-

Posts

5,764 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Constabulary

-

its a needle feed + drop feed machine so yes, it has a feed dog.

-

Grease for the miter gears on Singer 132K6

Constabulary replied to sandmanred's topic in Leather Sewing Machines

I cleaned the 2 gear boxed thoroughly and sprayed synthetic chain lube on the gears. Nice sticky stuff for sewing machine gears. I would never fill a sewing machine gearbox with grease again. I really love this stuff. Just what I do, others may have different or better solution. -

Thor brand machines are just another Chinese clone brand of Juki Sewing machines. I generally don´t think they are worse or better than other clone brands. How good or bad they are depends on how well adjusted they are to your specific needs and how well they are supported by their dealer(s).

-

PFAFF 145 H2 - conversion to H3

Constabulary replied to DanishMan's topic in Leather Sewing Machines

sometimes it can be a simple part like a different foot lift lever or just setting of certain parts but I don´t know the Pfaff details. -

Juki LU 563 - Need help or opinions

Constabulary replied to Bluestar's topic in Leather Sewing Machines

my preferred way of cleaning - very efficient!- 6 replies

-

- juki lu 563

- cleaning

-

(and 1 more)

Tagged with:

-

I have a 111G156 and 212G141 and they all take the same parts as the 111w. I haven't noticed any differences. But you never know what previous owners (plural) did with the machines

-

see above post (just edited it) - yes - difference is the reverse. since you own both machines just test them and see which one suits your needs better.

-

most likely I´d keep the 155 but I do not know your machines in terms of condition and so forth... . The 112 has a longer flat bed and does not fit into the 111 cut out. But it has reverse - thats nice. I have a 212G141. What info are you looking for? Its a double twin needle feed machine, approx 5SPI max stitch length, gauge set for different needle spaces are available cheap either on Eaby or from College Sewing UK. But be careful - there are 2 different types of needle holder, one push in type and one screw in type. The screw in type is more common today. If yours is a push in type you can to change out the needle bar for a screw in type needle bar. Foot lift depends on how the machine is set up but I get 9-10mm material under the foot of my 212G141. Here is a 112w140 manual - same machine but w/o reverse and US made instead of Made in Germany. 112W140.pdf

-

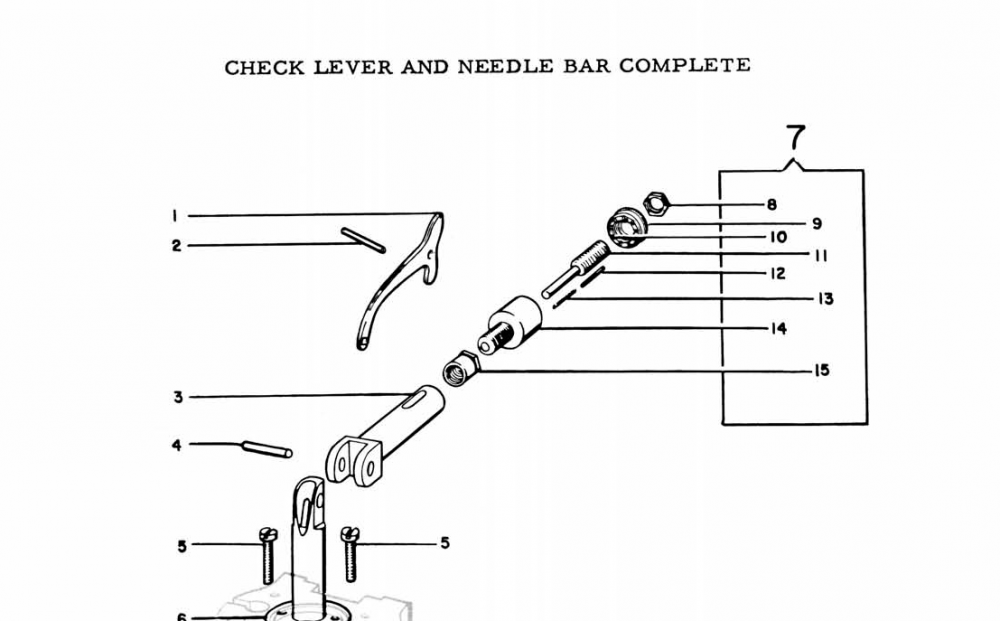

Yes, its nut #8. Reg. the front wheel - I don´t know where in the US you can buy all the parts but I guess Toledo Sewing Machines is a good source. I bought mine from College Sewing in the UK. But I´m on the other side of the pond. https://www.college-sewing.co.uk/parts-by-machine/singer-sewing-machine-parts/singer-29k-71-parts But first check if you have a gear on the top shaft. Its mounted in front of the cam.

-

105-64 are excellent machines in general. Maybe you can shot a video and load it up to Youtube and post the link here. Visualizing often is better that explaining. Regarding different thread sizes - I would recommend using a 2nd or even 3rd hook. You adjust either one to the thread size you prefer and change them out as needed and then you only have to adjust the top tension. Should not be too difficult. The 105 Machines are using the same hook as the Singer 45K or Chinese made GA5-1. https://www.ebay.com/itm/114221141266 Don´t know how good or bad the above hook is but I never had problems with the parts from this seller.

-

https://leatherworker.net/forum/topic/72789-singer-45d91-restoration/?do=findComment&comment=552471I would look for a servo with separate accelerator unit so you can mount it where you need it. I did that on my Singer 45D91 stand too (not a Sutton stand). It usually is mounted on the motor bracket (see link) but is detachable so I put it where I needed it (see picture). https://www.college-sewing.co.uk/jk-563a-220v-750w-1hp-servo-motor.html Some more images of the stand:

-

I have seen poorer machines that turned out very nice and functional. The thread lever adjuster is missing a nut as it seems (see picture). If you remove the gear box you may find a date stamped on. My 29K71 also is an EY and if I recall correctly my gearbox had a 64 or 67 date on it. This was mine when I found it:

-

How Much To Charge For A Small Laptop Bag?

Constabulary replied to AzShooter's topic in Marketing and Advertising

looks like her time and care is free soooo how about a gift? It´s of course up to you but if you want to value her work I would not charge anything. Just my thought. -

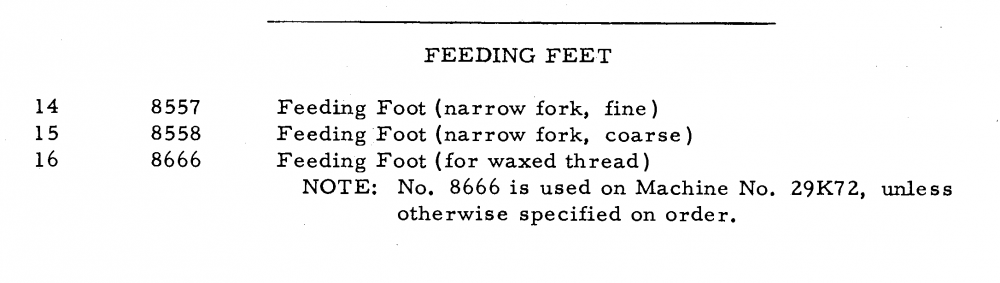

singer 29 sewing foot part #8666

Constabulary replied to shoepatcher's topic in Leather Sewing Machines

These are the two feet I have. The two numbers are mentioned in the 29K1 - 29K33 manual as standard feet that come with the machine. Dunu what the difference to the later feet mentioned in the 29K71 - 29K73 series manual is. -

singer 29 sewing foot part #8666

Constabulary replied to shoepatcher's topic in Leather Sewing Machines

Oh - I have an OEM Singer foot with #8666. I thought it is just the standard coarse foot. Not sure what the difference is compared with the standard coarse foot. But if you ask me it just look like the standard Adler 30 coarse foot. I will take some pictures tomorrow.... -

singer 29 sewing foot part #8666

Constabulary replied to shoepatcher's topic in Leather Sewing Machines

I noticed the number in the 29K manual but whats actually the difference? I mean technically. Will check what # my feet have - never did... -

When to buy first leather sewing machine

Constabulary replied to WannaBe's topic in Leather Sewing Machines

I would say when you are thinking about buying a machine you are "in the right mood" already. I started buying machines when I had ideas I wanted to accomplish and figured there is not other way than buying a sewing machine. Reminds me of how I started the "binding machine adventure" my 1st try was gluing and then stitching biding tape around edges - terrible result. Then followed by playing around with existing machines then all of a sudden I found a dedicated biding machine and I never want to go back . Little bit different story but a sewing machines really make things a lot easier. -

Nothing is too heavy to ship, it´s just a question of proper packaging. Post your add here with some good pictures: https://leatherworker.net/forum/forum/84-used/

-

Donn´t you have a wire cutter?

-

Singer 29K53 Patcher for sale In UK.

Constabulary replied to toxo's topic in Leather Sewing Machines

depends on your market and the condition - you can find them for a lot less and even a lot more. I´m glad my29K71 did not come with a stand cause I do not like treadling at all. -

thats for foot pressure too - never understood why they did that - Pfaff did that as well. Maybe for "fine tuning" EDIT: which one you mean? The screw on the top I guess The "collar" / thumb nut is for locking.

-

when the leather is to hard / stiff thread will not pull into the leather you have to make a groove before stitching. You find leather groover / creaser for less than 5 bucks on Ebay. Just bought one a couple of weeks ago. https://www.ebay.com/itm/7-In-1-Adjustable-Stitching-Groover-Crease-Edger-Leather-Craft-Tools-DIY-Set-Kit/362999943070 works surprisingly well for that money.

-

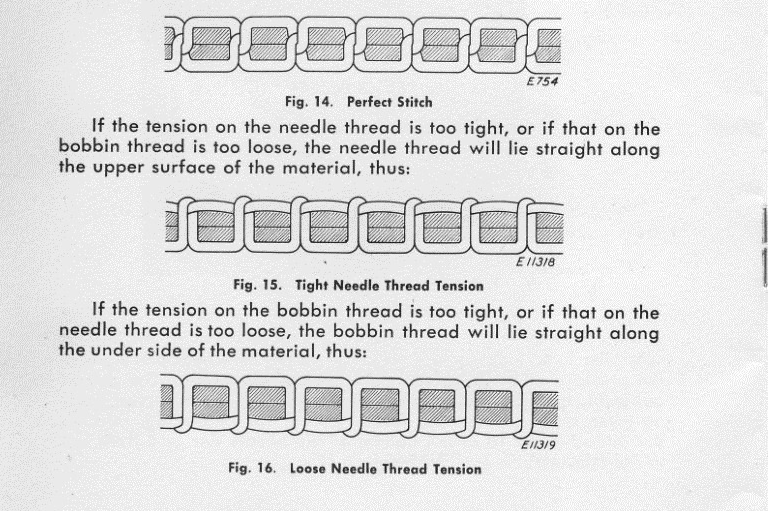

always post pictures.... Why more top tension when the thread is laying on top side? 110/120 sounds right for #92 thread. When the thread knot shows up on top side the needle hole is wide enough at least. When thread knot is visible on top the bottom tension is too low or top tension too high I´d say. Maybe dirt / lint has accumulated under the bobbin case tension spring and you do not get enough bottom tension because of that. Or reduce top tension...

-

Singer 29K53 Patcher for sale In UK.

Constabulary replied to toxo's topic in Leather Sewing Machines

nice restored patcher. Weak parts on the 29K5X are the shuttle driving gears. They are no longer available (smaller & finer teeth as on the 29K7x series and not interchangeable) -

The machine has just 1 major tension spring as it seems. I would shorten the spring by 1/2" or a bit more deepening on how light you need the foot pressure. EDIT: Haven´t noticed Pintodeluxe´s reply