Search the Community

Showing results for tags 'black'.

-

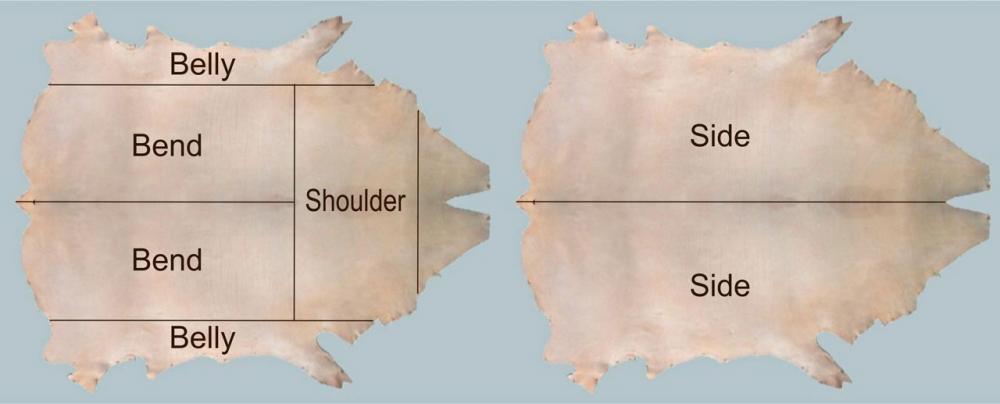

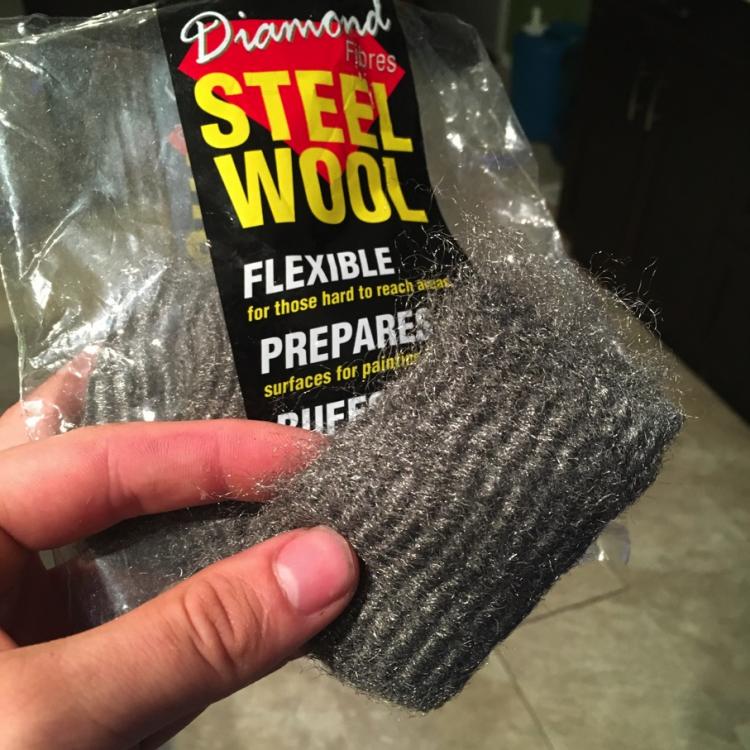

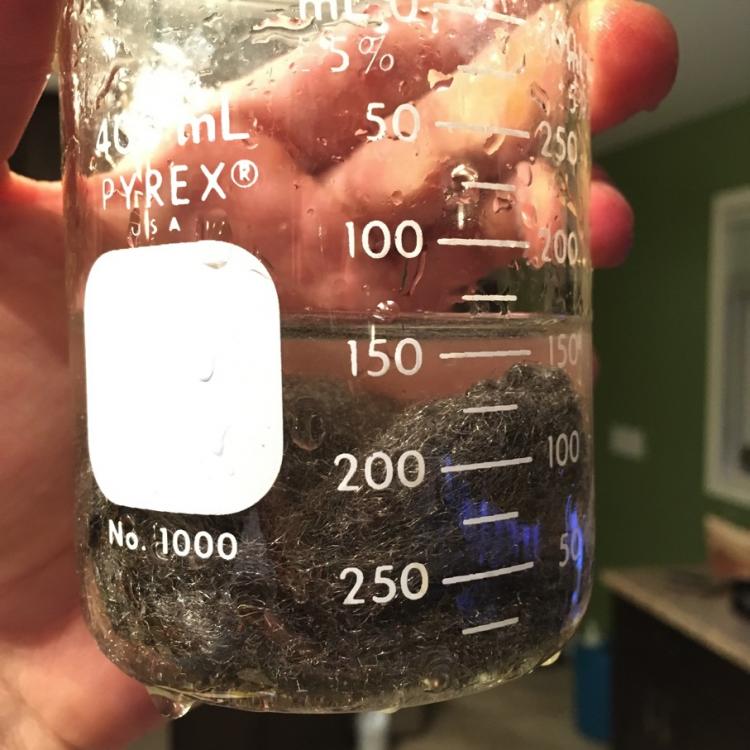

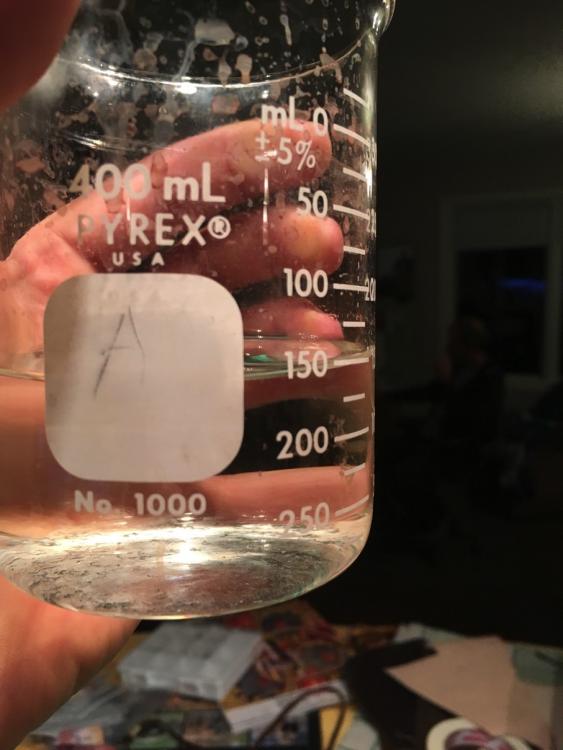

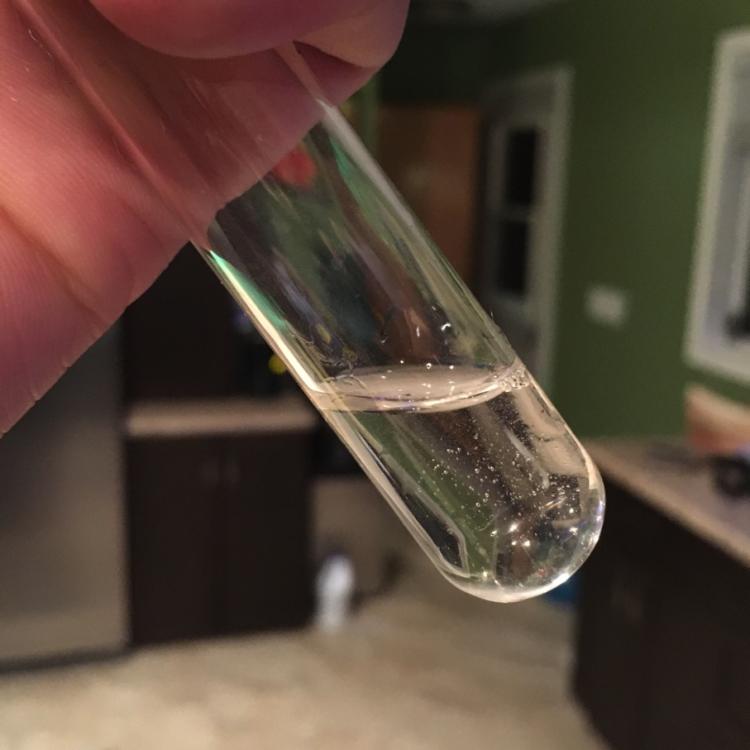

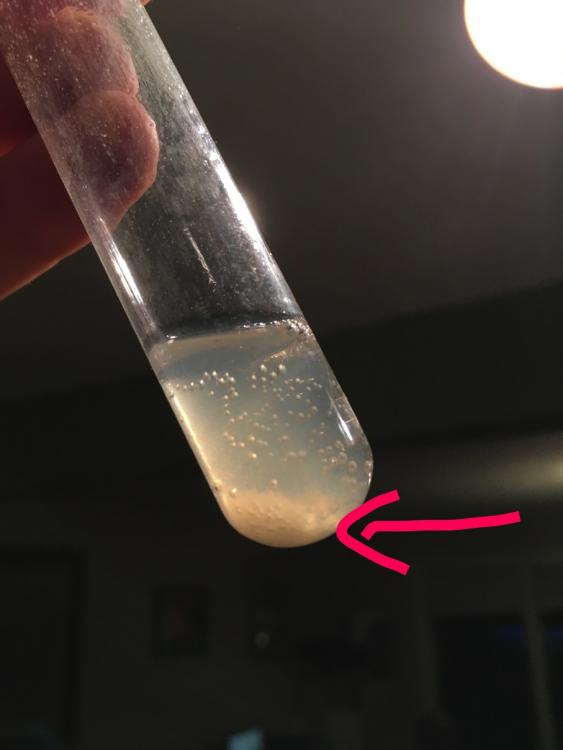

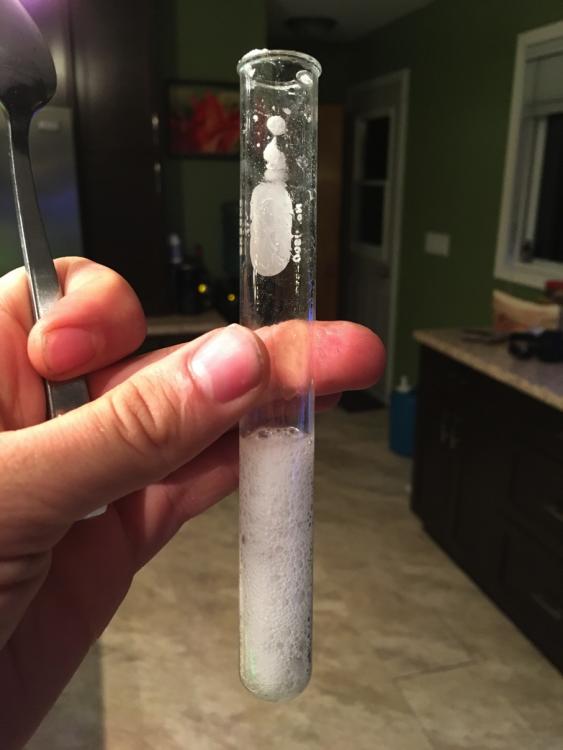

My all in one guide to Vinegaroon Hey everyone. I’ve been lurking around these forums for a while now and haven’t posted much, so I thought I’d finally make a contribution. I’m going to University for a Chemistry degree, and surprisingly some of the things I’ve been learning in my labs are actually applicable to my leatherwork! I thought I'd write up some of my observations and experiments with vinegarroon, to try and help shed some light on what is actually going on in the reaction. Please, read through and share any knowledge you have working with this stuff! (I know this is a lot. I was bored just typing it. You can skip to the bottom if you don't have time to read it all) Background Vinegaroon, or ‘roon, is a homemade black ‘dye’ that has been used by leatherworkers for centuries. It is also used by woodworkers to ‘ebonize’ wood, and was used since the 5th century as ink, called ‘iron gall ink’. It is not actually a dye, but a reaction between ferric acetate and the tannins that naturally occur in leather and wood. Tannins content varies between hardwoods and softwoods, and can be boosted by brewing a strong black tea and wiping it on the wood. I assume that this is also true of leathers. I have a few junky tandy's sides that are pale in appearance, and they seem to be low on tannins because roon has less of an effect on them. ‘Roon is used by many leather and wood workers but understood by few. It can be very useful alternative to commercial black dye in areas where dye is unavailable, too costly, or undesired because of environmental reasons. Also, because it is fundamentally different than other dyes, it will not bleed or crock (rub off) onto fabric. Pros: -easy to make with household materials -available in places where dye is not, or shipping is too expensive -nearly free -does not bleed or crock like other black dyes Cons: -often does not make a deep enough black colour without lots of neatsfoot oil added afterwards -can make your product smell like vinegar -acidic nature can cause issues with metal hardware in contact with the leather, might also degrade then leather after long periods of time Typical Recipe: (not recommended by me) Put some old rusty nails into a jar of vinegar and let it sit for a week, or a month. Filter it through cheesecloth and wipe it on your leather. This produces a nasty, smelly mixture of a whole bunch of iron complexes and compounds. The active ingredient, iron acetate, is in there, but along with a whole bunch of other junk you don’t need. It doesn’t have to be this way. With some chemistry and a little bit of research into the mechanism here, I’ve made a crystal clear, mostly odourless solution that only takes half a day to make. How I did it: I bought fine steel wool from the dollar store, which came in small bats. Any steel or iron will do, but fine steel wool has the greatest surface area so it will react the fastest. Metal shavings/powder would also work, but I’d think they would just clump on the bottom of the jar and prevent the vinegar from reaching the bottom layers. I washed one bat in soapy water to remove any oils left over from manufacturing. Some people have used acetone, which would work well, but seems a bit over the top when soap is cheaper. I pulled it apart and placed it in a beaker of regular vinegar, so that all the wool was submerged. You don’t need very much steel wool at all, even a quarter of the amount I used would be enough. The amount of metal actually being dissolved is in the order of milligrams or even micrograms. You probably shouldn’t keep a lid on it, because you are producing gas in the reaction. After a few hours, small bubbles form on the steel wool, causing it to rise to the top of the solution. I would mix it gently to dislodge the bubbles and keep it submerged. Every few hours I would use an eye dropper (so that I didn’t have to pour it out) to take a bit of the solution and test it on some leather. The darkening effect increased slowly over time until full strength was reached after about 12 hours. Still, I left the wool in there for 2 days to see if it got any stronger. Next time I won’t leave it in so long. After 2 days, I removed the wool. Since none of the wool was ever exposed to the air above, there was no rust in the beaker and I was left with a nice clear solution that didn’t smell much worse than straight vinegar. This is my vinegaroon solution. It turns leather black, is fairly stable, and is still acidic. The final product: a clear, nearly odourless solution of vinegaroon. Neutralization (optional): Next, I tried to neutralize the solution with baking soda to see if that changed the effectiveness of it at all. I took a small test tube of the ‘roon solution and put a spoon tip of baking soda in it. Obviously this will make it fizz up like your kid’s science fair volcanoe project, so I added it slowly. I didn’t have any pH paper to test the acidity so what I did was add an excess of baking soda (seen on the bottom of the tube), and then re-added the acidic ‘roon solution dropwise until there was no excess left. These images show the neutralization process, if pH paper is unavailable. A base (sodium bicarbonate/baking soda) is added in excess, which is seen in the bottom of the test tube by the red arrow. Then, the acidic vinegaroon solution is re-added slowly until this excess base disappears. The resulting solution is assumed to be neutral. This neutralized roon solution has the exact same reaction with the leather as the acidic solution. However, it was not as stable. After a hours sitting or a few minutes shaking, the solution turned into a cloudy grey-orange sludge. This is because the oxygen in the air oxidized the Fe2+ ions into Fe3+ ions, which are not soluble and have a rusty colour. Neutralized roon is good for immediate use, but turns nasty after a while What is happening? (skip this section if you don’t like chemistry) The iron is dissolved by the acetic acid and becomes a free-floating iron ion, in the +2 oxidation state, called Fe2+ or Iron(II). Hydrogen gas is produced in the dissolution process but in such small amounts that there is nothing to worry about. This ion is colourless and soluble in water, which is what we want. Furthermore, when this ion is in an acidic solution, like vinegar, it is relatively stable. Some of the ions complex with the acetate, which further increases its stability. When this mixture is applied to the leather, the iron ions interact with the tannins to form an iron-tannin complex, which is black. Oxygen messes with this system. Obviously there is oxygen in the atmosphere and dissolved in your solution, and this can oxidize the iron ions – it will take them from the 2+ state to the 3+ state. Fe3+ or iron(III) is NOT what we want, because it is orange and gross and not soluble in water. If this forms, it creates an orange/brown powdery solid that sinks to the bottom of the jar. To prevent the oxidation of the iron in solution, we need to keep the pH LOW and keep the oxygen out of the system as much as possible – by not pouring or shaking the solution. Now, the acidity of the solution is what keeps it stable – I’m assuming that you could store vinegaroon for a few weeks or months if you kept a lid on it. But the acidity is also what makes it dangerous for using with metal hardware. So what I’ve done is neutralized the solution with baking soda, just before applying it to the leather. The neutralized solution is just as effective, but noticeably less stable. The nice clear solution will turn orange overnight if untouched, or in seconds if shaken. So there you have it. Here’s a summary of what you SHOULD do: -keep the oxygen out of the system. Oxygen is your worst enemy, and turns this pure, clear solution of iron acetate into a sludgy, brown, stanky mess. -keep the solution acidic until you need to use it, then neutralize it if you need to before applying -use steel wool, as it has way more surface area than the same mass of solid iron And what you SHOULDN’T do: -don’t use rusty metal. It wouldn’t make a huge difference, it would just be introducing iron(III) into the solution which you don’t want. -don’t stir vigorously or pour the solution if possible -don’t use lots of metal, cause you only needs a little -don’t wait for a week, cause full strength is reached in less than a day -don’t put a lid on it until you’ve removed the iron, cause you’re building up gas in that jar -don’t worry about anything exploding either, there’s not that much gas -don’t filter it! Pouring it would introduce too much oxygen into the system. If you have stuff that you need to remove, it would be better to suck the ‘roon out with a turkey baster or something. What you could do differently than me: -using stronger vinegar, ie pickling vinegar, would speed up the reaction slightly and probably produce better results, since the pH would stay lower. Normal vinegar, however, is fine for most uses. -If you want to ensure that you have neutralized the solution, or gain a greater insight into the reaction process, pH paper would be very useful. -The solution could be neutralized with other bases, I only used baking soda because it was within an arms reach of the vinegar. Using sodium hydroxide, for example, wouldn’t cause it to bubble so much. -The solution can also be heated to speed the reaction, although I personally wouldn’t bother -Perhaps the best thing you could do is to calculate just how much iron will react with the vinegar and use slightly less than that amount of steel, to ensure that you have vinegar in excess. This will keep the pH from rising as vinegar is consumed by the reaction. This could be calculated stoichiometrically, or possibly by weighing accurately the mass of steel wool before and after to find out how much was consumed. I would assume that it wouldn’t be very much at all. Resources: The main reason why I found it so hard to find information on this reaction is because I initially had no idea what to search for. “vinegaroon” only can up with a few result, and most of them were not scientific explanations. I soon found out that it is more commonly used for “ebonizing wood” and that yielded a few more results. Finally I came across some scientific papers for Iron-acetate and iron-tannin complexes. Here are links to most of the pages I found helpful in my search: http://chemistry.stackexchange.com/questions/35351/iron-chemistry-acetates-for-ebonizing-wood http://chemistry.stackexchange.com/questions/5027/how-does-the-mordant-ferric-acetate-interact-with-tannins-when-ebonizing-wood https://en.wikipedia.org/wiki/Iron_gall_ink https://pubs.usgs.gov/wsp/1459d/report.pdf Thanks a lot for reading that, if you made it all the way through! Ask me any questions or share your experiences with roon below!

- 54 replies

-

- vinegaroon

- roon

- (and 10 more)

-

-

Just looked at some 8-9 oz black CXL sides (18 sq ft average) at The Tannery Row. $260/side Most economical shipping cost: $94 (ouch!) for up to 3 sides to ship to southern California. No tax though. Joseph

- 2 replies

-

- black

- tannery row

-

(and 5 more)

Tagged with:

-

I've got TONS of unique, one-off leather for sale. A range of sizes and colors and finishes, great for small projects. I'm about to list some large hides in addition to the small and medium I have for sale. Right now I'm posting on eBay but would love to sell direct. Here is the eBay link- https://www.ebay.com/sch/racbec-61/m.html?_nkw=&_armrs=1&_ipg=&_from= Better photos coming soon too! There are MANY more than shown below. Email me: Rachael@heavyleathernyc.com

-

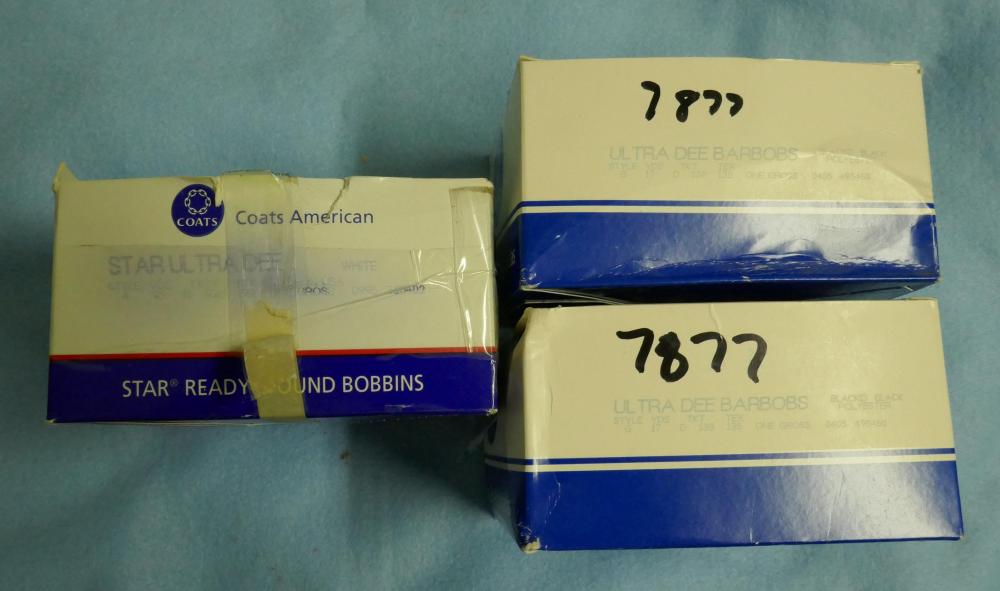

I have 3 boxes of prewound thread for sale. 2 boxes – Ultra Dee Barbobs, Style G, 17 Yards, D-138, Color = Black. 1 box - Star Ultra Dee, Style A, 25 Yards, D-92, Color = White I cant guarantee they are complete full. IE, all 144 bobbins are there in each box. I have attached photos of the boxes open so you can see. You can get all 3 boxes for 100 USD including USPS Priority mail shipping to your USA address. USPS Money Order is the required form of payment. If you cant or wont, then IM me and I will consider other forms. Thank you for looking

-

The following thread is for sale. Quantity and pricing are posted on the pictures. Please Note: you need to send a PM MESSAGE, leatherworker.net notifies us via email as we do NOT check the postings daily. Let us know what quantity you are wanting so we can let you know the cost with shipping. Thanks for looking

-

I am inundated with strap scraps that need a new home. Prefer to sell by the giant box full, weighing about 40-60 pounds per box. Come and see it all and make an offer for a truckload! Located in Aurora, CO. Herman Oak golden tan bridle, 8/10 oz veg tan, and 9/11 oz. struck through Black Latigo from Chahin. Most are mixed boxes, with both colors. Most leather is cut and edged, from 3/8" to 1" wide. Also plenty of random bits and trimmings from the edges of the sides. Asking $1.50 per pound, or $40 per big box. A few boxes full of ONLY the bridle leather cut to 9/16" width. This is beautiful stuff, it's just a little too short for the products we make with it. Asking $2.00 per pound, or $60 per box. Perfect for key fobs, bracelets, small projects, 4-H, scouts, crafts, etc. Remnant from dog leash/collar business (IE: nothing long enough or strong enough if this is what you want to make, because we've used what we can for this purpose). I have a continuous supply of this stuff. Feel free to reply here, but for faster reply, just give us a call. Call or text Brian three-o-three 653-184FIVE

-

Mixed box of cowhide leather remnants for sale in great condition. Some long, some wide, some small. Only selling this as a single listing, not individual pieces. $50+ shipping (likely around $30 domestic). Local pickup o.k.! These are in Los Angeles, CA. Thanks!

-

CHAHIN BLACK LATIGO 9/11 ounce, struck through jet black color (not just died on the surface like most). Heavy weight, superior quality, premium American hides tanned by Chahin. Asking $10 each piece of belly remnant, or 15 for $100. I have dozens available, and a continuous supply. Make me an offer for a truckload! There are hundreds of pounds. Located in Aurora, CO (Denver area). First image shows a random piece stretched out on 12" tile floor for size reference. Usually run about 12-18" wide by and about 5-6 feet long. Bellies are the bottom part of a full side of a leather hide and have some blemishes and soft spots but are excellent for craft projects. You will NOT find this quality leather at the local leather craft supply shop. (Inferior belly leather from Tandy is $30-40 each.) Tandy wants this much money for a pound of mid-grade leather scrap. Wholesale cost paid for this stuff is over $9/square foot. This really is a great price for amazing leather. Remnant from premium dog product business. Good for various crafts requiring heavy weight leather, like bags, holsters, whatever. IE: NOT for pet products, as I've used what I can for this purpose. You can post your interest here, but for faster replies just give us a call. Call Brian 303-653-184five

-

Hi all, This is a heads up that soon we will be launching our online sales page for our accumulated leather that didn't quite make the first-grade specifications. These will be sold in 'lot' jobs on our new website for you to purchase. Navigate your way to our 'Special Offers' page. J & E Sedgwick material is currently being held here at Sedgwicks in Walsall, UK. So once you enquire into the price of the leather using the 'quote' option, we can respond to you with the total cost including shipping. Hopefully you are interested in this topic for genuine J & E Sedgwick leather.

-

- 2 replies

-

- spartan

- thin blue line

-

(and 8 more)

Tagged with:

-

I saw something similar a while back and thought it was a cool color combination, and also a pretty awesome tribute to our law enforcement officers. I'd wanted to do something and I finally gave it a shot the other day. This is what I came up with. Comments, critiques, suggestions, questions, etc., are always welcome.

-

From the album: My Trade Crafts

-

- lady

- riding moon

-

(and 1 more)

Tagged with:

-

Hey all, I'm experiencing a problem with my Fiebing black dye. Often I get asked to make projects where people want my tooling to be painted black, with a bg that requires a antique or other overall color. Though when I apply the fiebings black dye first, it looks very good, until I apply an antique, other dye or even finisher. As soon as I try to do anything else with my leather afterwards, it seems most of the black dye just comes off again, only leaving a faint black grainy pattern (as if the dye has worn off due to excessive use of the product over several years). I do wait at least 24 hours after applying the black dye before doing anything else. I have tried applying the black as last to prevent this, but then it doesn't seem to dye completely, since I can still see the underlying color coming through (I've experienced this especially in combination with the red dye) and I'm afraid it will rub of on peoples clothing and such because I did not use a finisher over the black. Does anybody know why this happens or have a solution? I'm aware of vinegaroon, but here it's actually kind of hard to get by nails that rust easily (they only sell galvanized in all the dutch hardware stores), and in my experience my batch that has been rusting for 6 months now still needs multiple coats to get a nice black look (and is a bit harder to work into details then the regular dyes). Thanks in advance!

-

I have been making some black leather straps for several months now and I first used fiebing black dye, but the last few I used fiebings black oil dye because I have read that it is better. I admit that it seemed to go a lot further than the regular black dye but now that the product is finished it seems to me that the regular dye produces a much richer and blacker color. Has anyone else noticed this also?

-

Hey folks! Thought I would share a custom quiver order I took last month. I really enjoyed the way it came out. This was for a repeat customer, but they wanted a hip quiver with adjustable angle and the option of adding a shoulder strap for a walking quiver. I also put together a matching black and green arm guard. On the quiver I tried what I thought was the technique for getting a gradient transition between colors, but I think maybe I need to use a lighter green or thin it out. I've seen some quivers on etsy with very striking color transitions but I haven't nailed down the way to do it yet. Thanks for lookin'!

-

From the album: Wallets

Red and Black, Friend of Jack! Getting better... I kind of like the stitching on this one. I used Campbell's Satin Laid 332 Linen thread, red, on black leather for a cool contrast. YinTx© YinTx

-

From the album: Yzabel's

Made by Dad...my teacher ! R.I.P. May 8th 2013, this is a very nice little picture maybe 8" high,made maybe 30 years ago was carried a few times, some scratches ar visible on the highest lines of the profile. -

This is my latest holster. Solid black leather with black stitch work. Turned out really nice. Has a great look and feel and sits nicely away from the body for quick draw use. Let me know what you think of it!

-

Hi All! I've dyed some purse shoulder strap edges black (not veg tan), let dry 24 hours, and then have burnished with saddle soap. The edges look alright, but I tested with a little water and buffed with cloth to make sure that nothing would come off on someones clothes and sure enough, black. So, my "water resistant" dye is a bust? or did I make a mistake by using saddle soap? I want to make sure I get happy customers...not customers that need me to buy them new shirts. :/ Noted that I could try to roll edges, but I'm not quite at that level yet! Any help is much appreciated!

-

This is a belt for a friend. She bought like 1 new belt/year, because she was used to this standart-crap-belts which started to disintegrate after about 10 to 11 months.... so the Plan of her husband was to give her a lasting belt she could enjoy "a little longer" and which looks better than the stuff before. I used some 2mm veg tanned cowhide lined with about 1,5mm, so the backside of those rivet-like pyramids would scratch her pants and would be visible plus a nickel plated brass buckle, handstitched all the way around. (I know that the stichting line isn´t perfect.... but I am just waiting for my pricking irons to arrive! Hope they´ll come soon) Hope you like it

.thumb.jpg.bbabef8d577bb3518a04fd740fdae311.jpg)

.jpg.4489b5e9ebd69f599f32251c5ab2c778.jpg)