LatigoAmigo

Contributing Member-

Posts

1,012 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by LatigoAmigo

-

Canadian needs help On-line ordering From TANDY Canadian Store

LatigoAmigo replied to lawman133's topic in Suppliers

I'm feeling your pain. I use Amazon quite often for Tandy items, and one of their vendors is SpeckStore. It may not do you any good, as items ship from the US, but given the current state of affairs, it might be worth taking a look. https://www.amazon.com/sp?_encoding=UTF8&asin=&isAmazonFulfilled=&isCBA=&marketplaceID=ATVPDKIKX0DER&orderID=&seller=A1DOFKMTLCPOIO&tab=&vasStoreID= -

In my experience, I have had differences in color on the same hide. Maybe not as significant as yours, but still different enough to notice.

-

The metal will dig into your back when sitting, so I'd go with leather.

-

Thank you for accepting my advice. I would like to add that you will want to allow for some elasticity in your design. Most suspenders are elastic, but leather suspenders need some help. I have always added elastic to the back, but I don't know what will work best for you. Then the next question is... how are you going to connect them to your pants... with clips or buttons? The reason I ask this is that I do wear suspenders with my tuxedo, and the clips sometimes slip off the waistband.

-

You should use 4 oz. leather; the straps should be 1 inch wide; they should be the same width all over. Once you've made these and worn them for a while you'll have a better idea of what works best. Some suspenders are for function (wider) and some are for fashion (narrower), so that determination will probably drive you to your final design.

-

You managed to take a lemon and make lemonade. Nice job, it looks great.

-

It does, but I help it along as much as I can. First I coat the leather with a paste I make that I found on the site here. It is for braiding (Ivory soap, lard and water), but ends up like a very light saddle soap. I apply it before lasering and it picks up much of the residue that might find its way onto the surface of the hide, then wipe with a microfiber cloth. On the edges I use foaming saddle soap and work it in, then wipe with a microfiber cloth. Then I seal the edges with Tokonole edge paint. It applies easily, is water based and dries quickly. Two coats of that and I'm done. The smell is cleaned off of the surface, and any residual smells are sealed into the edges. If I do any engraving, I rub Fiebing's Antique Finish into the lasered area, and let the leather soak it up, then rub the excess off very gently. Laser engraving creates an image that is very fragile, so I don't rub it in, but I don't engrave often, so I have limited experience with it. Hope that helps. I must add that I don't cut veg-tanned leathers, only chrome and combo tanned (like latigo).

-

I create all of my own patterns using Adobe Illustrator. I spent some time studying graphic design, where I learned a few "tricks of the trade." On Craig's List, I found a 100-watt CO2 laser located nearby. It wasn't what I would have preferred, but it fit my pocketbook. The work area of the bed measures 20 x 30 inches. There is a bit of a learning curve when cutting various types of leather, and then there is the smell. I just installed a fume extractor to eliminate offensive odors.

-

The body of the bag is bison, the handle is latigo and the trim is cowhide, all purchased from The Hide House in Napa. The material is cut with a laser cutter (including lacing holes) and then hand-stitched. This bag took about 30 hours to produce. Here are some more pics.

-

Oh, now I see the liner. Very clean. I don't do turned bags, so I'm not hiding seams, but looking for an opportunity to add pockets and dividers. I typically use a leather that's softer than the shell and have used a variety of leather types (pig, sheep, goat, calf), but lately I've been using what Maverick Leather calls "horse front." It is a thin but sturdy material with some "character" built into the finish (I also cut it for lace). But... because of the pockets (sometimes with zippers) it means that I am building two bags, and dropping one into the other. Takes more time, but I can't seem to do anything less. I have read several books on bags, but it mostly becomes trial and error, because in order to fit correctly the interior bag must be shorter and narrower than the exterior bag, while at the same time they must be nearly the same size where they are attached. Otherwise the liner will not lay flat, and will not look or work very well.

-

Definitely worth looking at. Very nice job. I wish I could give you some critical feedback, but I can only say that it is an impressive bag that simply knocked me out. When I make a bag, I've found that I must line it. I know that many leather workers on this site don't line theirs, but I just can't bring myself to do that... it seems unfinished. Have you given thought to a liner of some sort?

-

Beginner here: What brand of thread should I buy?

LatigoAmigo replied to TestTube's topic in Sewing Leather

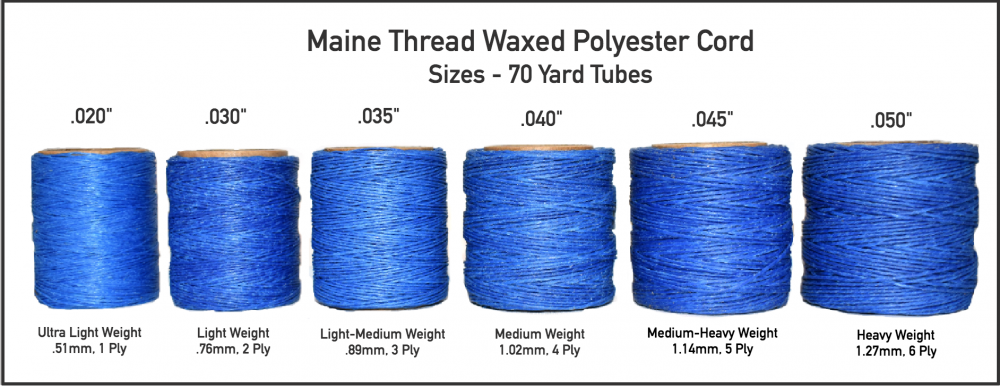

Waxed polyester hand-sewing thread has been made by the Maine Thread Company for over 60 years, and it is made in the USA. -

Beginner here: What brand of thread should I buy?

LatigoAmigo replied to TestTube's topic in Sewing Leather

Keep in mind that leather working has a long and storied tradition. If I was building a saddle, I might go for the bonded nylon, but I am a bag maker, and find that my bags are not put through the rigors of a saddle. Since you want to make things that will not be soaking up the rain, or baking in the desert sun, trust me, you will be happy with poly thread. -

Beginner here: What brand of thread should I buy?

LatigoAmigo replied to TestTube's topic in Sewing Leather

You ask soooo many questions... you might do what most of us did (before the internet) and simply experiment with materials. That's how you'll really learn, by trial and error, because there is more than one answer to what seems to be a basic question. For example, what kind of thread are you asking about? I have many sizes and styles of thread, but only hand sew, and use a range of sizes. I get most of mine from Maine Thread Company, and prefer their waxed polycord which comes in a wide variety of colors and weights. What I've found is that the weight of the thread is not directly related to the weight of the leather, but more a function of the spacing of the lacing holes and the overall look that I am going after. Sometime you will want the thread line to really "show up" and other times you will not want the thread to compete with the rest of your design. So get playful and experiment, you will never regret it. -

I think I bought the wrong type of leather to practice on? Or....

LatigoAmigo replied to TestTube's topic in Getting Started

Some of the rich colors seen in vat-dyed leathers cannot be duplicated with a bottle of dye. -

I stand by my earlier comments that each project has its own parameters, so there is no one answer as to the length of the lace. One thing I do know is that it's better to have the lace too long than too short.

-

I don't really know without seeing the project, so I tend to defer to Bruce Grant. Here is his explanation. Encyclopedia of Rawhide and Leather Braiding 162.pdf

-

Since this is a two-tone braid, would that be the total length of the two strands?

-

I thought I might offer my two cents. I've done quite a bit of braiding and lacing, and find that there is no single formula for determining the length of the lacing material because of the many variables at work (thickness, spacing, distance from edge). I would suggest that you create a sample piece before you put too much effort into your final project. It will provide you with an opportunity to see if you are getting the look you want, and to get answers to your questions. I almost always build prototypes for my projects, and find that in the end it is worth the extra effort.

-

Recent Laptop Bag

LatigoAmigo replied to JamesClifton's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That is a nice looking bag. I hope it's OK that I've downloaded and posted your photos. Links don't always work forever. -

I was fascinated too. I will never look at leather hides the same way again. Thanks for sharing.

-

The saddle looks just great! My wife is a meticulous cook and our son-in-law is a doctor, and they have many conversations about food turning rancid... and that was my first thought... can the duck fat go bad? Think of it... you're sittin' in that saddle on a hot summer day... is there any chance that a "duck like" smell might come wafting up? It would drive my wife crazy. Because of that possibility, I would stay away from animal fats and only use proven leather care products.

-

Strange thread on the hold-down screws of a domestic machine

LatigoAmigo replied to DrmCa's topic in Leather Sewing Machines

That's an engineer for ya. -

Removing mold from stone-oiled leather

LatigoAmigo replied to toolleather's topic in How Do I Do That?

I apply it to the leather, swirl it around with my fingertips, then wipe it off with a clean micro-fiber cloth.