-

Posts

6,539 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Northmount

-

In the future, please post your photos here. 3rd party hosted photos frequently disappear due to changes in the host's policies, host out of business, users moving files, deleting files, closing their account or the account expiring. When this happens, the post becomes worthless to all future users who are researching or looking for help to solve a problem. If your files are too large to post here due to file size restrictions, you need to resize your files to fit. Please use jpg or png format files as they load automatically when the thread is opened.

-

Moved your post to leather sewing machines. Have you figured out the problem or do you need more input?

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

spring flowers and good food

Northmount replied to chuck123wapati's topic in All About Us and Off Topic

It's a climbing rose, but I haven't tied it up so it's getting kind of droopy. We usually have snow, but many years it is a brown Christmas. We have SW winds called Chinooks that come in over the mountains. As the air descends about 3000 ft, it warms up 20C to 40C. A roaring Chinook can melt a foot of snow overnight. Wind gets pretty bad sometimes. Dec 31, 2018 Hwy 22 about 2 hours SSW of Calgary. Lots of semi-trailer roll-overs in this area as well as on Hwy 2, due south of Calgary. What the sign is supposed to like like. -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

The Classic Custom Leather Stitcher (Luberto's Sewing Machine)

Northmount replied to Howell's topic in Old/Sold

Moved your post to Home > Marketplace > Items For Sale > Machinery -- Sewing and Stitching > Used It doesn't belong in Announcements. And while you were there, did you read the rules? You need to post a picture or as many as needed to give a good representative view of the machine's condition. The image preview doesn't qualify! Pictures should be 800 pixels in the longest dimension to keep the size within the limits for pictures. -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

spring flowers and good food

Northmount replied to chuck123wapati's topic in All About Us and Off Topic

Your really cold weather is our summer temperatures. My wife's cousin asked when was the best weather here (Calgary, AB) to visit. Asked her what her winter temperatures were. 20 to 25 C. It's never a good time to come here! (Unless you are coming to Ski or Snowboard.) Current temperatures over the past few days have run from high of 17C to 30C. Lows around 9C to 14C. We have had snow every month of the year except July. Banff and the Rogers Pass have had snow every month of the year. They are just 1 and 2 hours west of us. Winter here, common daytime highs are from -10C to -20C. A cold snap is -35C with a strong NW wind, 20 to 60 km/h. In 1964 while I was attending Tech School here, we had over 30 days of -35F with 30 to 40 mph N and NW winds. (I'll leave the British units for you to convert.) That's the coldest I've ever been. Fort McMurray (10 hours north of here where I worked for 9 years) gets a week or 2 at a time of -40C to -50C. All vehicles have a block heater, and if you need to be able to jump in your vehicle and head out to handle an emergency (power and utility plant operations crew), the vehicles are left running 24/7. However, next to no wind, lots of ice fog in the valley. The wind makes a huge difference. We do get what we call, some nice weather here. -

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Tutorial, replacing zippers in riding boots.

Northmount replied to Mulesaw's topic in Shoes, Boots, Sandals and Moccassins

Moved this thread to Shoes, Boots, Sandals and Moccassins -

I believe it happened many months ago.

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

spring flowers and good food

Northmount replied to chuck123wapati's topic in All About Us and Off Topic

Remember to use your email address that you use with LW instead of the user/screen name. -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

spring flowers and good food

Northmount replied to chuck123wapati's topic in All About Us and Off Topic

That will be 220 Volt (VAC). Current (amperage) may be around 40A to 80A. You can check your breaker panel to see what the breaker was rated at if it is still there. Just for comparison: Dryers are typically on a 30A circuit (220 VAC). Electric ranges are typically 40A. For the past 50 years or so, most houses had a 100A service. Many now are 200A. -

You forgot to post the price. It is required.

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Tippmann 1500 15-Ton Clicker Press and Table for Sale

Northmount replied to Radam's topic in Old/Sold

You should tag or quote the user you want to correspond with as not all users have properly setup their notifications. To tag, type the @ symbol followed by the user's screen name and pick it from the popup box. Like this @Radam you have someone interested in your clicker press, see above. -

Since you want a steel rule die bender, I split your post off its initial location and moved it to the Marketplace > Wanted. This is where it belongs.

-

Moved to leather sewing machines. You'll get more help here.

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Screws ripped out of saddle tree

Northmount replied to Mendosa's topic in Saddle Identification, Restoration & Repair

Somewhere, maybe here, I have seen T-nuts used for saddle attachments. Quite a range in sizes available 8-32, 1/4 20 tpi, etc. If you have access to the underside of the tree without too much work, they won't pull out. Lots more holding power than screws. Can enlarge the damaged screw hole to insert them. Just scrolled back through to the beginning of this thread and see this is what @Hildebrand suggested @Mendosa in the 2nd post! -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Screws ripped out of saddle tree

Northmount replied to Mendosa's topic in Saddle Identification, Restoration & Repair

There is a big difference in holding power when you compare screws run into end grain versus screws run across the grain. The screws that are run into end grain easily shear and pull out. Compare to chopping with the grain (splitting wood) versus chopping across the grain. Anyone that has chopped wood knows the difference. I've had screws in end grain pull right out where they didn't when screwed into cross grain. -

Just scroll back up a couple posts and it is right there, still available. Just downloaded it to test, it downloads just fine.

-

Copy not attached

-

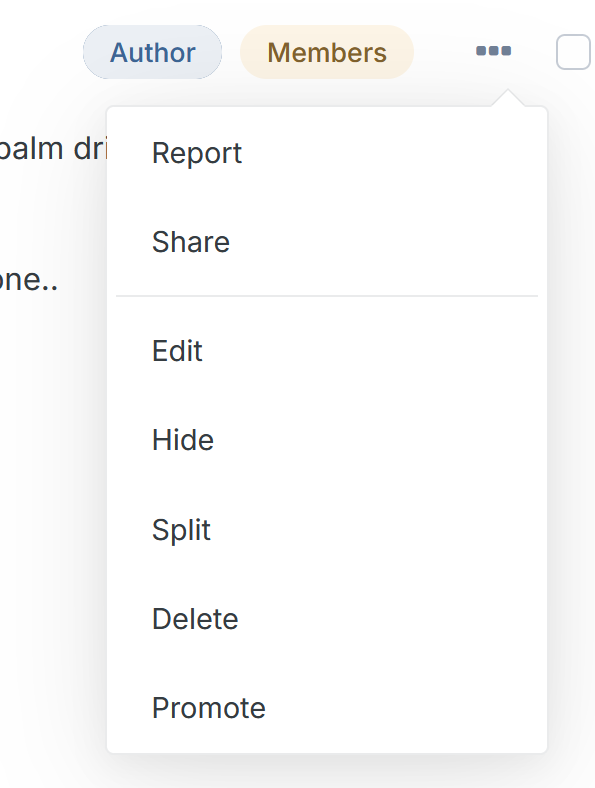

Three dots upper right on your screen The edit window is open for a couple hours. After that, just reply to the thread. If a fix is really required, a moderator can fix it. Message a moderator.

-

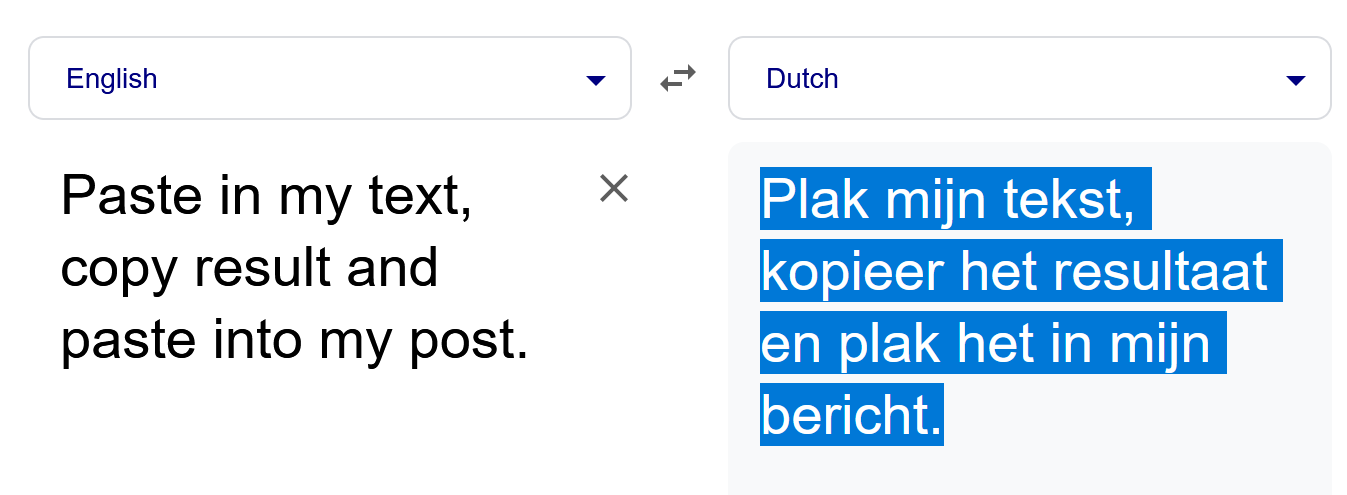

In my browser, I go to google translate and set the languages for it to use. Ik ga in mijn browser naar Google Translate en stel de talen in die gebruikt moeten worden. Paste in my text, copy result and paste into my post. Plak mijn tekst, kopieer het resultaat en plak het in mijn bericht.

-

I've split your post off the old thread you tagged onto. Much better to start a new thread and specific to your machine.

-

@edge Moved your post to Leather Sewing Machines Je bericht verplaatst naar Leernaaimachines

-

Translated: Who can tell me what this adjustment button is for Thanks in advance for the answer English is the language for this forum. You can use Google translate or other tool to translate and post in English Engels is de voertaal op dit forum. Je kunt Google Translate of een andere tool gebruiken om in het Engels te vertalen en te posten.

-

You need to tone down a notch or two. Keep it civil.