-

Posts

493 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BlackDragon

-

An image I found does show a possible stirrup. It's pretty basic, made out of wood and covered with leather, much like the saddle.

-

I put the saddle into Grok. The information from AI can be suspect but you'll have to do more research to determine if what Grok put out is reliable. This is Grok's result; Based on the photos you shared, this appears to be a Plains Indian woman's saddle from the 19th century, commonly referred to historically as a "squaw saddle" (though that term is now considered outdated and derogatory toward Native American women). A more accurate and respectful name is "prairie chicken snare saddle," named after the shape of the high pommel, which resembles snares used for catching prairie chickens. These saddles were used by tribes like the Blackfoot, Sioux (Lakota), Piegan, Nez Perce, and Crow in the Great Plains and Rocky Mountain regions. ### Key Features Matching Your Item - **Structure**: It's a frame saddle with wooden sidebars (bars) covered in rawhide or leather. The high pommel (front) and cantle (back) are typically made from bent elk or deer antler (softened in water and shaped), forming an arched, U-shaped loop with an open hole at the top. This design provided stability for riders and allowed for securing loads when used as a packsaddle. - **Decorations**: Yours has brass tacks or studs along the edges, which were a common embellishment on Native American gear from the period, often traded from Europeans. While basic versions were undecorated, variations included tacks, beads, or quillwork for aesthetic or status purposes. - **Stirrups and Straps**: The attached leather-covered wooden stirrups and rigging straps (for cinching to the horse) are typical. The overall worn, aged leather suggests heavy use and antiquity. - **Size and Use**: These were lightweight (around 20-25 inches long), all-purpose saddles for women, children, or older men. They doubled as riding saddles for long journeys and packsaddles for hauling buffalo meat, camp gear, or attaching to a travois (a drag sled). They were quick and inexpensive to make compared to pad or full wood saddles. These saddles became widespread in the mid- to late 1800s during the buffalo hunting era but fell out of common use after 1850-1870 as tribes adopted more Western-style saddles. Women in these cultures were often the saddle makers, using local materials like antler, cottonwood, and buffalo rawhide stuffed with grass or hair for padding. If this is authentic (which it looks to be from the craftsmanship and patina), it could have collectible value—similar examples from Crow or Blackfoot origins have sold at auction for $1,000-$5,000 or more, depending on condition and provenance. I'd recommend consulting a Native American artifacts expert or museum (like the Museum of the Plains Indian) for authentication, as reproductions exist. For visual comparison, here are some examples of similar saddles:

-

I thought it was for sheetmetal as well. Could be the cobbler adapted a metal shear to cut leather. Maybe someone gave it to him or he got it cheap and adapted.

-

Merry Christmas everyone!

-

I've been trying to find out about this machine but I'm not finding much. The words "Marca depositata" is Italian for "registered trademark" so it's likely this is Italian made. The possible machine name may be Lince which is Lynx in Italian and Spanish. On the label in front of the L the graphic seems to have a tail and you can see the 2 front legs leading to it being an animal. So (Lince) Lynx may be correct. More than likely, since you got it from a cobbler, it's a sole trimmer. Sort of like a 5in-1 but it's a guillotine cutter and it only does one thing

-

mountain man moccasins pattern #3 By Gene Noland

BlackDragon replied to chuck123wapati's topic in Patterns and Templates

Really cool! Just add some shearling on the inside and you have nice winter shoes. Just watch out for ice lol. -

It's hard to say really. Can the error be viewed by a potential customer as a scratch because of use? I wouldn't worry about it. I tend to focus on my mistakes and I don't like something that's glaring to me. Other's may not see it but I tend to catch it and it bugs me. If I want to show off a purse that I'm selling for $250 I don't want something obvious showing up. It's my name on the bag and the price tag warrants redoing a strap that will cost me $5 to replace.

-

When you say groove line are you meaning an indentation with something like a compass or an actual groover where you're taking off the top layer of the hide? If it's the first one I would do it as Bruce said. You may be able to undue the indent and it won't be noticeable. If it's the second I'd start over. I would keep that belt for myself or someone that doesn't mind a blemish but I wouldn't give that to a customer that's paying top dollar for a belt

-

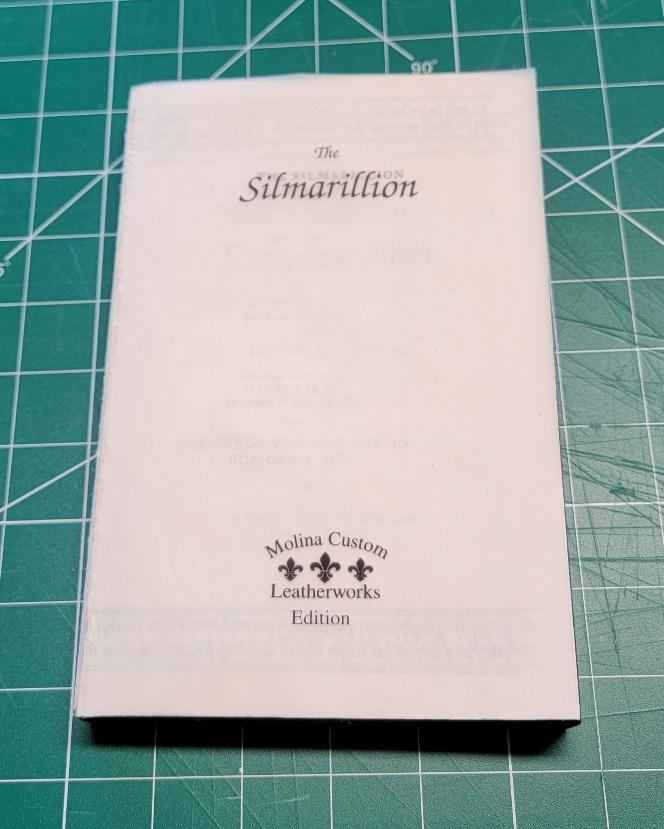

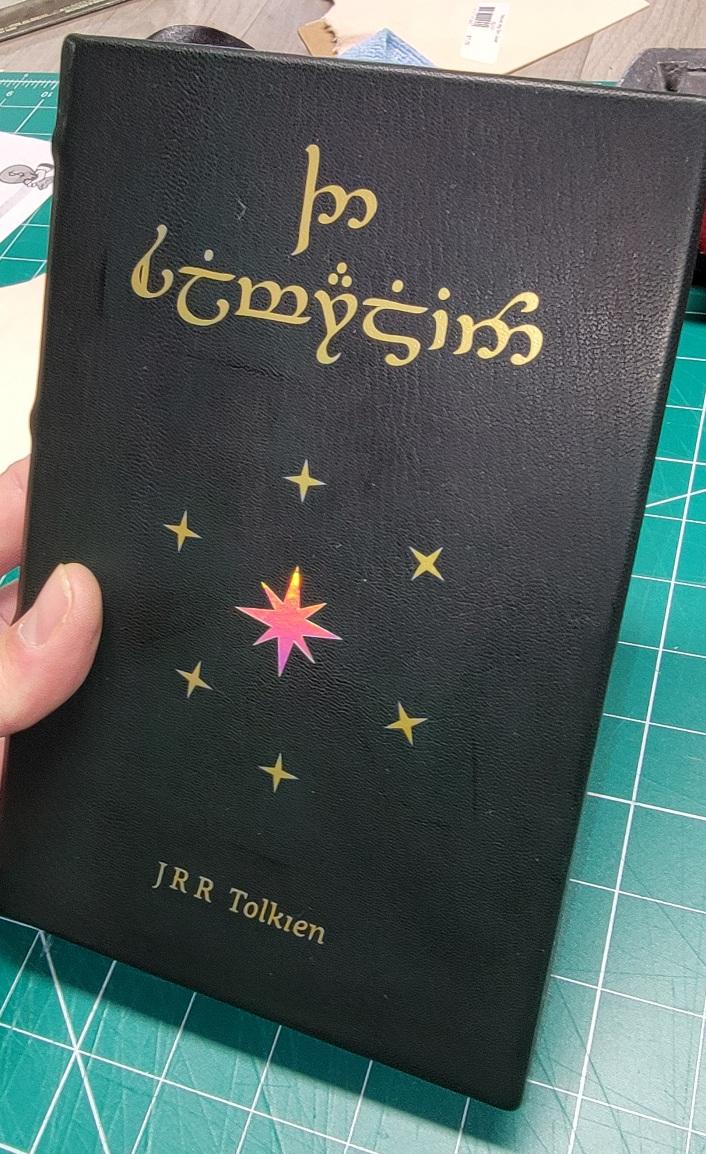

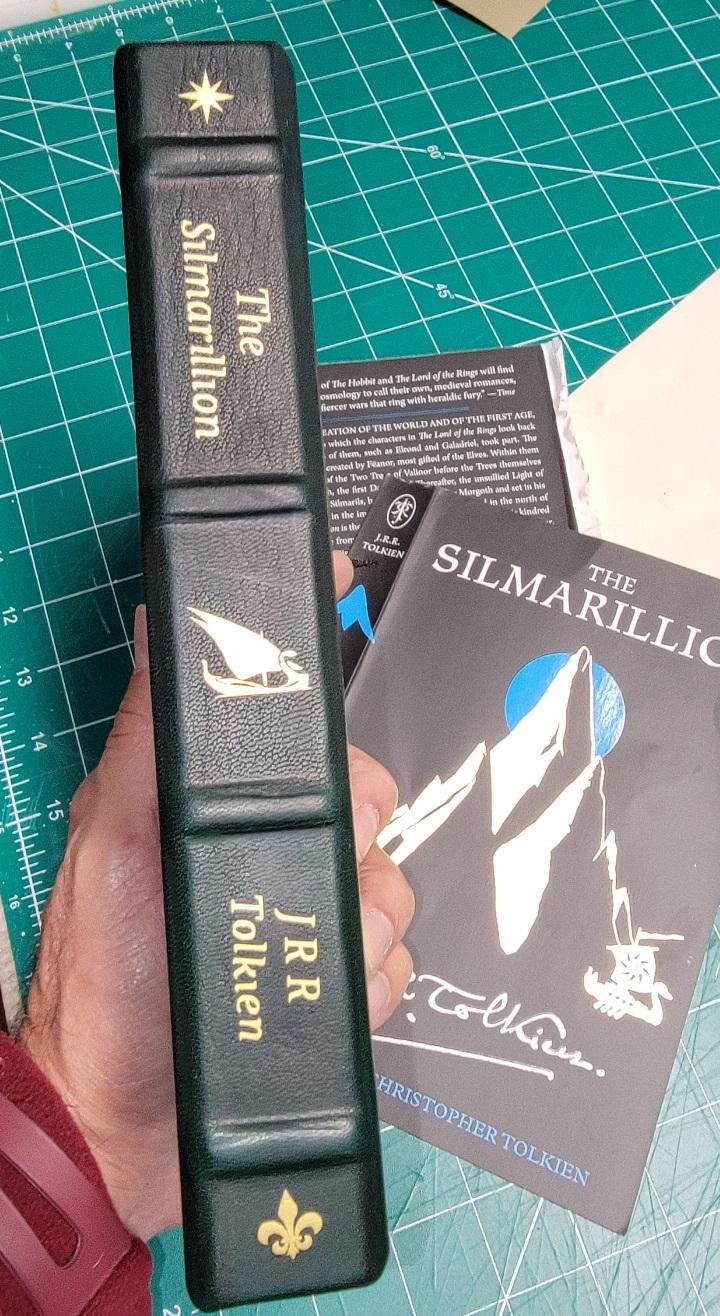

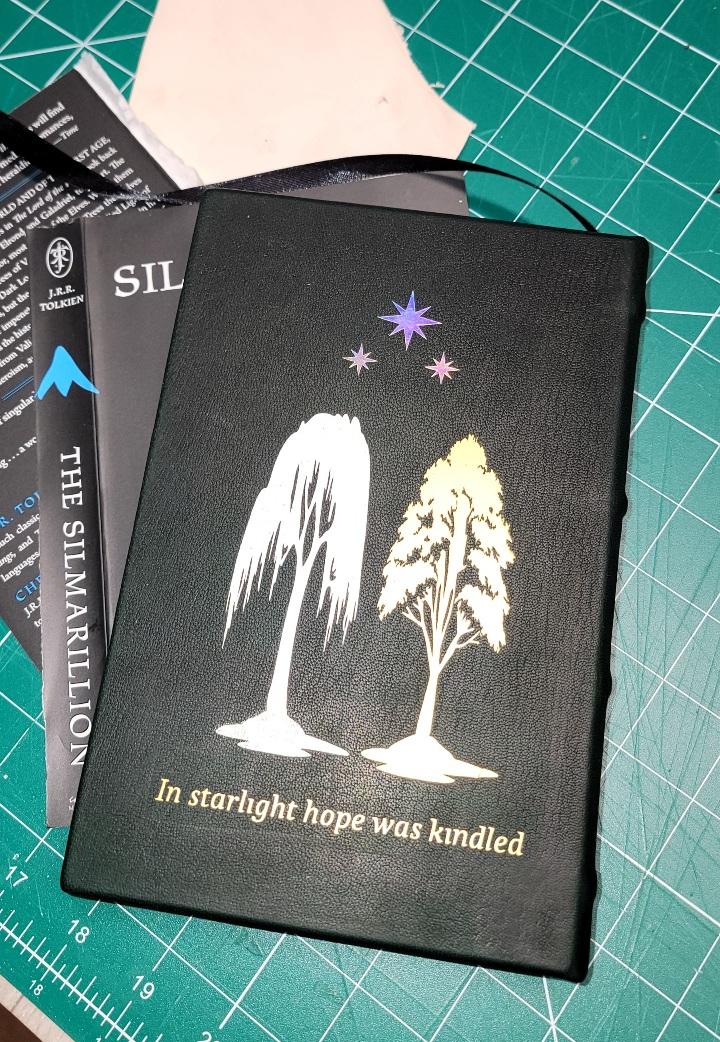

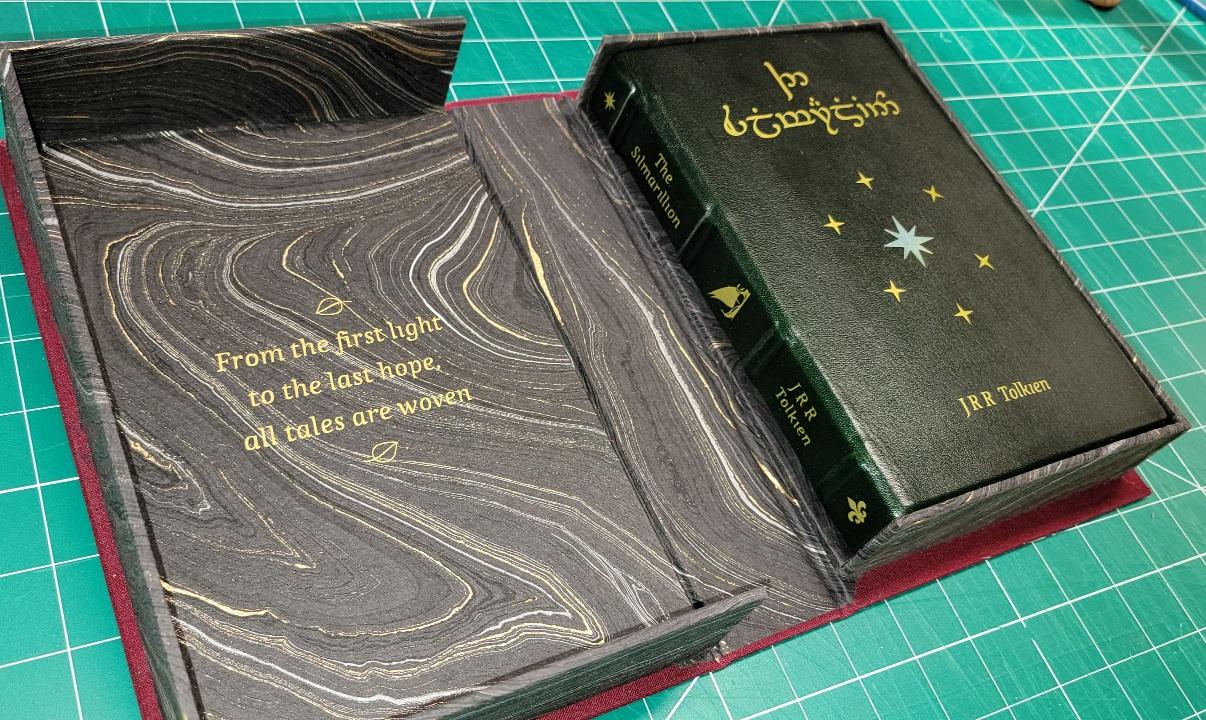

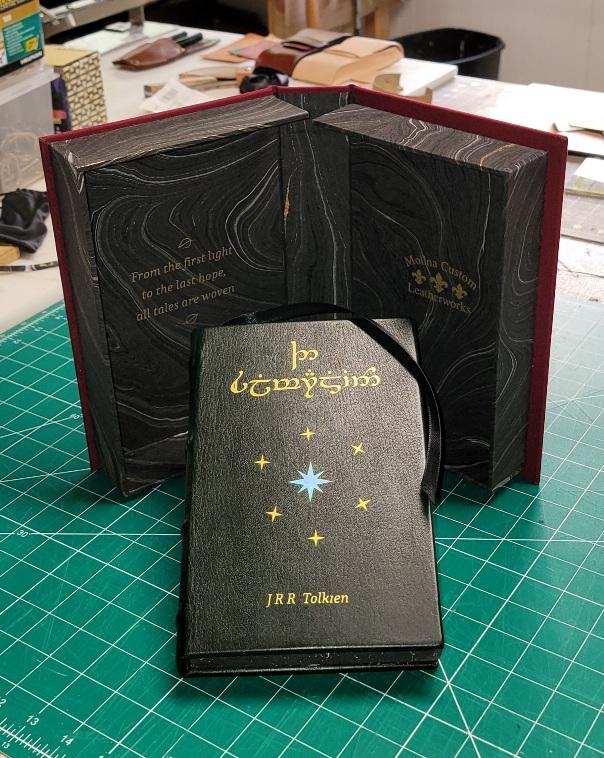

Thanks! Generally when I mention The Silmarillion people don't know much about it, this is why it's in a separate clamshell. Everyone knows The Hobbit and Lord of the Rings so it makes sense to have those 4 books in one box. I like to joke The Silmarillion is for the Tolkien nerds lol. Thank you, I really appreciate it. After taking a few product pictures I find that it's missing something to make it more cohesive. On the back cover especially, everything just looks to be floating there. I think a border will bring more balance to it, like putting a picture frame on a photograph. Making the borders gold on all the covers will tie the books together while the other things, like end pages, being different will state that you're in a different part to the story.

-

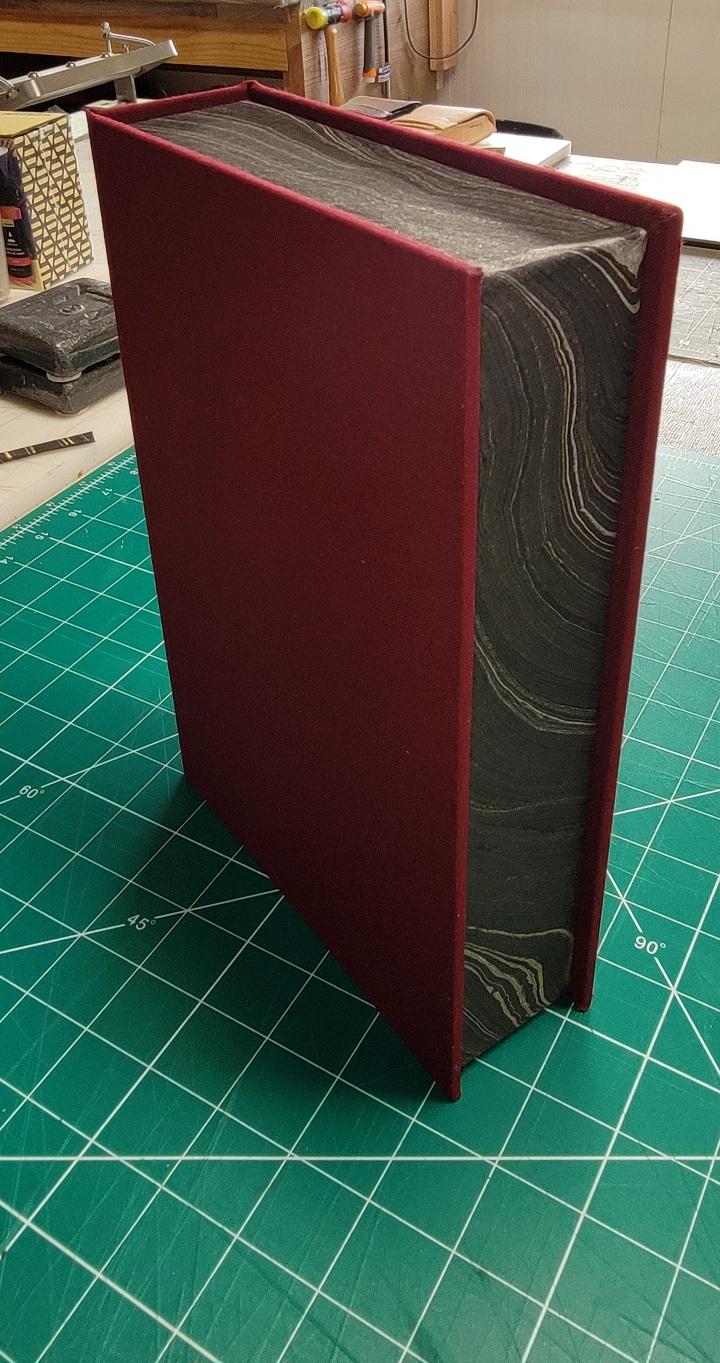

Each book will have different color marbled end pages, speckled page edges, and ribbons to match. Each of those colors will reflect the mood of the book. For instance, The Hobbit will have light brown marbled end pages, a dark brown ribbon, and light brown w/rust speckles page edges. It gives the feel of the earth because Hobbits like to grow things. As to the border lines around the covers I still haven't decided but I want to be consistant with all the books.

-

The single star on the front and the 3 on the back are holographic so they change color. The silver may work because one of the trees on the back is silver but it would break continuity with the other Tolkien books I plan to make.

-

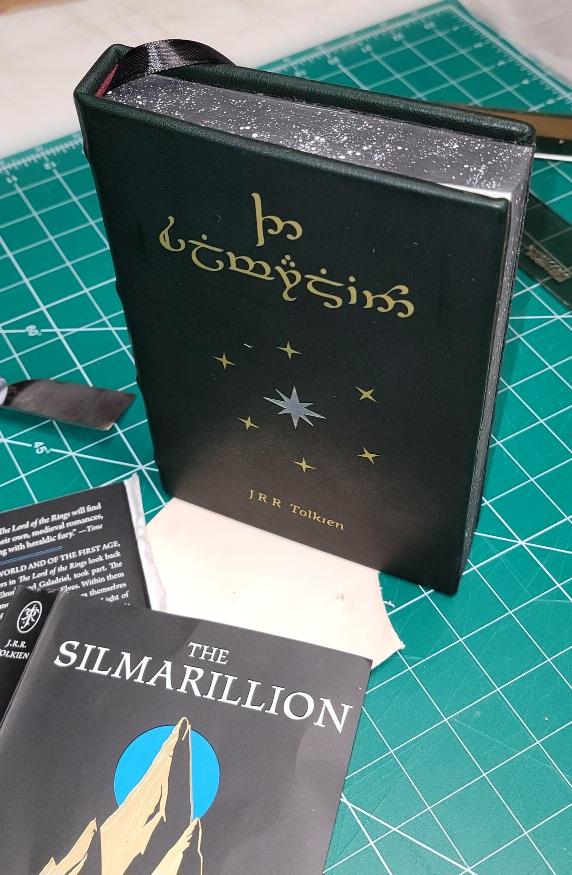

Thanks! No issues with copyright. With rebinding as long as I dont make changes within the text block I'm safe. So I can't add my own art or any extra pages inside the text block. I can add things on the back and front though. I can't recreate any Tolkien, Warner Bro, or Amazon art. Even their elvish script is protected. Thankfully a guy made his own "elvish" script that he gives permission to all to use for private and commercial work.

-

Like Chuck said neatsfoot oil will soften and darken. Adding to much oil can turn your leather into oily mush, so take it slow. Do a few test pieces from the same leather you'll be making the headstall. The dye looks to be Fiebings Pro dye in dark brown When I do a vegtan headstall I tool it then add pure neatsfoot oil, you dont need a lot just enough to dampen the leather. I let it set in for a few hours then apply dye. The neatsfoot oil will act as a carrier for the dye and help it spread evenly. Let that set for a day. If its still stiff I work the leather a little. I roll it up with the skin side up and again flesh side up, I do this a few times. If it's still stiff add a little more neatsfoot oil. If it's not dark enough add another coat of dye. After dying it a second time it may be stiff. Just work the leather and it should soften. If not add a little more oil.

-

Thanks a lot, I really appreciate the feedback. The thought process was to make it to sell. If it doesn't sell it was going to go on my bookshelf. Before I put the leather on it I showed it to a friend and he wanted it for his son. He just really liked the page edges and end pages. Lol Do y'all think I should put a 2 line border on the front and back covers?

-

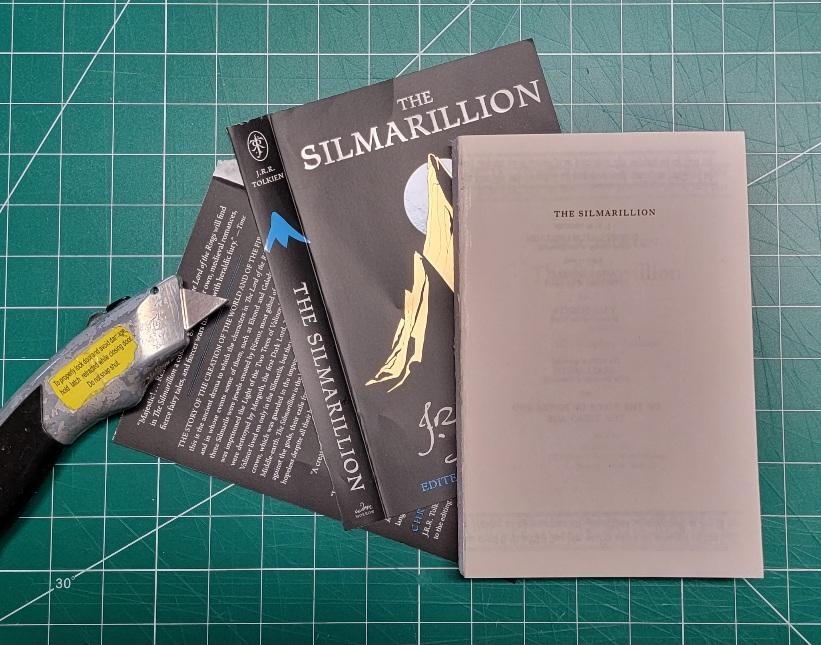

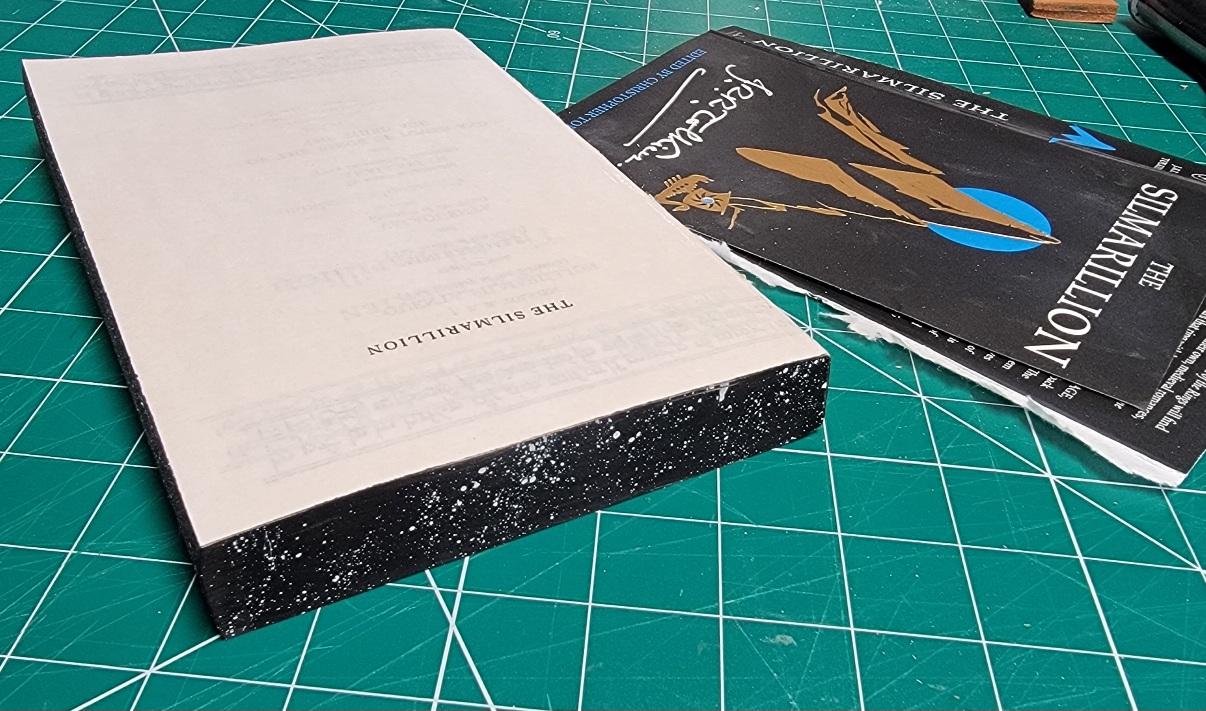

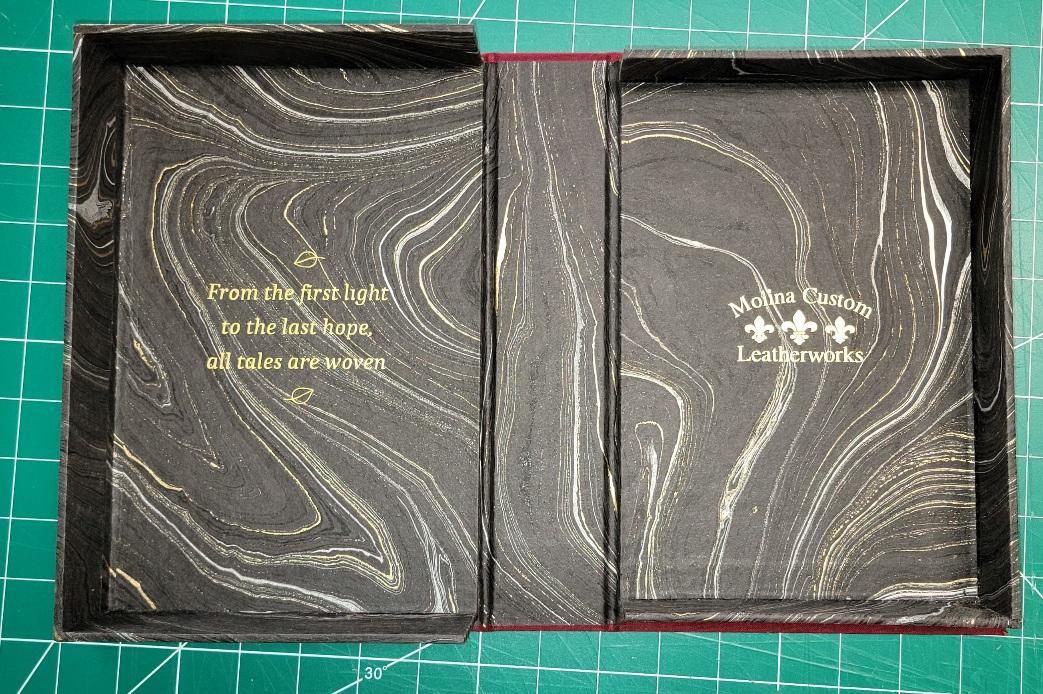

I started a book rebinding project. It's going to be JRR Tolkien's The Silmarillion in a clamshell box and after the holidays I'll do a box set of The Hobbit and Lord of the Rings trilogy. I started by tearing off the paper covers from the text block. I painted the page edges black with white specks. I added a vellum title page, a black silk ribbon, burgundy headbands, and black marbled end pages. For the cover I used 2-3oz vegran goat hide. I gave it 3 coats of Fibing's green Pro dye, .095" binder's board. For the cover art I used gold and holographic heat transfer vinyl (htv). I sealed it all with a few coats of a mix of Resolene and carnuba wax. The clamshel box I used .095" binders board, burgundy book cloth, black marbled paper, and the art was htv.

-

Just saw a post on Facebook that Cobra Steve from Leather Machine Co has passed. Their website states: "It is with great sadness that we announce the passing of Steve Tayrien, lovingly known as Cobra Steve. As one of the founders of Leather Machine Company, he believed deeply in people and dedicated his life to helping others grow and succeed. His kindness, vision, and unwavering faith in those around him made a lasting impact on our community." My prayers go out to his family and friends.

-

There are a number of ways to make this but like Bland said it depends on the current design. You can make one that has elastic bands on the bottom, a slip cover style, I replaced mine by taking the old one off and using it as a template for a new one.

-

showoff Sharing one of our favorite recent projects.

BlackDragon replied to Teddy Patches's topic in Show Off!!

I going to throw out a guess and say there is a backing, like what you see on the inside of a ball cap after it's been embroidered, and since this is just a patch it's not really going to have much strain put on it. It look pretty cool I would like to see it in white against the black leather. It would really pop and give it a heavy metal vibe. -

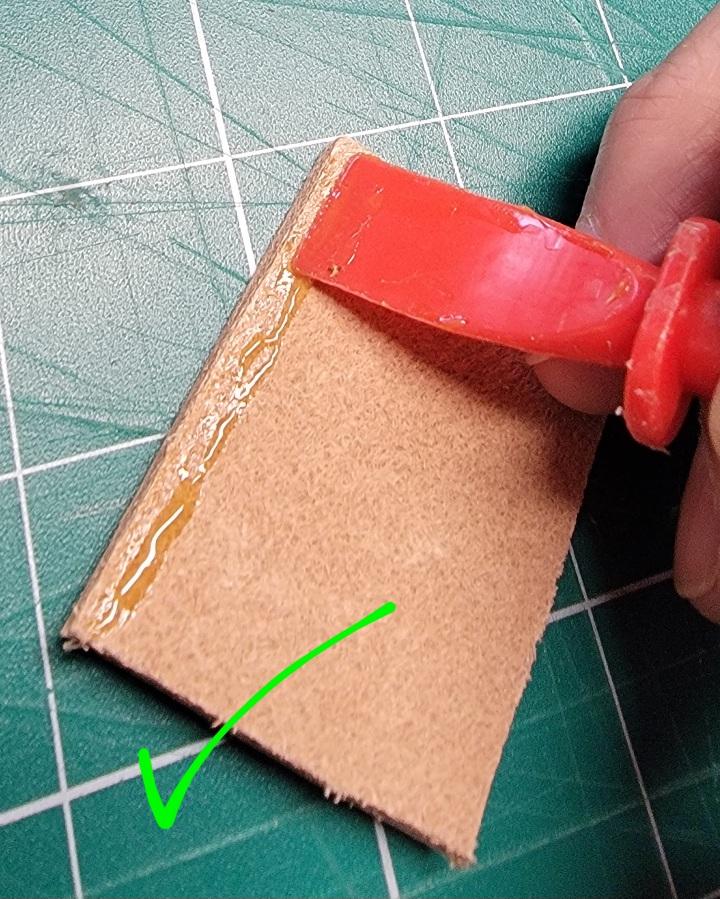

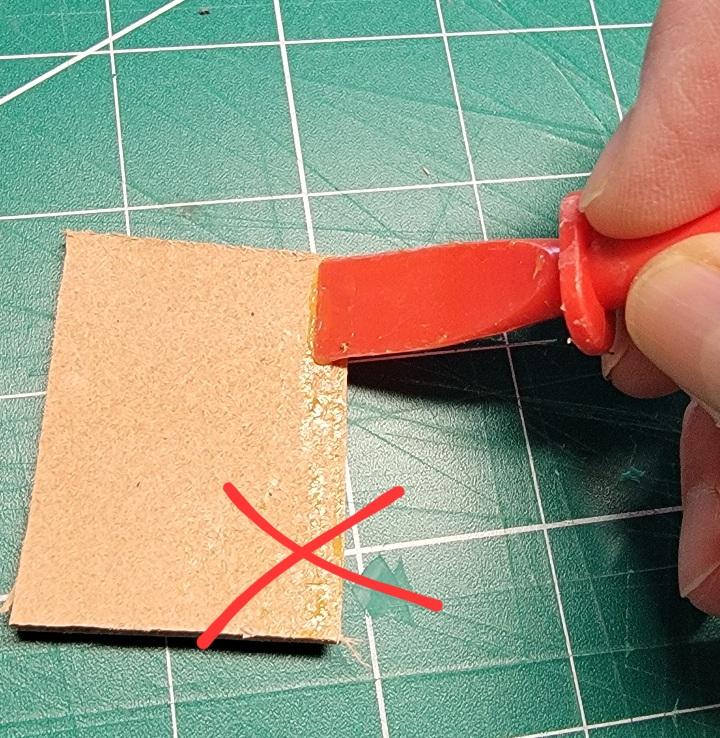

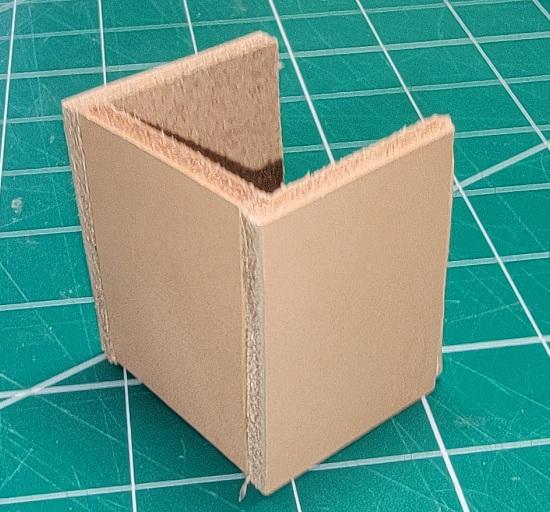

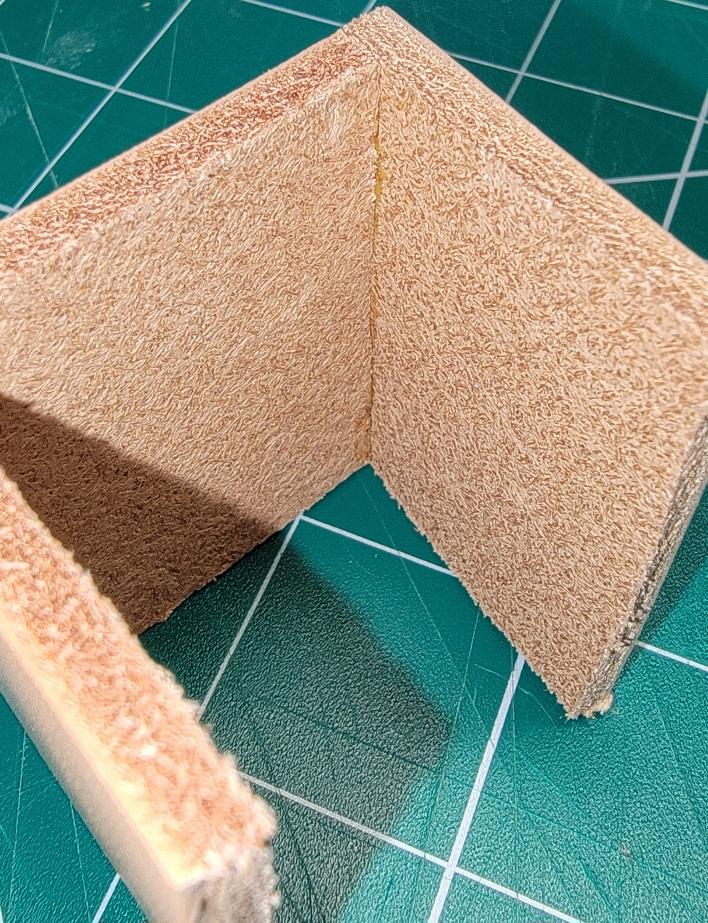

I use Barge cement and I don't use the cement as a fastening agent. It's more to hold in place until I stitch it together type of thing. When I glue up larger projects I use the can brush. When I want to do more refined work on small projects I use a plastic spreader. They're made of plastic and easy to clean. Even if the contact cement has been on there a few days I can use a rubber eraser and it comes right off. When gluing I pull the brush from the can and use the spreader to pick up some glue. I then spread the glue by pulling towards the inside, away from the visible edge. If you pull towards the visible edge there's a good chance it'll be seen when finished. When starting out you can draw a line where to stop pulling your glue. After a while you'll get the hang of it. Let it set until it's tacky (about 10min) then put the two together. This is kind of a one shot deal. Once the two pieces touch it's going to be tough to get them apart cleanly. After putting them together I let the cement finish setting. How long it actually takes I'm not sure. I go to another project and work on that then come back. So maybe a couple hours. This would be a box stitch and if I was actually doing this I would have punched my holes and finished the visible edge before gluing.

-

I aquired this a couple years ago from an estate sale where I bought a few things. Honestly I've only used it a couple times. I'm not in a hurry and my knife works well enough. If I was cutting large amounts of thick leather I can see it being useful.

-

I was working on a prototype on Friday and did this three times in one row. Admittedly I was using thread thats to thick for the project. Just keep one keeping on.

-

Hand-sewing and zips. Bane of my existence!

BlackDragon replied to HondoMan's topic in Sewing Leather

This is what I do. I use 1/4" (6mm) double sided tape, if you don't have thin tape you can cut wider tape down the center long ways. -

This is why I keep a pair of channel lock pliers on my bench.