-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Singer class 7-33 leather sewing, which needle ???

Constabulary replied to Jadu's topic in Leather Sewing Machines

794 / 7x1 / 7x3 are approx 69mm long in total No idea what needle you have there. Is the machine functional with the needles you have? Can you post pictures of the needle and if you have the needle package. But you should be able to lower the needle bar to accommodate 794 / 7x1 / 7x3 needles.- 12 replies

-

- singer class7

- 7-33

-

(and 1 more)

Tagged with:

-

You have to install the needle / throat plate otherwise it will never work. If the thread still keeps hanging on the bobbin case opener you have to adjust it. This videos by LW member UWE should give you an idea

-

Open the face plate on your machine, the pivot point of your needle bar rock frame it on the top so the needle bar moves back and forth in an angle and the thicker the material the shorter the stitches. You have the same effect on patcher sewing machines. Or draw a triangle and move the ruler from the bottom further up. The distance between the legs becomes shorter the higher the ruler goes. Maybe it´s of interest: There are needle feed machines which have an even stitch length no matter what thickens you sew but there are very few. So far I only know two (I owned both). One is the BUSMC #6HM (and similar models) and one is the Singer 108w Class (and similar models). That is because they have no pivot points on the top and their needle bars are always straight (not in an angle) when feeding the material.

-

Thats the pendulum effect on most needle feed machine - the thicker the material the shorter the stitches.

-

Singer Balance wheel replacement help

Constabulary replied to Campleathergoods's topic in Leather Sewing Machines

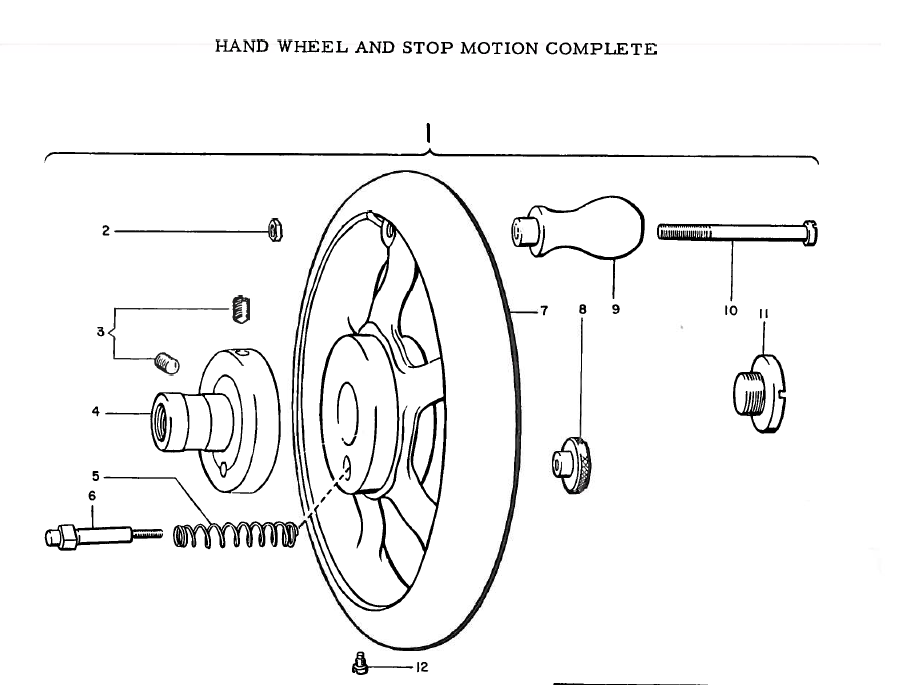

Be careful with 29K71 parts! The 29K71 fly wheel does not fit on early 29 / 29K models without installing additional parts - it´s a totally different system. You need a sleeve and the all clutch parts for engaging / disengaging the fly wheel clutch - it will not work without these parts. EDIT: You need all these parts if you want to install a 29K71 FW to a 29-4 - if it works at all If it was my machine and I want to restore it on a budget I would install an adjustment ring / sleeve as DONINRENO suggested. If you want to DIY the whole thing: Grind down re remaining bushing until its flat, look for a shaft collar that fits the shaft and is wide enough, drill 4 - 5 holes (approx 5mm diameter) into the shaft collar and around the bushing of the flywheel (holes have to line up), fill the holes with JB weld and hammer in some slightly oversized spring dowel pins. Let it dry, sand down the JB and finish it with black paint. Instead of dowel pins you can also tap some thread and bolt the shaft collar the fly wheel. As I said - a budget repair.- 11 replies

-

- singer 29-4

- industrial sewing machine

- (and 2 more)

-

Consew 206RB-1 Adjust Reverse Stitch Length

Constabulary replied to jackalopes's topic in Leather Sewing Machines

haven´t touched a 206 yet but system looks a bit like Pfaff. On Pfaff machines sometimes the #10 is worn or mounted 180° rotated / upside down. Maybe yours is mounted that way and reversing it will give you a better result. Just a guess. -

Agree that you disagree. I had one too but I only had 8mm foot lift. But it was a phenomenal simple machine with an extremely long stitch. I really liked it. I have a parts list for 78-2 78-3 but file is too big to attach here. But you for sure find it online. Also look for Consew 28 thats the same machine.

-

Modifying things (like attachments or presser feet and so forth ) is a fairly common work when dealing with industrial sewing machines. For certain machines you can buy "special" things off the shelf but for some sewing tasks or others machines you have to be DIY things or you have to pay big $$ and buy them from attachment manufacturing companies. There are many many variables you sometimes have to consider... There are certain right angle binder kits for 206RB machines But they are not "swing away" This is how a binder plate looks like EDIT: just to give you another idea - there are "swing away brackets" for sewing guides but I´m but sure if they can be attached to the 206RB: https://www.college-sewing.co.uk/226292-swing-guide-singer-111w-211w-211g.html https://www.ebay.com/itm/Swing-Away-Edge-Sewing-Guide-226292-For-Industrial-Walking-Foot-Sewing-Machine/401372513600 But it for sure requires some tingeing if you want to attach a binder bracket. So regarding tinkering and figuring out the "how to" - here is an interesting thread for attaching binders to 111 type machines. You see - not always a simple task but doable.

-

The coils are just tape guides. agree - the "off the shelf" binders usually work very well and if one fails try another but so far they are all good! An interesting setup you have there! BTW - College Sewing in the UK offers a hard copy catalogue and there are plenty of folding / hemming attachments in it - great overview. Just for the case someone places an order there ask for a hard copy of their catalogue. Its not their full program in it but really a lot - great info source. But they also have a PDF: https://www.college-sewing.co.uk/pub/media/brochures/CSMP-Catalogue-2018.pdf

-

I have to apology - I mixed up Consew 18 and Consew 28 - Singer 78 is similar to the Consew 28 but not to the 18 - I`M SORRY! I think DonInReno is right - the Consew 18 is like the Singer 16-188 Again - sorry - my bad! So forget what I have written.

-

The Singer 78 / Consew 28 have a driven top feed and needle feed but no feed dog (does not mark the leather on the bottom side). Max. stitch length is approx 8 - 8.5mm (not many in this class have such a long stitch length), machine has no reverse and foot lift is approx 8mm. Max. needle size is 140. Problem is you barely find feet and parts for this machine and the few you find are very expensive. I owned one. But it is a really cool machine IMO but other than the stitch length it hat no advantages to my 111G156. But it was a pleasure to play with - really. If you can get one cheap buy it and try it out.

-

Your binding does not look like a huge problem. You should not have have serious issues with "ecconoomic" binders but there are too many out there to make a basic statement. Anyway - all my binders are cheap, one is custom made but I bought is used along with 132K parts a while ago and I´m barely using it. All binders are working w/o problem. When I stared my "binding experience" I bought the cheapest I could find cause It was just for trying out and to gain some experience. I really did not expect that they work so well. Of course you need to set them up properly. The 3 numbers I mentioned a above are essential the rest is proper mounting (basically). The first 3 sets I bought were these flat bed binder / needle plate / feed dog / presser foot sets for approx 10€ - 15€ or so and I just modified the bracket. And I´m really happy with them. I meanwhile have 7 binders. The one I use the most is an el cheapo and I run fairly thick 3/4" wide cotton mil spec edge tape through it. This is what I´m using (my first 3 binders) but I paid less back then on Ebay Germany. You may note the distinguish wire bracket on the mouth. But as I said I modified the bracket and the rest went to scrap metal box. https://www.ebay.com/itm/Sewing-Machine-Right-Angle-Raw-Edge-Top-Bottom-Binder-Set/162106978932

-

Searching machine for sewing boots.

Constabulary replied to Gusta1's topic in Leather Sewing Machines

Yeah - yours is bigger than mine Very cool machine - up the arm feed + zig zag. Excellent find! -

but the one on ebay shows a picture with a tape measure on the mouth - check the pictures or ask the seller.

-

Pfaff 491: hook timing / upper thread loop problem

Constabulary replied to SSL2013's topic in Sewing Leather

I guess you have removed the throat / needle plate, right? Is it the same with installed throat / needle plate? 1st guess is - wrong thread path. Why? Cause a thread loop also appears left of the needle (but that may be machine specific - not sure). Do you have a manual? Is the machine correctly threaded? Please show some pictures of your thread patch. 2nd guess - bad thread? What thread is it? I guess bonded nylon? Maybe try plain polyester thread.- 1 reply

-

- pfaff 491

- sewingmachine

-

(and 2 more)

Tagged with:

-

Basically YES but you have to look up the specs. There are usually 3 measures you have to consider when looking for a binding attachment (beside the way the tape is folded) 1: tape width (cut size) 2: tape thickness and 3: mouth width. On some attachment these values are marked if not ask the seller. On ebay you sometimes find "wide mouth binders" but still - ask the seller for the mouth width.... EDIT: not sure if this one could help you: https://www.ebay.com/itm/RAW-TAPE-BINDER-WIDE-MOUTH-for-Typical-GC2605-Cylinder-Arm-machines/322427577045

-

This manual + parts list is for sure helpful 29k71-71-73 Service Manual and Parts List.pdf

-

How to identify my Singer model and make it work

Constabulary replied to Schlaumeier's topic in Leather Sewing Machines

29K8 is basically the same as the 29K1 / 29K3 / 29K4 and the like with just minor difference which could be a different needle plate or an oil cup... It´s approx 100 years old or older. Very few parts are still available, major wear parts are no longer available, gear box pinions of the more modern 29K7x series do not fit. 29K7x series bell crank levers can be modified to fit. Needle / hook timing on these early models cannot be adjusted. Only thing you can adjust is the needle holder which often can be moved to the right a little bit. If this does not help you may try a new shuttle / hook which remained the same until today. Parts # is 8604 I have restored a 29K1 a while ago - maybe it helps: https://leatherworker.net/forum/topic/60554-29k1-pre-christmas-barn-find/ -

The 31-15 also is a drop feed machine. A lot larger than the 99 but still a drop feed machine. When ever I tried to sew suede with a drop feed machine it caused troubles. The problem always was the friction between the suede and the presser foot. Maybe it depends on the kind of suede. Maybe a Teflon foot can be helpful but I haven´t tried it. If others have different experiences it would be nice to share them.

-

Best Machine to Stitch Leather Patches on Hats

Constabulary replied to Bwhichel's topic in Leather Sewing Machines

Agree with Wiz #69 or #92 is sufficient for sewing on patches to hats, caps, uniforms... I have used a patcher (Singer 29K71) or my drop feed post bed machines for that (Singer 34K earlier and now Singer 51w) Sometimes gluing the patches in place with a water soluble glue stick before sewing helps. Sewing on patches IMO does not require "big tech" / super high $ machines. Look up "810 post bed machine" - thats basically what I´m using but mine (Singer 51w) is many decades older and has no reverse. Maybe a CB-810 or the like already does the job. Not sure what you can find locally but checking with dealers who have adverts on top of this site (turn of add blocker if using one) is a good idea. But what ever machine you decide to buy test them before buying with the thread and needle size you want to use or have the dealer to sew off the machine with what you want to sew. -

You are hopefully aware that the Singer 99 is a tiny domestic drop feed sewing machine, right? 4/5 oz one layer or multiple layers of it? When you put a layer of fabric on top of the suede it may work better as it reduces the friction between suede and presser foot. If sewing suede on top and bottom I´d rather use a needle feed or even better a triple feed machine. My 2 cents.

-

34K11 is a heavy one among the 34K class machines - lets hope it has the shuttle and bobbin cause they are obsolete (not the same as for 34K5 and the like). The machine is using 328 needles.

-

Vintage Singer industrial class 16 machine

Constabulary replied to twebber's topic in Leather Sewing Machines

usually it is just the need bar height you have to adjust (in best case) - most likely lowering it a tiny bit does the job. maybe this thread here is helpful: https://leatherworker.net/forum/topic/93484-singer-16-41-hook-and-needle-timing-help/ -

sorry if I got you wrong

-

Durkopp 241-5 needle bar centering

Constabulary replied to DanishMan's topic in Leather Sewing Machines

Hard to tell when not siting inform of the machine. If the needle bar rock frame is a bit off / has play sideways you can try to loosen the set screw screw (#1) for the pivot point stud #2 (don´t know the name) on the top side of the needle bar rock frame and carefully tap in the stud a little bit (if it really is loose). When done make sure you adjust #3 if necessary. Hope this helps