-

Posts

5,807 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

its the logo of one of many far east manufacturer I guess. I have seen it before but who recalls all the Chinese brand names.

-

Finding certain Pfaff feet can be pain. Thats one reason why I like Singer so much -> tons of different feet available. I´m not sure how the needle presser foo bar distance is on the Pfaffs but if it was my machine I would try a plain needle feed foot and lower he presser foot bar. College Sewing is a good source or you may find them a bit cheaper on Ebay. https://www.college-sewing.co.uk/parts-by-type/sewing-machine-presser-feet/needle-feed-lockstitch-feet

-

No - does not disengage. Thats correct. You have to wind the bobbin in an unthreaded machine and lifted presser foot or while sewing or use and "external" electric bobbin winder. https://www.google.com/search?client=firefox-b-d&q=electric+bobbin+winder+site%3Aleatherworker.net

-

Agree with 52w. This one seems to have a roller foot and a very narrow needle distance. Maybe a model for sewing vamping / shoe uppers and the like. If you need a few more details, this one seems to be similar. http://www.usa-dealer.net/SINGER-52W22-TWO-NEEDLE-POST-SEWING-MACHINE_p_1242.html I case you will ask I don´t think you will find gauge sets for a wider needle distance for this model (though they were available - back then) Maybe the manual gives you some more details: 51W19_52W21_W22.pdf

-

Maybe you can provide some pictures of the original items that are stamped with these signs. What machine is the presser foot for? Most likely not this but who knows: https://de.wikipedia.org/wiki/Datei:WHZ-Logo.svg

-

W/o sitting in front of your machine or having seen any pictures I guess either the top thread causes tension due to hanging thread at some point in the thread path or the shuttle hook spring is faulty (for what ever reason) and thread moves out of the spring.

-

Interesting machine. How do you know it has a (special?) hardened shuttle hook? All shuttle hooks are at least surface hardened afaik.

-

Singer mystery machine - need help to identify

Constabulary replied to vonL's topic in Leather Sewing Machines

The class and subclass should be visible on the oblong badge. I guess its a 46K15 fur sewing machines or similar. -

I´m surprised to see a 132K (OEM Singer, not clone) with reverse. @Oldiesfan - can you please post a picture of the underside of your machine? I´m curios how the reverse works on this machine / what is different to the "plain" 132Ks.

-

This for sure is not new but I think not much known so I thought I show what I did. Since I´m fiddling with my vintage Singer a lot and have added several different type speed reducers to different machines I always hated that I do not have the right left V-Belt on hand. Of course in some cases you can adjust the SR or the motor angle but still annoying IMO. I have used round leather belt in some cases (meant temporarily) but they stretch with the time and you have to shorten them. I also had issued finding the right length especially for the machines with higher post (see below). Long story short - I ordered some round PU belt with rough surface for testing and so far I´m quite pleased with them. This is what I have ordered (cheapest I could find for testing) https://www.ebay.com/itm/PU-Polyurethan-Rundriemen-mit-rauer-Oberflache-fur-die-Antriebsubertragun-PLA/312661290102 I have ordered 9mm / 5meter. I haven´t yet tested the belts on my "heavy machines" / heavy materials that require a certain punching power on some projects. ATM I only have set up the 51w post bed and 108w binding machines with the round PU belts but I´m very pleased. Both rather light / medium duty machines but both machines appear to run a bit smoother. I cannot explain it technically but they overall just appear to run smoother. Just to have it mentioned - other that industrial V-Belts the PU belts are a little bit stretchy but not too bad. So I´m not sure (yet) how well they work with "heavy Duty" machines with heavy / thick / dense materials. Optically black V-belts are nicer IMO but technically I´m quite pleased with the green round belts. Nice thing on the PU belts you can easily shorten them, melt the end (flame, soldering iron, heating iron....) and put them back together if the belt it a bit too long / need more tesnion. Some pictures:

-

Roller foot? Could you and would you?

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

EDIT: deleted - got you wrong. I would not "downgrade" a walking foot machine even if it was possible. better look for a needle feed or drop feed machine you can convert. A cheap Singer 31 / 31K comes to my mind. The 31K has the same bed size as your 225 so you can just switch the machine heads as needed (space saving) but you may need a 2nd V-Belt. -

Just from this single picture I guess its a Dürkopp 211 (drop feed) or 212 (drop feed + needle feed) or 219 (top + bottom feed). Class number should be on the oval badge next to the reverse lever. Tailoring machine - no heavy duty leather machines.

-

I Never bought a new car - guess why? Same with sewing machines. Advantage of sewing machines is that at least some models remain "a certain value" no matter their age. It does not matter if your Singer 111w or Pfaff 545 is 30, 40 or 50 years old as long as they are looking "good", are functional and well setup. In best case in 10+ years you can get back what you paid for your used machine. But that's a different story. I absolutely agree with that!

-

Really an interesting solution - too bad I have no need for timing belts at the moment But I will keep that in mind!

-

@Thomo - sounds like a good solution. Can you please post some pictures of your spare belt and maybe give some detailed instruction how in particular you spliced the belt? Thats for sure interesting not only for 307G2 owners. There are for sure several vintage machines with obsolete timing belts.

-

looks like some one bubbaed a 2nd tension unit form a Singer 212 or the like onto the machine. Interesting modification The DB-121 is one of many other industrial plain sewer (straight stitch bottom feed) machines. I´m pretty sure a lot of parts (not all but a lot) are the same as on other machines of this class even from other brands. Juki 555 and the like are very similar. I´m pretty sure certain parts are standard parts and are interchangeable. Looks like some on retrofitted a roller foot + needle plate and feed dog.

-

Singer 211-A1121K Information needed

Constabulary replied to Hoarder's topic in Leather Sewing Machines

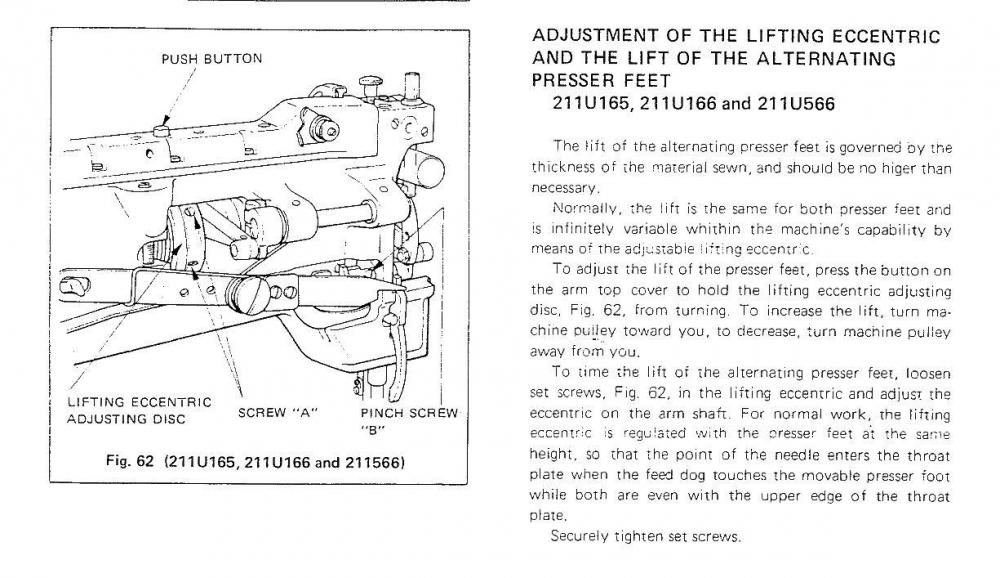

Unfortunately there are not manuals for all the 211 sub classes so you have to crawl through the 211 manuals available. Look for 211G, 211A, 211U manuals. Some may contain more information for your machine than others. U and A are made in Japan, G is made in Germany. This is an extract from a 211U manual but does not cover your specific sub class. I also attach the complete manual. Hope this helps. Singer 211U157A_165A_166A_566A THE MANUAL.pdf -

Singer 211-A1121K Information needed

Constabulary replied to Hoarder's topic in Leather Sewing Machines

afaik all 211 models have a cam on the top shaft for adjusting the walking foot height. You either have a push button on the top of the machine near the cam or there is a hole where you an insert a screw driver to block the cam and then rotate the hand wheel clockwise or counter clockwise let me check if I have a manual.... -

Still having same problem please help

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

2 things I noticed. 1st is it possible that the foot is a piping foot and 2nd to me it looks like the needle hole in the inner foot is too small for the needle and the thread. I´d try a standard foot set with wide enough needle hole. Just a guess. -

Yamata gy810 for Leather hat patches?

Constabulary replied to KennethM's topic in Leather Sewing Machines

The 810 is not a walking foot machine. Off the shelf it has a roller foot. -

Gregg of Keystone Sewing Machine

Constabulary replied to CowboyBob's topic in Leather Sewing Machines

I´m sorry to hear that. Just 46 years old... Rest In Peace, Gregg! -

Another issue with my Techsew 2750

Constabulary replied to brushew93's topic in Leather Sewing Machines

Have you checked is the rear side of inner foot is touching the outer foot in some way? -

Keep in mind - this is a workaround / tinkering solution. I haven´t installed the adapter to a 153W. My pictures show a 107w flat bed machine but the 153w103 is using a similar presser foot bar. The 153w has no presser foot bar coil spring and looks like the upper foot bar bushing is open on the topside (see picture - not my machine) so you don't have to cut the foot bar. But maybe you have to raise the lower foot bar bushing and maybe (don´t know for sure) cut it down if you have problems with lifting the foot because the adapter adds length and it may hit the casting or internal parts may interfere with the raised bushing. But I´m not in front of your machine so I only can guess. On my 107w I had to raise the lower bushing. Anyway - if you successfully have altered your machine please show some pictures. They may be useful for others.

- 14 replies

-

- and many more

- singer 153w

-

(and 4 more)

Tagged with: