Search the Community

Showing results for tags 'wallets'.

-

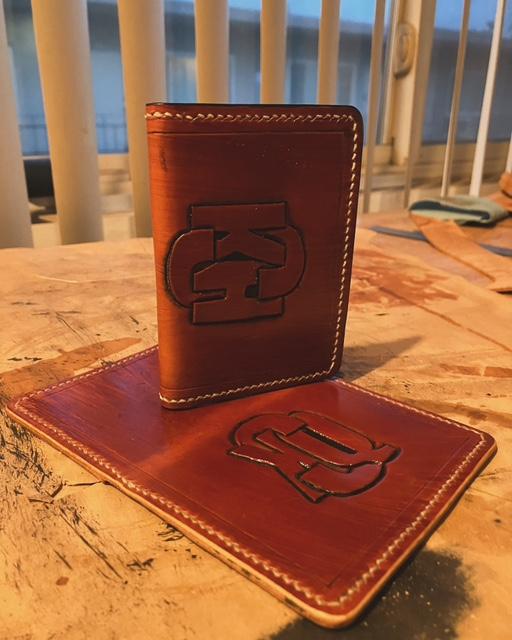

I get impatient, share stuff before it's done...so, here I go again... I was watching Kingdom Glory Leather stuff on the Tube, whence I discovered a couple of his "Leveling up my old wallet..." videos. That got me to thinking, maybe it's time for me to do the same. The artwork is very much inspired by KGL artwork, but I really like the style so I'm thinking I'll play around with it some more. It's not perfect, but I reworked the parts a bit to allow for better stitching. Now if I can just improve my edge work and my finishing, I'll feel pretty decent about this one. The design of the parts is my own, no more kits or purchased patterns for me on the wallet front. Anyhew, just thought I'd share...fire away! Mike P.S. I bought the set of TLKKUE edgers off'n the Amazon...90 bucks for five edgers, two sharpening blocks, and a case...so far, I love the edgers! One of them needed a little work out of the box, but the others all made great cuts immediately. Once I got the #3 honed up, it worked like a charm as well. The handles aren't works of art, but they are comfortable and seem sturdy; angles and ergonomics are good; all things considered, they're MUCH better than the handful of edgers I've used for the last 20 years...one day I'll learn to trust my gut when it says 'move on.' Anyways here's the link in case anyone wants to poke around: Amazon.com: TLKKUE Leather Trimming Tools, 5 PCS of Leather Edge Beveler Skiving Kit with Sandalwood Handle, 2 Sharpener Guide for Leather Cutter Head, Different Sizes Trimming Leather Edges for DIY Leather Craft.

-

-

Anyone know where to get clear vinyl windows with thumb slots used for ID’s in wallets?

-

Sunflower Wallet

mikesherman posted a topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

This here is a mid wallet I'm working on...assembly design is mine. I'm sure the 'Eagle Eyes" among you will recognize Jim Linnell's sunflower pattern. I got it years ago, but this is the first time I've tried it. Those same sharp eyes will see a couple of tooling mistakes, but I'm trying to ignore them for now, as this is my first attempt at this pattern; I'm sure I'll have to tweak some things a bit and do it all over again. I'll post an update when it's done. -

Hi Everyone I have enjoyed viewing the topics on this site for sometime, but once I turned creating leather goods from a hobby into a business, I knew it was time to join. I may at some point have a tip or two to help others, or need a few myself. My business is J. Scott Handcrafted. I am located on the Sunshine Coast in Queensland. A coastal town. I create watch bands, slim card holders and am beginning patters for shaving kits, mouse pads etc. I prefer to work from scratch or make a pattern for the work at hand. Next creation I start again with a fresh pattern. This is slower than using templates etc., but suits me at least for now. It also allows me to make small changes and keep the process of creating fresh, rather than same each time. My main leather is Kangaroo, which is quite popular here. I only sell within Australia, due to the issues of exporting Kangaroo leather (forms, permits etc.). Here is my site handmade leather goods Here are a few pics of the watch bands done recently. One is Australian Barramundi, One is Cane Toad, shrunken grain Sheep, which is my favourite. And last is snake. All four have Kangaroo under- lining.

- 5 replies

-

- watch straps

- handmade

-

(and 3 more)

Tagged with:

-

Hi! My name is Chip. I’m new to leather working. I instantly loved it because it involves sewing with a sewing machine and reminds me of wood working (which I also love). I want to make nice bags and wallets for both women and men to sell. No website yet as I am just getting started learning about this, but… I’ve already made two bags using a Singer 128 and a Kenmore Model 21 “Purple Monster”. The Singer does not have reverse, so that was a bummer. The Kenmore has reverse and is a left homing needle (kind of an annoyance, but works). Both of them had their issues and I realised I can’t use them for quality work. Even still, both prototype bags I made came out “ok”. Those are going to be gifts. I have not settled on what specific items I will be making for sale, but totes will be on the list! Chip from CHIPPER BAGS

-

What are some suppliers who produce good quality kits for skilled leather workers, not kids at summer camp or beginners? If you believe a couple of suppliers stand head and shoulders above the others in this area, please tell me about them!

-

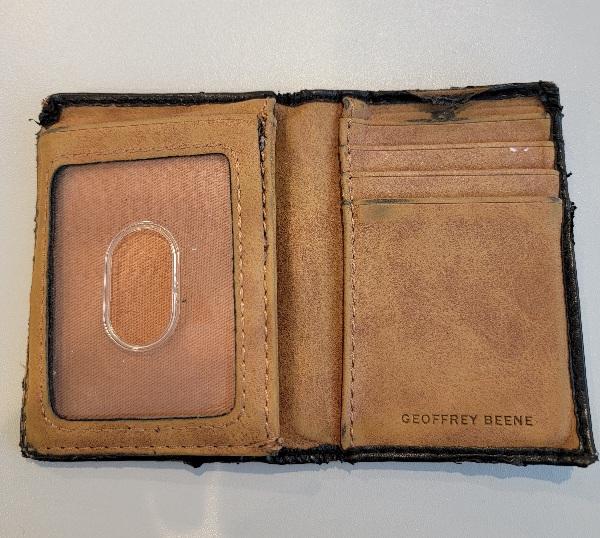

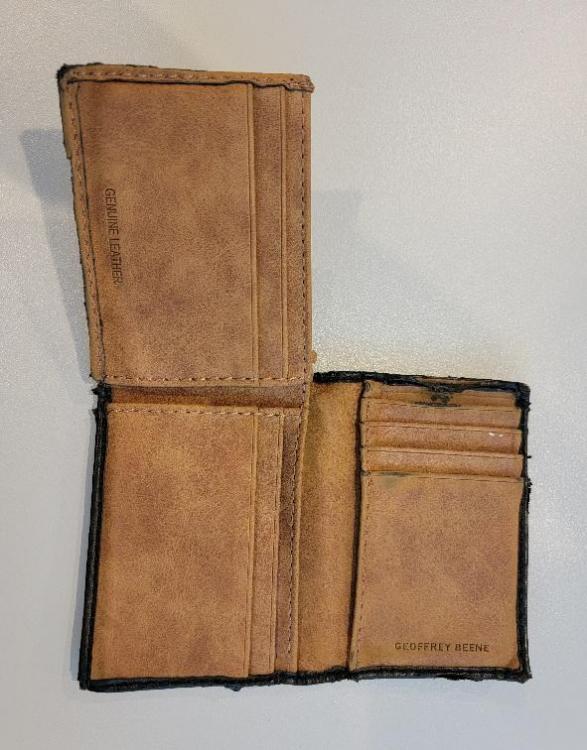

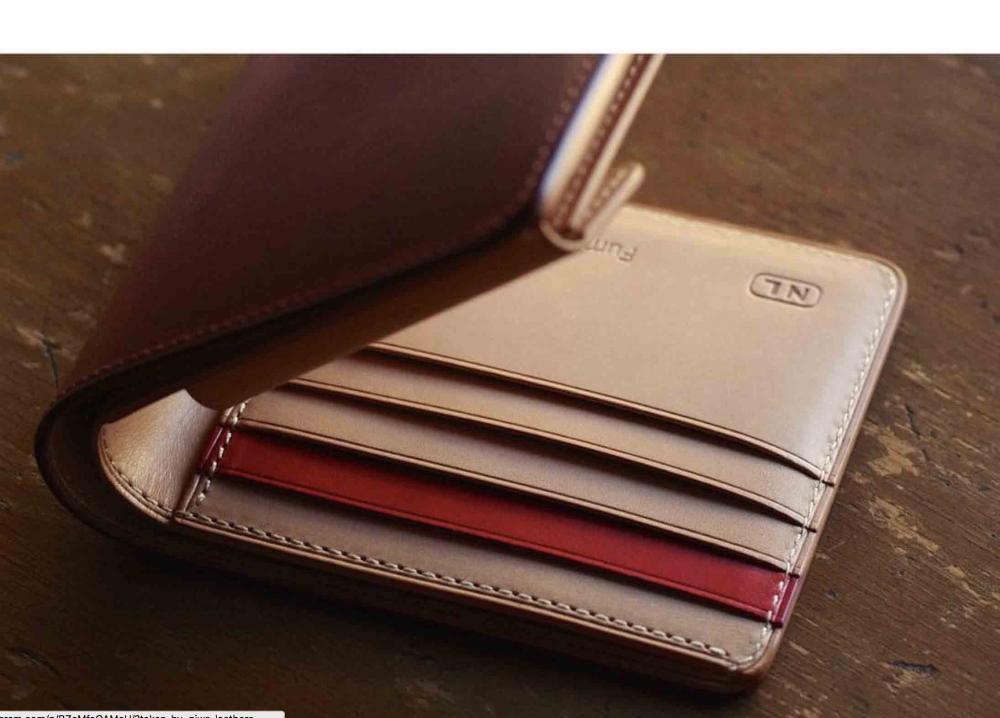

I'm looking for someone to make a wallet. I have a particular design I like, L fold, and I can't seem to find one like this that lasts for longer than a year or so. I've gone through several of this style of wallet over the years, and I really want something that lasts. I'm wondering if anyone could make a wallet to match the design of this one, or something similar along the lines of this style. Pictures included -James

-

We are custom designers and craftsman of baseball glove leather items such as wallets, purses, bags, etc. Our main focus is wallets. We need a craftsman that can layout and hand stitch these wallets. We provide everything you need. You can do just finish stitching ....to complete design based on what you are comfortable doing. We are a small family operation that sells exclusively online. My partner, (sister), wants to slow down and we have built a large following online. We also do custom glove to wallet orders as well. You can work at your own pace and do as much or as little as you want. Quality of craftsmanship is our number one priority so experience is a must. We are willing to pay according the work you do on a piece by piece basis. I am a new member here so help me out if I break the rules unknowingly. Best thing would be to contact me and we can have a conversation on the phone about what you would like to do. Our website is whenitwasagame.org and you can see what we do there. I don't care where you are located or where you work from as long as we can count on you to do what you tell us you're goin to do. Looking forward to hearing from creative people that love doing quality work. Thanks... My Name is Les

-

Hi everybody. I make a lot of wallets and I recently got a new set of pricking irons. In the past, I've used the diamond stitching chisels from Weaver leather supply, and they were okay. I switched to the Sinabroks 3.38 mm pricking irons because I wanted something a little more refined. I've really enjoyed using them so far but I've come across a problem. If I'm stitching down a row of pockets like in a vertical long wallet, I can't seem to figure out a good placement for the holes. If I put one tooth on the bottom edge of one pocket and another tooth on the top edge of the next pocket, there isn't enough clearance because of the slant of the teeth, so there's only a tiny bit of leather there to hold onto the thread. If I were to stitch that up, it usually rips the edge of the leather. On the other hand, I can't put a hole between the two pockets because then there will be thread going between them and they won't meet up edge to edge flush and clean. Is 3.38 mm just too small? I'm pretty certain I've seen people stitch up wallets with that size before, even finer sizes. Any advice would be appreciated. Thank you.

- 2 replies

-

- wallets

- pricking irons

-

(and 2 more)

Tagged with:

-

Hey y'all, my name is Brian, owner of Upstate Handmade. Thanks for accepting me to this channel. I want to show off some of my work but my photos are to big. Please findme on instagram: https://www.instagram.com/upstatehandmade/ Would love to hear what y'all think!! Thank you all

-

So I've been getting the hang of card holders and wallets. I'm trying to move up to long wallets with zippers and multiple rows of card pockets and I'm running into some trouble. What I normally do is attach my t pockets onto a larger piece of leather that will in itself become a pocket as well. So when I make my patterns, I give the edges of my t pockets an extra 1/8" on either side. Then, after I've sewn on each pocket, I can trim off the excess and then finish the edges. That's the idea, anyway. The issue is the bulk. Even when I skive as much as possible in the appropriate areas, I can just barely get the pockets to sit down on the main piece of leather by the time I get to the third or fourth one. This this leads to poor glue adhesion along the edges because the pockets are hardly even touching the base, which then also leads to sloppy stitch lines, and therefor uneven stitches. I've included some pictures to try and make what I'm talking about more clear. What bothers me is I see folks on youtube go through this process with no bulk issues what so ever. Look at this video for example: https://www.youtube.com/watch?v=-UEauYrGzAE&t=346s Skip to 4:40. This guy doesn't even give himself any extra trim allowance, and he even pre-punches every piece of leather so they have to line up PERFECTLY. And he just goes along and slaps them right on with no alignment issues, no trimming, no bulk, nothing. Does he maybe make each pocket slightly wider than the last so they all just line up? Do any of you do that? Seems like that would be really hard to get right. Any advice on this topic would be much appreciated. Thank you. This link will take you to the pictures of what I'm talking about. I had to use a link because the file sizes were too big to upload them directly. https://docs.google.com/document/d/1Z3bio0Yub_EJYTLHcxcJELhUux8t0nYlbgrhRQqTwPQ/edit?usp=sharing

-

What do you use to sew wallets, purses, and the like. Please use a simple answer and not a long winded response I need to know the machine and model number, needle size, thread size, and clearance I’m told if I get real answers my puppy won’t pee on my rug

-

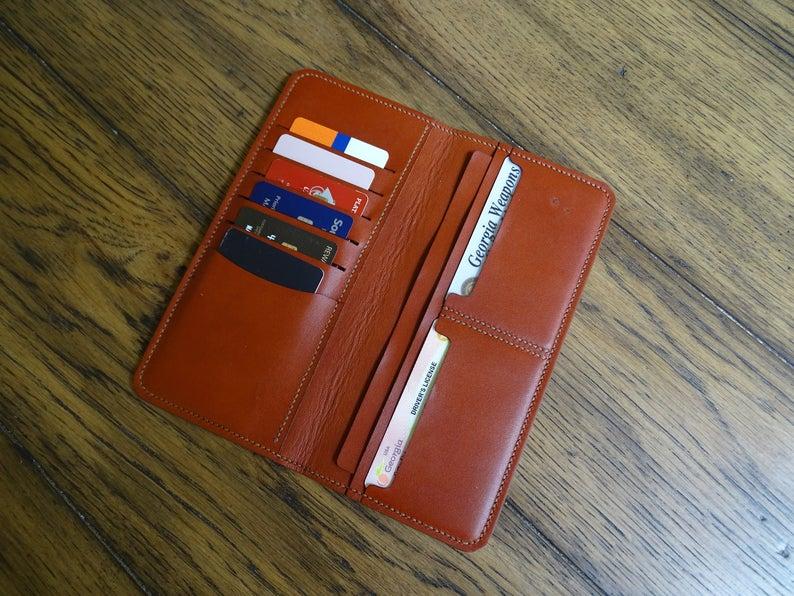

Brand new to my store page is an acrylic template for a beautiful long wallet pattern. The template comes complete with the 6 individual pieces pictured, and will help you produce a beautiful, yet functional long wallet. Each template piece has been laser etched describing its function to help simplify order of operations. The template will help you produce a wallet that features:A slim 7.5" x 3.5"design when foldedA left panel that features 5 hidden card slots, and one standard pocketA right panel that includes a bill pocket, receipt pocket and two card pockets. Leatherworker.com users can get 15% off by using the promo coded “insta” at check out. Click the following link to be routed to my etsy page: Smithleatherco Etsy Happy Leather Crafting, Mark

-

- acrylic template

- wallets

-

(and 2 more)

Tagged with:

-

Ill just get right to it. First.. if I am using an 8-9 Herman Oak veg tan leather, dyed with pro dye, do I need to also apply neetsfoot? Usually my process goes: Dip Pro dye, neetsfoot, leather balm (with atom wax) and then beeswax I have tried resolene, but didn’t research well and tried to apply straight out of the bottle. Knowing now, it needs to be diluted. On my wallets I used the same process, but with the leather balm, it actually pulled out an oily color after it dried. That is on 2-3 oz kipskin from Weaver. Second.. I have a real problem with dye rubbing off onto cash and cards with the wallets. Is it because it is kipskin? Tonight I tried applying leather sheen to the flesh side to prevent that from happening. Before that, I have tried rubbing until my arm is numb with little difference. Also, on the holsters, would I use the same technique as on a wallets flesh side to prevent bleeding? My main concern is the inconsistency. And then the amount of time I spend appying the leather balm, especially if it has no real benefit to these projects. Ideally, if I could get away using just the pro dye and beeswax, it would be great, but I’m not sure if that is okay? Thank you in advance! Frank

-

Hi I own a small UK brand, and I'm looking for someone to produce wallets and cardholders in England. The wallets etc are to be machine stitched, used a heavyweight thread (ticket 10), and must be produced to a high quality. Press knives, leather and thread will be provided by ourselves. If anyone has interest in this, and can help, please get in touch. Many thanks

- 5 replies

-

- wallets

- cardholders

-

(and 2 more)

Tagged with:

-

Hi all, I'm currently searching for a source of vegetable leather for wallets and belts. I need 2-3 oz for the wallets and I'd prefer 10 oz for the belts. I've found some places that have sides of 10 oz for around $230, but I'm just a beginner and although I'd like a full side for belting, this is out of my price range. I've also been able to find 2-3oz shoulders and remnants but I've been unable to find a full side yet. If anyone can point me in the right direction here it would be greatly appreciated. Thanks, Sam

- 5 replies

-

- vegetabletanned

- vegtan

-

(and 7 more)

Tagged with:

-

Hello everyone, Recently I have been exploring long wallets and upon examining my wife's wallet (can't remember the brand but it cost her (me) a wopping $700) I found that the largest piece of the wallet, the exterior cover, is only glued on the outer rim so the two pieces are floating against each other in the middle. What does everyone do when making a long wallet here? Recently I made a mock long wallet and glued the whole piece, but I could see it coming apart over time and being uneven. I know Equus leather seems to glue the whole piece, at least from video footage. Also, could the same floating principle be applied to bifolds? Sam

-

Hello, Went to a store today that had really nice wallet edges that were painted with an alcohol or oil dye instead of edge paint. They looked really good so I want to try to replicate it. Does anyone have any recommendations, maybe Fiebings, for a dye to use on edges? I'm really confused about the difference between alcohol/oil as well as this pro dye Fiebings has. Also, how do I seal the leather after it is all done? Resolene? Are there any other products? Is Tokonole the same? So confused... Regards, Sam

-

wallets WALLETS - Specifically card slots/edging for them.

samNZJP posted a topic in How Do I Do That?

Alright, hello, and thank you to anyone who can point me in the right direction. So, recently I have started working with leather and I just want to master making wallets, but I'm confused as to how people do card slots. I've been following some people on Instagram and have been inspired by their work - Maybe someone could tell me how they do their card slots? Here are the examples I'm looking at: So judging by the stitching around the card slots, I believe that each slot has been cut so that each piece can line up with each other where I assume there is only two layers on the edge, a back and all the card slots lined up. Here's a T-slot! So, at this point I'm thinking, OK - Make T-slots, easy... But when I made a wallet there were "tightness" issues where the card slots at the back worked fine, but the card slots at the front were very tight - SO, do people make different sized card slots for the first, second, third and fourth card slot? Another side note, Mattnudi from this T-slot photo told me that he glues two pieces of leather together 0.5m leather x 2. IS this common practice as well?! Right moving on... Here's my biggest confusion.... So obviously this wallet is layered and T-slots are not used. I wonder if their are two pieces of leather glued together for each slot as well. Anyway, I have big problems with T-slots and whether they should all be the same measurements, and if so how do I avoid tight card slots? And how can I make non-t-slots viable without super ugly edges? Was going to include edge tips as well in this - Anyone know a good edge paint product? Sam -

I'm new to leatherwork. I'm looking for a glue I can use to stick leather pieces together so I can stitch them perfectly without all the parts moving around. Are there any glues I can use that can only stick temporarily And won't destroy my leather when I try to make my wallets. Thank you so much!

- 6 replies

-

- leather glue

- glue

-

(and 1 more)

Tagged with:

-

Alright, hello, and thank you to anyone who can point me in the right direction. So, recently I have started working with leather and I just want to master making wallets, but I'm confused as to how people do card slots. I've been following some people on Instagram and have been inspired by their work - Maybe someone could tell me how they do their card slots? Here are the examples I'm looking at: So judging by the stitching around the card slots, I believe that each slot has been cut so that each piece can line up with each other where I assume there is only two layers on the edge, a back and all the card slots lined up. Here's a T-slot! So, at this point I'm thinking, OK - Make T-slots, easy... But when I made a wallet there were "tightness" issues where the card slots at the back worked fine, but the card slots at the front were very tight - SO, do people make different sized card slots for the first, second, third and fourth card slot? Another side note, Mattnudi from this T-slot photo told me that he glues two pieces of leather together 0.5m leather x 2. IS this common practice as well?! Right moving on... Here's my biggest confusion.... So obviously this wallet is layered and T-slots are not used. I wonder if their are two pieces of leather glued together for each slot as well. Anyway, I have big problems with T-slots and whether they should all be the same measurements, and if so how do I avoid tight card slots? And how can I make non-t-slots viable without super ugly edges? Was going to include edge tips as well in this - Anyone know a good edge paint product? Sam

-

Hi all, I'm currently searching for a source of vegetable leather for wallets and belts. I need 2-3 oz for the wallets and I'd prefer 10 oz for the belts. I've found some places that have sides of 10 oz for around $230, but I'm just a beginner and although I'd like a full side for belting, this is out of my price range. I've also been able to find 2-3oz shoulders and remnants but I've been unable to find a full side yet. If anyone can point me in the right direction here it would be greatly appreciated. Thanks, Sam

- 2 replies

-

- vegetabletanned

- vegtan

-

(and 7 more)

Tagged with: