-

Posts

1,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by TomE

-

A glass slicker is useful for burnishing the flesh slide with wax, glue, etc. Loose fibers on the back side might indicate a loose structure overall that makes for a weak, stretchy strap. I mostly use bridle leather with a moss-back (pasted back). A flexible, pasted back can be created with this product that I use if I split the back off bridle leather. It is sold in quarts and gallons. https://campbell-randall.com/product/sup-bt639-g-leather-finish-for-sealing-flesh-side-moss-back-suede-1-gal

-

Polish has waxes and leaves a shiny finish that is somewhat water repellent. Mostly a surface treatment. Leather conditioner creams, balms, etc. aim to add some moisture to the fibers. They soak into the leather and typically leave a satin finish. The choice of finishes depends on the use of the item and your preferences.

-

Learning to sharpen the tools is part of learning to use them. Another reason to start with modestly priced tools. I have enjoyed using CS Osborne tools once I learned how to sharpen them. Like most tools, they need some sharpening when new to work correctly. Stohlman’s book on Leather Tools has some good tips. This cheap Japanese style skiving knife works surprisingly well once it is sharp. https://a.co/d/cuO9tG1

-

Thanks, @jcuk. From the pictures the temper looks similar to the Beiler's apron split that I purchased. Softer than the apron I am using for a pattern. The apron is 6/7 oz (~2.5 mm) and the Beiler's apron split is 7/8 oz (3 mm). Plenty heavy IMO but it will lay differently when working under the horse. The client/friend will stop by tomorrow to check out the leather for his apron. I might order the firm pearl split from Hide House and give him a choice. He's highly skilled and kind enough to shoe a couple of horses for us (I trim the others) so I want to keep him happy. I might make mayself an apron with the other split.

-

I am making a farrier apron and ordered a double bend of pearl gray apron split (7/8 oz) from Beiler's. Was surprised how soft the leather is compared to the apron I am using as a pattern, and my own trimming apron. @bruce johnson's comment about preferring a soft apron split caught my notice, and I am wondering if anyone has experience with Beiler's apron splits for a shoeing apron or other heavy use. I was looking at Hide House as a second choice. They offer firm and soft versions of pearl splits in a a 6/7 oz weight that is similar to what I am used to. Of course, I will ask my farrier friend what he would prefer for this apron. Appreciate any suggestions or your experience with either supplier's apron splits.

-

Impressive figure carving. I like your floral pattern as well. A distinctive piece of art.

-

Good tips! I will look into the speed reducer. Here's a link to the video.

-

Welcome! I make bridles as well, and the Antares bridles are a favorite. Your friend @FrenchMich is friends with sellier Jean-Luc Parisot whose work I have long admired. Not sure if Jean-Luc is doing leatherwork these days but his Instagram account has pictures of many beautiful items.

-

Happy Easter, @chuck123wapati.

-

Cobra class 4 foot pedal: Thread Release

TomE replied to DieselTech's topic in Leather Sewing Machines

Probably an easy fix. I have assembled the release incorrectly before, when I had the cover plate off to adjust the walking foot mechanism. -

Cobra class 4 foot pedal: Thread Release

TomE replied to DieselTech's topic in Leather Sewing Machines

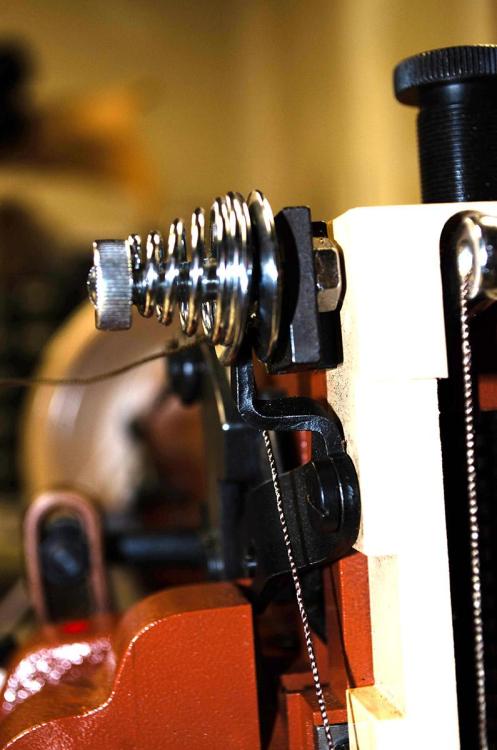

That pointy tip should insert between the tension discs when engaged. You can remove the beige cover plate (2 screws) to reassemble the tension release lever. I would first try just repositioning the lever and reassembling. If it is still misaligned then I would consider that either the tip is bent or the tension disc assembly is missing a spacer that holds it out away from the beige cover plate, more aligned with the lever tip. The first 2 pictures are with the tension release engaged. The third picture is the lever disengaged and the tension discs closed together. -

I think depends on your starting point and process for belts. I have a 4x8 ft work bench in the middle of my space with machines around the outside. I am rolling out sides on the bench to cut straps. I use hand tools on the bench for cutting, edging, creasing, skiving, dyeing, burnishing, and assembling. I like being able to spread out my work.

-

The link didn't work so I couldn't see the defect, but it sounds like lifting of the grain. There is a natural junction between the grain and the underlying flesh layer (corium) that is rather weak and open in structure. It is vunerable to breaking and more so in low quality leather, a defect referred to as "looseness." The "break" of the leather refers to the ripples created when the grain is sharply flexed (concavity). Good quality leather makes fine ripples (fine break) and low quality leather makes coarse ripples with more separation of grain and flesh layers. Blistering caused by uneven wetting of the leather is the same phenomenon. If you're interested in the structure and chemistry of leather the book "Tanning Chemistry. The Science of Leather" by Covington and Wise is a very detailed (685 pp) reference.

-

Where does this piece go? Cobra Class 4

TomE replied to DieselTech's topic in Leather Sewing Machines

That's a thread guide and it goes where you put it, I think. My Class 4 didn't have one and it is not mentioned in the LMC instructions for threading. My Class 26 has this guide and you can route the thread straight through one hole, or make a serpentine pattern through additional holes to add tension to the thread. My Class 4 has been happily running for 3 years without this thread guide. -

I did a Google search "site:leatherworker.net stitching pony" and found quite a few designs.

-

How to fix this mess? Bicycle seat cover.

TomE replied to panchoskywalker's topic in How Do I Do That?

I suggest you cover the seat with a smooth grained leather or vinyl. The suede will create friction and it won't wear well. My first job (51 yrs ago) was working in a bicycle shop assembling bikes. The top bikes had Brooks saddles that are still made today. -

I think gluing and sewing all the layers would do the trick for constructing it flat than curving into a circle. I'd consider sewing the strap with the dee rings to the wider strap before sewing the pad on the back, unless you're OK with the additional stitching going through the padded layer. Could add some wedge shaped welts on either side of the dee rings. JH Leather videos show this method for the dee on a padded dog collar. Since you're hand sewing with an awl you'll be able to jump over each dee, and possibly overstitch the dee as shown in her videos. That's how I've been fixing the dee to the buckle turn of a dog collar.

- 21 replies

-

- foam padding for leather

- layer

-

(and 2 more)

Tagged with:

-

No room for two needles in stitching holes (pics)

TomE replied to Dannyman's topic in Sewing Leather

I didn't watch the videos, so this might be redundant. To avoid piercing the thread when pushing the second needle through pull the first thread backwards as you advance the second needle then pull up the stitch. This requires clamping the work in a pony/horse/clam so you have both hands free to manage the needles. In the perfect world you would use a sewing awl instead of chisels. Pliers are sometimes needed especially when overstitching at the beginning/end of a stitch line. I wax the thread with beeswax, or a mixture of pine resin-beeswax, which makes my fingers slightly tacky and improves grip on the needles. Stohlman's book on hand sewing covers basic technique and some construction methods. -

I think at the end of the day if the collar fits then you've made the right choice. How tight/loose it fits is a matter of the owner's choice (in my experience for dogs and horses) so this is not an exacting process. I typically measure a collar/bridle that fits to the owner's satisfaction and make mine the same size (plus padding allowance if needed). The calculated padding allowances are small and I only recently did the calculation out of curiosity. I haven't had a problem making dog collars and nosebands as flat straps then wrapping them in a circle. The noseband above is made from 2 layers of 9 oz leather and I've made dog collars in a similar manner. They close in a circle without a problem. I sometimes bend the buckle turn with my fingers to match the curvature (3 layers thick and skived on the end). I am using Hermann Oak regular veg tan or bridle leather. I typically apply a light coat of neatsfoot oil followed by conditioner at the end of the project. Perhaps you could show us pictures of a collar that isn't shaping up.

- 21 replies

-

- foam padding for leather

- layer

-

(and 2 more)

Tagged with:

-

Looks like a winner! That is an interesting girth. Guess you have materials to make all your relatives suspenders for Christmas.

-

That's some nice craftsmanship, Jonas. Not sure if this long dee ring would be large enough. https://www.weaverleathersupply.com/products/571-long-dee

-

The stretch of leather is of interest for saddlery and harness making - how much the length changes with use. I'd be interested in comparing different tannages for stretch under a controlled load. Bridle, harness, and regular veg tanned of similar weight. Also there is some debate about how much the grain contributes to the strength of a strap versus an equal thickness of a flesh side split. How much leather would you need for testing?

-

I knocked my machine out of time when I was learning to sew and this video by @Uwe got me back on track. He also has a video on adjusting the walking foot that is very well done.