-

Posts

7,811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wizcrafts

-

Metro Spezial 9346 Patcher What Subclass?

Wizcrafts replied to JJN's topic in Leather Sewing Machines

Google Translate converts it into English, as follows: Good day everyone! I'm looking for a special meter for sale that can be shipped to Mexico! Stay tuned, greetings and good day! -

@Southerngunner My heart skipped a beat when I saw your photos of this 19th Century machine! It is in mint looking condition! When these types of shuttle machines were the rage, they were built strong enough to sew leather. I refurbished a few Singer 27 and 127 boat shuttle machines from the late 1880s and 1890s and they were able to sew 9-10 ounce bridle leather strips with #92 bonded thread (using a #19 or 20 needle)! I included a sewn sample with the machines to help sell them. If your machine can even sew 8 ounces, with #69 thread, it's worth 10 times what you paid for it!

-

budget options for sewing machines

Wizcrafts replied to AlanLessing's topic in Leather Sewing Machines

You'll want a compound (triple) feed walking foot machine for multi-layer garment or chap leather jobs. If the shirts are also made of leather or suede, the same machine can be used. However, if the shirts are made of cloth, and it is anything lighter than heavy denim, a walking foot machine may eat the fabric! For these projects, a bottom feed machine is better. There are plenty of those out there. Every alterations shop has tailoring machines that are bottom feeders with a flat presser foot. I have a bottom feeder at home. It's a Singer 31-15 that was made in the early 20th Century and still runs just fine. My Dad had one for his entire professional life as a tailor. He bought his new in 1920 and retired in 1975 or 76. These machines have interchangeable feed dogs and throat plates. Some feeders are for fine work, like dress shirts, and others are more aggressive for heavier materials, like coats. The 31-15 machines are able to sew chaps and even shoe and boot uppers if you use a roller foot. There is another type of walking foot machine that just has top and bottom feed. It is commonly used to sew vinyl, canvas and webbing. There are teeth on the presser foot that claw the work on top in sync with the feed dog on the bottom. The needle only moves up and down in dual feed machines. While they are great for use on materials that don't hold tooth marks, they shouldn't be used to sew veg-tan leather. Ask me how I know. -

Machine Sewing Leather Magnetic Bookmarks

Wizcrafts replied to Boake's topic in Leather Sewing Machines

I sew around round magnets when we make phone cases and other items with magnetic closures. The trick it to attach a single toe presser foot that presses on the outside of the stitch line, not one that goes on top of or right next to the magnet. In our case, we use a right toe foot and allow sufficient clearance on the project to keep the foot on the leather. It can be trimmed afterward. One reason to not have the presser foot come down on a magnet is that the magnet might crack from the impact. -

budget options for sewing machines

Wizcrafts replied to AlanLessing's topic in Leather Sewing Machines

@AlanLessing, Since you are just coming out or a hand sewing environment into a sewing machine environment, you need to assess how each item you assemble would be sewn on a machine. Obviously, flat seams and things that will be sewn while laying flat can be sewn on a flat bed machine, which is the most common. But, if the pieces become curved, or have shapes on the bottom on one or two sides, a flat bed won't do. Those may require either a cylinder arm or a post bed machine. In order to give you any accurate advice, we'd need to see the items you want to sew. Since you mentioned wanting to make shoes, you're already into the realm of needing two or three different machines at a minimum. I have a friend who delved into bespoke shoe making. He bought an old Singer 107 zig-zag machine to start. Then, he added a flat bed walking foot machine with reverse. Next, he discovered he needed a post bed machine, then a cylinder arm. He acquired a sole stitcher along the way. I thought he was done until he called and asked me to help find a suitable side-seam stitcher! Crime-n-Ebblies! When does it stop! If it turns out that you're going to need multiple types of machines, forget your imaginary budget! Poof, it's gone! Be prepared to spend lots of bucks. Even if you find every machine used and in good condition, it will end up costing several thousand dollars. Ask me how I know. -

Cobra Class 3 binding during Reverse stiching

Wizcrafts replied to TrigoLaneTrading's topic in Leather Sewing Machines

@TrigoLaneTrading Since you bought the Cobra machine new, you are entitled to free support from the parent company: Leather Machine Company, in California. Their contact info is on the bottom of the home page. Until you are able to contact them and open a troubleshooting ticket, here are some tips for you to follow. Make absolutely certain that you have threaded the machine exactly as shown in the user guide that accompanied your machine. I recommend inserting the top thread through the top hole in the top mounted guide post, then turn it around counterclockwise and feed it through the bottom hole to the loop under the top tension disks. This can counteract any right twist in the thread that can cause the thread loop to dissolve prematurely in reverse. Make sure that the top thread is fully seated in the top tension disks and that it moves freely when you lift the feet, then tightens when you drop the feet. Make sure the top thread feeds through the loop in the check spring and that the spring moves up with the take-up lever and stops moving down as the tip of the needle meets the top of the feed dog hole. Make sure that the needle is aligned so that the scarf above the eye faces due right and the ribbed side faces due left. Make sure the needle is fully seated up in its mounting hole and tightened in. Make sure that the bobbin thread feeds smoothly without any jerkiness or binding and that it has good tension on it. These machines don't like operating with light spring tensions. There are two spring loaded screws that secure the shuttle assembly to the head. Screw them all the way in, then back off each screw 1/2 turn. This lets the thread push the shuttle outward to avoid binding as it goes around the shuttle.The springs over the screws push it back in after the thread finishes its cycle. Add some more top tension via the large hollow screw on top of the head, where the presser foot bar moves up and down. If the tension is too light for the material and thread, the work can lift with the needle, causing skipped stitches and mangled top thread. If none of these steps fix the problem, your hook timing or position may need adjusting. Try to get LMC to walk you through the process. They have videos about this on the website. Do NOT try this without a visual guide or expert assistance the first time you need to adjust it. If you get it wrong, the machine may not sew in either direction. Once you understand the process, you can adjust it any time the timing goes out. Your timing can be knocked out if the screws on the hook, or its driving cam on the bottom shaft are loose. It can also be knocked out it the needle hits metal and the needle bar screws aren't really tight where they connect to a driving crank shaft inside the head.- 2 replies

-

- cobra 3

- reverse sew

-

(and 1 more)

Tagged with:

-

I've been using bonded nylon thread to sew patches since 2012. I normally use #69 thread, top and bottom, with a #18/110 Schmetz Serv 7 round point needle in system 135x17. I discovered that leather point needles tend to separate the edge threads, which are usually sewn with a serger. Round points don't usually ruin the edge appearance like leather points. I think that if I lived in a hotter location, where there was a lot more sunlight, and sewed for local clubs, I might switch to bonded polyester thread. It is only slightly weaker than nylon. While #69 (T70) thread is adequate for securing patches on a thin vest, it may not do so a padded leather jacket. If the owner expresses concern about the thread letting go, or the patches being too easy to tear off, move up to #92 thread and use a #19/120 round point needle. Try to sew close to the border on club name or logo patches, to make them harder to pull off. Ambushes happen in Biker life.

-

Binding with a right angle binder on a walking foot machine

Wizcrafts replied to Dave9111's topic in Leather Sewing Machines

I bought this inexpensive binder platter on Ebay, a couple years ago. I clamps onto the edge of the table. -

Binding with a right angle binder on a walking foot machine

Wizcrafts replied to Dave9111's topic in Leather Sewing Machines

Bring some of your material with you. Have them try to bind it with their tape and binder. Then, let us know how it plays out. -

Binding with a right angle binder on a walking foot machine

Wizcrafts replied to Dave9111's topic in Leather Sewing Machines

@Dave9111 Have you tried contacting Sailrite using their online chat? They deal with people sewing canvas and nylon. All of their machines have special binder attachments available that work with the bias tape they sell. This ain't yo Momma's bias tape either. Some of it is made out of canvas. They sell Sunbrella and matching bias tape. Chances are that their folders and tapes will get your jobs done correctly. Here is one of the Sailrite videos demonstrating how to sew both inside and outside 90 degree turns using Sunbrella bias tape and fabric. -

Parts for old Singer Industrial sewing machines - where?

Wizcrafts replied to customizer's topic in Leather Sewing Machines

It is very unlikely that there are any dealers with the original parts for a Singer 18-3. That series was made in the 1920s and 30s. Singer's industrial division has been out of business for a long time. They sold off all of the remaining parts to various dealers. Still, the chance that some dealer, somewhere has that part is above zero percent. Parts can also be salvaged from another machine if you can find one. -

Those are not industrial leather sewing machines. They are domestic, or household hobbyist sewing machines. They are neither heavy duty, nor meant for leather. This is the wrong forum to get information about domestic sewing machines. I posted a picture below of a real heavy duty leather sewing machine as a reference. It can sew over 3/4 inch of hard leather with needles as large as roofing nails and thread 10 times thicker than anything the domestic machines can handle..

-

Binding with a right angle binder on a walking foot machine

Wizcrafts replied to Dave9111's topic in Leather Sewing Machines

@Dave9111; Many years aago I had a sew ing gig that required me to sew binding onto the edges of road workers' safety vgave ding run off the top or bottom on turns, especially inside turns. The vests had outside and inside curves. I tried inexpensive oriental binders, but they let the bindinsg run off the top or bottom on inside curves. My dealer recommended getting a custom binder made by a specialist. It cost the boss $400 for that binder, but it worked flawlessly. If you aren't getting satisfactory results with a stock binder, look into a custom made binder that's made to work with a particular binding material. The right angle binder I had made double-folded binding out of flat 1.25 inch polyester edge tape. -

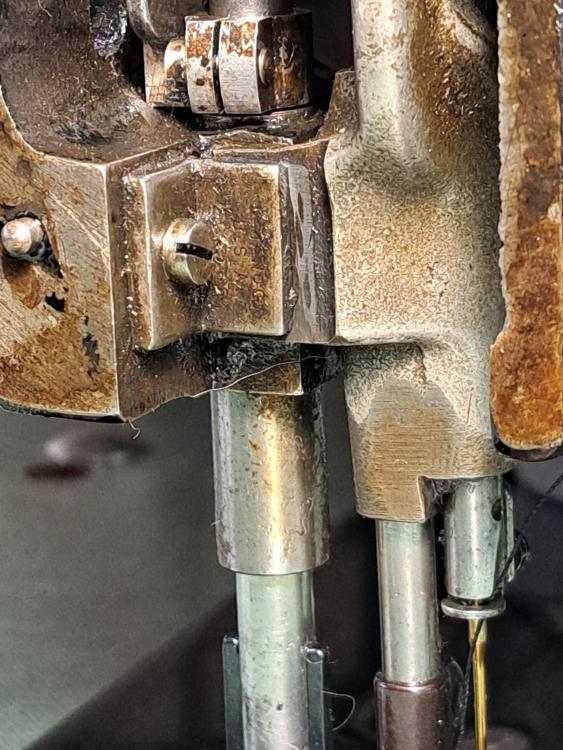

@SaraJ There is a possible explanation for your sideways needle bar motion. That could be caused by a loose or misadjusted L shaped bracket at the bottom of the head, on the left end. This bracket secures the needle bar, inside (aka: alternating/vibrating) foot bar and presser bar, keeping them aligned laterally. Here are two photos showing the wide and close=up view of the parts. My machine is a flatbed 111, but the mechanism is the same on your Singer 153. The screw secures the bracket. The hole in the bracket is wider than the screw. This lets it move to the right and left to set the clearance to a minimum, or maximum, as desired by the user. Try tightening it while pushing it to the right. But, don't let it bind the shafts. They must move freely, but without noticeably shifting to the right or left.

-

Machine for alcantara and other textiles, no leather.

Wizcrafts replied to DvidSnchez's topic in Leather Sewing Machines

The Juki 8700 is a bottom feed only machine. You will have to either order one with the most aggressive teeth, or buy an aftermarket feed dog with aggressive teeth if you're to have any hope of the moving the material. Really, auto upholstery, like any other type of upholstery, calls for a walking foot machine, with at least dual feed. The Sailrite portables all have top and bottom feed. The Consew 206 series machines all have triple/compound feed, which is the strongest and keeps all layers aligned as the needle move with the feed dog and the inside foot. You may be able to find a used Singer, Consew or Juki walking foot machine, complete with a table and motor, well within your stated budget. -

When does the thread advance off the spool and bobbin

Wizcrafts replied to Lint's topic in Leather Sewing Machines

It is always best to feed spooled thread off the top. Feeding sideways adds unpredictable friction that changes as the spool unwinds. If you need a thread stand, buy one. They come with raised bottom plates that screw onto a table. The stand threads into the plate and there are usually two cone brackets, and thread loops above them. -

@Cumberland Highpower I just remembered about another machine that had a jump foot AND needle feed. It was called the Number 9. It disappeared in the mid 20th Century, then was reborn as the Luberto Classic. This then disappeared about 10 years ago. These were heavy duty harness stitchers, not well suited to delicate work. Both used a really long needle system that could deflect in the thinner sizes (for thinner thread).

-

I don't know. I only had a 204-374 flatbed. Weaver used to sell the 205 models. Ask somebody who still owns one.

-

Pfaff 3334 Y-Axis adjustment

Wizcrafts replied to greatwhitetrading's topic in Leather Sewing Machines

How did you get the pattern centered in both axis'? Others may want to know. -

I had a 204-374 for a short time in 2010. It had a smooth feed dog. The -370 feed dog has teeth. This also applies to the Adler 205 machines. The -370 has teeth and the -374 has a smooth feeder.

-

My guess is that the gears are worn beyond their ability to time the machine within specs. Or, the driving pinion gear might be loose on the shaft that has the shuttle driver on top. There is a small set screw that's accessible from the rear side of the nose, via a hole. If you line up the gear just right you can get a small blade screw driver on it and tighten it if it was loose. That would be the cheapest fix. It's unusual for the eccentric screw under the main body to get worn out, but hey... Flakey sewing is often caused by a worn paddle spring. If there is a thread channel gouged into the spring, or the needle bar, then the loop will dissolve before pick-off time.

-

troubles with cb3500 threading on upper tension

Wizcrafts replied to TonyGreen3455's topic in Leather Sewing Machines

Here's one part of the problem of thread coming out of tensioners. I found out that not every spool of thread unwinds smoothly. Some, especially black thread spools are what I call "twisty or coily." They unwind with a twist that's in the direction they were wound in. The worst offender is from Weaver. Sometimes, thread is double-dyed to get a solid black color. This really stiffens the thread and can cause it to become a coil that twists around guides and jumps out of tensioners. I have come up with a way to counteract this twist. This is specific to the Cowboy and Cobra 441 clones, and similar machines that have a top guide post containing at least two holes that are about an inch apart. My solution is to feed the top thread through the top hole, then turn it counterclockwise and feed it through the bottom hole. From there, it goes to the eyelet under the tension disks. I also lowered that eyelet to get a tighter feed into the disks. I've never tried feeding the thread back through that eyelet because my reverse feed seems to counteract the twisty thread.

.jpg.d60258221c476480a6e073a8805645bb.jpg)