Handstitched

Members-

Posts

2,797 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Handstitched

-

My 1st bag

Handstitched replied to the gafer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

G'Day, Thats nice, lovely finish , and I love the brass hardware. I've never used bridle leather as its too expensive here in Australia . Around $500+ per side. HS -

G'Day, I've only just found this post. I'd be too embarrassed to ' show my shop' on here, seriously . I love my workshop and I know where everything is , well.....almost, but its a mess . I do tidy up every Monday, but doesn't take long to mess it all up again. I had a look at the pics on here and I have to admit that I am a bit jealous . Your workshops are so......so.... tidy !!! HS

-

G'Day, I have done a 3" wide ' Father Christmas' belt' . I used a 3" wide chrome girth buckle. Customer was really happy with it Over the years doing leather work, I have had quite a wide variety of odd custom requests , odd shaped tool cases , phone cases etc. including a request to do some ....well .....you know ......... ' kinky' stuff. The customer kept insisting "theres a lot of money to be made" " No doubt there is I'm sure, but its not a path I wish to go down " was my reply . Needless to say I politely declined that one . The other 'odd' request, was for a left hand shoulder holster, but this made me nervous as the person asking was from a ' particular type of bikie club'. Thankfully he never followed up on his request....phew. In a small country town , reputation is everything HS

-

Walking foot is leaving marks on leather

Handstitched replied to howlback's topic in Leather Sewing Machines

G'day, Thats what I did as I had a similar problem . But I was never too sure how much pressure was on the spring and how far I could adjust it without it " getting some air time" as someone on here put it when I inquired out it. But I now have it juuuust right , ........and haven't touched it since . HS -

Adler 291 3 phase. Is it worth it?

Handstitched replied to radrider's topic in Leather Sewing Machines

G'Day, Is this of any help ? https://www.manualslib.com/manual/461794/Duerkopp-Adler-291.html#manual I know nothing about these machines, but just wondering if the ' lump in the middle' has something to do with air operated foot lifter ?? I'm sure someone on here will help you, and hopefully it will be a good investment after all . Good luck HS -

WOW ! what a great conversation ! Heres my contribution. Like most , I do a bit of both , hand stitching and machine sewing. It all depends on the job. I originally got a H/D machine to do the heavy stuff, like tool belts, heavy harness etc. the stuff that my ( often sore) hands can't always stitch by hand. I also use the machine to assemble numerous projects, as we all have. However, when I'm really ... really pressed for time and the order is to be handstitched, I have ...on rare occasions , removed the thread, and used the machine needle to make the holes, but hand stitch the rest ( ' forgive me fellow leather workers for I have sinned ' ) . But is it hand stitched ? But even using a sewing machine to make a product, to me its still hand made. I have designed the pattern , made a template, traced it onto leather, cut the leather out , done all the cutting ,shaping, tooling, burnishing, dying , added hardware, but used the sewing machine to put it all together. And besides, I'm using my hands ( and feet) and skills to operate the machine. Just wondering if I'm splitting hairs ? HS

-

Where does Tandy’s leather come from?

Handstitched replied to rivetandchain's topic in Leatherwork Conversation

G'Day Rockoboy, I probably can guess where you are from by your name ? Without getting too specific, I'm in the Central Wheatbelt. But I can say where I get my hides from, ' Leather Direct' in Ozzie Park They're an agent for NSW Leather Co. I have an account with them , and with Birdsall , also in NSW. HS -

Where does Tandy’s leather come from?

Handstitched replied to rivetandchain's topic in Leatherwork Conversation

G'Day, I'm glad I'm not the only one that finds Tandy leather expensive. And trying to get wholesale pricing , BTB with an ABN ( Australian Business Number) is like getting blood out of a stone....Or I could join a club...for a price Theres only one Tandy here in Australia, and thats in Minto, NSW.....on the other side of the country. But they do have heaps of great stuff ...just very pricey. If I have to order anything anywhere from the east, its 2 weeks. I'm in WA, (Western Australia) and theres only one leather supplier ( not Tandy) , and I have to drive 2 1/2 hrs to Perth ( from the bush) for my hides. I could get them shipped out, but I like to see what I'm buying. They get a lot of their leather from Italy, and its quite good. I also get my leather & supplies from Birdsall Leather, also in NSW, but a lot cheaper, and happy to do wholesale business to business, just like all my other suppliers ... and without joining a club. Not too many tanneries left in Oz . My 2 cents worth HS PS: W.A. also stands for " Wait Awhile " for us westies HA !!! -

Using Single Needle on a Double Needle Machine?

Handstitched replied to LloydChristmas's topic in Leather Sewing Machines

G'Day, I have a Seiko STW 28-B . It was a twin needle, but I haven't had the need for a twin needle set up. ( The machine was pretty much given to me ) . I use the Consew 226 manual for this as they are very similar . 28-B manuals are hard to find. I've had it for at least 6 years . I use mine mainly for horse rug repairs, canvas work, shade sail repairs etc. and medium leathers using industrial strength threads and suits my needs . Its regularly serviced and it works fine . Had no issues with any imbalance or uneven wear . Its 51 years old. Its a bit hard to see, but if you zoom in , you can see the ' twin needle bar' but its set up with a single needle. Hope this helps HS -

G'day, I concur with NVLeatherworx, I shape all top pieces according to Al Stohlman Soak the leather, then shape and pin it, let dry. Wood stoves are handy in Winter Then after any tooling/carving etc. I lightly oil, dye, , (use a sealer if required) , assemble, burnish and finish off with either neatsfoot, or a leather , saddle dressing. Its always best to have the clients knife / tool . I wrap mine in gladwrap, or plastic packing tape....or both prior to molding and remove just as the leather is drying. I use a block on some sheaths. HS

-

Crocodile edges. Can you burnish them?

Handstitched replied to Leahlovesleather's topic in How Do I Do That?

G'Day Leahlovesleather , I have found ,with experience, that some leathers simply don't burnish and a fold is better. I have have tried croc, mainly on belts, but its takes work. BTW , I'm in the Central Wheatbelt WA about 2 hrs drive from you. Its rare to see anyone from Perth on here. Good to see. HS -

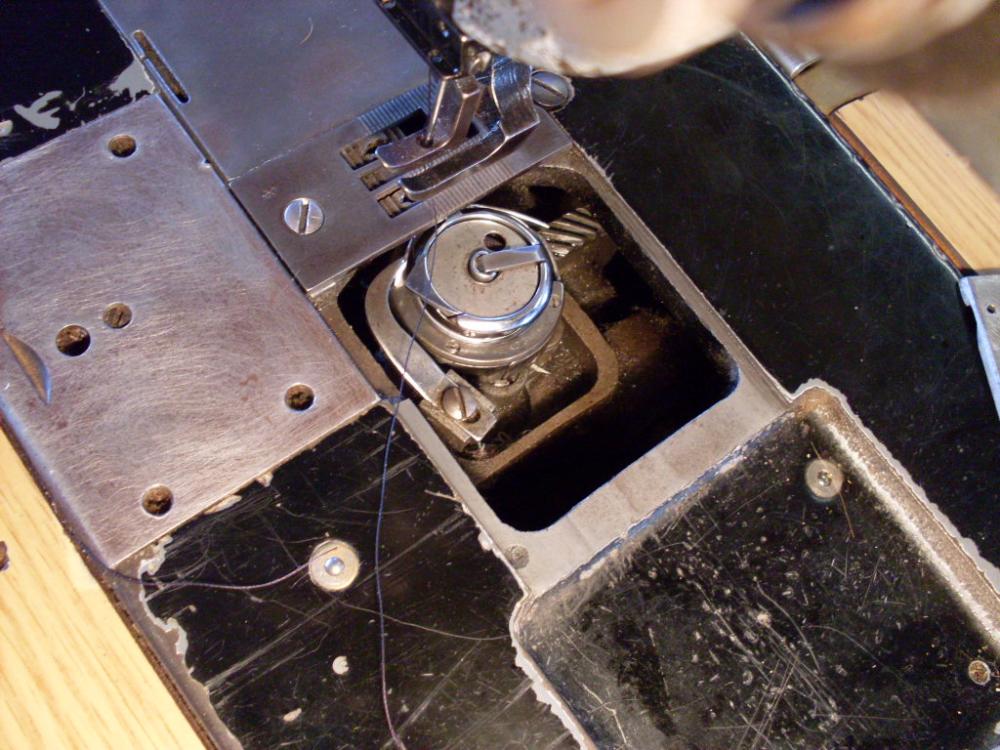

G'day, I know my response is a bit late, but I have a Seiko STW-28B ( converted to single needle ) , pretty much the same as a 226 . But mine is 51 years old....same age as me Ha ha !! I use mine for horse rug repairs and light to medium leathers. Anyway, if that little tongue isn't in the slot in the centre of the plate, nothing works right. Take the plate right out and it spins around like an idiot.... ha !! You can only just see the tongue in the pic. I've lost count the amount of times I've pulled out bits of thread from underneath the shuttle & bobbin. And it uses a LOT of oil. With horse rugs, often dirty , its absolutely necessary . Happy sewing and good luck with your 226 HS

-

G'Day, Some good hints & tips in there, especially from JLS Leather about moving the blade to make it last longer. I too have learnt to angle the cutter slightly . I mainly use butts & shoulders, but if the belt needs to be longer, then I use a side. And I guess, if push comes to shove and you run out of blades, use a ( good) pencil sharpener blade. Thats what I thought they were when I got my very first strap cutter. HA !! ( P.S , I sure I saw scalloped leather blanks in a (old ? ) Tandy catalogue once a long time ago ? Or, It may have been Birdsall Leather NSW Australia , haven't seen them since. ) Handstitched

-

G'Day, I have never used gum trag. Just a bit of water, and a slicker. My slicker is the plastic sort, but wood is better. Dye still soaks in fine. I also use the wide part of a wood handle on one of my bevellers as a ' burnisher '. Also the narrow curved part of the handle is just ideal to get into some tricky bits, like burnishing the inside of a hole or tight curves for example. Once I have dyed, I run the beveller handle over the edge once more. Works great. Something else I have used, if theres a tiny hole or a gap in between two layers , like on a leather case and won't burnish out, I have used some old left over boot polish thats has gone hard in the tin as a filler , burnish a bit more. Hardly the done thing I know...but it works a treat , and looks just as nice as the burnishing in the pic when I'm finished. Handstitched

-

G'Day , I see on the inside of the strap that theres a number still visible. I try to remove these . I have tried dying over the top, but some can be a bit ' shiny' and the dye doesn't always adhere. So instead, I get a bit of very fine sandpaper or wet & dry and very gently & carefully remove them and then dye over any marks left behind. Nice hand stitching. Handstitched.

-

G'Day, Another good tip (?) , give your machine a name. I call mine 'Brutus' . Its about time I removed the " F" & " R" magnets . I put those there on day one when I had my " L " ( learner plates) on when I was learning about my new toy....er....friend , many years ago I have a lot of respect for ' Brutus' .Its worked so hard and has now paid for itself. I have all the adjustments just perfect now to suit all my sewing and rarely needs re-adjusting. I regularly check all the nuts & bolts, the belt , cleaning and polishing as I go . Its regularly oiled and has never let me down.

- 22 replies

-

- cobra

- artisan toro

-

(and 6 more)

Tagged with:

-

'Re-cycled' boots.

Handstitched replied to Handstitched's topic in Shoes, Boots, Sandals and Moccassins

Not that this is of any importance, but I convinced the client to go buy a new pair of boots today .... ha !! And these can go right where they belong.... and where they should have stayed.....in the rubbish bin. -

G'day and thank you for your replies, Yes, they are in a bit of a state aren't they ? And I still have the martingale to do yet. Your answer is pretty much want went through my head too Big Sioux . I will be replacing the crew holes with some new ones, with the leather approx 10" in length, tapered, shaped etc as close to the orig. and spliced in. The other ends are the buckle in type, I'll be doing the same there too, approx 22" worth. They have been repaired once before with 'bits of this and that' .But I do agree with you, they would be better off with some new ones.....but...the client wants these repaired. So I will do my best to repair them, assuming they are for use. I do like the option of the synthetic webbing TT . , thanks for that. And yes, the stitching is pretty worn pretty much along the pair of them . But now I've read your replies, I will definitely keep the old thread in place.It might...'sort of' ..give some extra strength.....maybe, and may save a little time ( not sure about that comment either ) , and perhaps some cost for the client. It might take a while to get the awl & needles through, but I have handstitched some pretty thick leathers before. And , I know this sounds really silly, I'll be using my saddle machine ( without thread) to punch out the holes on the new sections so save a bit of time too. O'h well, I'll post some pics when I've finished....wish me luck I might have another chat with the client as well. Thank you very much for your replies, I do appreciate it. All the best, HS

-

G'Day, I'm just in the process of repairing a pair of old trace straps and a martingtale as per clients request. The bulk of the straps are in two layers of harness leather and are in fairly good condition, although in some parts are a bit cracked and in all honesty, I'd rather make brand new ones, but thats not what the client wants. I have to replace the strap-ends , and the crew holes( see pics) and re-stitch the two layers. But, I don't think it will be a good idea to machine stitch them as the needle may split or damage the old original leather parts, and... despite my best efforts , the machine may not align exactly with original holes. . So the whole lot will be handstitched. So, I'm thinking of keeping the old original threads in place as a way of keeping both layers of leather aligned and handstitch over the top. It would also save me quite a few hours unpicking the old thread . As many would know, it can be a long laborious job. I would normally unpick on smaller jobs , like on the martingale that will come after this. Some input would be great. Thanks HS

-

G'day, I too have had similar issue. However, what I have been using is this: Not the tool itself, but the wooden handle. (this is not mine, just an example) I have the same shaped handles on my bevellers .......who hasn't? duh I use slickers for all the 'straight stuff' belts etc. but I use the handles of my beveller for awkward corners , internal cuts etc. I have many other tools with smaller but similar wooden handles & shapes to my beveller handles that I use for a variety of curves etc. Wooden handles work best , I have found. I hope this helps HS

-

G'Day, now its my turn. I too have had problems. Mainly with the post being too short. I have found, from my own experience , its depending on which supplier I get mine from . ( I'm in Western Australia) Some are the 'Tandy ' sort, and some are from Birdsall Leather NSW, and some are even some 'non-descript' brand off ebay. I prefer the long durables, 8mm ( line 24's ) from Birdsall Leather. They are also cheaper, but sometimes not always in stock. Before setting, I have a tool that is used for another type of snap. It has a hole in the centre that accomodates the length & diameter of the posts . I place that over the top of the post first on both the eyelet & cap, and give it a few firm taps. That pushes the leather around it downwards exposing a bit more of the post . I guess the same could be achieved using a small socket from a socket set. It makes it so much easier when it comes to setting the stud . Depending on the brand , the hole is either set high or low( if that makes any sense ? ) . This is where the Birdsall brand are good, the hole in the stud is low. My old setters are so 'rounded' & worn now, but they set just perfectly . All the best HS

-

Thread keeps breaking in my sewing machine

Handstitched replied to Ed the Hunter's topic in How Do I Do That?

G'Day, Have a look at the pic. Spot the difference? theres not a lot in it eh ? That and a Consew 226? It took me a while to figure out why my thread was breaking when I first got my machine some years ago. ( My STW 28-B is now a single needle set up , not a twin needle ) . And even to this day, the same problem occurs occasionally . I use mine for horse rug repairs, medium leathers etc. First, my tension was all wrong. I messed around with the tensioners, so basically now , backed right off and totally loose now, that helped . Thats how it is now, don't ask me why, but it works fine. The second problem is....I think...... is the take up lever. My machine is just over 50 years old , and the holes for the thread in the take up lever are now a bit worn almost to a sharp edge. So every now and then, if/when the thread is at the right 'angle' (?) it 'catches' and cuts the thread . Yeh, I know time to replace it, but apart from that, it runs sweet. I also had a look at the tension spring on the shuttle, as the thread was ' codging' up underneath. You can barely see the tension screw in the pic. So I adjusted that too, it was too loose , all sweet now. There maybe other issues with your machine, but I hope that my experiences may help. All the best HS -

Neatlac

Handstitched replied to Handstitched's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

G'day, and thank you for your replies. The lacquer that was available from NSW Australia, was called 'clear lac'...or something like that from Birdsall Leather NSW. . I guess it was the Aussies answer to Neatlac. Neatlac was the only thing that seemed to work, but I don't have much left. I did try ordering some ( clearlac) several months ago, only to be told that it can't come by air as its highly flammable. Road freight was out of the question, it would have cost more than the product. But now, I can't find it on their web site. So originally I 'thought outside the leather square', and took a punt. I tried some varnish I found in the shed, on a scrap piece, even though it was 'cedar' in colour ( also water based) . That worked. After it dried, I bent it ,twisted it, and it looked good. Thats when I decided to go to my local hardware shop and get some clear varnish. The product I now use is called ' Pascol Clear Varnish' . Its made in Australia. Water based. In either gloss or satin. I have the gloss. Looks nicer imo. https://www.masters.com.au/product/100842441/pascol-interior-varnish-clear-gloss-1l.jsp;jsessionid=j5R2l1zCBn-5NEDFGEHWMA__.ncdlmorasp1202?bmUID=lpqsJJr#product-overview Its white in colour in the tin, but dries clear. Very little odor. No nasty chemical vapours. I tried one coat first, but only a tiny bit of dye was visible on some paper towel after the first coat dried, so to be sure, I applied two coats. It dried fairly quickly , but as its been cold down here, I used my trusty hair dryer to speed things up a bit. I guess if it was oil based, it will take longer to dry, and may have issues later. You may not even have to try this as 'Neatlac's variants are readily available in the US and theres so many suppliers in the US . I really do envy you guys. Theres a LOT that we can't get down here. As a result of my little experiment , I can now go ahead and make a heap of heavy belts with a retail value of approx $4500 - $5000 . I do appreciate that to many leather workers, this is not the done thing, but........it works. Thanks once again Best regards, HS -

Neatlac

Handstitched replied to Handstitched's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

G'Day , Thank you for that, and handy to know. But the same problem still exists, it can't be shipped internationally by air. I just had a look at one of my leather suppliers in the east ( australia) . they no longer supply the lacquer that was available before. Just a heads up, there are very few leather suppliers in Western Australia. Nearly all my supplies come from the eastern states where there are several suppliers and it takes 2 weeks for them to get to my place. There is one( very small one) in Perth ( Western Australia) ...and thats it. Even he has limited supplies. I have a wholesaler for my sides of leather in Perth. The clear varnish seems to be working quite well . Its white in colour , water based, and dries clear, and is flexible . I use 2 coats .Dries pretty well on its own, but I use a hair dryer to speed things up ( its winter here right now) I can now finally make a heap of belts with these hides...yey ! All the best, HS -

First Pair of Cowboy Boots

Handstitched replied to Tim Schroeder's topic in Shoes, Boots, Sandals and Moccassins

G'Day, Just had a quick look at a few vids by Lisa Sorrell, and I'm hooked. She makes some very good points about bespoke . Those boots are just stunning. HS