-

Posts

3,794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by YinTx

-

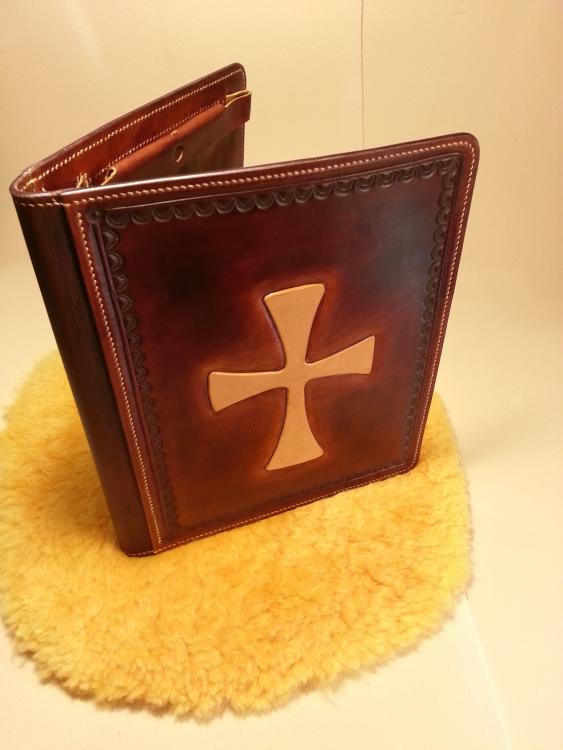

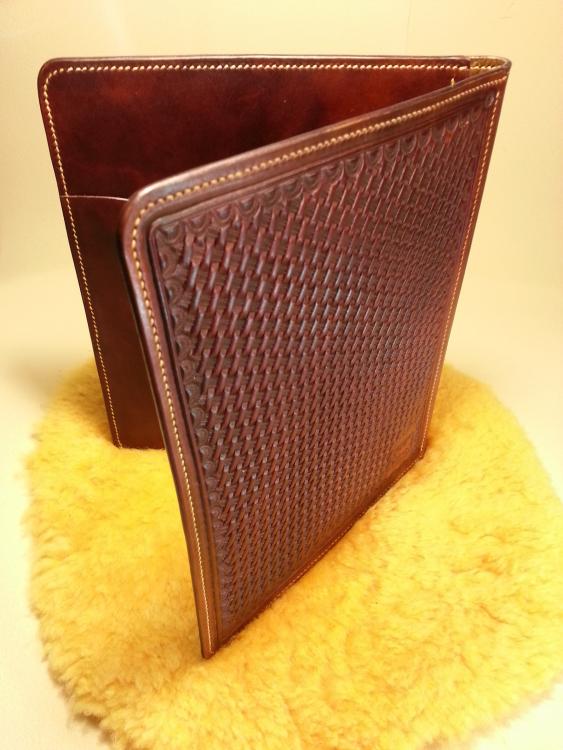

Took me long enough. Custom tooled cover for an IPad, all Hermann Oak Leather, saddle stitched. YinTx

-

Great video, would be nice to see it in action, to compare the three different blade widths and their results. Also, tried to find ?Rickert? via interwebs, but came up short. Never saw it spelled out anywhere, and I don't know where their website is, not sure if I missed it from your video or not, but I did watch twice trying to figure it out. Can you help a guy out here? YinTx

-

Most likelly my last one

YinTx replied to katsass's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Sheeeoooot. I thought that was the way it was supposed to be! Why just this last month, I've scrapped two ladies long wallets made from Barenia and Chevre Chagrin leather because I wasn't happy with some part of it, and I haven't finished the third one yet to decide if it is good or not! Used up the entire side of Chevre Chagrin to get there, and I've been doing this for a few years at least! Always have loved seeing your work, look forward to seeing your comments on other's works and general inputs in the near future, make a thing or two that you have always wanted to but haven't taken the time or had a request for! Then it won't matter when it is done, or how great it looks... but that you enjoyed doing it! and yeah, hospital stays suck, I try to avoid em at all costs... even left at 3am once just cuz I couldn't take it no more! YinTx -

Pancake knife sheath

YinTx replied to mick86's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If you are really offended by the color, you could always apply antique as a last ditch effort prior to donating to the scrap bin. Or just simply dye it black. Useable, but not the original intended look! I think it came out pretty cool. YinTx -

EMS Radio strap

YinTx replied to Horsewhishper's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Are the heavy trigger snaps necessary? Seems you might be able to replace one or two with an O ring or D ring to reduce weight, especially since you have the connected to each other. For me, having all that metal clanging around would get annoying, and I'd be looking for ways to reduce weight - also would reduce cost! Are those solid rivets or rapid rivets? I think I might be inclined to use Chicago style screws. Overall I like it,would be interesting to see it with radios etc. attached... YinTx -

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Haha, yeah I haven't had that problem yet... 'cept for the free gifts I ship out, even then I'm paying the shipping... YinTx -

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks! And this is something on the lines of what I do with my other product offerings, so if folks order this, it'll be priced with a structure like this. YinTx -

I see it. Nice trick. Your use of color on the wood does wonders too. YinTx

-

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I want folks to use my items as well, also trying to make it worth my time to make things. Am happy to be doing what I want with my time vs. what someone else wants me to do as well. I have put this out on social media, and it has garnered a lot of attention as far as my works go. No one has yet asked me how much $ or if I'd make one yet tho...suspect they may be afraid to ask lol. Now, if I could stop giving things away as gifts, and taking so long at making things, I might actually make some money! YinTx -

Awesome, but what is that I spy on the left side of the first photo? They look nice too... YinTx

-

Hollywood rig for Dan Wesson 357 CO2

YinTx replied to plinkercases's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That came out super nice! YinTx -

A few Holsters I just finished

YinTx replied to hashtagartz's topic in Gun Holsters, Rifle Slings and Knife Sheathes

No prob, was just curious. I know leather softens up some with use, and that would be against the body, so had me wondering. You are right, simple adjustment to the curve would take out the concern. YinTx -

A few Holsters I just finished

YinTx replied to hashtagartz's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Holsters look nice. But I have a question: any risk of the holster depressing the magazine release button? YinTx -

I too have been looking for some kid safe products. I have noted that Fiebeng's has a "School and Institutional" line of products, Springfield Leather's "Goof Proof" is something they claim to be safe for kids, but with all items, I'll have to pull up the MSDS before I give it a go ahead. Beeswax should be a safe thing, and I suspect neatsfoot oil will be ok. Looking to hear from others what they use for sure! YinTx

-

WIP Another mountain lion. Carving and embossing

YinTx replied to ABHandmade's topic in Figure Carving

Just phenomenal! YinTx -

Police Shield Bifold Wallet

YinTx replied to Jetdoctorbox's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I'd say that came out top notch!I like the cover flap - its a nice touch. YinTx -

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I like the thought process. I think this one was a bit big, so maybe a smaller version, and cut out several waiting for selection of tooling pattern and thread? Appreciate the positive comments on the looks and quality! I think the big factor is the amount of time I spent on it, really needs to be reduced to be a viable product for me. I think it was JLS that mentioned goin fishin vs. break even. I think I even posted some commentary regarding "fair" pricing on a post he had about some positive customer feedback he'd received on a holster he made. Oddly enough, at $150 and 13 hours labor with $30 materials would probably make this one of my more profitable items, I suppose I should ignore the $30 bags out there and motor on, reduce the time input and see what $ the market will bear. I've been waiting for the recipient to get the package I sent before I put other photos on social media, it'll be interesting to see what the non-lw community thinks of it also. Thanks also for the positive comments, the piping was a bit of a pain to make, and it complicated the stitching. I have only done a little bit of it and was wondering if it was worth doing more of or not. Something that could reduce time and materials input, but detracts from the flourish if it is absent. At any rate, if I do more of it, I suspect I'll get faster at it just due to practice! YinTx -

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks, ScoobyNewbie! YinTx -

I bought the alcohol creaser, and promptly burned some leather, not knowing how hot the thing really was. Electric would reduce that issue. Also, if you are doing a lot of creasing, the electric would not need to be continually reheated, allowing longer work runs. Electric has this silly cord hanging off the back that the manual does not. Electric is much more expensive. Manual requires alcohol, and probably a wick or two over time. Price is obvious. I still want an electric. YinTx

-

I've used 5 oz up to 7 oz. Both are pretty heavy for a small bible, I would think a 4 to 5 oz leather would do well, especially if you have a liner leather on the inside. YinTx

-

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I wish I could, but then I'd have one custom item sold and 4 on the shelf. Everything I do is one-off, someone wants a particular color thread, certain type of leather/color, different liner, a particular pocket, certain length shoulder strap, custom tooling, etc. I keep wanting to make a bunch of one item, and say "this is what I've got," but when I do, the customers say "Thats nice, can you do it in green?" I tried a tiny run of basic black belts, sold 3, still have one finished and one half way finished that I stopped on, waiting for someone to buy. The life of a leatherworker, I suppose. I show photos of what I've done, let the customer select size/color etc, and get to work. If I want to try something different, I have to make a gift like this so I have something to photograph and show! YinTx p.s. I do plan to do some shows, so for that, you are right, I'll make 5 each of things, see how it goes. -

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks much, Ferg! Means a lot, coming from an old man. The gift is going to someone in their 80's, so gives me confidence they'll like it! I liked it enough I think I want one now... just have to find the time to make another, lol. Appreciate that, RockyAussie. I'll put it out there and see what kind of a response I get, if they do sell, awesome! This explains the plethora of leatherworkers on social media! Even the not so good ones get a lot of traction, it seems. This is a recent phenomena, I believe. But, there are a lot of folks willing to pay to BIFL, and I have been one of them. Thanks also for the compliment. YinTx -

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks, Bikermutt. I think you are probably accurate with the pricing, and I know I ain't the Fastest Leatherworker in the West, but the tooling took me nearly 3 hours to do, from start of drawing to finish, and the bag took me another 8-10 hours, including making the piping, hand stitching, etc. All this totaled up for over 13 hours work, $10 zipper, $20+ leather, I'd be not be making much money. I think if someone offered me $150+, I'd do it, but I suspect they'd be shopping around at that price! YinTx -

My take on the Dopp Kit

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks! I try to remember that, but always back of my mind telling me folks are bargain hunters.... just have to keep my focus! thanks for the compliment! Not many changes to the typical dopp kit design, just some flourishes, and it is probably larger than most. And out of some really nice leather! Experience can be a heck of a teacher for sure! YinTx