kgg

Contributing Member-

Posts

3,355 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

The original greased pig sewing machine!

kgg replied to Flatcapper's topic in Leather Sewing Machines

I am sorry to hear about your experience with assembling your new machine. Glad you and your son were not severely injured when the machine got away from you. All the industrial sewing machines can be a chore to install. I think the cylinder bed and patcher machines are the worst to install as they always want to fall forward, nose first until you get a couple of bolts into the rear of the base. The problem is getting machines usually from the floor to the surface of the table and mounted. They are heavy and clumsy at the best of times. I am surprised the machine had that much oil / grease / etc on the surface of the casing to pose a problem. This is a cautionary tale for other buyers of industrial sewing machines and they should wipe the machine down before attempting to lift the machine into place. Maybe before they are shipped, they should be cleaned during the pre delivery process???? kgg -

Really nice edging in your photo's. This was my solution for my KOBE LS-1341. This was done with no changes to the feed dog or presser feet. The binder was an inexpensive in line using a swing away binder bracket. This may spark your inner mechanic. kgg

-

Very frustrating loss of bobbin tension mid-stitching, help!

kgg replied to medion's topic in Leather Sewing Machines

A good chart for needle / thread sizing for future reference is: https://www.tolindsewmach.com/thread-chart.html kgg -

Sounds like most of us when thinking about trying something new particularly when it could be expensive. The cheapskate in me always gets first priority until proven wrong. i) The 90 degree binders I have measured have about 1.25 mm space so accommodating .5 - 1.0mm thick material through the binder itself shouldn't give much of a problem but bending the thicker / stiffer tape 90 degrees probably will be a chore. That is where a custom binder will or should solve that problem. To mount the 90 degree binder to the machine will also require a specific type of mounting frame. The bookkeeper ain't going to be happy with a that purchase. ii) The standard inline binders I have measured have about 1.75 mm so accommodating .5 - 1.0mm thick material through the binder itself shouldn't be much of a problem. This style of binder can be gently pried to 2+mm. The bookkeeper would be happy. The downfall is you will need some sort of flatbed attachment to mount this type of binder attachment to cylinder bed machines. I have one for my LS 1341 clone. iii) Some people have difficulty with binding irregardless of the style of binder attachment or binding material they use. To get acceptable results it is more then likely it isn't going to be a simple bolt on affair. It is probably going to require a bit of practice til you are satisfied with the end result. Is there a chance you could post a photo of what you are planning on binding maybe someone can suggest a different solution. kgg

-

Handwheel becomes stiff at needle's lowest point

kgg replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

The feed dog maybe set to high above the needle plate and when the presser feet come down they are striking the feed dog. kgg -

Handwheel becomes stiff at needle's lowest point

kgg replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

I just tried my 1541S and handwheeled it through a couple of cycles. I found about the same amount of tension throughout the cycle with no noticeable tight spot like hat you are showing in the video. I would try to narrow it down by: i) removing the needle and see if there is any difference. ii) remove belt from handwheel and see if there is any difference. kgg -

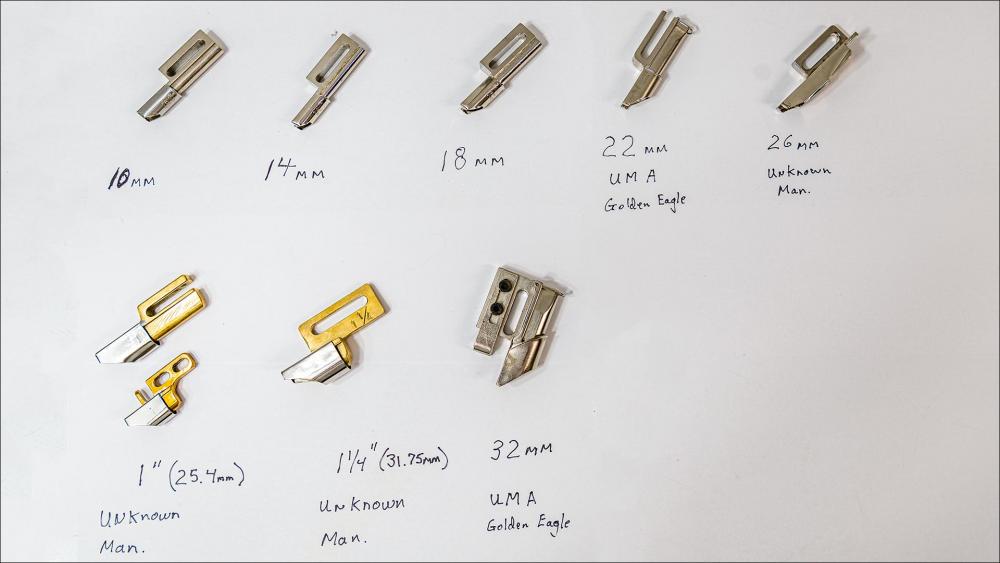

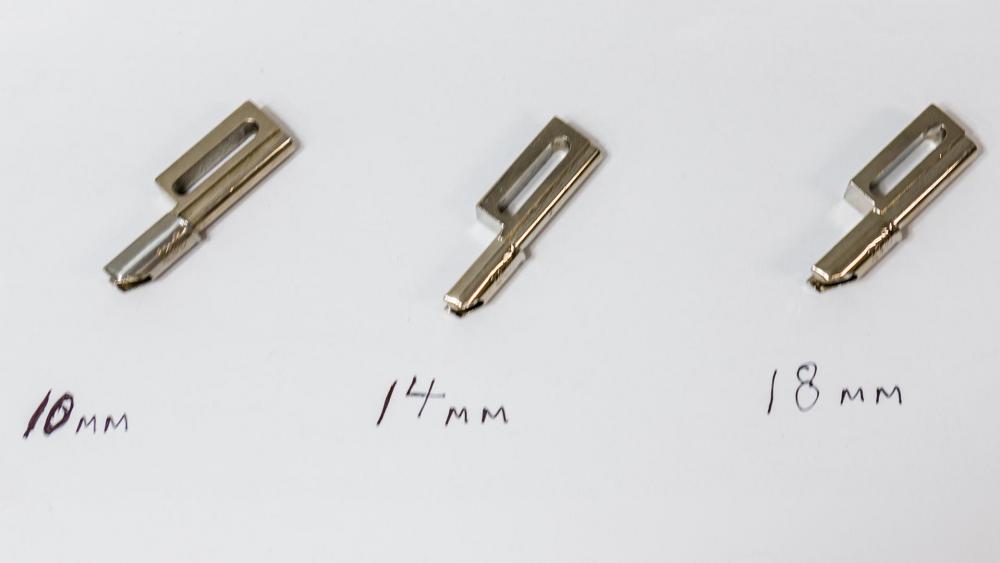

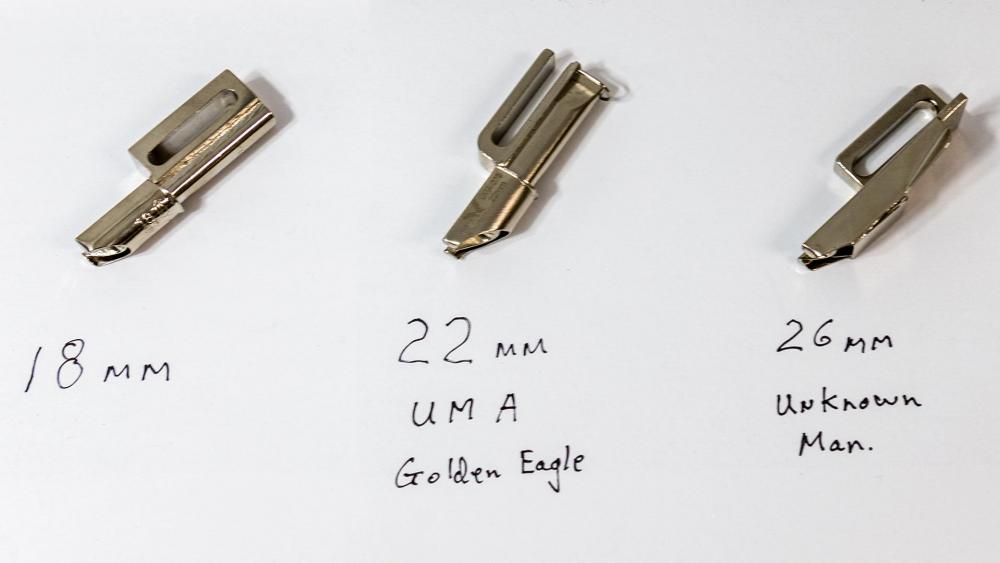

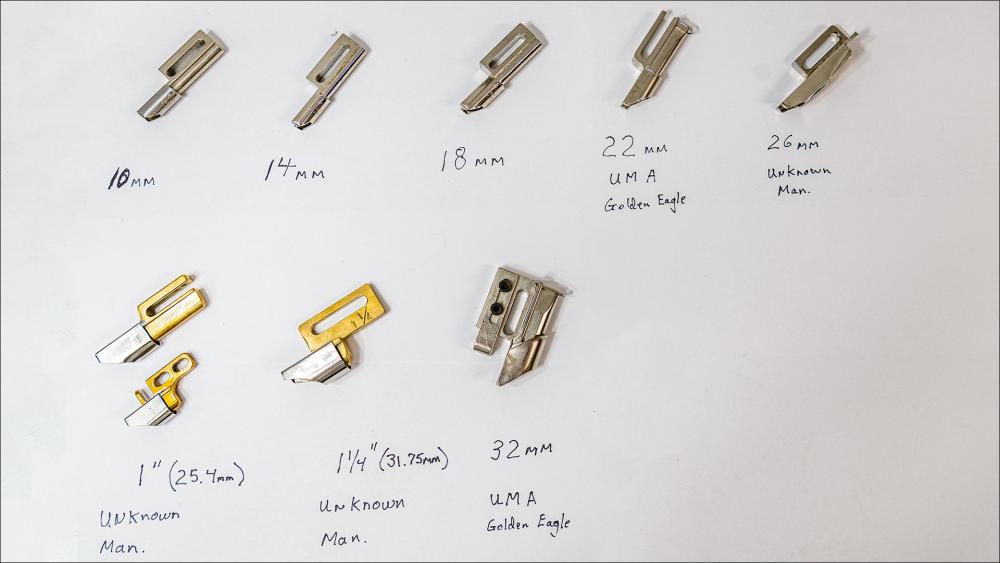

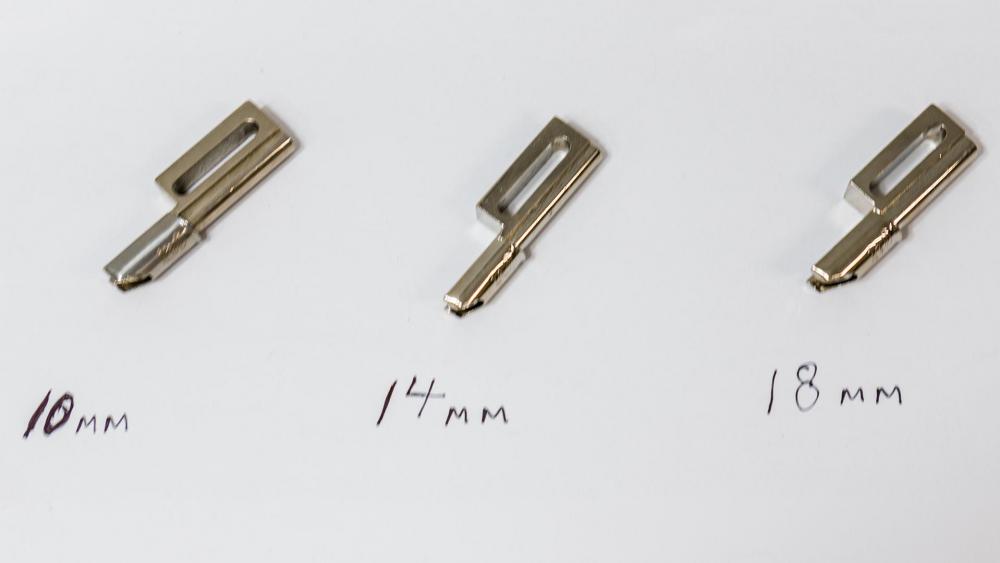

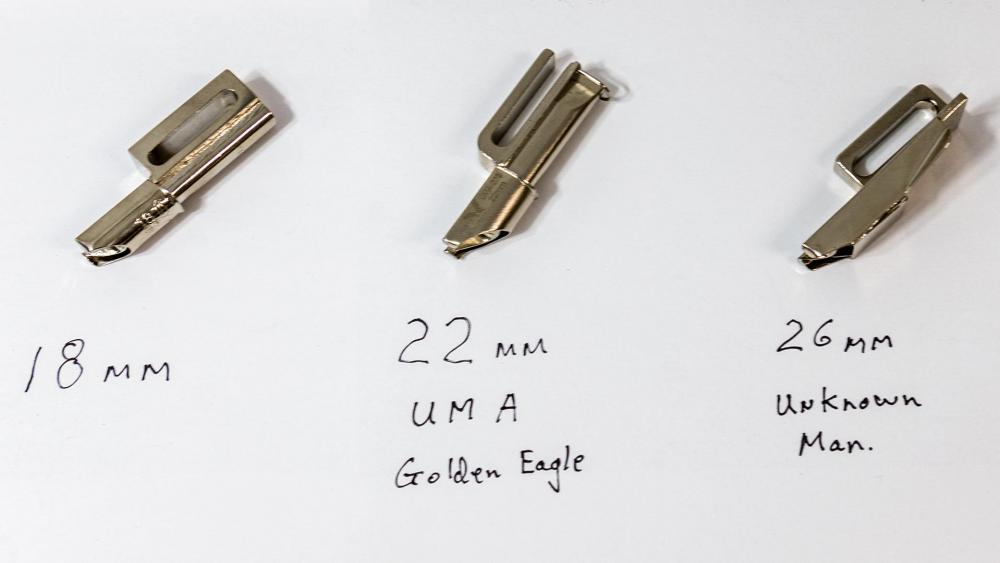

These are new old stock binding attachments. Price for each is $35 CAD approximately $27 USD. Please view photo's for available sizes. Thanks in Advance,

-

As promised these are what I have found so far in this style of folder. The 32mm binder has a adjustable front binding tape guide and the small two hole 1" has a built in tape guide. If you are interested pm me. These are "new" old stock. kgg

-

Very frustrating loss of bobbin tension mid-stitching, help!

kgg replied to medion's topic in Leather Sewing Machines

You never mention what size of thread or needle combination you are using. My suggestion to try would be to go up one needle size to give just a little bigger hole size so the thread isn't as tight in the hole. If that doesn't work when you are making the turn and lifting the pressor foot slightly make sure the needle is almost bottomed out before twisting the item. kgg -

Setting up your sewing machine guide for no hands sewing

kgg replied to RockyAussie's topic in Leather Sewing Machines

That is what I figured you had done with that style of edge guide but others may have not gotten it. I do like the outside guide mounted to the cover of the PFAFF nice simple simple solution. kgg -

The advantage of a spool holder it allows you take advantage of the lower per meter cost vs small flats. In the long run it is a lot cheaper to buy say a 304 mm (12 in ) diameter spool holding 150 meters of binding tape then a 4m flat of binding tape and you wind up with less wastage. On short runs once you are finished just pin the end to the spool and store for latter use rather them throwing out the unused piece left over from the flat. Yes the thinner binding tape will go through easily but there lays the problem. If you put a thin binding tape say .2 mm through a binder that is custom made for 1mm tape it may have to much free space to wonder around and have a tendency to slide about inside the folder which may affect how it feeds over the edge of the material. I think you need at least two binders one to handle the 1mm thick tape and another one that can handle the typical thickness size of binding tapes you use. The cost is about €99.00 or $133 CAD or $104 USD that to me is expensive. For the price of one of those binders I can buy 6 standard binders. I do have some of those style binders from when I bought all the new old stock binders from a company going out of business last year. I will check and see what sizes I have. To cost will be awful lot cheaper. kgg

-

Setting up your sewing machine guide for no hands sewing

kgg replied to RockyAussie's topic in Leather Sewing Machines

Nice informative video of how the guide should be setup. My only comment is it maybe helpful if you also showed how you set the guide itself to that angle. kgg -

cylinder arm machine - which is best for my needs

kgg replied to Blanka's topic in Leather Sewing Machines

I agree. The clones from the US are really not viable options for Canadians largely due to the exchange rate and the fact there are dealers in Canada that import similar machines from China or Taiwan. I am not saying the clones brought into Canada are better or worst as that basically comes down to the ability of the individual dealers to source / spec / prep / service / support their machines. The base price of the Cowboy 4500 is $2995 USD which is $3798.95 CAD. The minimum cost to get it across the border would be an additional 13 percent bringing the total to a minimum of $$4292.81. Since Blanca is in Montreal she would be better off buying the Techsew 5100 which can sew 7/8" locally from their office in Montreal for $4507.56 with all provincial / federal / duty taxes included. The other benefit for her would be local service, no shipping or travel etc. Another option in Quebec would be the Highlead GA2688-1 or if she wanted to travel she could find something similar in Ontario. kgg- 22 replies

-

- handbag

- cylinderarm

-

(and 2 more)

Tagged with:

-

Gotta remember that one. kgg

-

A lot of binding tape spool holders that hold the tape in either the horizontal or vertical position do NOT have bearings to help reduce drag and a lot don't have spool centering insets to center the spool of tape on the device. kgg

-

The tape guides on some binders serve two basic purposes. 1) to guide the tape to the entrance of the binder at the correct angle and 2) add / reduce back tension. If a normal coil or length of binding tape weights XXX and you have to lift or drag that total amount to the guides it is going to add extra and inconsistent drag before the binder. The object as I see it is to keep the drag before the binder to a minimum by using horizontal platters or holders with real bearings. kgg

-

I agree with Constabulary. The 1mm thick leather is going to be to thick for most inexpensive binders you will find online. The surface of the leather will probably cause more friction then most other binding materials. Like Constabulary the best solution would have a binder custom made for your needs. Another consideration to keep in mind is how and from where you are going to feed the binding tape into the binder. Are you going to let the tape just drape to the floor, coil the tape and be dragged on a flat surface or ???? You need to try and reduce the amount of drag friction to get the best results. Just having it being dragged into the binder is going to increase the load which will affect the feeding of tape to the needle. If you are going to be doing a lot of binding invest in proper horizontal binding tape platter or for smaller lengths a binding tape cup holder preferably one with a real bearing in the base to provide the least amount drag resistance giving you consistent feeding of the tape to the binder. I use the regular inline inexpensive style binders on all my machines (flatbed or cylinder bed) but I think the thickest tape I use is about .5 or .6mm and use horizontal platters or binding tape cup holders. kgg

-

My first carved holster.

kgg replied to dikman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks great to me, nice job. kgg -

To help you decide which way to go, portable walking foot or an industrial sewing machine for the items you want to sew. I would recommend you watch the video's of the Juki DU-1181N (~$1400 US w/ table and motor) and the DNU-1541S (~$1800US w/ table and motor) sewing light weight, medium weight and heavy fabrics. It really is going to come down to what you want to sew, it's thickness, the thread size you want to use and your budget. Juki DU-1181N: www.youtube.com/watch?v=IKJuKTrjsbw&t=300s DNU-1541S: www.youtube.com/watch?v=4JES-2I7h3o&t=3s Buy Once, Cry Once kgg

-

The portable walking foot machines do have their place for a number of reasons but there are other considerations like you will be limited to V92 thread, the stitch length (stitches per inch) will diminish as the thickness increases and of course the resale value as compared to brand name machines like Juki. I have a LSZ-1 clone which I table mounted and setup for a single purpose in a specific location. I recommend you consider table mounting it in a standard or cutdown sewing machine table or the one that Sailrite offers as you will find it easier to feed items if the table surface is at the same height as the sewing machine bed to avoid material catching on the left corners of the base which the Sailrite comes mounted in. kgg

-

There are two covers. 1) at the front a flat plate that covers the housing for the all the drive mechanisms driving the needle which is held in place by two screws removing that plate allows for inspection and oiling. 2) the flat plate on the top of the machine next to the hand wheel allows for inspection and oiling / greasing of the drive bevel gears which is held in place by one screw. A couple of links: Manual: www.manualslib.com/manual/505004/Pfaff-145.html?page=20#manual General instruction video: www.youtube.com/watch?v=iuzoN-I6ydI A restoration video may help with redoing the table top: www.youtube.com/watch?v=rMerpCgK1po Looking at the second photo I noticed the belts which appear to be made for other purposes then sewing machines. One has a tooth type profile made so the teeth can engage with the teeth of a gear to give better grip. The squeak could be coming from them as they don't appear to be seating properly in the pully's as their profiles are different then that of the pulley. This may cause a squeal as the belt rubs against the sides of the "V" pulley. Another possible cause is the belt tensions particularly the one going to the sewing machine needs to have a little slack and appears to be bar tight in the photo. A to0 tight of a tension on the pulleys will cause eventually the bearing to wear in the motor / reducer or the sewing machine. I would try to locate the noise by removing: 1) the belt to the sewing machine , remove the top cover by the handwheel and oil the bearing where the shaft goes through the casting to that the handwheel. That bearing maybe dry. 2) with the belt still on the servo motor and the belt to the sewing machine removed run the motor and see if there is any squeal from the reducer pulley bearing 3) with no belts attached to the servo motor run the motor to see if there is any squeal from the motor. 4) replace the belts with new proper belts and adjust the tensions as needed The price for the machine if it is a simple fix would be a good price but if the sewing machine needs a new bearing or other parts they are going to be expensive to replace, if the bearing is gone in the reducer it is going to expensive to replace (new ~$200) and if it is the servo motor pulley bearing gone it will also be expensive (new motor ~$200) while the belt replacements are fairly cheap ($$?? as it depends on the lengths). Also what are you planning on sewing as this may all be mute point as it may not be the best machine for your needs. Lets know how it works out. kgg

-

Like nylonRigging I would drill and tap two holes to accept 4mm x 0.7 thumb screws in the slide plate. The hole size for a 4mm x 0.7 screw would be 3.4mm. kgg

-

I would remove the top cover and see if there is a issue in that area. With that cover removed you will also be able to see if the machine was regularly maintained with oil and grease. If it looks dry or parts are worn you have to wonder how well it was cared for. If parts need to be replaced add that cost to your purchase price. If you are in Canada parts are going to be expensive. If you have any doubts about the machine pass on purchasing it there are always plenty of used machines. A photo of the machine would help in determining possible other problem areas to look for and give also give an indication as how hard it was used and abused. If it is an ex factory / industrial / commercial setting machine I would pass unless it was dirt cheap. What are they asking for the machine and where are you located? kgg

-

Left Stand Singer 45K Variant → Singer 145K1

kgg replied to Constabulary's topic in Leather Sewing Machines

Excellent work, nice to see the old iron as good as the day they were made. kgg