Search the Community

Showing results for tags 'question'.

-

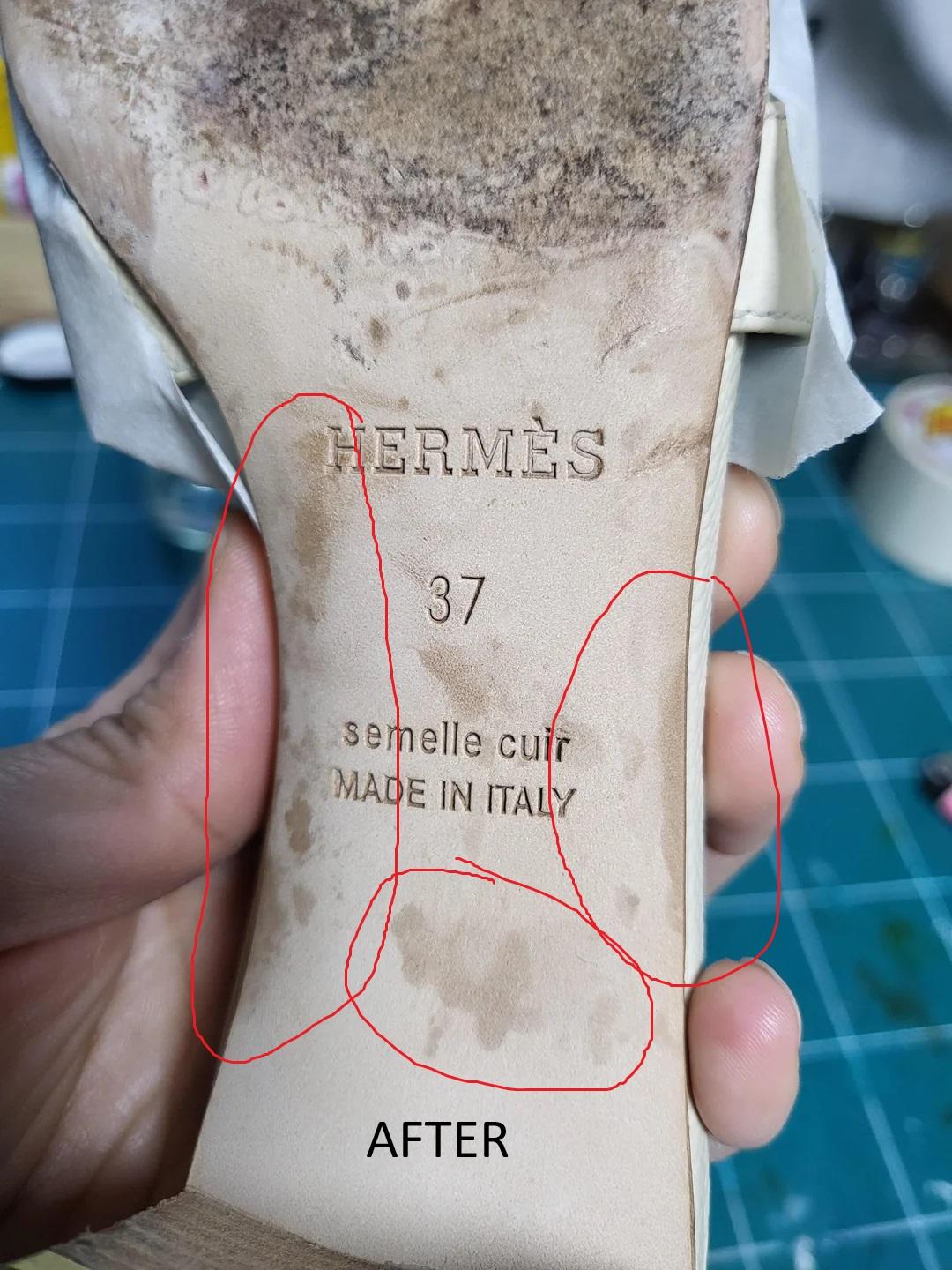

Hello! I am a novice shoe repairman. While washing your Hermes Oasis sandals with saddle soap, the soap bubbles and soap water got on the natural leather sole. At first, I thought it would be okay if I dried it well, but the stain does not come off no matter how much I dry it. How can I get it back to its original condition? The saddle soap is a Fiebings product.

- 3 replies

-

- question

- question about technique

-

(and 2 more)

Tagged with:

-

Guys & gals in feburary or march I'll be getting a new cobra class 4 sewing machine. My question is will it sew thru kydex plastic used in holsters & knife sheaths? Will it sew thru a plastic bicycle seat pan? Some type of flexible plastic. No sure what yet thou. Thanks any & all help will be greatly appreciated.

-

Good Afternoon, I have been thrown in at the deep end as Dad has left me with a shop full of items. Can anyone help me confirm this machine is a RAFFLENBEUL Type RODI 50 SL combined cutting and skiving machines for sole materials? I have reversed searched it but there is another make landis (I think) There are no badges on this machine. I have cleaned and oiled it and even put a rubber heel through it and by god it actually works! It needs a new home but I am not 100% sure if its a RODI 50 SL Any help appreciated Thank you Pauline

-

- hand operated

- question

-

(and 2 more)

Tagged with:

-

New to sewing machines. Need to know if the tippman boss is a worthwhile upgrade being that it's completely manual. I plan on using it for belts and holsters with 9 to 10 oz of leather. I know it'll give my poor fingers a rest from poking leather but my question is, for those that have or had one, is it worth it? I was looking at the model R with reverse.. or stick with the original or go with something else completely?

-

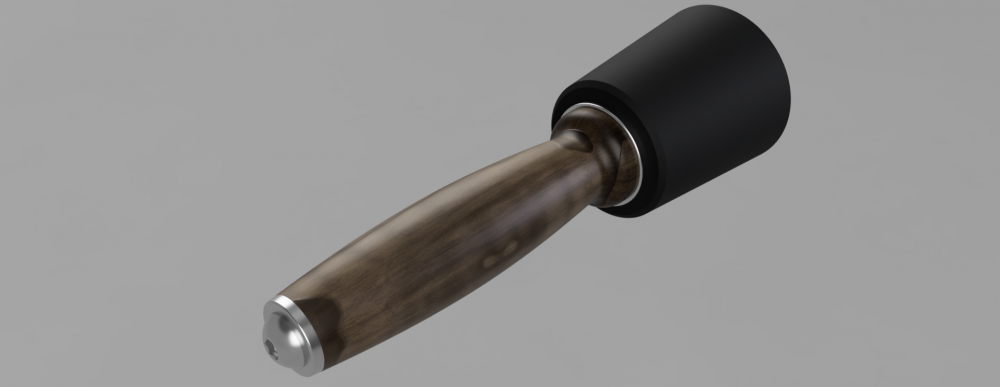

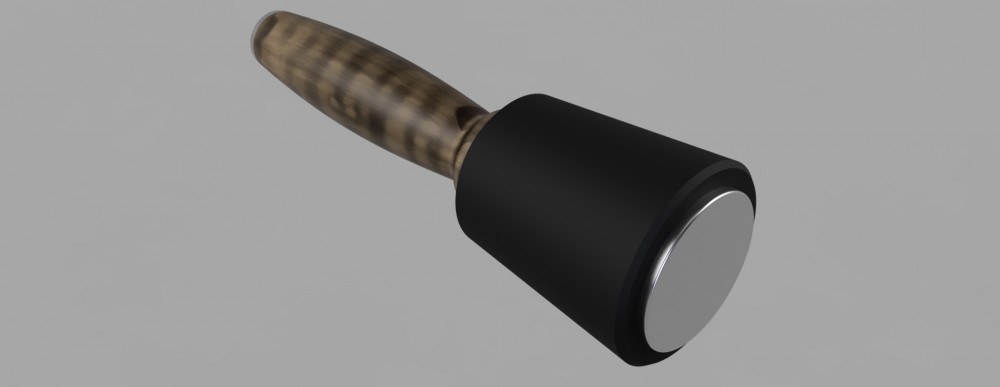

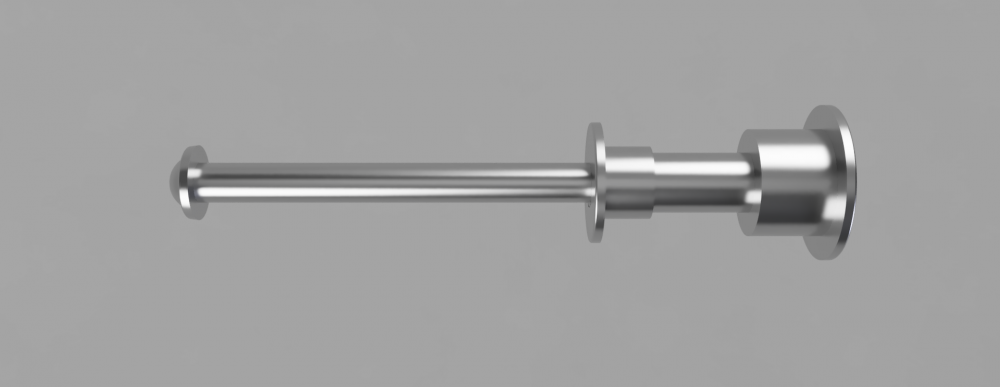

Even though the raw materials for my maul have arrived , it's still far too cold in the shop to even think about machining it. Thus, I've been learning about stitching ponies as I know I will need one, and i have a few questions. how wide should the jaws be? I've seen them as narrow as 2 inches and as wide as 8. Is it just personal preference? what's with the 360 degree rotating base? I understand being able to tilt forward & back for ergonomic reasons, but I don't get the rotation, nor have I seen someone actually using this feature.

-

Hey there! I am looking into purchasing a Pfaff 145 H3 from a local seller and have ran into an issue with the machine. When manually turning the wheel in either direction, we hear a squeaking noise. The machine seems to work fine and produces beautiful stitches so it is very odd. A friend of the seller who is more knowledgable about machines believes it may be an issue with a bearing, as the noise is much less obvious when sewing, and also went away a little after oiling the areas near the handwwheel. Any ideas on resolving this issue?

-

Hi all. Was just doing some troubleshooting on my Juki 1541 which I still have backlash issues with (see previous post) when I noticed this. https://imgur.com/a/xXCrUWJ On each rotation of the hook it doesn't stop in the same position. Is this normal? Kind Regards,

-

Hello, I recently acquired a PFAFF 335 H2 for my leatherwork. I was wondering if any of you could help me in regards to where I would oil + grease this machine? Any help is appreciated. Thanks

-

I'm just getting into leather work (still gathering tools in fact), and I plan on making my own maul. Since I have the ability to machine the various metal components to size, I have the ability to shift the balance point/ center of mass forward and back. Would it be better to have the center of mass as far forward as possible, or more back towards the handle? This is my current design.

-

Hello everyone! We are a company that sells fish leather, specializing and taking special pride in producing sturgeon leather. The problem that we face is that little to no one has ever heard of the availability of such a material and the possibility to apply it to their works. So our main question is whether you have heard about working with sturgeon and would be eager to try it, as it has certain specific features to it. And if you have any questions to us, feel free to ask!

- 21 replies

-

- question

- exotic skins

-

(and 2 more)

Tagged with:

-

I have a Cobra class 4 sewing machine, was hoping it was going to do everything I was going to make. Few years later I'm starting to need a machine for wallets and watch bands. I use leathers between 2 to 5 oz either split or skived down. Was thinking about a Juki 1508, huge cost but a solid machine, of course, the salesman is pushing the most expensive. Looking for suggestions; good machine lower price. I know, I know the subject has been most likely been covered a thousand times but I cruised the topics and didn't see a topic that seemed to fit. Not sure what I'm going to end up with, but I need something...

- 1 reply

-

- question

- sewing machine

-

(and 1 more)

Tagged with:

-

Hello- We recently purchased a used Singer 7-34 and we are having a tough time finding the type of needles to purchase for replacements. We also haven't had any luck tracking down a manual. Does anyone know what needle size this machine might take or where a person could track down a manual? thanks!

- 4 replies

-

- singer 734

- needle type

-

(and 4 more)

Tagged with:

-

Opened my water based glue (Saregum) and found mold on the walls of the container. The glue inside the bottle doesn't have visible mold. I am very apprehensive to use the glue and will probably throw it away. I've occasionally dipped (new, dry) q-tips directly into the jar of glue in application, and almost certainly, tiny pieces from the leather have gotten back into the jar. Wondering if anyone knows why the glue could have molded? Wouldn't have expected it to, but I'm not very familiar with water based glue yet. Also, would you agree that it's best to throw it out? Will pour from my main container into a per-use container next time so as to not contaminate the main jar of glue.

-

I'm relatively new to the world of sewing and I've begun to get my Singer 111W113 back in working order after having it in storage for the past two years. When I bought the machine back in 2014 everything was aligned and the outer presser foot operated properly. While putting everything back together I'm realizing that the outer foot has far too much clearance, especially when sewing a few layers of material. I'm currently working with a lot of Cordura and heavy canvas for making bags. 6+ layers of Cordura are thick enough to make contact with the outer foot and provide pressure. Less material just slides around freely. I've made attempts to adjust the height of this bar but it seems to be in it's lowest possible position. Is there more to adjusting the outer foot pressure / clearance than just the screw on the top rear of the machine? Thanks in advance!

-

Hi gang, I'm finding it difficult to pick out which kind of leather to buy. I looking for black leather to make things like belts, collars, harnesses, wallets. Which oz would be best, should I buy an entire hide since the thickness varies? Any suggestions would be helpful. I will have to buy from an online supplier.

-

Well you all present such a lot damn beautifull wallets, bifolds, cardholders, etc... and I really would like to make a wallet, too someday. But there is one question running through my head everytime I see a new wallet in the show off section: "What about the coins?" There are really only a few wallets that got a pouch or sth else for coins. As I see most of you seem to have nothing but bills and cards, where do you put your coins? I am just not sure whether you put them somewhere else or maybe just avoid to get some, but it looks kind of weird to me.... and I´d really be interested in an answer (or some more ) Greetings from germany Sona

-

I made my first wallet today, which is my second finished leather project to date. I designed It myself. I know it is nowhere near perfect, and I have learned a lot in the process, but I still have a few questions: Im pretty sure the reason why the dye on the edge transferred to the other side of the wallet on the inside is because I didnt do a final burnish with some gum trag (second picture). As far as I know that helps the dye from bleeding/transferring. Am I right? The wallet is really thick, probably because I used what I am assuming is around 3 oz leather (I dont have a thickness gauge, I should probably pick one up) It wont stay shut by itself. What oz leather do you think would be best for this style wallet? To finish the wallet, I applied a couple of coats of neatsfoot oil, then topped it off with 50/50 acryllic resolene (only on the outside), and then some obenaufs leather preservative(also only on the outside). However, I didnt do any of this until after I stitched it all together. Is that the recommended process, or should I have done something different? I dont really like the glossy looking finish you can see on the outside (you can see in the third picture). What do you think is giving it that look? I like leather that looks more satin than glossy. I also noticed the color on the backside has a slightly pinkish hue. Is there anyway to remedy that without using dye? I know, I ask a lot of questions. I am a perfectionist, and as you can probably guess, I am pretty frustrated with the outcome of this wallet. Thanks! Zayne

-

Quick question on flat plate rigging - Had an old timer tell me that all properly built, heavy ranch saddles will have a piece of nylon webbing material riveted to the 7/8ths rigging at the front. The webbing runs over the ground seat just behind the horn, creating a continuous rigging is what he tells me - Anyone ever heard of this? Seems to me like you could run the risk of crushing your ground seat... He says just screwing the rigging up front isn't strong enough? I've understood that that was all that was necessary...Can someone please comment? I have attached a rough sketch of what he is talking about...I am making myself a saddle for roping and want to ensure it is strong enough to handle anything I might latch onto so wondering if this nylon is necessary. Many Thanks, rdl

- 11 replies

-

- rigging

- flat plate

-

(and 2 more)

Tagged with:

-

Hello Leatherworker community! I'd like to make a rugid and tough belt. Simple and traditional looking belt. Something like this image attached. Where do I buy leather for this in bulk? What sort of weight/thickness do you recommend? How do I cut? (How do I make it basically) If someone can direct me towards a good step by step forum post or website that would help too. How would I stain or finish it? Any recommended market/website to purchase the items above? What tools do I buy? Many questions and many belts to be made... -Kim

-

I have a Chandler 406RB that mostly works great, but I'm having some trouble with thickness changes while sewing. I make wallets, and when I'm sewing from the thinner section along the top to slightly thicker to down the edge where the pocket assembly starts, often I get this long loose stitch on the bottom where the thickness changes. Sometimes it's literally a loop a half inch or more long. Everything else looks good though, tension-wise, so I'm not sure what to do about it. Any suggestions for keeping this from happening?

-

- machine stitching

- question

-

(and 1 more)

Tagged with:

-

Hello everyone! Just discovered the site and am really enjoying the community! I did a bit of searching around (probably didn't have the best search parameters) but have a few general questions for a completely new craftsman. I believe my interests revolve around more simple design, not so much carved, just hand stitched. I would like to start with maybe a wallet or belt, maybe a dog lead. Question is, what are the basic tools I need to get going? Is a stitching chisel the way to go or maybe a prickling chisel maybe ever just punches? Basically I was hoping for opinions of a good "starter" loadout for a simple, no carve workbench. I don't have a ton of money to spend but do not want to have to rebuy after junk tools break so medium grade sounds like a plan. PS: The Art of Hand Sewing Leather is already on order.