chrisash

Members-

Posts

2,133 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by chrisash

-

29k15 shuttle gear remanufacturing

chrisash replied to 29k15engine's topic in Leather Sewing Machines

The beauty of 3D metal printing is that you can do quite a few at the same time making it more attractive price especially cogs, worth asking for a quote in your country -

Need help threading Brother machine

chrisash replied to rivercityleather's topic in Leather Sewing Machines

How long before any vibrations make the arm fail its been weakened so much, send it back and claim a full refund it trouble either today or next week -

T move from Hobby to making a living, you need to concentrate on efficiency, cut out doing time consuming jobs one at a time, If you can cut out and prepare one belt why not do 2 or 3 at the same time much quicker and just cut to length when required. Have 2 sewing machines each set up for one size of thread saving time adjusting and running samples each time you change thread size

-

29k15 shuttle gear remanufacturing

chrisash replied to 29k15engine's topic in Leather Sewing Machines

Have you considered metal 3D printing -

Sorry but that is very wrong we did know it would be difficult, but we never voted to join in the first place, we had voted to join the common market and then the government agreed to Masseteric without going to the people. The brits have complained about the EU ever since and have always wanted the government to be sovereign powers The damage done to German and French relations is massive with many refusing to buy goods marked from either country, the remainer's are few but loud but seeing the inflexibility of the EU is slowly killing them off, many of the young were remainer's but have now seen they have not lost much I guess article 16 is the next step and FTO rules as the more likely outcome as NI cannot be separated from the UK If you are looking for small items to be posted over, I may be able to help, thinking get CS to send to me and i post them onwards, might be worth a try

-

It also works the other way, last week i tried to order a bag pattern valued at 3 euro from a German company, they refused to send the PDF file to me even though i offered a 6 Euro paypal payment . We dared to leave the EU and now we are public enemy to the whole of Europe. we must have been bad to them by saving them from the Germans

-

D they teach Indian history in all schools in the USA to a good level about their history or is it just washed over

-

What makes you think its the tool and not the skill of the operator?

-

I brought a speed reducer for £70 a few months ago from the German company at info@sieck.de, that could be the best option plus a 40-45mm pulley on the existing motor

-

29k15 shuttle gear remanufacturing

chrisash replied to 29k15engine's topic in Leather Sewing Machines

I dont know if this YT video would assist you -

"Make America Great Again" and the leather trade

chrisash replied to TinkerTailor's topic in Leatherwork Conversation

The things that make a Great Country is the people and who they elect as there government, none of which will ever be perfect, but if the majority are fair and just they may succeed -

I am not sure I understand the need for a double needle to make French seams as they are only another sewing line on each side of a seam holding down the overlap What am I missing

-

Consew 206RB-5: Not picking up bobbin thread

chrisash replied to MtlBiker's topic in Leather Sewing Machines

Half a dozen photo's of the needle v hook may well help others decide whats wrong, the old saying a image is better than a thousand words (or something like that) -

Having problems binding around corners

chrisash replied to chrisash's topic in Leather Sewing Machines

Thanks guys your advice always welcome, My thoughts were to learn a new skill at low cost to myself, just for the hell of it with no real idea of what Project if any I would use the skill for It does look like my machine and cheap binders are against me at nearly every turn, so will put it on hold for the moment as have a few ladies handbags planned to make, using Chrome and fabric non of which require the binder So frustrating that these machines do not have a couple of standard holes, to fit attachments to, but just like cars a few years ago, horn switch, light switch or headlight dimmers could be anywhere around the steering wheel and as a heavily user of hire cars where i could drop off and join ships anywhere, the first 20 miles of driving a hire car was always interesting finding out that models eccentricities especially on a dark winters morning -

Having problems binding around corners

chrisash replied to chrisash's topic in Leather Sewing Machines

The college swing away did not work just placed the guide alongside the needle, but attaching the binder would still leave it to far away from the needle so back to drawing board for a binder that has adjustment screws on the outside of the binder not the inside as at present. Well at least i now have a fixed guide rather than magnetic ones -

New Options for cutting and folding leather straps

chrisash replied to RockyAussie's topic in How Do I Do That?

Great video astonished you get such nice closed seams, You could place say a white piece down the centre with wild harry printed on it say 3 or 4mm wide and glued down the centre before it goes through the binder and close the seams to that so you make a feature of the join -

Having problems binding around corners

chrisash replied to chrisash's topic in Leather Sewing Machines

My arn't you clever -

I understand your frustration, but hopefully things will be better now you have the machine, still you most likely still have a learning period to look forward to if you have not used a machine before. Suggest practice on small offcuts and leave the big projects for a few weeks. Sorry dont have that machine so can't help you but should not be oil over the surface, just clear it off

-

Having problems binding around corners

chrisash replied to chrisash's topic in Leather Sewing Machines

Many thanks folks for the suggestions, It looks like i need to by a swing adapter from College tomorrow as unable to get this binder any closer. and apart from the rather expensive binders available, cannot see and that offer 45% which would possible give more fixing flexibility -

Reading your posts I think the only thing you have not done is to shake hands with Neil Armstrong on the moon , but I could be wrong

-

Have brought a binder for my 111G155 but having problems going around corners with the bias tape, it looks so simple on yt but not for me. I think its the position of the binder as i cannot get it very close to the machine so about 5mm away from the end of the straight guide after the 90% bend. have placed magnetic guide alongside zip feet and needle to fill in the gap but still having problems, I have been trying to swivel the material at the needle position but tape is coming away from material, any clues to my stupidity Limited holes n machine to place the binder and cannot move it closer to needle as would require a hole drilled through the thin part of the right plate so would not take a thread

-

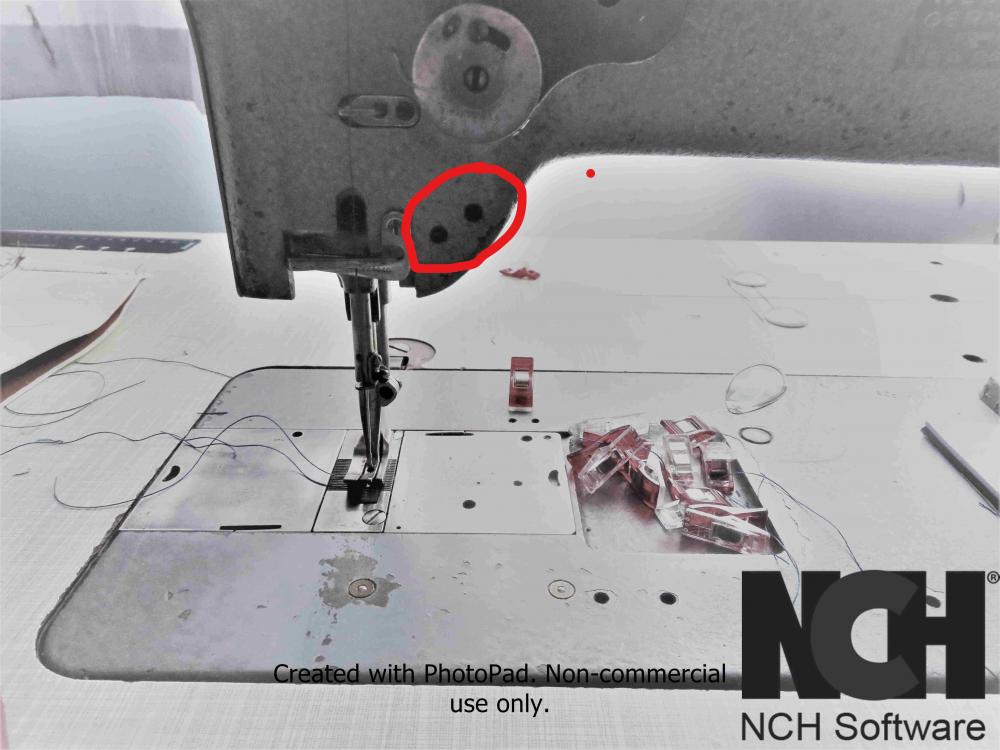

Any pull down guide to fit these threaded holes

chrisash replied to chrisash's topic in Leather Sewing Machines

Not sure how to, most pull downs i have seen tend to be screwed in on the back side of the head, hence the question about something using this side -

Also a modern brushless servo motor allows you to control start up and top speed functions as well as fitting a needle positioner so that when you take your foot off the pedal the machine stops with either the needle up or down every time and a slight back movement moves it to the opposite position

-

29k15 shuttle gear remanufacturing

chrisash replied to 29k15engine's topic in Leather Sewing Machines

You need to accurately measure your finished items and then make a percentage adjustment to your slicer to get the best results, all 3D filament's react slightly different on different printers -