clicker dies. Billets shown with ruler for size. The regular and crossdraw holsters are Meanea patterns and make the final product pictured. The holster dies are for 7 1/2" Colts and clones and the pattern can be shortened to fit shorter guns. Pictures are of 7 1/2" and 5 1/2" holsters Sorry I didn't have better images. Prefer to sell as a lot for total $450. PM me for additional info. Shipping at cost.

-

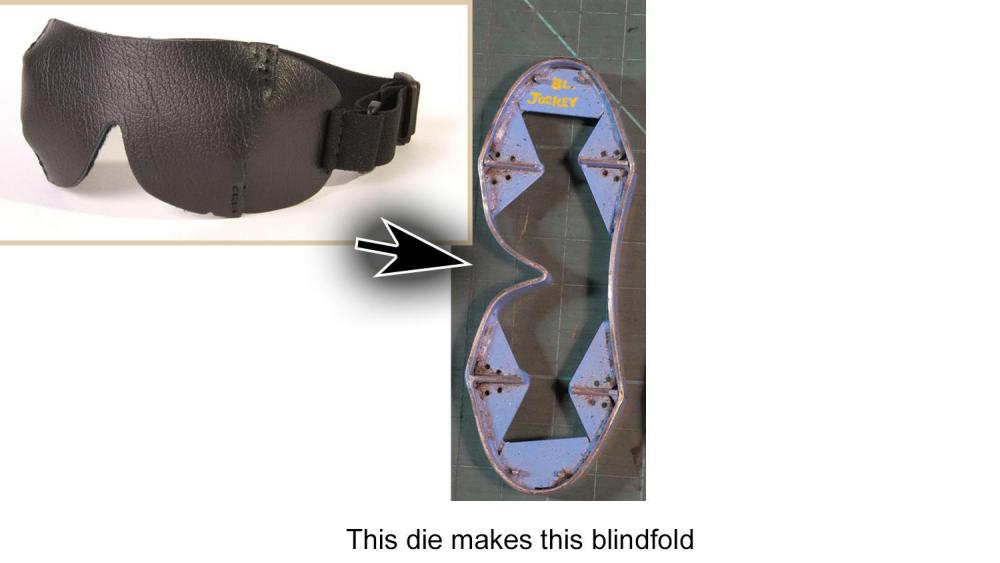

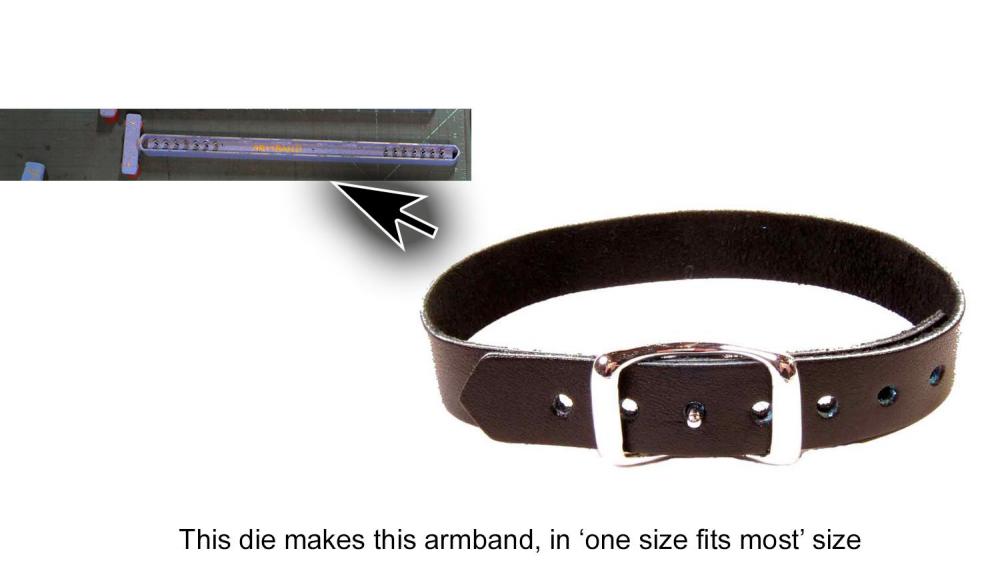

Asking $100 each for these dies. We have sold literally thousands of these items. Jockey (top) retails at $30, Sashay (middle) at $35, Whisper (bottom) at $25.

-

Hello First post here. I am looking for parts, pieces, manuals, etc for royal and peerless perforates I own. Besides Campbell-Randal, does anyone in this forum have experience with these? I will needing some advice, parts and dies made for them if none are available off the shelf. Also I would like to get user and maint. manuals for them if available. Thanks everyone!

-

Has anyone ever modified a manual turret punch to be used as a clicker for leather, rather than punching holes in steel? I can get a working turret punch cheap locally and was just wondering if anyone’s done this before? Pic attached

-

Like new Cobra Class 4 premium package. Used less than 1 hour. I had a holster business and Tandy Leather dealership years ago. Thought I would get back into it and changed my mind. Machine, several spools of thread (black, brown etc.), tool box, maule, punches, knives, bevelers, swivel knife, HD stamp/rivet press, dies for press, Clicker Dies: two types of western holsters, iwb, pancake, foldover for small caliber, cowboy cuffs (2), gun belt buckle and tongue dies, rounder, practice piece, arrow head, spur straps, iwb leather belt loop. These are high quality clicker dies with almost no wear. YOU DO NOT NEED A CLICKER TO USE DIES - you simply lay the die on concrete or other hard surface (blade up), place you leather over the die and tap around the die with a maul or mallet. In minutes you have a perfect cut out. The concealment holster dies are not shown and are steel rule/plywood dies. The press is not shown either. I forgot to mention that I have an extra motor/tabletop for the sewing machine. Also some gun molds (red gun and Duncan alum) $3800. These items are included with the machine: Premium Accessory Package: Left Toe Presser Foot $75* Open Toe Center Foot $65* Double Toe Presser Foot $80* Right Toe Presser Foot $75* Work Platform $95* Holster Plate $156* Stirrup Plate $156* Slotted Plate $85* Blanket Set (Inside & Outside Feet w/ Feed Dog) $150* Heavy Duty Roller Edge Guide $95* Pair of Thread Nippers $2* LDA-1 Magnetic LED Light $20* Owner and parts manual

-

I had trouble locating dies for the Press-N Snap, snap setter for line 20 snaps. I thought I would save the rest of you the trouble. I found them at Wawak Sewing. http://www.Wawak.com Phone # 1-800-654-2235 Stock #PLR61. They work great!

- 1 reply

-

- press-n-snap

- line20

-

(and 2 more)

Tagged with:

-

Hello! Beginner trying to figure out exactly what I need to do a few basic projects. Specifically belts, with lots of hardware (think bondage style stuff), wallets, and small bags. Would you recommend 6-7oz or 8-9oz leather for these projects? I have already invested in the Pres-n-Snap tool but need more dies. It is frustrating trying to decode the many brands/sizes of rivets! Is there such thing as Medium (5/16" post) and Large (1/2" post)? Hoover told me they manufacture the following double sided rivet die sets for my tool. Can you recommend to me which of these die sets are best suited for riveting 2 pieces of leather together for belts, wallets and small bags? Would I need a whole different die set to add decoration rivets- just in 1 piece of leather? Is one brand preferable? How do you translate "Line" to size? The "mm" sizing refers to the head, not the post? DOT Speedy Rivet 11 Line DOT Speedy Rivet 16 Line Fasnap 9mm Rivet Fasnap 10 mm Rivet THANK YOU SO MUCH for your help!

- 2 replies

-

- pres-n-snap

- dies

-

(and 1 more)

Tagged with:

-

I am interested in any dies and other attachments that would fit the Weaver MT900 or Little Wonder Thanks

-

I am interested in any dies and other attachments that would fit the Weaver MT900 or Little Wonder Thanks

-

I did a blog post review of Texas Leather Dies. I won't recreate it here, but the condensed version is --they are amazing. Ten outta ten! If you'd like the details, check it out on my website at https://www.BruceGibsonDesign.com If you're in the market for clicker dies, mallet dies, etc., I highly recommend these folks. They are also Leatherworker.net supporters. Awesome all-around!

- 3 replies

-

- texas custom dies

- dies

- (and 9 more)

-

Where can one purchase stock mallet dies? I am specifically looking for a mallet die for cutting a 1/8" by 3/4" rounded end slot. I see the Texas Mallet Dies offer customs but from their website they don't go this small.

-

I'm seeking the advice of members who have experience of using strip knives/clicker dies for manufacturing small strap goods in the high dozens or low hundreds. I manufacture dog collars in a few standard sizes from two layers of waxed 2mm chrome-tan. At the moment my procedure is: Cut strips to final width using wooden strap cutter Mark all holes and lengths using a story stick and dividers Cut to length with knife and end punch Punch rivet and tongue holes using standard hole punches Skive turnback Glue Add buckle and rivet in place Machine stitch all round Add D-ring and rivet in place Punch buckle holes (The leather I use is through-dyed and the fibres quite tight so I don't edge finish in any way. Both I and my customers are happy with that.) With sales speeding up and trade enquiries coming in I'm looking at getting cutting dies made. The objectives are to reduce production time and eliminate errors caused by mismeasuring and operator error (strap cutter!). A further objective is to test the feasibility of this approach with a view to offering other products that cannot be made using a strap cutter and would be uneconomically slow to cut by hand. I've specced about a dozen dies before and been happy with all of them however I've never specced any that need very tight alignment between two different dies. My dilemma is this: can I reasonably expect the backer/lining die to cut a piece that matches perfectly with the top piece? This is in reference to outline and adjustment holes. If not I could spec the lining to be cut a little wider and longer than the top piece and trim the lining by hand once stitched together. Similarly, I could spec the die with adjustment holes only in the top piece and punch the holes through the lining manually. However both of these approaches still allow for operator error and will take some time, reducing the efficiency savings that using dies might bring. My main alternative plan is to spec some dies without cutting edges just punches in the relevant places. I will mount it into my fly press and use it to punch pre-cut strips held by an alignment jig. These dies will be long, involve several punch tubes, and I need to order them in several sizes so they represent a significant financial outlay. Any relevant advice will be greatly appreciated!

-

Hello all, Forgive me if this has been covered. I am sure it has been at some point. I am having some brass stamps made so I can do some hot stamping. I currently stamp my makers mark and some requested stamping patterns with a shop press. I am wanting to use an arbor press for accuracy in layout. I plan on buying something inexpensive and having a machine shop bore out the arbor for an insert. My question is does anyone known the thread size and pitch of the most commonly available dies for setting snaps/rivets etc. The insert I have made will be threaded as appropriate and I also want to advise my brass stamp maker on what size rod to make fit the brass stamps. If I am thinking right, the rod that the brass stamps thread onto could be the same size as the insert that will go into the bored hold and fasten with a set screw. The same bored hole will accept the insert that is tapped for the snap setting dies. Clear as mud? Any help you might offer is greatly appreciated as well as a source for good quality snap setter dies. I know Tandy sells them but non sure if they are worth buying or if there is a better option. Thanks in advance, Scott

- 11 replies

-

- arbor press

- stamping

-

(and 4 more)

Tagged with:

-

Hello all, I have been reading clicker die threads for about an hour or so and haven't seen this mentioned. I really do try to search before posting so here goes. I have a clicker press and have used dies to cut out various projects but I have not ever cut them from the flesh side. (I didn't have the need to before) I am wanting to have some more dies made and it would be much more affordable to have a single die made that I could simply flip the leather to get the other side cut out. Doe it work just as well cutting from the flesh side as it does the other way around or does it look different? IE: Distort the grain side or leave a lot of fuzzy bits? I have noticed when cutting from the grain side it leaves a very nice cut edge that slightly rounded over. It is beautiful and as close to perfect as I need but haven't paid a lot of attention to the flesh side when I have been cutting. I am trying to not have more dies made than I need and if they will cut just as well either way it would basically save me half by not having the mirror die made. If anyone has tried it both ways please let me know what you would recommend. On the outer edges they will be sanded and burnished so it's not as critical. On the edge of an inner flap or pocket it may or may not be burnished depending on the style I am shooting for. I appreciate any feedback you might be able to provide. Thanks in advance. Scott

-

I have a whole lot of dies for setting rivets, stamps and other tools that I have collected over the years. All of them are hand held. Now I'm thinking of getting a small arbor press for some of that work. I would like to mount the dies I have in the arbor press. Several of the dies are hand made for custom projects and it would be good to use them in the future. Have anyone any idea how to do that? I'm guessing some kind of chuck and somehow attaching that to the press?

- 20 replies

-

- arbor press

- dies

-

(and 2 more)

Tagged with:

.thumb.jpg.023628625d7bb0752f9a4d4c0a614c9b.jpg)